The best pickleball paddle for 2025 is one that combines advanced materials, innovative production processes, and superior quality control to deliver exceptional performance and longevity. In this article, we dissect upcoming trends and production innovations that set industry leaders like NEX Pickleball apart in a competitive market.

In a rapidly evolving sports equipment market, the best pickleball paddle in 2025 will rely not only on breakthrough materials but also on sophisticated manufacturing techniques. As distributors and product development executives weigh supplier options, it is important to scrutinize the nuances of paddle manufacturing1. From the type of carbon fiber2 used to production methods like hot pressing3, cold pressing, and thermoforming4, manufacturers lay a technical foundation that influences both performance and cost-effectiveness.

At NEX Pickleball, we have developed expertise in leveraging diverse materials and advanced production techniques to create paddles that provide unrivaled power, control, and comfort. This post explores key innovations that will drive the best pickleball paddle manufacturing decisions in the coming years.

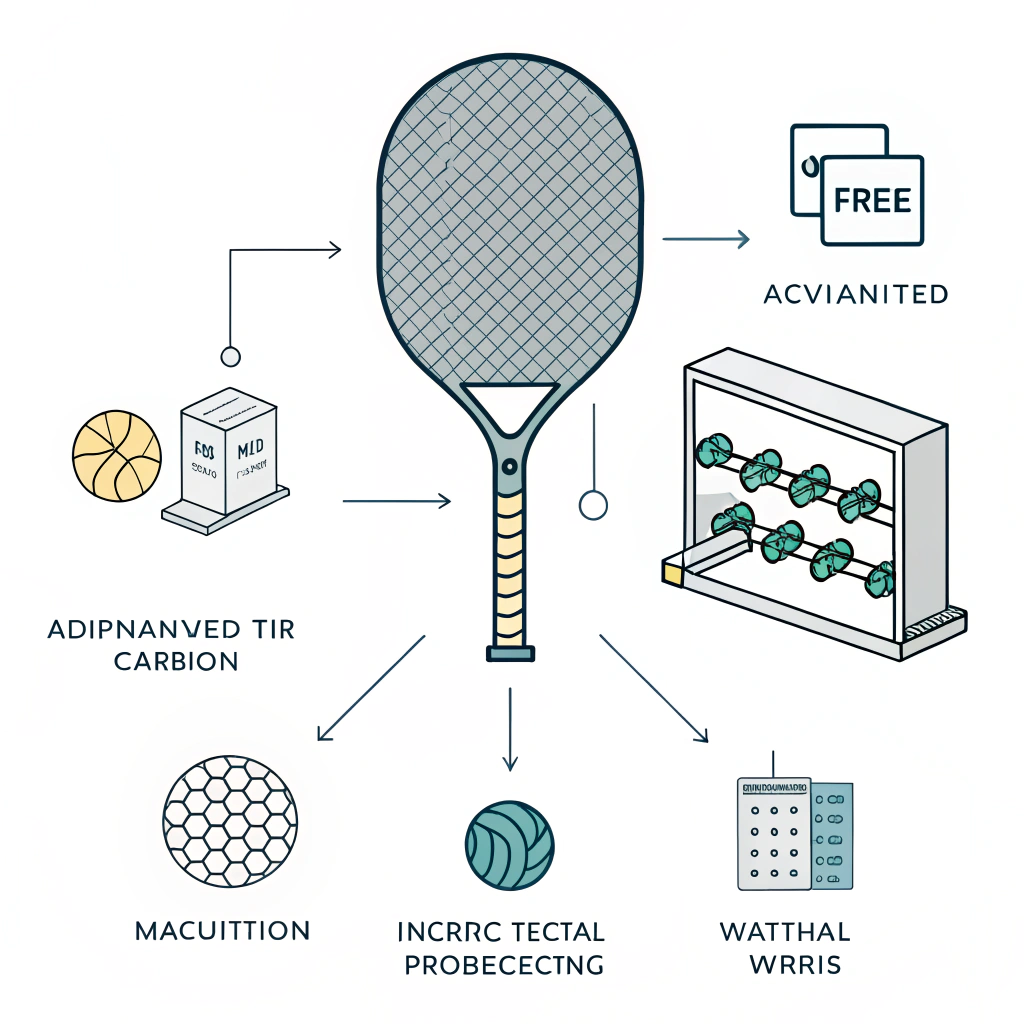

The leap in performance pivots on the evolution of materials. Manufacturers now have multiple options to refine paddle characteristics:

-

Carbon Fiber Varieties

- 3K Carbon Fiber: Offers an excellent balance of strength and flexibility. Ideal for paddles that demand a high rebound force while minimizing vibration, making it perfect for both professional and recreational use.

