Quick Answer: High-performance pickleball paddles achieve their excellence through advanced materials—such as carbon fiber1, fiberglass2, and innovative composites3—paired with state-of-the-art manufacturing processes like hot pressing, cold pressing, and thermoforming4. By carefully balancing weight, durability, and playability, NEX Pickleball’s solutions provide procurement managers with a competitive edge in sourcing superior sports equipment.

For B2B purchasing professionals and sports equipment distributors, selecting the right pickleball paddle means evaluating how design, materials, and production precision converge to deliver optimum performance. At NEX Pickleball, we leverage innovative production techniques and high-grade materials to produce paddles that meet the rigorous demands of competitive play while ensuring longevity and superior control.

In today’s market, where athletic performance and product durability are paramount, understanding the manufacturing nuances is key. Our engineering-driven approach empowers you to make fully informed procurement decisions that consider both performance data and manufacturing reliability.

One of the core strengths of high-performance pickleball paddles lies in the selection of materials. A variety of materials is utilized in the construction process to ensure that each paddle delivers excellence on the court. At NEX Pickleball, our offerings include:

-

- 3K Carbon Fiber: Renowned for its flexibility and strength, ideal for paddles that require high rebound force while reducing vibration.

- 12K Carbon Fiber: With a higher thread count, it offers an ultra-smooth surface, increased hardness, and excellent impact resistance.

- T300 Carbon Fiber: Balances strength with lightweight performance, allowing for both power and maneuverability.

-

Fiberglass2:

Fiberglass paddles offer excellent elasticity and wider sweet spots. They provide a remarkable balance between ball control and power. Our E-Glass Fiberglass is engineered to offer stability while maintaining a comfortable ball feel. -

Innovative Composites:

We also integrate innovative composites3 such as:- Carbon Fiber and Fiberglass Composite: This hybrid material offers a harmonious blend of power and control.

- Bamboo Core Composite: Known for its lightweight impact resistance and a crisp hitting feel.

- Honeycomb Core: Engineered from high-density polymer, delivering exceptional shock absorption and reduced vibrations during gameplay.

Below is a detailed comparison of the key materials used in high-performance pickleball paddles:

| Material Type | Key Benefits | Ideal For |

|---|---|---|

| 3K Carbon Fiber | Flexibility, reduced vibration, high rebound | Competitive play with high speed |

| 12K Carbon Fiber | Smooth surface, durability, superior hardness | Extreme strength and impact resistance |

| T300 Carbon Fiber | Excellent tensile strength, lightweight | Balanced performance in power and control |

| E-Glass Fiberglass | Enhanced elasticity, improved ball control | Recreational and competitive play |

| Carbon Fiber & Fiberglass Composite | Optimal combination of strength and flexibility | Players needing both power and finesse |

| Bamboo Core Composite | Lightweight, strong impact resistance | Long-lasting play with a clear hitting feel |

| Honeycomb Core | Superior shock absorption, vibration reduction | Durable performance in intense play |

This comparative table illustrates that the choice of material not only influences the paddle’s performance on the court but also its durability in the long term. For B2B procurement managers, such detailed specifications are invaluable for comparative analysis with competing products.

