If you're looking for the ultimate high-performance carbon fiber pickleball paddle in 2025, the answer is clear: combining advanced production techniques with premium materials such as 3K Carbon Fiber1, 12K Carbon Fiber2, and T3003 enables manufacturers to deliver paddles with unparalleled strength, rebound force, and control. In this article, we break down how advanced production methods—including hot pressing, cold pressing, and thermoforming4—play a critical role in producing paddles that meet the rigorous needs of competitive play and high-end B2B procurement.

The growing demand for high-performance pickleball equipment has led to significant innovation in materials and production techniques. Today's professionals in sports equipment distribution and product sourcing need paddles that not only offer superior durability and performance but also tick the boxes for precision and consistency.

The challenges include:

• Intense competition in the market with many products vying for attention.

• Increasing standards for ball control, weight distribution, and overall playing comfort.

• The need for materials that offer both high rebound force and superior shock absorption.

Advancements in carbon fiber technology, especially the differentiation between 3K Carbon Fiber, 12K Carbon Fiber, and T300, provide a solution for these challenges. These materials, each with unique properties, serve as the foundation for the best pickleball paddles available in the market.

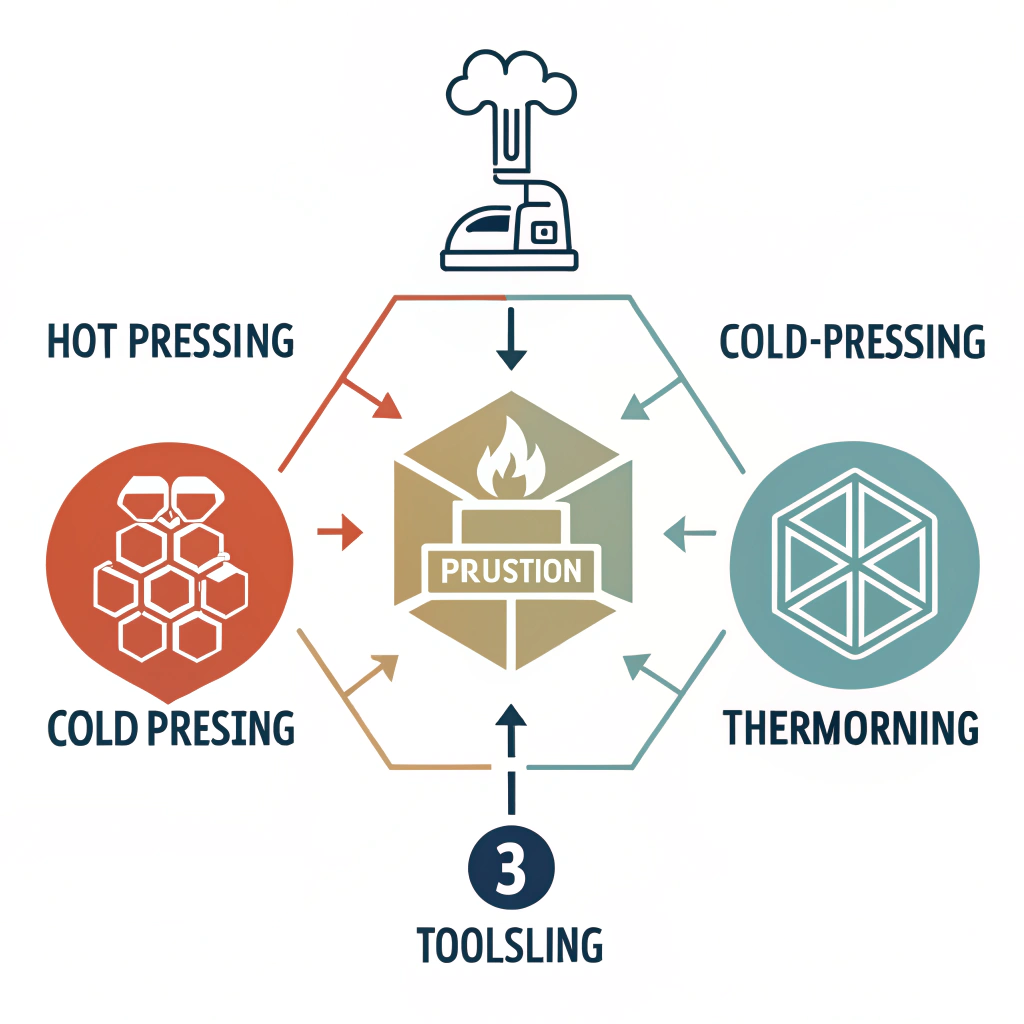

To understand how modern production techniques translate into game-changing performance, let's drill down into the three most common methods used by leading manufacturers like NEX Pickleball.

