For intermediate players, the 6 best pickleball paddles combine balanced power, superior control, and durable construction—making them ideal for players transitioning from beginner to advanced skill levels. In this article, we compare six top-performing models and explain their technical merits, manufacturing techniques, and real-world benefits to help you make informed B2B purchasing decisions.

Intermediate players require paddles that offer a mix of forgiveness and precision. These players are past the beginner stage and are looking to improve their game with equipment that offers:

- Enhanced power without sacrificing control

- Improved comfort and reduced vibrations

- Durability suitable for frequent play

A key factor in meeting these demands is selecting paddles that not only perform well on the court but also align with market trends and consumer preferences. The models analyzed here integrate advanced production techniques and premium materials, such as carbon fiber1, fiberglass2, and composite materials, ensuring both quality performance and longevity.

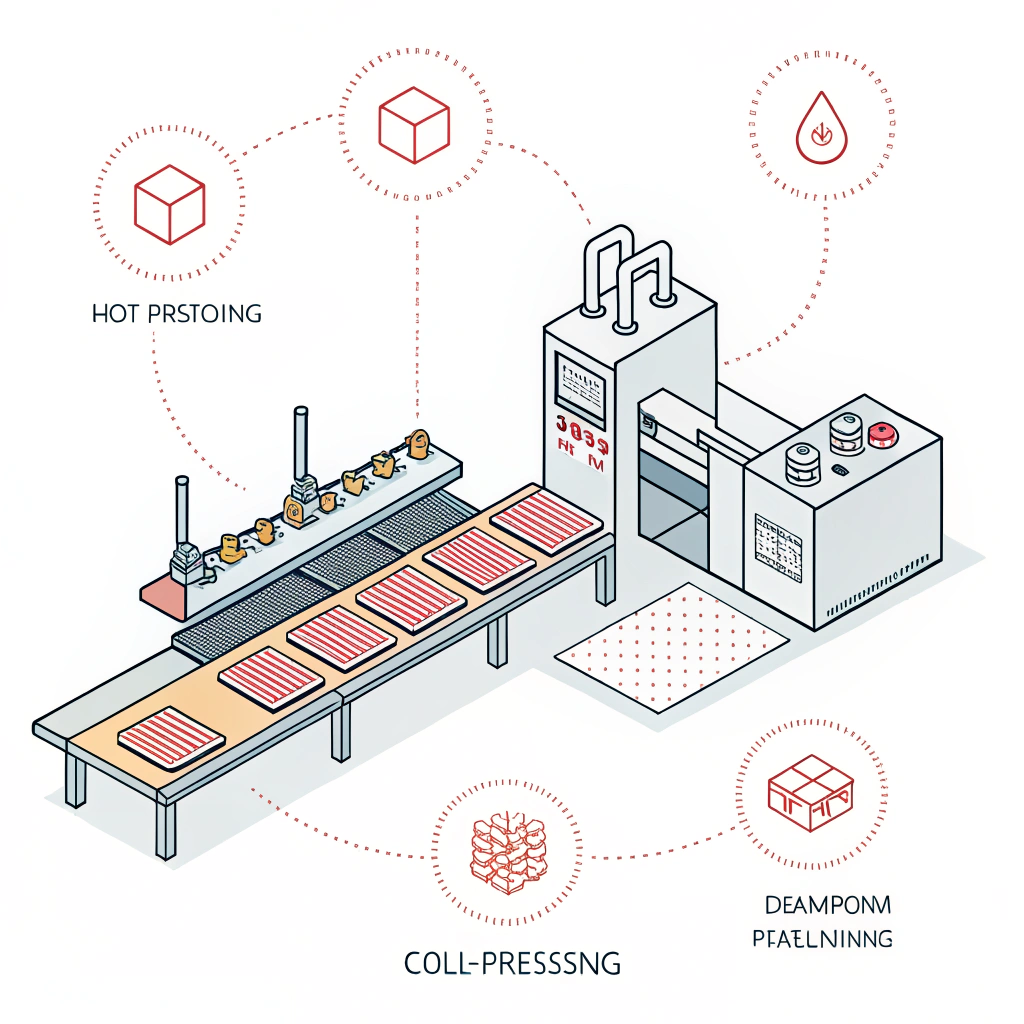

The performance of a pickleball paddle is largely determined by its construction. At NEX Pickleball, modern production techniques are used to create paddles that excel in performance and consistency, including:

- Hot Pressing3: Involves heating combined with pressure to form a strong and durable paddle. This process is known for high production efficiency and results in paddles with excellent impact resistance.

