Advanced high-performance pickleball paddles are crucial for competitive play. In this article, we compare production techniques and material compositions to help sports equipment procurement managers, advanced sports retailers, and pickleball club directors make informed decisions. We detail the advantages and limitations of different manufacturing processes, analyze material choices, and provide a decision guide for sourcing the best paddles for competitive and advanced-level play.

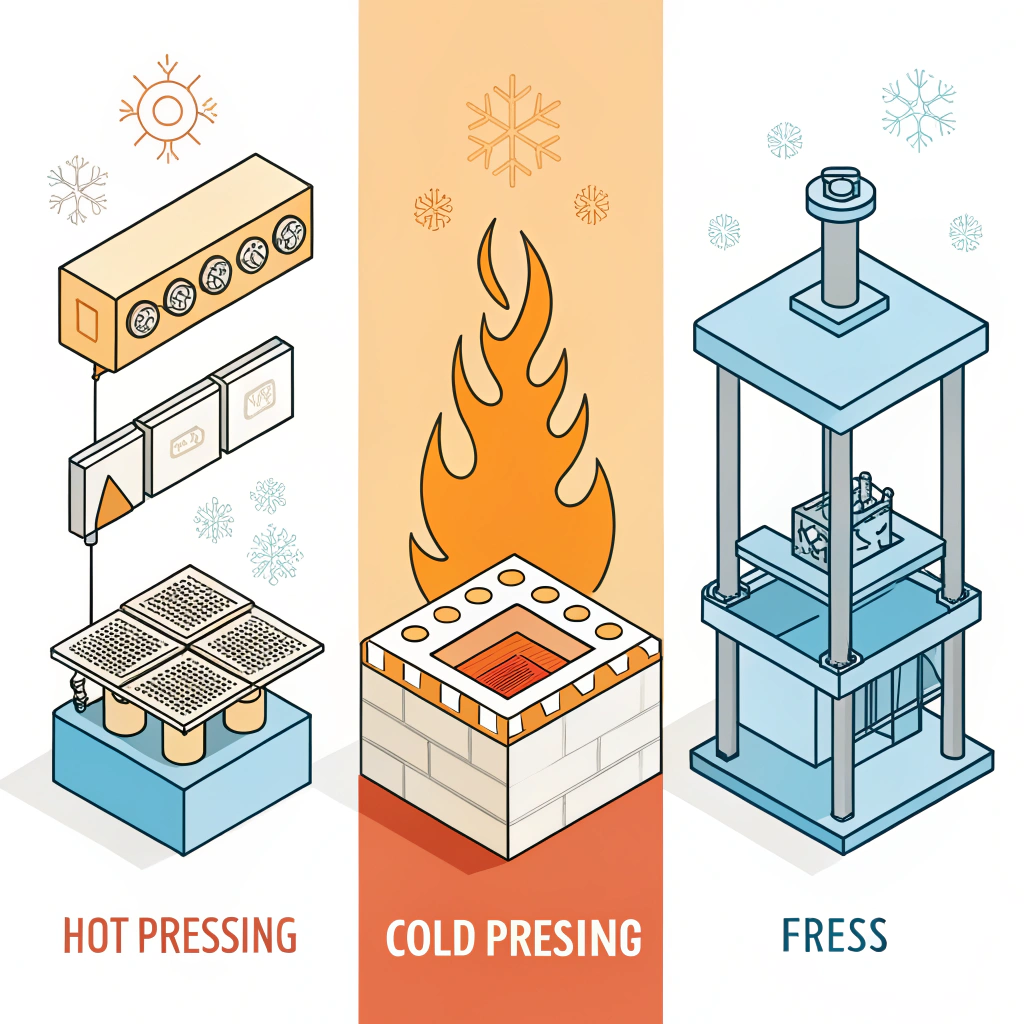

Manufacturing Processes: Hot Pressing, Cold Pressing1 and Thermoforming2

The manufacturing process greatly influences a paddle’s performance, durability, and production efficiency. At NEX Pickleball, three primary production methods are used, each with unique benefits and trade-offs.

Hot pressing involves heating materials and applying pressure to form the paddle. This method is widely used for its high production efficiency and ability to impart excellent impact resistance to the paddle.

- Advantages:

- High production output, suitable for large-scale manufacturing.

- Enhanced structural integrity and impact resistance.

