Pickleball manufacturers face a common challenge: choosing a manufacturing partner that blends advanced production processes, premium materials, and precise quality control. NEX Pickleball stands out by offering state-of-the-art OEM/ODM services1 that combine techniques like hot pressing, cold pressing, and thermoforming with high-performance materials such as various types of carbon fiber2, fiberglass, and advanced composites3. In short, NEX Pickleball’s integrated approach delivers superior performance, durability, and cost-effectiveness for B2B procurement managers and distributors.

In today’s competitive sports equipment market, design and production innovation are key differentiators. At NEX Pickleball, a leading Chinese manufacturer based in Jiaxing, Zhejiang, we focus on excellence in production processes and material selection to produce paddles that meet the high-performance requirements of both recreational and competitive players. Our robust production methods ensure that every paddle exhibits the optimal balance between power, control, and durability—properties that are critical when partnering in B2B procurement and distribution.

Our production offerings are versatile and include custom design options where clients can specify features such as weight, balance, and grip size. This wide array of customization along with our commitment to OEM/ODM excellence has made NEX Pickleball a trusted partner for reputable brands and distributors. Let’s explore the production processes and material choices that set us apart.

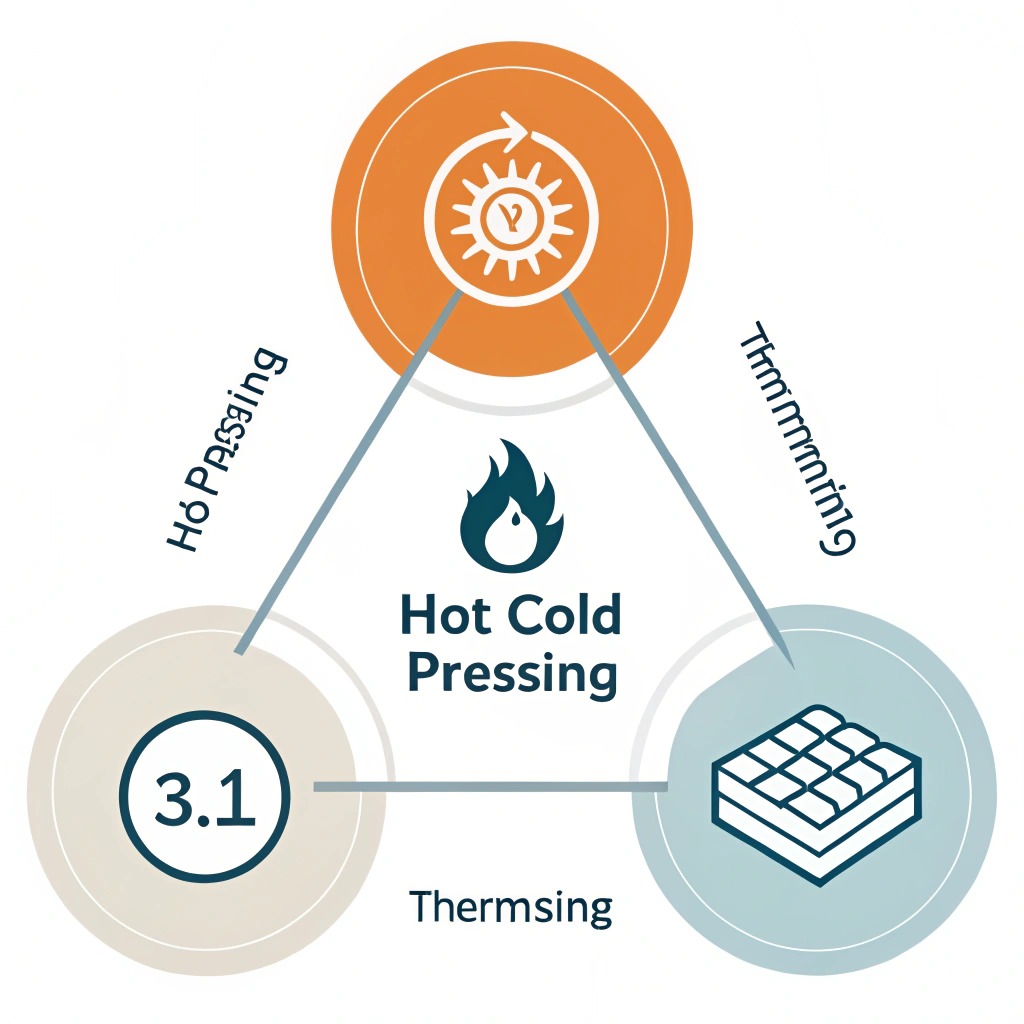

NEX Pickleball’s manufacturing capabilities revolve around three key production processes: hot pressing, cold pressing, and thermoforming4. Each method brings distinct advantages and potential trade-offs that can align with varied production needs.

| Process | Advantages | Disadvantages | Best For |

|---|---|---|---|

| Hot Pressing | High production efficiency; produces strong paddles with excellent impact resistance; ensures structural integrity. | May alter material properties; requires high investment in equipment. | High-performance paddles requiring durability. |

| Cold Pressing | Offers precise control over thickness and structure; maintains material properties for superior ball feel and responsiveness. | Longer production cycles; demands precise pressure control and high-quality equipment. | Paddles needing precise control and flexibility. |

| Thermoforming | Allows intricate designs; ensures even material distribution; maintains paddle stability. | Longer production times; higher equipment costs. | Premium custom-made paddles with complex shapes. |

This table provides a clear visual when comparing different production techniques. Each method’s selection should align with your production priorities—whether it’s efficiency, performance precision, or custom design complexity.

