A quick answer: Choosing the ideal pickleball paddle requires balancing technical specifications with production methods. Consider materials such as carbon fiber1, fiberglass2, and composite cores, along with manufacturing processes like Hot Pressing3, cold pressing, and Thermoforming4 to ensure the paddle delivers the right trade-off between power, control, and durability for your market needs.

In today’s dynamic sports equipment market, introducing a high-performance pickleball paddle can open significant business opportunities for distributors and retail chains. However, making an informed procurement decision is challenging. B2B procurement managers must balance paddle performance, cost-effectiveness, and production reliability. This article explains the key components and manufacturing processes that influence paddle performance. It also compares various materials and provides practical guidance to help you select the best paddle for your portfolio.

Introducing a new pickleball paddle line involves several decisions:

- Which materials assure peak performance while remaining cost-effective?

- How do various manufacturing methods impact the final paddle's feel and durability?

- Which paddle configuration meets the target market’s play styles, from beginners to competitive players?

The problem often lies in understanding the interplay between the paddle materials, production techniques, and design customization. B2B professionals need a detailed breakdown of these aspects to drive their purchasing decisions.

Materials play a crucial role in defining the paddle's performance standards. Below is a comparison of key materials:

| Material Category | Characteristics | Common Uses | Benefits | Considerations |

|---|---|---|---|---|

| Carbon Fiber | High strength; light weight | Competitive paddles | Provides excellent power and responsiveness. Options include 3K, 12K, and T300 variants, each differing in density and performance. | Higher cost; stiff feel which may not suit every player. |

| Fiberglass | Flexibility; wider sweet spot | Beginner to recreational paddles | Offers excellent ball control with a textured surface for added spin. | Slightly less durable compared to high-end carbon fiber. |

| Composite Materials | Blend of materials | Versatile paddle designs | Combines benefits from more than one material; e.g., carbon fiber with fiberglass or bamboo core composites for improved impact resistance and balanced performance | Complexity in manufacturing; may involve higher production costs. |

| Core Materials (Honeycomb) | Varying densities; shock absorption | Determining paddle “feel” | Options include Nomex Honeycomb, Aluminum Honeycomb, and Polymer Honeycomb. They provide a mix of power, control, and vibration reduction. | The suitability depends on the targeted player profile; more resilient cores usually cost more. |

Insight: For new product lines, it is crucial to match material selection with the targeted customer’s needs. Competitive players may prefer T300 carbon fiber for its strength and balance, whereas recreational players might lean towards E-Glass fiberglass for its controllability.