- Disadvantages:

- The applied heat may alter some inherent material properties, potentially affecting the feel.

- Requires significant investment in specialized equipment.

Cold pressing shapes paddle materials at room temperature using mechanical pressure, ensuring that the material’s natural properties are well preserved. This process is especially valued for precision control over surface thickness and structure, which can optimize ball feel and overall handling.

- Advantages:

- Maintains the original material properties, offering superior control and responsiveness.

- Precise control over paddle dimensions and structure.

- Disadvantages:

- Typically a longer process than hot pressing, which may reduce overall production efficiency.

- Demands high-precision equipment for consistent results.

Thermoforming uses controlled heating to soften materials for molding into complex shapes. This method allows for intricate designs and precise material distribution, ensuring stability and performance even with high-performance materials.

- Advantages:

- Ideal for creating paddles with complex geometries and design innovations.

- Offers precise material distribution, enhancing paddle stability and durability.

- Disadvantages:

- Longer production cycles and higher equipment costs compared to other methods.

- Best suited for premium or custom products where unique item attributes justify the cost.

To give a clearer comparison, consider the following table:

| Production Process | Advantages | Disadvantages |

|---|---|---|

| Hot Pressing | High efficiency, strong impact resistance | May alter material feel; high equipment investment |

| Cold Pressing1 | Superior control; preserves material properties | Lower efficiency; requires high precision |

| Thermoforming2 | Intricate design; precise material distribution | Longer cycle time; higher costs |