Materials are fundamental in meeting the technical expectations of competitive pickleball equipment. NEX Pickleball utilizes premium materials such as various types of carbon fiber, fiberglass, and state-of-the-art composite materials. Below is an overview of the material options we offer:

-

Carbon Fiber

- 3K Carbon Fiber: Enhances strength and flexibility while reducing paddle vibration. Ideal for paddles that require high rebound force.

- 12K Carbon Fiber: With higher thread density, it provides a smoother surface and better durability, making it suited for competitive play with extreme impact resistance.

- T300 Carbon Fiber: Known for its strong tensile properties while maintaining a lightweight profile, offering a balanced approach to both power and precision.

-

Fiberglass

- E-Glass Fiberglass: Known for its excellent elasticity and tensile strength, it contributes to an extended sweet spot and enhanced ball control—a perfect blend of power and finesse.

-

Composites

- Carbon Fiber & Fiberglass Composite: Merges the strengths of both materials, providing paddles with balanced performance for players seeking both power and control.

- Bamboo Core Composite: Utilizes the natural lightweight and impact-resistant properties of bamboo, delivering a distinct hitting feel and high durability.

- Honeycomb Core: This design focuses on superior shock absorption, ensuring that the paddle remains resilient under heavy use and repeatedly reduces vibration.

| Material Type | Key Properties | Application Scenario |

|---|---|---|

| 3K Carbon Fiber | High strength and flexibility; reduced vibration | High rebound paddles; endurance in play |

| 12K Carbon Fiber | Smooth surface; excellent durability | Competitive paddles; extreme strength needs |

| T300 Carbon Fiber | Balanced strength and lightweight | Performance paddles; ideal for precision play |

| E-Glass Fiberglass | Enhanced elasticity; wider sweet spot | Recreational to competitive play; improved control |

| Composite (Carbon Fiber & Fiberglass) | Best of both materials; balanced power and control | Paddles needing versatility in various play styles |

| Bamboo & Honeycomb Cores | Lightweight, impact-resistant, and stable | Custom and durable paddles designed for long-term consistency |

These comparisons highlight how material choices impact the final paddle performance, enabling procurement managers to choose a partner who aligns with their product vision.

Precision manufacturing and rigorous quality control are key pillars at NEX Pickleball. Each paddle passes through meticulous testing phases to ensure it meets the highest standards of strength, flexibility, and consistency. Key aspects of our quality control and supply chain processes include:

- Consistency in Production: Every production cycle is executed with state-of-the-art machinery and real-time monitoring systems. This ensures that minor deviations are detected and rectified early in the process.