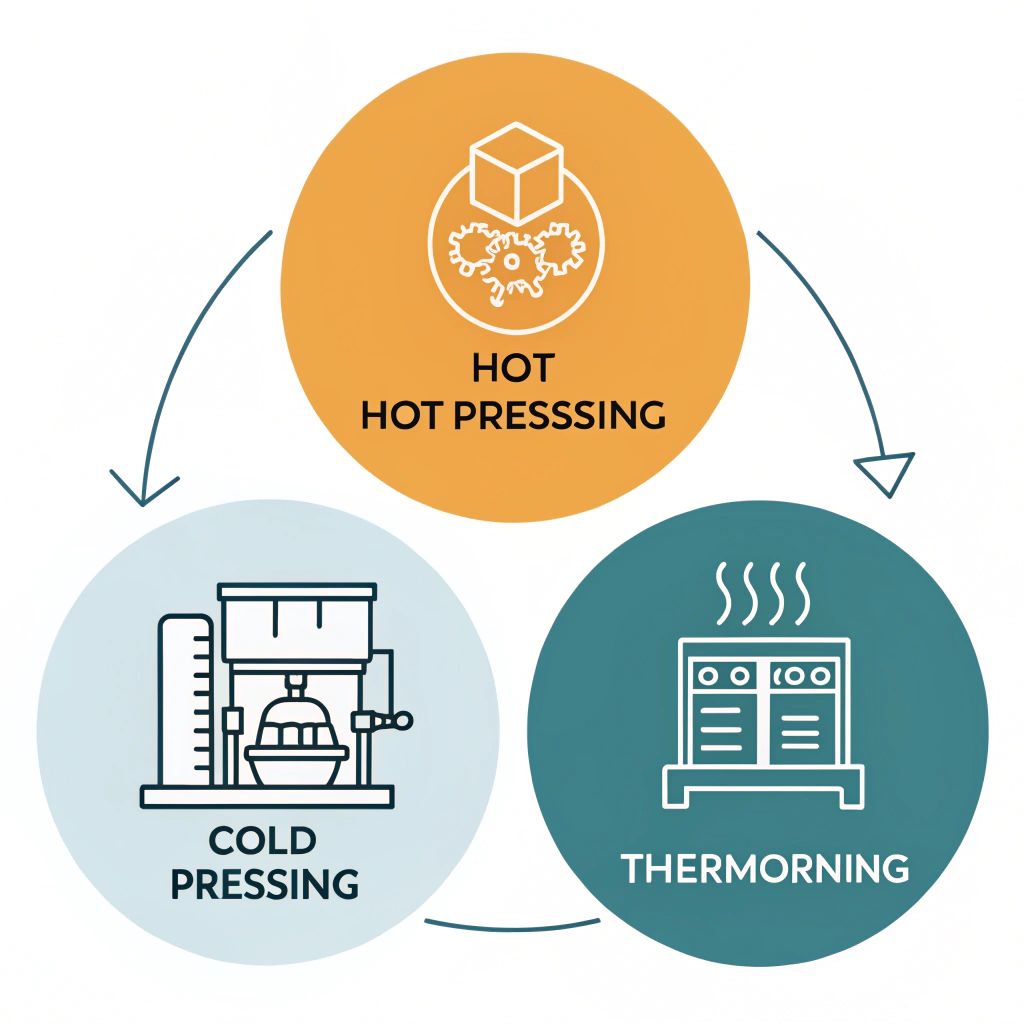

The production process directly affects the paddle’s performance, playability, and longevity. Here’s a closer look at the three primary methods:

| Production Process | Advantages | Disadvantages | Ideal For |

|---|---|---|---|

| Hot Pressing | High production efficiency; creates strong, durable paddles with excellent impact resistance. | Can change some material properties, potentially affecting paddle feel; requires high equipment investment. | Large-scale production and high-performance paddles. |

| Cold Pressing | Maintains original material properties; allows precise control over thickness and structure. | Slower production cycle; demands precise pressure control which may need advanced equipment. | Designs requiring precise control over texture and feel, ideal for paddles emphasizing touch and responsiveness. |

| Thermoforming | Enables creation of intricate designs; ensures even material distribution and stability. | Longer production time; higher equipment costs; best suited for premium or custom-made paddles. | Custom designs and premium product lines where paddle aesthetics and performance are finely balanced. |

Insight: When selecting the production process, consider your client base and market positioning. For example, a paddle aimed at elite players may justify thermoforming's longer production cycle for a unique design, while a more budget-friendly alternative might benefit from cold pressing to maintain material integrity and cost-effectiveness.

To effectively introduce your first pickleball paddle product line, align material choices and production processes with the specific needs of your target market:

-

Competitive Paddles: Target high-performance players by employing T300 carbon fiber with a Nomex honeycomb core. Use hot pressing for robust impact resistance. These paddles offer precision and power, ideal for competitive play.

-

Entry-Level Paddles: For newcomers, choose E-Glass fiberglass coupled with a polymer honeycomb core. This combination maximizes control and offers a forgiving ball feel. Using cold pressing can maintain the material’s inherent properties and help novices learn proper techniques.

-

Customizable Paddles: Offer paddles designed using composite materials5. Clients can choose between combinations like carbon fiber/fiberglass or even bamboo core composites based on desired balance, flexibility, and durability. Thermoforming can be used for custom shapes and tailored performance characteristics.

Besides technical performance, consider these operational factors:

-

Production Scale: Align your production method with expected order volumes. For high-volume orders, hot pressing can boost efficiency, whereas smaller premium orders might benefit from the custom touch of thermoforming.

-

Cost Implications: While high-performance materials increase initial costs, targeting niche markets can command a premium. Assess long-term market returns relative to production expenses.

