Quick Answer: High-performance pickleball paddles require a careful evaluation of materials, manufacturing techniques, and quality control—key elements to ensure performance, durability, and responsiveness. This article delves into the technical details and supplier comparison, helping procurement professionals make informed B2B decisions.

In today's competitive sports equipment market, selecting the right pickleball paddle manufacturer is crucial. Procurement managers and distributors need suppliers who not only understand advanced production techniques but also offer products that blend innovation, quality, and cost-effectiveness. At NEX Pickleball, we specialize in high-performance paddle manufacturing with a focus on precision, innovation, and customizable solutions. This article compares key manufacturing processes and materials to help you assess the best options for your business.

Businesses in the sports equipment sector often face challenges when selecting a supplier for pickleball paddles. Some of the common issues include:

- Variability in Product Quality: Not all manufacturers maintain the same quality standards, leading to inconsistencies in paddle performance.

- Diverse Production Techniques: Different production processes (hot pressing, cold pressing, and thermoforming) offer distinct advantages and drawbacks, complicating the decision-making process.

- Material Selection: Paddles are made from various premium materials such as carbon fiber, fiberglass, and composite materials. Each offers unique benefits in terms of strength, control, and durability.

- Customization Needs: Many retailers and distributors need custom paddle options in varying designs, weights, and grip sizes.

- Supplier Reliability and Production Volume: Ensuring that a supplier can manage large-scale production while consistently delivering high-quality products is a common concern.

To overcome these challenges, it is essential to understand the link between materials, production processes, and the final paddle quality. Let’s break this down:

Carbon Fiber Variants:

- 3K Carbon Fiber: Known for its strength and flexibility, this material provides excellent durability and reduces vibration. It is ideal for paddles that require high rebound force.

- 12K Carbon Fiber: With a higher thread density, it offers a smoother surface and superior impact resistance, making it perfect for competitive play.

- T300 Carbon Fiber1: Balancing strength and light weight, T300 is used in paddles that demand both power and a quick response.

Fiberglass:

- E-Glass Fiberglass: Offers a balance between power and control. Its elasticity and tensile strength contribute to a wider sweet spot and excellent ball control.

- Carbon Fiber and Fiberglass Composite: Merges the advantages of both materials to achieve optimal power and precision.

- Bamboo Core Composite: Provides a lightweight yet impact-resistant option, which is crucial for long-lasting play.

- Honeycomb Core: Made from high-density polymers or pulp, these cores provide superior shock absorption, reducing vibration and extending the paddle's lifespan.

Core Materials:

- Nomex Honeycomb Core3: Known for durability and stability, ideal for players who demand longevity.

- Aluminum Honeycomb Core: Offers balanced weight and precision, contributing to the paddle's overall performance.

- Polymer Honeycomb Core: Preferred by recreational players due to its elasticity and vibration reduction, providing a comfortable playing experience.