Hot pressing is a production process where materials are heated and pressed into shape. This method creates paddles with excellent structural integrity and durability.

Advantages:

• High production efficiency, suitable for large-scale manufacturing

• Produces paddles with robust impact resistance

• Ensures strong bonding of carbon fiber layers

Disadvantages:

• Elevated temperatures may alter intrinsic material properties

• Requires significant investment in specialized equipment

Cold pressing involves applying mechanical pressure at room temperature to shape the paddle. This process is known for its precision, preserving the delicate properties of materials.

Advantages:

• Enhanced control over paddle thickness

• Maintains the natural properties of materials, ensuring a superior ball feel

• Offers refined control and flexibility in paddle design

Disadvantages:

• Generally longer production cycles compared to hot pressing

• Demands high precision equipment to maintain consistency

Thermoforming4 heats the material until it softens, then forms it accurately in a mold. This method is particularly effective for paddles with complex designs and precise material distribution.

Advantages:

• Ideal for intricate paddle designs and precise material layouts

• Maintains paddle stability with balanced weight distribution

• Suitable for premium product lines where detail is paramount

Disadvantages:

• Longer production times and higher initial cost for molds

• Best applied to custom or premium paddle products

To visualize the differences, here is a quick comparison table:

| Production Process | Advantages | Disadvantages | Best For |

|---|---|---|---|

| Hot Pressing | High efficiency; strong impact resistance; excellent structural integrity | May alter material properties; high equipment cost | High-volume production, competitive play paddles |

| Cold Pressing | Precise control over thickness; preserves material properties; improved ball feel | Longer production cycle; requires precision equipment | Custom and performance-oriented paddles |

| Thermoforming | Intricate design capability; precise material distribution; stable weight balance | Time-consuming; higher cost for molds | Premium products and custom designs |

The core of every advanced pickleball paddle is its material composition. Manufacturers such as NEX Pickleball leverage various types of carbon fiber and composite materials to fine-tune performance.

-

3K Carbon Fiber1:

Known for its strength and flexibility, 3K Carbon Fiber provides excellent durability and reduces vibration. Its ability to deliver high rebound force makes it a favorite among competitive players who require precise control and consistent performance. -

12K Carbon Fiber2:

With a higher thread density, 12K Carbon Fiber offers a smoother surface, greater hardness, and improved durability. This makes it ideal for players engaged in fast-paced, competitive matches where impact resistance is critical. -

T3003:

T300 is synonymous with high performance, combining both strength and lightness. This balance is crucial in scenarios where both power and maneuverability are required.

Beyond carbon fiber, manufacturers sometimes integrate fiberglass or composite materials for added benefits:

• Fiberglass: Known for flexibility and a wider sweet spot, it offers enhanced ball control and durability.

• Bamboo Core Composite: Provides a lightweight yet impact-resistant core for a precise hitting feel.

• Honeycomb and Polymer Cores: These ensure superior shock absorption, maintain optimal paddle weight, and reduce vibration during play.

The choice of core material can significantly change the paddle's dynamics. For instance, Nomex Honeycomb Core5 is perfect for those who prioritize durability while seeking stable performance in intense game scenarios. Meanwhile, Aluminum Honeycomb Core offers a balanced profile, targeting players who desire both strength and precision.

For professionals responsible for sourcing B2B sports equipment, here are some practical insights and action steps on partnering with advanced pickleball paddle manufacturers:

- Look for detailed technical data that clearly differentiate between types of carbon fiber.