- 12K Carbon Fiber: With its higher thread density, 12K carbon fiber creates a smoother paddle surface. The increased hardness and durability of this material help provide outstanding impact resistance.

- T300 Carbon Fiber: Recognized for its high tensile strength, T300 enables the production of paddles that are both lightweight and robust. This combination is critical for achieving both speed and control on the court.

-

Fiberglass Options

- E-Glass Fiberglass: This material elevates the paddle with superb elasticity, resulting in better ball control and a larger sweet spot. It provides a balanced approach where power and control share equal importance.

-

Composite Materials Integration5

- Carbon Fiber and Fiberglass Composite: Combining the advantages of both materials results in paddles that not only possess incredible strength but also maintain finesse and responsiveness.

- Bamboo Core Composite: Incorporating bamboo cores delivers a lightweight paddle that boasts high impact resistance, complementing the clarity of the hitting feel.

- Honeycomb Core: Utilizing high-density polymers or pulp, honeycomb cores contribute to superior shock absorption and reduced vibration during play.

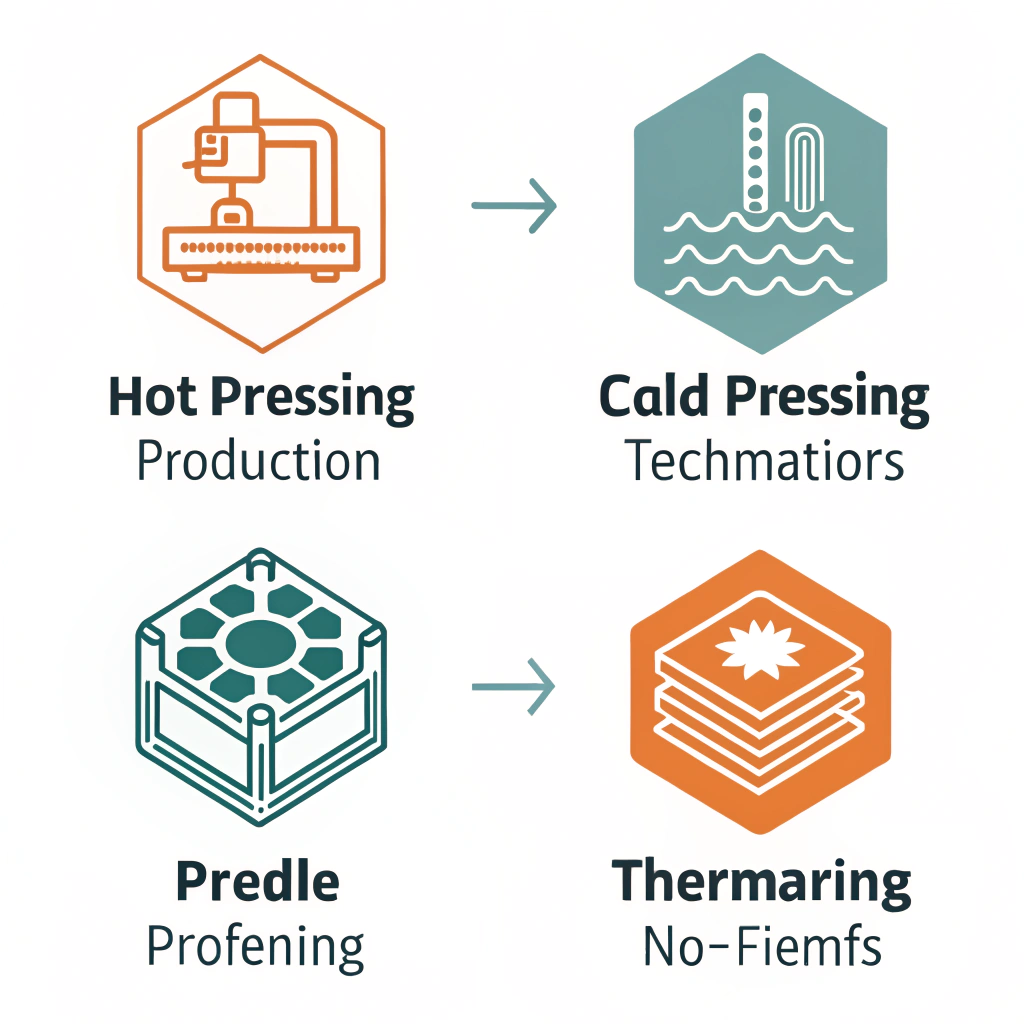

The production process is a cornerstone of performance optimization. Manufacturers typically deploy three main techniques to form and finish paddles:

-

Hot Pressing

- Advantages include high production efficiency and excellent impact resistance. This method ensures strong paddle integrity, particularly attractive for high-performance applications.

- However, the process can sometimes alter certain material properties, which might affect the paddle's feel.

-

Cold Pressing

- The benefit of cold pressing lies in maintaining the inherent properties of the raw materials, resulting in better ball feel and flexibility. Even though the production cycle is longer, the process allows precise control over paddle thickness and structure.

- This precision often appeals to customers who prioritize technique and detailed customization.

-

Thermoforming

- Thermoforming uses heat to soften materials and shape them on complex molds. This method is invaluable for designing paddles with intricate geometry and optimized material distribution.

- Though the process is time-consuming and involves higher costs, it produces premium paddles that are ideal for competitive play.

An in-depth production process comparison reveals key performance aspects that matter for the end user and business decision makers. The table below encapsulates these differences:

| Production Process | Advantages | Disadvantages | Ideal For |

|---|---|---|---|