- Cold Pressing4: Maintains the natural properties of the paddle's materials through room temperature processing. This method allows for precise control over paddle thickness and structure, ensuring a responsive feel.

- Thermoforming5: Uses heat to soften materials, which are then molded into intricate designs and shapes. This process is ideal for paddles that require a well-balanced weight distribution and enhanced grip.

Each process has its advantages and limitations, but collectively they ensure a high level of quality control and performance. The advanced manufacturing methods used by NEX Pickleball guarantee that each paddle can help intermediate players maximize their skill set while offering durability suited for continuous use.

Below is a detailed comparison of six outstanding pickleball paddles tailored for the intermediate market. Each paddle is selected based on its material composition, manufacturing process, performance features, and market appeal.

- Material: 3K Carbon Fiber

- Manufacturing Process: Hot Pressing

- Features:

- High rebound force and improved impact resistance.

- Excellent durability with reduced vibration during play.

- Ideal for players needing enhanced power.

- Performance Benefit: This paddle is favored for its robust build and consistent ball response, making it suitable for fast-paced games.

- Material: 12K Carbon Fiber

- Manufacturing Process: Cold Pressing

- Features:

- Smoother surface providing a balanced mix of power and control.

- Higher thread density for greater hardness.

- Exceptional durability in competitive play scenarios.

- Performance Benefit: The 12K paddle appeals to players demanding precision and high impact resistance, making it a solid choice for tournaments.

- Material: E-Glass Fiberglass

- Manufacturing Process: Cold Pressing

- Features:

- Wider sweet spot and enhanced ball control.

- Offers flexibility ideal for players looking to fine-tune their technique.

- Improved elasticity resulting in great paddle feel.

- Performance Benefit: With a balanced power-to-control ratio, this paddle is perfect for intermediate players refining their swing mechanics.

- Material: Composite of Carbon Fiber and Fiberglass

- Manufacturing Process: Thermoforming

- Features:

- Combines the strengths of two premium materials.

- Provides both the lightweight sensitivity of fiberglass and the robust power of carbon fiber.

- Intricate design for optimal weight distribution.

- Performance Benefit: This paddle offers versatility and is especially attractive to distributors due to its dual-material innovation, meeting the varied needs of intermediate players.

- Material: Bamboo Core Composite

- Manufacturing Process: Hot Pressing with additional refinement

- Features:

- Lightweight structure with high impact resistance.

- Clear hitting feel optimized for extended play.

- Eco-friendly materials with a modern design.

- Performance Benefit: Ideal for markets promoting sustainability paired with high performance, this paddle is popular among players seeking a unique blend of tradition and innovation.

- Material: Polymer Honeycomb Core

- Manufacturing Process: Thermoforming

- Features:

- Superior shock absorption with minimal vibration.

- Offers enhanced elasticity for a more comfortable playing experience.

- Balanced weight making it great for long, competitive matches.

- Performance Benefit: Perfect for intermediate players who prioritize comfort as much as performance, this paddle stands out with its impressive control characteristics.

The table below summarizes the key specifications and manufacturing methods of these six pickleball paddles:

| Paddle Model | Material | Manufacturing Process | Key Advantages | Best For |

|---|---|---|---|---|

| Paddle A – 3K Champion | 3K Carbon Fiber | Hot Pressing | High rebound, durable, low vibration | Fast-paced, power players |

| Paddle B – 12K Performer | 12K Carbon Fiber | Cold Pressing | Smoother surface, hard, high impact resistance | Precision and competitive play |

| Paddle C – Flex Master | E-Glass Fiberglass | Cold Pressing | Wide sweet spot, excellent control | Technique improvement |

| Paddle D – Fusion Pro | Carbon Fiber & Fiberglass Composite | Thermoforming | Versatile material blend, balanced weight | Versatile play, dual benefits |

| Paddle E – Bamboo Dynamics | Bamboo Core Composite | Hot Pressing | Lightweight, eco-friendly, clear feel | Eco-conscious, innovative use |

| Paddle F – Precision Edge | Polymer Honeycomb Core | Thermoforming | Superior shock absorption, comfort | Long matches, comfort seekers |

When evaluating these paddle options, B2B buyers should consider not only the technical specifications and manufacturing processes but also how these products perform in real-world scenarios. Here are several important performance and business considerations:

-

Balanced Performance: Intermediate players expect paddles that enhance both control and power. The composition of carbon fiber1 (either 3K or 12K) is a clear winner for their strength-to-weight ratio, while composite options bring additional benefits by merging high performance with greater flexibility.