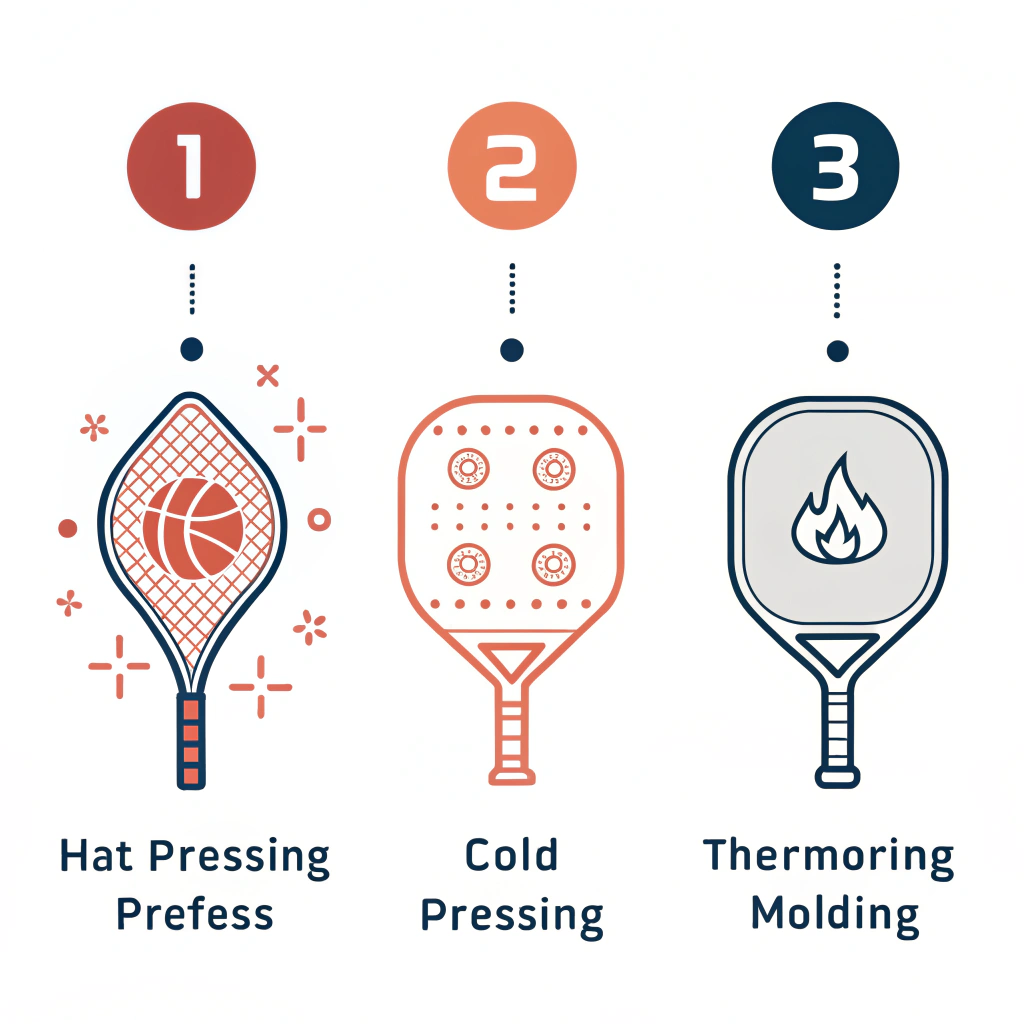

Each production process contributes uniquely to the paddle's characteristics:

| Process | Advantages | Disadvantages |

|---|---|---|

| Hot Pressing | • High production efficiency • Excellent impact resistance • Strong structural integrity | • Can alter material properties affecting the feel • High equipment investment required |

| Cold Pressing4 | • Precise control over thickness and structure • Maintains the material’s natural properties • Superior ball feel | • Longer production cycles • Demands high precision and quality control equipment |

| Thermoforming5 | • Allows complex shapes and precise distribution of materials • Enhances paddle stability • Suitable for premium products | • Longer production time • Higher equipment costs, best for custom or high-end paddles |

By understanding these processes, procurement managers can better evaluate the trade-offs between production speed, product performance, and cost.

Selecting the right supplier for high-performance pickleball paddles involves a step-by-step evaluation. Here’s a clear solution roadmap:

Identify the key performance attributes you need:

- Rebound strength: For players who require quick ball response.

- Control and precision: Ideal for competitive play.

- Durability: Ensuring the paddle stands up to high-impact use.

Examine the materials used:

- Carbon Fiber and Fiberglass: Prioritize suppliers who offer a range of high-quality carbon fiber options such as 3K, 12K, and T300 along with fiberglass alternatives.

- Core Materials: Evaluate the type of honeycomb or polymer core used, which impacts stability and vibration absorption.

Review manufacturing techniques:

- Hot Pressing: Suitable for meeting high-volume orders with consistent quality.

- Cold Pressing: Offers precision, which is critical for custom paddle designs.

- Thermoforming: Best for complex, premium designs.

This evaluation matrix helps you quickly compare suppliers and understand what fits best with your market needs.

Customization is a significant benefit in the B2B market:

- Custom grip sizes and weight adjustments can align with specific customer preferences.

- On-demand print services allow for branding and marketing opportunities, critical for team or retail distribution.

Reliability is non-negotiable:

- Ensure that the supplier runs rigorous quality control tests to maintain high-performance standards.