| Hot Pressing | High efficiency, excellent impact resistance, strong structural integrity | Potential alteration of material properties, high equipment investment | High-performance mass production |

| Cold Pressing | Precise thickness control, better ball feel, maintains material properties | Longer production cycles, high-quality equipment needed for precision | Customized paddle designs, niche markets |

| Thermoforming | Intricate design capabilities, optimal material distribution, stability enhancement | Longer production time and higher cost | Premium paddles, competitive game level |

NEX Pickleball strategically utilizes these techniques based on product requirements, ensuring that each paddle meets the highest standards.

For purchasing managers evaluating supplier capabilities, quality control and process innovation offer significant competitive advantages. While many manufacturers offer similar features, differentiators include:

-

Material Quality and Variety

- A diverse selection of carbon fiber and composite materials allows for differentiated product performance. Each material type is selected to offer precise benefits, whether it is enhanced rebound force or minimized vibration.

-

Production Technique Proficiency

- The use of multiple production methods—each with advantages specific to performance and durability—positions leading manufacturers ahead of competitors. The technical expertise to deploy hot pressing or thermoforming effectively underlines a commitment to innovation.

-

Rigorous Quality Control

- At NEX Pickleball, each paddle undergoes stringent testing to ensure that performance benchmarks are met. Quality control extends from material sourcing to the final finish, ensuring consistency and longevity.

-

Custom Paddle Options

- Customization is a key criterion for many dark horse buyers. The ability to work closely with clients, offering tailored design, weight, balance, and grip options allows manufacturers to meet specific market demands.

Consider a scenario where a sports equipment distributor sought to upgrade their product lineup using paddles that can perform exceptionally in competitive settings. The distributor collaborated with a leading manufacturer that specialized in hybrid production techniques.

The distributor needed a paddle that balanced power and control while minimizing vibration. They required a design that could serve both professional players and enthusiasts alike without compromising on durability.

The manufacturer combined T300 Carbon Fiber with a Nomex Honeycomb Core using thermoforming. This process involved:

- Using thermoforming to create a stiffer, unibody design.

- Employing T300 carbon fiber to deliver a perfect balance between weight and strength.