-

Durability and Quality Control: Advanced production methods like Hot Pressing3 and Thermoforming5 ensure that each paddle stands up to the rigors of regular competitive play. For distributors, this translates into longer product lifecycles and fewer returns, increasing overall customer satisfaction.

-

Cost Efficiency vs. Performance: While high-end materials such as 12K carbon fiber1 might have a higher production cost, they bring significant benefits in performance which are crucial for competitive middle-tier athletes. Offering a range—including more cost-efficient options like fiberglass-based paddles—allows retailers to cater to a broader market segment.

-

Market Trends and Innovation: Innovations such as eco-friendly bamboo core composites or advanced polymer honeycomb cores resonate with evolving consumer priorities. As players become more conscious of both performance and environmental impact, these innovations can be significant selling points.

-

Customization and Branding Opportunities: With technologies that allow on-demand printing and tailored paddle designs, businesses can offer customized products to teams or specialty stores. This personalization enhances product appeal and can create a competitive edge in the retail market.

NEX Pickleball stands as a leader in the high-performance pickleball paddle market — not only because of their carefully selected materials but also their rigorous manufacturing processes. By employing techniques such as Hot Pressing3, Cold Pressing4, and Thermoforming5, NEX Pickleball ensures that every paddle delivered meets the highest standards in terms of strength, balance, and longevity.