- Look for consistent documentation on extensive testing for durability, flexibility, and overall performance.

Before finalizing a supplier, request detailed technical documentation and sample products. Compare:

- Manufacturer's precision in paddle construction.

- Real-world performance data from durability and quality tests.

NEX Pickleball stands out in the market with an emphasis on both innovation and reliability. Here’s how we address common procurement challenges:

-

Advanced Material Selection:

Our product portfolio includes advanced 3K, 12K, and T300 carbon fiber options, as well as high-efficiency E-Glass Fiberglass and superior composite materials. This ensures we provide paddles that meet varying performance needs. -

Diverse Production Techniques:

By employing hot pressing, cold pressing, and thermoforming, we maintain the flexibility needed to produce both high-volume and custom premium paddles. Our approach allows us to deliver products with the perfect balance of durability and performance. -

Strict Quality Control:

Every paddle undergoes rigorous testing. Our dedicated quality assurance process means each product meets precise performance criteria—ideal for pro-level play and recreational markets alike. -

Customization Capabilities:

We offer extensive customization options from paddle sizes to on-demand design prints, ensuring our paddles can be tailored to individual market demands. This flexibility has made us the choice for organizations needing unique branded equipment. -

Reliable Production and Supply Chain:

Our streamlined processes and on-time delivery protocols ensure that large orders are managed efficiently and that we meet the urgent demands of B2B clients consistently.

Collectively, these practices underscore why partnering with a manufacturer like NEX Pickleball is a strategic move for stakeholders in the sports equipment market.

For procurement managers who want to secure a reliable, innovative, and high-performance supplier for pickleball paddles, the decision-making process should focus on a detailed comparison of materials, manufacturing processes, and quality control standards. By following the steps outlined in this article, you can:

- Clearly define your performance requirements.

- Evaluate and compare materials and supplier capabilities.

- Ensure that manufacturing processes align with your quality and production volume needs.

- Leverage customization options to enhance your market positioning.

We strongly recommend initiating discussions with manufacturers that provide in-depth quality assurance and customization flexibility. This proactive approach ensures that the final product not only meets the high standards of competitive play but also supports your business growth in an increasingly demanding market.

By analyzing the advantages of techniques like hot pressing, cold pressing, and thermoforming, alongside comprehensive material assessments, you can mitigate risks and solidify your supply chain commitments.

For further insights into the technical aspects of paddle manufacturing or to request a sample evaluation, please contact NEX Pickleball. Our team is ready to support your procurement decisions with expert advice and cutting-edge product solutions.

What paddle do most pickleball pros use?

Top professional players favor paddles that combine precision and power. Leading brands like JOOLA and Selkirk offer models such as the JOOLA Perseus and Selkirk VANGUARD, known for their superior control, power, and spin performance.

What are the best racquets for pickleball?

While paddle selection varies, models that hit the sweet spot between quality and value often emerge as favorites. Industry choices include the Six Zero Double Black Diamond Control and the JOOLA Perseus Pro IV, offering a balanced mix of speed, accuracy, and durability for competitive play.

What is the best reasonably priced pickleball paddle?

Finding a good paddle under budget is possible. Options recommended in various guides include models like the Warping Point Control, which provide excellent value while maintaining good playability and performance without breaking the bank.

-

T300 Carbon Fiber: Read the article to understand how T300 Carbon Fiber balances strength and weight, offering a material solution that delivers both power and rapid response for high-performance paddle requirements. ↩ ↩

-

Composite Materials: Click here to learn more about composite materials, which integrate the benefits of multiple fibers to optimize precision and durability in manufacturing high-quality sports equipment. ↩ ↩

-

Nomex Honeycomb Core: Discover the advantages of Nomex Honeycomb Core in maintaining stability and durability, making it ideal for products that demand longevity and consistent performance. ↩ ↩

-

Cold Pressing: Explore the cold pressing process and how its precise control over material properties can enhance the overall quality and feel of the final product in sports equipment manufacturing. ↩ ↩

-

Thermoforming: Learn about thermoforming techniques and how they enable the creation of complex shapes with enhanced stability and premium product design, critical for custom and high-end paddle production. ↩ ↩