- Integrating a Nomex honeycomb core to optimize shock absorption and reduce vibration.

The result was a paddle that surpassed performance benchmarks in rigidity, impact resistance, and control. The product received consistent acclaim in competitive play, demonstrating that innovative material selection and production techniques can translate into real-world advantages.

This case study exemplifies how manufacturers can effectively harness technology and process efficiency to produce a leading-edge product that meets market demands.

For distributors and product development executives deliberating on supplier partnerships, the following strategic recommendations can guide decision-making:

-

Evaluate Material Innovations:

- Closely examine the types of materials used by manufacturers. Advanced carbon fiber variants and composite formulations should be considered for their performance benefits and cost-effectiveness in producing high-end paddles.

-

Assess Production Methodologies:

- Scrutinize the production processes. Whether it’s hot pressing’s efficiency, cold pressing’s precision, or thermoforming’s custom design potential, understanding these processes is crucial for aligning with your market needs.

-

Demand Rigorous Quality Control:

- Ensure that the supplier’s quality control protocols are robust. Regular testing for material strength, vibration reduction, and overall durability is critical when selecting a manufacturing partner.

-

Seek Customization Capabilities:

- Custom paddle options create unique market opportunities. Evaluate if the manufacturer offers personalization in weight, grip size, and balance along with on-demand printing services for branding purposes.

-

Consider Competitive Benchmarking:

- Compare your potential supplier’s product portfolio against market leaders. A well-rounded PCI (Performance, Cost, and Innovation) analysis will help to identify a manufacturer that not only follows trends but also sets them.

-

Plan for Scalability:

- Future-proof your purchasing decisions by selecting suppliers who can scale production without sacrificing quality. Efficiency in production processes like thermoforming may be higher initially, but with a dedicated production line, scalability becomes a significant advantage.

By aligning quality, innovation, and scalability, distributors can secure a competitive edge in the pickleball market for 2025 and beyond.

The best pickleball paddle for 2025 isn’t defined by a single product but by a synthesis of advanced materials, refined production processes, and strict quality control standards. With the rise of new manufacturing technologies and innovative materials like T300 carbon fiber and proprietary composite cores, suppliers like NEX Pickleball are well-positioned to meet market demands.

Distributors looking to retool their product lines must focus on material quality, customize according to market specifics, and ensure that the production process aligns with both high performance and scalability. Armed with detailed comparisons and strategic recommendations, decision-makers can confidently select suppliers that will drive quality and innovation in their sports equipment offerings.

Q: What is the best pickleball paddle for 2025?

A: The best pickleball paddle for 2025 effectively combines advanced materials such as high-performance carbon fiber and sophisticated production processes like thermoforming to deliver superior strength, control, and durability. Manufacturers who focus on innovation, quality control, and customization are leading the market.

Q: What is the #1 rated pickleball paddle?

A: While ratings may vary, top-rated pickleball paddles generally feature premium materials, advanced design techniques, and rigorous testing. These paddles are crafted to balance power and control while minimizing vibration, meeting both competitive and recreational standards.

Q: What is the newest technology for pickleball paddles?

A: The newest technology in pickleball paddles involves thermoforming techniques that create stiffer, unibody designs with enhanced precision. This process, combined with raw carbon fiber innovations and integrated composite materials, is setting new performance benchmarks for the sport.

-

Paddle Manufacturing: Click to learn about the comprehensive processes and methodologies that underpin the production of high-performance paddles, including design precision, material handling, and quality control measures. ↩

-

Carbon Fiber: Click to explore the properties and applications of carbon fiber, a key material known for its high strength-to-weight ratio and durability in advanced sports equipment. ↩

-

Hot Pressing: Click to understand how hot pressing as a manufacturing technique enhances structural integrity and production efficiency, crucial for scaling high-performance sports gear. ↩

-

Thermoforming: Click to discover the process of thermoforming, which enables intricate design capabilities and optimized material distribution for superior paddle performance. ↩

-

Composite Materials Integration: Click to delve into how combining materials like carbon fiber and fiberglass offers balanced performance, durability, and innovation in modern paddle design. ↩