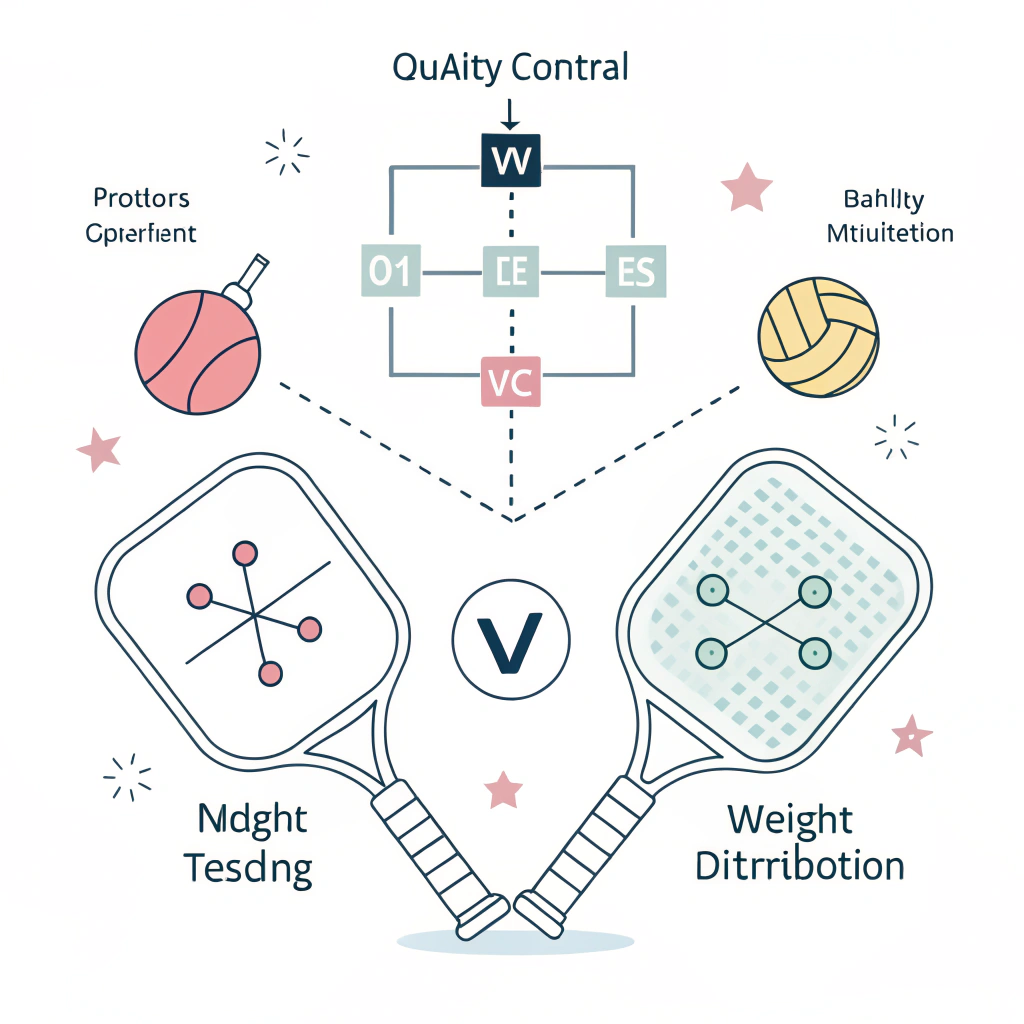

Quality control at NEX Pickleball is critical. Each paddle undergoes strict testing, including:

- Impact resistance tests: To ensure durable performance even under intensive play.

- Vibration analysis: Guaranteeing a comfortable playing experience by reducing shock.

- Weight distribution checks: Providing consistency across different production runs, which is crucial for retail buyers who aim to offer reliable products.

These quality measures ensure that products not only meet but often exceed the practical requirements of intermediate players. For B2B buyers, partnering with a manufacturer committed to innovation and reliability is a key factor when deciding on inventory for retail or distribution purposes.

To cater successfully to the intermediate pickleball market, distributors and retail buyers should consider the following:

- Diversify Your Portfolio: Offer a range of paddles—from the power-focused 3K Carbon Fiber Champion to the comfort-centric Polymer Precision Edge—to meet diverse player needs.

- Focus on Innovation: Leverage the latest advances in production processes and materials to stand out in highly competitive retail spaces.

- Emphasize Customization: Use on-demand printing and design customization options to maximize branding opportunities, catering to both individual consumer needs and team requirements.

- Evaluate Total Cost of Ownership: Consider not only the unit price but also the extended durability and performance benefits that reduce long-term costs.

Ultimately, the 6 paddles discussed here provide a robust selection for intermediate players. Their advanced material usage and precise manufacturing techniques ensure that they deliver both performance and reliability. Distributors and retailers stand to benefit from partnering with a manufacturer that prioritizes quality and innovation, ensuring that your product portfolio remains competitive and aligned with market demands.

By selecting the right mix of paddles, you can cater to a broad spectrum of the pickleball community—ensuring increased customer satisfaction, repeat business, and a strong market position as the sport continues to evolve.

Q1: What are the key features to consider when selecting a pickleball paddle for intermediate players?

A1: Intermediate players benefit from paddles that balance power and control. Key features include optimal weight distribution, durable core materials, reduced vibration through advanced manufacturing, and a design that supports both accuracy and speed.

Q2: How do advanced manufacturing processes contribute to paddle performance?

A2: Advanced processes such as Hot Pressing3, Cold Pressing4, and Thermoforming5 ensure consistent material properties, precise control over thickness and curvature, and improved structural integrity that enhances both durability and performance on the court.

Q3: Why is carbon fiber considered an excellent material for pickleball paddles aimed at intermediate players?

A3: Carbon fiber1 provides high strength and low weight, which are crucial for quick reaction times and powerful shots. It also reduces vibration and offers superior durability, making it a favorite choice for intermediate players looking to upgrade their game.

-

carbon fiber: Reading this article will help you understand the characteristics and benefits of using carbon fiber in high-performance equipment. ↩ ↩ ↩2 ↩3 ↩4

-

fiberglass: Reading this article will provide insights into the properties and advantages of fiberglass in manufacturing. ↩ ↩

-

Hot Pressing: Reading this article will explain the process of hot pressing and its impact on product durability and performance. ↩ ↩ ↩2 ↩3 ↩4

-

Cold Pressing: Reading this article will detail how cold pressing is used to maintain material integrity and achieve precise product specifications. ↩ ↩ ↩2 ↩3

-

Thermoforming: Reading this article will discuss the thermoforming process and its role in shaping advanced composite materials. ↩ ↩ ↩2 ↩3 ↩4