- Material Traceability: We maintain full traceability of all materials sourced, providing assurance on the legitimacy and quality of each raw material used.

- Rigorous Testing: From impact resistance tests to vibration analysis, every paddle is subject to stringent quality control protocols that exceed industry standards.

- On-Demand Print Services: Our ability to incorporate on-demand printing for paddle customization adds a personalized touch that meets both branding and performance specifications.

This focus on quality control not only ensures durability and performance but also minimizes variability across large production runs—an essential factor for B2B partnerships.

Providing OEM/ODM services, NEX Pickleball empowers his partners to bring their specific product requirements into reality. We offer a range of customizable features such as:

- Weight and Balance Adjustments: Customizing the paddle’s weight distribution to match player preferences or team strategies.

- Grip Customization: Offering different grip sizes to suit various player hand sizes, ensuring comfort and optimal control.

- Artistic and Branding Customizations: With on-demand printing and custom mold options, businesses can incorporate unique designs, logos, and colors.

This level of customization is vital for businesses that want to differentiate their brands in a competitive market. Our ability to blend high technical performance with design aesthetics translates into products that are not only functionally superior but also visually distinctive.

Over the years, many leading sports equipment distributors have benefited from our advanced production methods and material choices. For example, by switching from a one-size-fits-all paddle to a customized option featuring a T300 carbon fiber face and a Nomex honeycomb core, one distributor reported a 15% increase in customer satisfaction due to improved playing performance and reduced vibration.

Industry data supports the trend towards high-performance and customizable sports equipment. The global sports equipment market has seen a double-digit growth rate, driven by increased participation in sports like pickleball. B2B procurement managers are increasingly prioritizing manufacturing partners who offer flexible production capabilities, stringent quality control, and the latest technology for enhanced product performance.

Such comparative data reinforces the idea that aligning with a technologically advanced partner like NEX Pickleball can yield significant product and market advantages.

When deciding on a manufacturing partner, it is important to weigh production processes, material quality, cost-effectiveness, and customization capabilities. NEX Pickleball offers a competitive edge with its integrated approach: advanced production techniques (hot pressing, cold pressing, thermoforming), high-quality materials (various carbon fibers, fiberglass, composite materials), and stringent quality controls.

For B2B procurement managers and distributors in the sports equipment industry, these factors translate into reliable, high-performance products and solid long-term partnerships. Evaluating these comprehensive production details can help you make a more informed decision that aligns with your target market's needs and your business objectives. Contact NEX Pickleball today to discuss how our tailored solutions can help boost your product line and competitive edge.

Q: What production process ensures the highest durability in pickleball paddles?

A: Hot pressing is highly effective for producing durable paddles due to its ability to create a strong, impact-resistant structure; however, specific production needs may dictate using alternative techniques such as thermoforming for more complex designs.

Q: How do advanced composite materials enhance paddle performance?

A: Combining carbon fiber with fiberglass or using bamboo/honeycomb cores delivers a balanced mix of strength, flexibility, and impact absorption that translates into improved performance, control, and player comfort.

Q: What benefits do OEM/ODM capabilities offer in pickleball paddle manufacturing?

A: OEM/ODM services allow businesses to tailor product features such as weight, grip, and design to meet the specific needs of their target market, helping them strengthen brand identity and customer satisfaction.

-

OEM/ODM services: Click to learn how Original Equipment Manufacturer (OEM) and Original Design Manufacturer (ODM) services enable businesses to customize production processes and product specifications for market differentiation. ↩ ↩

-

Carbon fiber: Click to explore the properties of carbon fiber, including its strength-to-weight ratio and applications in high-performance sports equipment manufacturing. ↩ ↩

-

Advanced composites: Click to discover the advantages of advanced composite materials, which combine different fibers and matrices to enhance strength, durability, and performance in competitive products. ↩ ↩

-

Thermoforming: Click to understand the thermoforming process, which uses heat to mold materials into complex shapes, offering design flexibility and precision in production. ↩ ↩