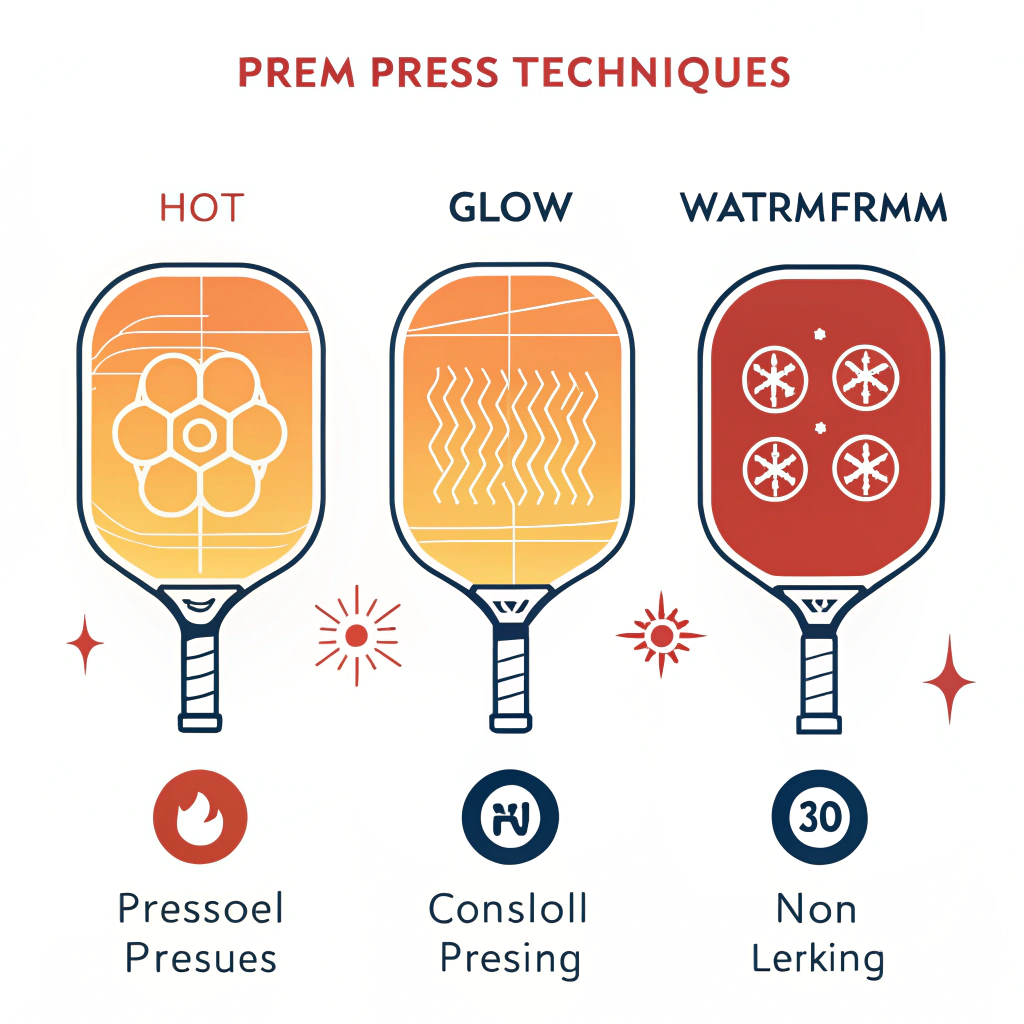

Regardless of the exceptional material properties, the production process is equally critical. NEX Pickleball employs three primary techniques to manufacture our paddles, with each offering distinct benefits for quality and precision.

-

Hot Pressing:

In the hot pressing process, materials are heated and then pressed under high pressure to form a paddle. The heat helps to distribute the material evenly, ensuring a uniform hardening that imparts superior impact resistance.Advantages of Hot Pressing:

- High production efficiency suitable for bulk manufacturing.

- Creates a robust paddle with excellent structural integrity.

- Ideal for producing durable paddles for high-intensity play.

Limitations:

- The heating process can alter certain material properties, potentially affecting paddle feel.

- High initial investment in heating machinery and press equipment.

-

Cold Pressing5:

Cold pressing shapes materials at room temperature under controlled mechanical pressure. This method preserves the innate properties of the material, ensuring a finely tuned balance of control and flexibility in the final product.Advantages of Cold Pressing:

- Superior control over paddle thickness and material structure.

- Maintains the material’s original properties, ensuring a responsive ball feel.

- Ideal for paddles where precision and tactile feedback are paramount.

Limitations:

- Generally requires a longer production cycle, reducing overall throughput.

- Demands high-quality equipment for precise pressure control.

-

Thermoforming4:

Thermoforming involves heating the material until it softens, then press-molding it into the desired shape using customized molds. This process is particularly effective for paddles with complex geometries and specialized design features.Advantages of Thermoforming:

- Facilitates intricate designs and exact material distribution.

- Enhances paddle stability by producing consistent thickness across the surface.

- Suitable for premium products and custom-ordered paddles.

Limitations:

- Higher production time and equipment cost compared to other methods.

- Most effective for smaller production runs or high-end products.

The decision when choosing between these production techniques often rests on the balance between efficiency, material preservation, and design complexity. The table below summarizes the key aspects of each production method:

| Production Process | Key Advantages | Key Disadvantages |

|---|---|---|

| Hot Pressing | High efficiency, robust structure, excellent impact resistance | Potential alteration of material feel, higher equipment costs |

| Cold Pressing | Enhanced control and responsiveness, preserves material properties | Longer production cycles, requires precision machinery |

| Thermoforming | Intricate design capabilities, precise material distribution | Increased production time, higher cost for premium designs |

Such detailed comparison helps procurement managers and B2B partners weigh the pros and cons of each manufacturing method. By understanding these processes, customers can better predict performance outcomes and maintenance requirements for their bulk orders.