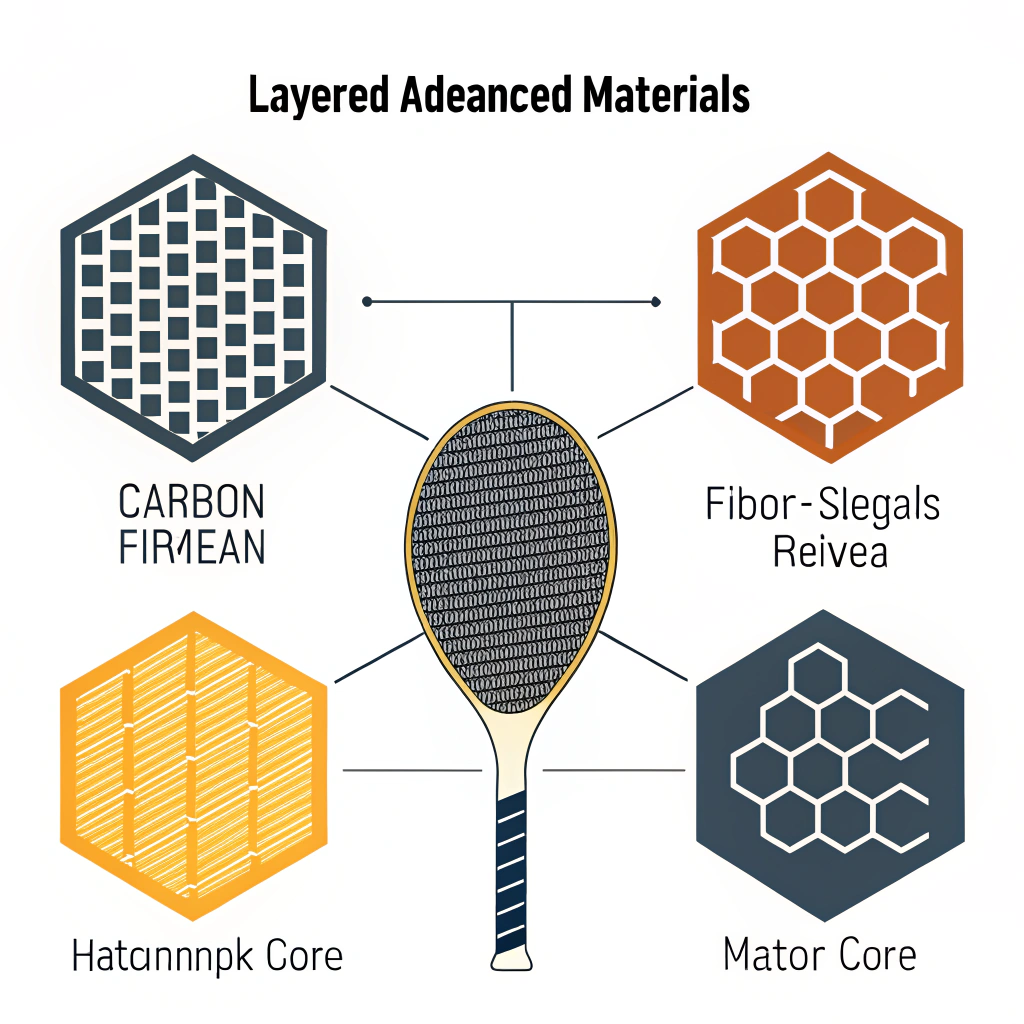

The choice of materials in high-performance pickleball paddles directly affects power, control, durability, and overall playing experience. At NEX Pickleball, advanced materials are carefully selected to target the specific needs of competitive play. Below are the primary materials we use:

Carbon Fiber3 Varieties

Carbon fiber is a staple in competitive paddles due to its unmatched strength and lightweight properties. Each variant brings distinct performance attributes:

-

3K Carbon Fiber:

Known for its strength and flexibility, the 3K variant provides significant rebound force while minimizing vibration—a perfect choice for players who demand both power and durability. -

12K Carbon Fiber:

Featuring higher thread density, 12K offers a smoother surface and greater hardness. It lends extra impact resistance, making it ideal for high-stakes competitive play where paddle stability is paramount. -

T300 Carbon Fiber:

Renowned for its exceptional tensile strength, T300 provides a well-balanced combination of strength and light weight, perfect for competitive play where agility is as important as power.

Combining different materials can lead to an optimum balance of attributes:

-

Carbon Fiber and Fiberglass Composite:

This mix leverages the strength of carbon fiber with the flexibility of fiberglass, offering an ideal blend of power and ball control. -

Bamboo Core Composite:

Bamboo provides a lightweight structure and remarkable impact resistance. Using a bamboo core ensures a clear hitting sensation and extended durability. -

Honeycomb Core:

Made typically from high-density polymers or pulp, honeycomb cores offer excellent shock absorption. This helps in reducing vibration while significantly increasing the paddle’s longevity.

The core is a critical aspect that determines the paddle’s feel and performance. The following options are available:

-

Nomex Honeycomb Core5:

A durable polymer-based core known for its shock absorption properties, ensuring long-lasting durability and stability in high-impact situations. -

Aluminum Honeycomb Core:

Offers a balanced weight and provides excellent power combined with precision control. This core is highly effective for players targeting both strength and finesse. -

Polymer Honeycomb Core:

Highly elastic and excellent at reducing vibration, this core is most appreciated by recreational players and beginners due to its comfortable feel.

To simplify material selection, consider the table below:

| Material Type | Key Benefits | Ideal Use Case |

|---|---|---|

| 3K Carbon Fiber | High strength, minimizes vibration | Competitive play requiring durability |

| 12K Carbon Fiber | Smoother surface, high hardness | High-impact competitive settings |

| T300 Carbon Fiber | Superior tensile strength, balanced weight | Competitive play with agility needs |

| E-Glass Fiberglass | Wide sweet spot, excellent control | Recreational to competitive with controlled feel |

| Carbon-Fiberglass Composite | Optimized power and control | Players seeking balanced performance |

| Bamboo Core Composite | Lightweight, impact resistant | Extended play with clear hitting feel |

| Nomex Honeycomb Core5 | Exceptional shock absorption, long-lasting durability | Professional-level competitive environments |

| Aluminum Honeycomb Core | Balanced weight, effective power control | Competitive use requiring mix of strength and precision |

| Polymer Honeycomb Core | Enhanced elasticity, reduced vibration | Beginners and recreational players who value comfort |