- Verify the advantages of core materials such as Nomex, Aluminum, and Polymer Honeycomb.

- Request performance certificates and testing results that reflect impact resistance, durability, and rebound consistency.

- Assess the production process and its suitability for the intended target market. For instance, hot pressing may be best for high-volume orders, while thermoforming is ideal for custom premium products.

- Analyze production cycle times versus quality outcomes. Cold pressing, although time-consuming, often yields a better "feel" for the ball, which is critical for end-user satisfaction.

- Prioritize suppliers who offer on-demand printing and customization options. This flexibility is key for retailers and sports organizations looking to brand or tailor their paddle specifications.

- Check for integration or compatibility with high-performance materials. For example, combining Carbon Fiber and Fiberglass Composite can offer a balanced mix of power and control.

- B2B buyers should develop strong, transparent relationships with manufacturers to ensure regular quality updates and innovations.

- Evaluate supplier track records, such as partnerships with leading brands like Joola and Selkirk, which are indicators of reliability and technical expertise.

Consider a scenario where a high-end sports equipment distributor faced challenges in finding paddles that could consistently deliver top performance. They required a paddle that balanced power, control, and durability for competitive play. By partnering with a manufacturer using advanced carbon fiber technologies and state-of-the-art production processes, the distributor received paddles designed with a combination of 12K Carbon Fiber and Aluminum Honeycomb Core. The outcome was a paddle that not only met but exceeded expectations on shot precision and impact absorption, leading to heightened player satisfaction and improved market competitiveness.

This case exemplifies how choosing the right combination of materials and production processes can significantly impact the success of retail products. Decision-makers should always weigh every technical detail against their strategic needs to ensure optimum return on investment.

In summary, the best high-performance pickleball paddles in 2025 are those that integrate cutting-edge carbon fiber materials with advanced production methods. For B2B procurement, it is essential to focus on the following action points:

• Understand the technical differences and applications of 3K, 12K, and T300 Carbon Fiber.

• Compare production techniques—hot pressing, cold pressing, and thermoforming—to match your volume and quality requirements.

• Validate core materials and design specifics with performance data and supplier certifications.

• Build strategic supplier partnerships that offer customization and OEM capabilities for branding and tailored specifications.

By considering these factors and leveraging data-driven insights, B2B professionals can make well-informed decisions that translate into increased market competitiveness, improved product performance, and enhanced end-user satisfaction. As technology evolves, staying abreast of these advancements and production methods will be key to achieving long-term success in the sports equipment industry.

Q1: What is the best pickleball paddle in 2025?

A: The best pickleball paddle in 2025 is one that successfully balances power, control, and durability. Top choices typically utilize advanced production techniques and premium materials like carbon fiber to deliver consistent performance across various playing conditions.

Q2: What is the best carbon fiber pickleball paddle?

A: The best carbon fiber pickleball paddle leverages materials such as 3K, 12K, and T300 Carbon Fiber to provide optimal strength, superior rebound force, and enhanced ball control while minimizing vibration. These paddles are designed for competitive play and are highly rated by industry professionals.

Q3: What is the #1 rated pickleball paddle?

A: While ratings may vary, the top-rated pickleball paddle is generally recognized for combining advanced production methods with premium materials, ensuring excellent durability, performance, and a balanced playing experience ideal for both intermediate and advanced players.

-

3K Carbon Fiber: Click here for an in-depth exploration of 3K Carbon Fiber properties, including its strength, flexibility, and applications in high-performance sports equipment. ↩ ↩ ↩2

-

12K Carbon Fiber: Click here to understand how 12K Carbon Fiber offers a smoother finish and enhanced durability, and why it is favored in competitive play scenarios. ↩ ↩ ↩2

-

T300: Click here to read about T300’s unique balance of strength and lightness, and how it contributes to superior paddle performance. ↩ ↩ ↩2

-

Thermoforming: Click here for a detailed explanation of the thermoforming process, including its advantages in achieving intricate designs and precise material distribution. ↩ ↩ ↩2

-

Nomex Honeycomb Core: Click here to discover the benefits of Nomex Honeycomb Core, which provides high durability and stable performance in intense play conditions. ↩ ↩