-

Quality Control: Regardless of selected manufacturing methods, rigorous quality control is essential. Every paddle should be tested for durability, balance, and vibration reduction. Investing in consistent quality checks helps maintain market reputation and reduces return rates.

-

Customization Capability: With on-demand-print services available, offering tailored options enhances customer satisfaction, especially for sports teams or retail chains wanting brand identity. This feature supports marketing differentiation in a crowded marketplace.

A quick comparison table for decision-makers:

| Feature/Attribute | High-Performance (Elite) | Entry-Level (Recreational) | Customizable (Hybrid) |

|---|---|---|---|

| Primary Material | T300 Carbon Fiber | E-Glass Fiberglass | Carbon Fiber/Fiberglass Composite, Bamboo Core |

| Core Material | Nomex Honeycomb | Polymer Honeycomb | Honeycomb Core (tailored) |

| Production Method | Hot Pressing | Cold Pressing | Thermoforming (for intricate designs) |

| Key Benefit | Maximum power and durability | Enhanced control and comfort | Flexible design and performance balancing |

| Cost Factor | Higher cost; premium price point | Cost-effective solution | Moderate to high, depending on customization |

| Target Market | Competitive athletes | Beginners and recreational players | Niche market segments requiring unique designs |

Consider a recent case where a sports equipment distributor introduced a dual-range pickleball paddle line. The competitive line used 12K carbon fiber with aluminum honeycomb cores and hot pressed manufacturing. The entry-level products used E-Glass fiberglass with polymer honeycomb cores manufactured via cold pressing. Sales data showed a 25% higher repeat order rate due to improved performance consistency and tailored pricing structures.

This case illustrates how aligning product specifications with player needs can significantly impact the market reception. It also emphasizes that flexibility in production processes, combined with customer-centric material selection, leads to long-term success in competitive sports equipment markets.

In summary, selecting the right pickleball paddle involves a careful evaluation of materials, core types, and production methods. Here’s a final checklist to guide your decision-making:

- Identify your target market's needs (competitive vs. recreational).

- Choose the right material:

- Carbon Fiber1 for high performance and durability.

- Fiberglass2 for better control and user-friendly play.

- Composite Materials5 for custom approaches.

- Decide on the production process:

- Hot Pressing3 for efficient, high-volume production.

- Cold Pressing for fine control and superior tactile performance.

- Thermoforming4 for premium, custom-designed paddles.

- Ensure rigorous quality control measures are in place.

- Leverage customization options such as on-demand-print services to differentiate from competitors.

- Evaluate cost pressures versus expected market returns to optimize production and pricing strategies.

By following these steps, your organization will be well-equipped to introduce a pickleball paddle that meets your customers’ expectations, stands out in a crowded market, and drives long-term success.

-

How do I choose my first pickleball paddle?

When selecting your first pickleball paddle, consider factors such as weight, grip size, material composition, and core structure. Matching these elements with your targeted playing style ensures a balanced combination of power, control, and durability. -

What is the best paddle surface for beginners pickleball?

For beginners, a paddle with a textured surface is ideal as it adds spin and control. Fiberglass paddles are often recommended because they offer flexibility and a wider sweet spot, making them accessible for players still mastering their technique. -

What is the best budget paddle for beginner pickleball reddit?

Budget-conscious beginners often look for paddles that offer solid performance without premium pricing. Products like the Vatic Prism Flash provide a nice balance of features and value, ensuring that even entry-level players can enjoy a quality playing experience.

-

Carbon Fiber: Click here to learn how carbon fiber integrates lightweight strength into sports equipment, enhancing performance in competitive markets. ↩ ↩ ↩2

-

Fiberglass: Click here to explore how fiberglass contributes to greater flexibility and control, ideal for products designed for a broad range of users. ↩ ↩ ↩2

-

Hot Pressing: Click here to understand the hot pressing process and its benefits for mass-producing robust, high-quality sports equipment. ↩ ↩ ↩2

-

Thermoforming: Click here to delve into the thermoforming technique, which enables intricate design detailing and superior product aesthetics for premium markets. ↩ ↩ ↩2

-

Composite Materials: Click here to discover how composite materials blend multiple substances to optimize durability and balance in high-performance products. ↩ ↩ ↩2