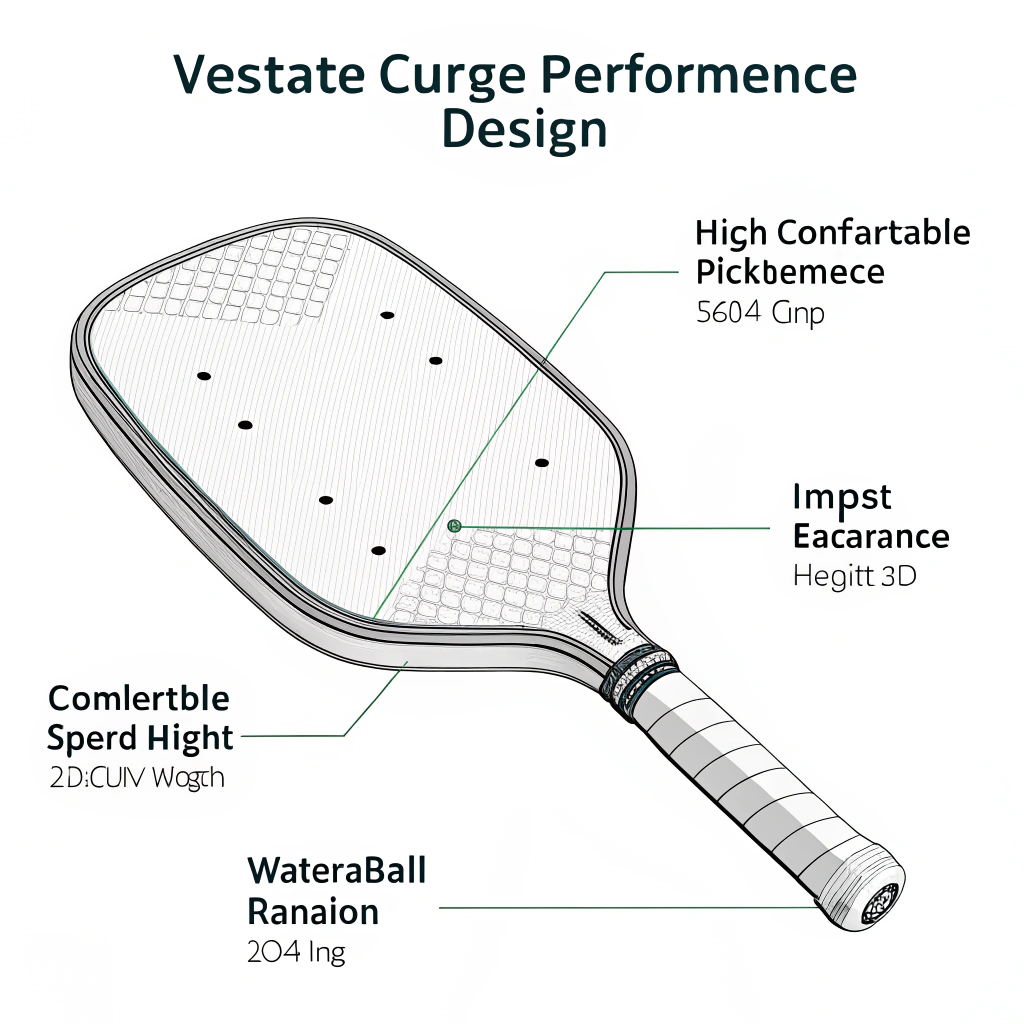

Aside from materials and production methods, design elements are essential in crafting a successful pickleball paddle. The following are key design aspects to consider:

An ergonomic grip and balanced weight distribution are vital for both comfort and performance.

-

Grip Design:

A comfortable and durable grip enhances control and reduces hand fatigue. Different grip sizes are available to match various hand dimensions, ensuring an optimal fit. -

Weight Distribution:

Consistent balance improves swing speed and maneuverability. A well-distributed weight allows for better power generation while minimizing the risk of injury.

The paddle surface plays a significant role in the ball’s spin and the overall response.

-

Textured Surfaces:

Special treatments on the paddle surface can enhance grip on the ball, improve spin, and boost accuracy. -

Finished Precision:

The quality of the finish affects not only performance but also the paddle’s longevity. Advanced manufacturing techniques ensure that the paddle surface remains consistent across batches.

High-performance paddles must withstand rigorous play while minimizing vibrations to reduce player fatigue.

-

Core Innovation:

Cores like Nomex Honeycomb or polymer honeycomb reduce vibrations significantly, providing a smoother playing experience. -

Material Synergy:

The combination of carbon fiber and fiberglass or composites can offer additional shock absorption, leading to enhanced durability, even under intense play.

When deciding on which advanced pickleball paddle to incorporate into your product portfolio, consider both the type of play and the end-user requirements:

Players at the highest levels require equipment that delivers on power with precise control.

-

Material Choice:

For instance, paddles made from 12K Carbon Fiber or T300 Carbon Fiber paired with a Nomex Honeycomb Core are optimal due to their high-impact durability and superior responsiveness. -

Production Method:

Hot pressing may be preferred for bulk production of highly durable paddles with consistent performance characteristics, while thermoforming is ideal for premium, custom designs.