Beyond raw materials and production processes, the design elements of pickleball paddles—including grip size, balance, and surface texture—are integral to overall performance. At NEX Pickleball, we pay careful attention to ergonomic design:

-

Ergonomic Grip:

Our paddles are available in multiple grip sizes to accommodate diverse hand anatomies. Customizable grip options ensure that the paddle feels natural while reducing fatigue during extended play. -

Weight Distribution:

Balanced weight ensures that players can swing quickly without compromising on stability. Our production processes are optimized to achieve an ideal balance between power and control. -

Surface Texture:

Specially treated paddle surfaces help enhance ball spin and accuracy. Surface treatment is critical, especially when using composite materials, to maintain friction and performance consistency across thousands of units.

B2B customers benefit greatly from customization options, both for branding and performance tuning. Offering customization not only differentiates products in a competitive market but also allows distributors to tailor inventory to meet the specific demands of their target segments. Manufacturers like NEX Pickleball provide on-demand-print services and bespoke design adjustments. This flexibility is particularly appealing to sports teams, clubs, and retail brands seeking to combine quality, performance, and brand identity.

Understanding the technical specifications of different paddles is paramount for effective decision-making. When comparing our products with other well-known brands, procurement managers should consider:

-

Performance Metrics:

Metrics such as rebound force, vibration damping, and balance consistency are vital. NEX Pickleball uses rigorous testing protocols to ensure that every paddle meets high-performance benchmarks. -

Cost-Effectiveness:

While premium materials and advanced processes typically command higher prices, the long-term benefits—such as durability and consistency—result in lower maintenance and replacement costs. -

Scalability and Supply Reliability:

With state-of-the-art production facilities located in Jiaxing, Zhejiang, China, we offer timely production and delivery. Strong supply chain management is crucial for large-scale orders and ensuring product consistency across batches.

We recommend that procurement managers request detailed technical data sheets when comparing products. These documents provide insights into:

- Material properties (e.g., density, tensile strength)

- Manufacturing tolerances and quality control measures

- Real-world performance data from professional players and competitive events

Case studies and performance comparisons with leading brands help highlight where NEX Pickleball stands apart in terms of quality and innovation. By leveraging data-driven analysis, decision-makers can confidently assess products for bulk procurement applications.

In today’s competitive marketplace, the careful evaluation of pickleball paddle materials, production processes, and design elements is crucial. NEX Pickleball’s integrated approach—combining advanced carbon fiber1, fiberglass2, and innovative composites with precise manufacturing techniques such as hot pressing, cold pressing5 and thermoforming4—ensures that our paddles meet the highest performance standards.

For businesses looking to enhance their sports equipment portfolio, our products offer:

- Reliable performance benchmarks validated by rigorous testing.

- Customization options for tailored brand identity and ergonomic fit.

- Consistent supply and quality control through high-efficiency production methods.

Procurement managers and sales professionals are encouraged to evaluate these key technical attributes alongside market-specific data. The choice of materials and manufacturing method directly impacts long-term durability and customer satisfaction. By partnering with NEX Pickleball, you are selecting a solution that not only meets today’s competitive demands but is also poised for future advancements in sports technology.

Take the next step in optimizing your sporting goods inventory—speak with our technical team today and discover how our high-performance pickleball paddles can transform your market presence.

-

What is the #1 rated pickleball paddle?

The top-rated paddle on the market is often determined by its balance of power, control, and durability. Leading models generally incorporate advanced materials like carbon fiber and undergo comprehensive testing to ensure consistent performance in competitive play. -

What pickleball paddle is most used by pros?

Many professionals prefer paddles that offer a precise balance of power and control. Models such as those incorporating elite carbon fiber materials—with designs that reduce vibration and enhance spin—are commonly chosen by top athletes in the sport. -

What are the best racquets for pickleball?

While the best option depends on individual play style, paddles that hit the ideal sweet spot between quality and value are favored. High-quality paddles typically combine advanced composite materials with meticulous production processes, delivering reliable performance during intense competitive play.

-

carbon fiber: Click to read an article on the properties and benefits of carbon fiber in high-performance sporting goods, including its strength-to-weight ratio and durability advantages. ↩ ↩ ↩2 ↩3

-

fiberglass: Click to explore how fiberglass is used in sports equipment manufacturing, its elastic properties, and why it can enhance performance on the court. ↩ ↩ ↩2 ↩3

-

innovative composites: Click to learn about composite materials, their role in enhancing product performance, and how integrating multiple materials can offer a competitive edge. ↩ ↩ ↩2

-

thermoforming: Click to understand the thermoforming process, its application in creating complex designs, and how it ensures consistency in high-end production. ↩ ↩ ↩2 ↩3

-

Cold Pressing: Click to read about the cold pressing technique, its benefits in preserving material properties, and its role in achieving precise manufacturing tolerances. ↩ ↩ ↩2