Retailers targeting high-end consumers need products that can be marketed as both innovative and reliable.

-

Balanced Compositions:

Products featuring carbon fiber and fiberglass composites offer broad appeal, combining the hardness and smoothness of carbon with control and flexibility from fiberglass. -

Customization Options:

Offering custom paddle options with adjustable grip sizes, weight distribution, and surface texture can significantly enhance the product portfolio. This approach caters to both team branding and individual preferences.

| Scenario | Recommended Material & Core | Production Process | Key Performance Benefits |

|---|---|---|---|

| High-Level Competitive Play | 12K or T300 Carbon Fiber with Nomex Honeycomb Core | Hot Pressing or Thermoforming | Superior impact resistance, precise ball control |

| Advanced Retail/Custom Play | Carbon-Fiberglass Composite with Polymer or Aluminum Honeycomb Core | Cold Pressing for precision; Thermoforming for custom designs | Balanced performance, enhanced comfort, customizable design |

| Mass Volume with Consistency | 3K Carbon Fiber with Aluminum Honeycomb Core | Hot Pressing | High throughput, durability, consistent quality |

- Durability & Performance:

High-performance competitions demand paddles that not only offer power and control but can withstand long, grueling sessions. - Production Efficiency:

For large-scale orders, production methods that optimize both quality and output are critical. - Customization Needs:

Modern players and retailers increasingly value paddles that can be tailored to specific ergonomic and performance requirements.

Selecting the right advanced pickleball paddle involves balancing technical specifications with practical application scenarios. In summary:

- Production Techniques:

Hot pressing, cold pressing, and thermoforming each offer unique advantages and should be chosen based on production scale, cost considerations, and desired paddle performance. - Material Composition:

The choice between various carbon fiber types, fiberglass, composites, and core materials such as Nomex or aluminum greatly affects the paddle’s power, control, and durability. - Design and Application:

Ergonomic design, surface treatment, and vibration damping are essential components that round out a paddle’s performance. Customization options further enhance market appeal, especially in competitive and high-end retail segments.

For procurement managers and retailers, the next step is to evaluate your target customer’s needs and align them with the product specs detailed here. Equip your portfolio with paddles that bring together the best in technology, performance, and customization. Consider partnering with trusted manufacturers like NEX Pickleball who are experts in advanced production processes and premium material selection.

We recommend a thorough review of production methodologies and material attributes before finalizing your procurement decisions. Detailed technical comparisons such as those provided in this article will empower you to make data-driven purchasing decisions, ensuring that your inventory meets the high standards required by competitive players.

Take action now to source paddles that truly enhance performance on the court. Contact our team at NEX Pickleball for further technical consultation and customized product solutions that align with your retail or club needs.

People Also Ask

Q1: What makes advanced pickleball paddles suitable for competitive play?

A1: Advanced pickleball paddles combine premium materials—such as higher-grade carbon fibers and specialized cores—with precise manufacturing processes to ensure superior performance, durability, and consistent control during high-impact gameplay.

Q2: How do different production processes affect paddle performance?

A2: Production methods like hot pressing, cold pressing, and thermoforming each impact the paddle’s structural integrity, material properties, and design accuracy, thereby influencing factors such as impact resistance, ball feel, and overall durability.

Q3: Which material compositions offer the optimal balance of power and control?

A3: A combination of high-performance carbon fiber variants (like 12K or T300) with a complementary core material (such as Nomex or aluminum honeycomb) typically offers the best balance of power, control, and durability for competitive play.

-

Cold Pressing: Click here to learn about how cold pressing preserves a material's natural properties and ensures precise control in shaping high-performance equipment. ↩ ↩ ↩2

-

Thermoforming: Click here to explore the thermoforming process, a method that uses controlled heating to create complex shapes and optimize material performance. ↩ ↩ ↩2

-

Carbon Fiber: Click here to understand the unique properties of carbon fiber, including its high strength-to-weight ratio and its role in enhancing durability and performance. ↩ ↩

-

Composite Materials: Click here to discover how combining different materials can achieve an optimal balance of strength, flexibility, and performance in advanced manufacturing. ↩ ↩

-

Nomex Honeycomb Core: Click here to learn how Nomex honeycomb cores provide exceptional shock absorption and durability, making them ideal for high-impact competitive applications. ↩ ↩ ↩2