Quick Answer: For competitive tournament play, the choice of pickleball paddle comes down to material quality, production process, and performance characteristics. By comparing paddles made from carbon fiber1, fiberglass, and composite cores, using manufacturing techniques such as hot pressing2, cold pressing3, and thermoforming4, buyers can identify paddles that deliver the best mix of power, control, and durability to meet professional requirements.

When evaluating high-performance tournament paddles, procurement managers need to understand the technical differences in materials and production methods. This detailed analysis compares paddles in three key dimensions: materials, production processes, and performance characteristics for competitive pickleball play. In this guide, we break down the pros and cons of various materials like 3K Carbon Fiber, 12K Carbon Fiber, T300 Carbon Fiber, and E-Glass Fiberglass; and we look at production techniques including hot pressing, cold pressing, and thermoforming. Our goal is to provide the insights necessary for smart B2B procurement decisions.

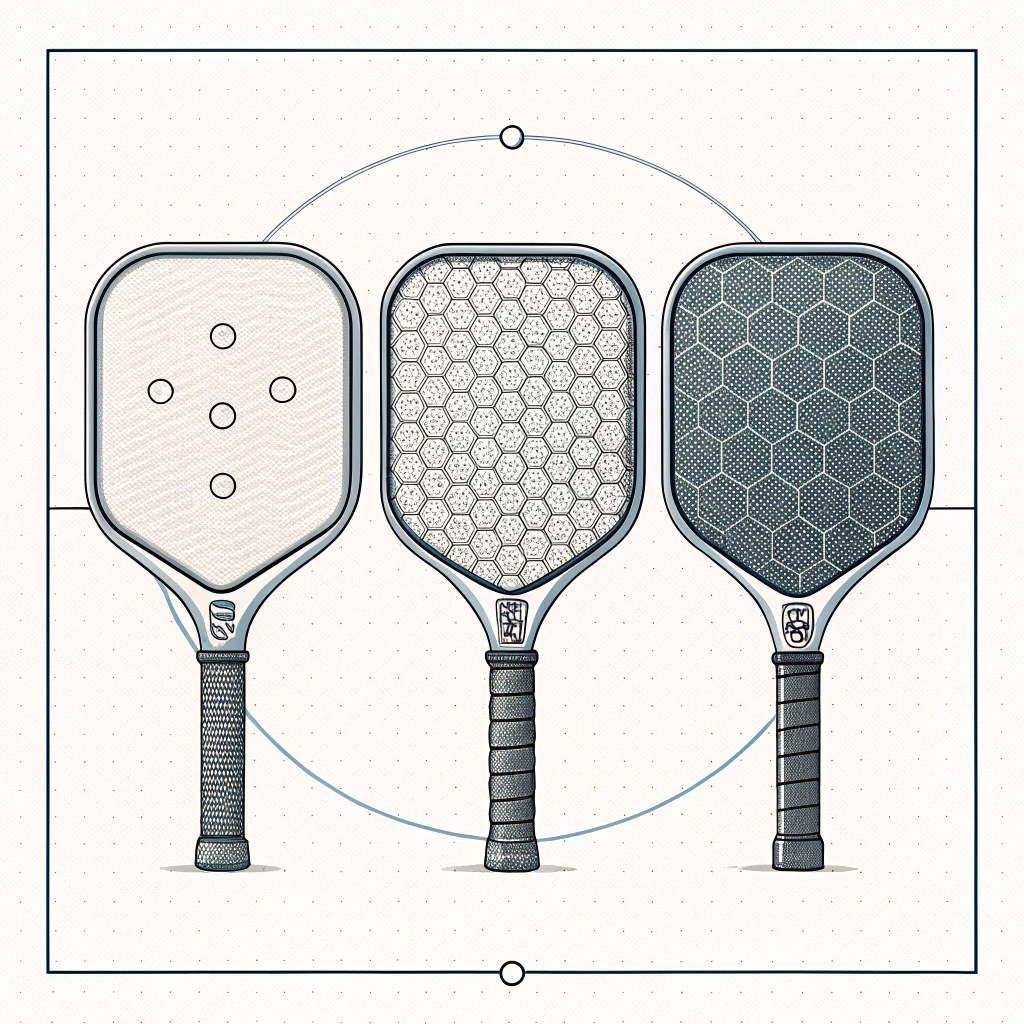

When it comes to material selection, high-performance paddles are largely divided into three groups:

-

Carbon Fiber Paddles:

These paddles use advanced grades of carbon fiber for enhanced strength, rebound force, and vibration reduction.- 3K Carbon Fiber: Provides excellent durability and flexibility, offering superior impact resistance.

- 12K Carbon Fiber: Offers a smoother surface with greater hardness and impact resistance, ideal for competitive impact.

- T300 Carbon Fiber: A balanced option combining strength and lightweight attributes.

-

Fiberglass Paddles:

Fiberglass paddles, typically made with E-Glass Fiberglass, offer enhanced elasticity and a wider sweet spot. They are known for excellent ball control and a comfortable touch, which can be essential in tournament situations. -

Composite Materials:

Composites offer tailored performance features by combining various materials:- Carbon Fiber and Fiberglass Composite: This blend balances power and control.

- Bamboo Core Composite: Provides lightness and excellent impact resistance.

- Honeycomb Core: Typically crafted from high-density polymers for shock absorption and reduced vibration.

- Nomex, Aluminum, and Polymer Honeycomb Cores: These cores further refine the paddle’s feel and durability. For example, Nomex Honeycomb5 cores deliver outstanding shock absorption while Polymer cores reduce vibration to provide a comfortable hitting experience.

Below is a table summarizing materials characteristics and performance indicators:

| Material Type | Key Advantages | Typical Use or Benefit |

|---|---|---|

| 3K Carbon Fiber | High durability and flexibility | Fast rebound, reduced vibration |

| 12K Carbon Fiber | Smoother surface, extreme impact resistance | Competitive play with high power requirements |

| T300 Carbon Fiber | Optimal balance of strength and weight | Balanced performance for advanced players |

| E-Glass Fiberglass | Superior elasticity, wider sweet spot | Enhanced control and ball feel in dynamic play |

| Composite (Carbon/Fiberglass) | Combination of power and control | Perfect for players needing versatile performance |

| Nomex Honeycomb Core | Excellent shock absorption | Ideal for long-lasting stability and durability |

| Polymer Honeycomb Core | Reduced vibration, improved comfort | Great for recreational and professional play |

The manufacturing process significantly influences the performance characteristics of a paddle. Here, three primary techniques are used:

-

- Description: Materials are heated and then pressed to form a strong, rigid structure.

-

Advantages:

◦ High production efficiency, suitable for large-scale manufacturing.

◦ Produces extremely durable paddles with excellent impact resistance.

◦ Ensures the integrity of the paddle’s overall structure. -

Disadvantages:

◦ The high temperature can alter some material properties, potentially affecting the paddle’s feel.

◦ Larger capital investment in high-tech equipment is required. - Ideal For: Bulk production of high-durability paddles engineered for tournament play.

-

- Description: Shapes materials at room temperature under mechanical pressure to maintain the original properties.

-

Advantages:

◦ Provides precise control over paddle thickness and overall structure.

◦ Maintains the inherent material properties, delivering superior ball control and tactile response.

◦ Lower risk of negative thermal impact on performance. -

Disadvantages:

◦ The production cycle is longer compared to hot pressing, reducing throughput.

◦ Requires a high level of precision and quality equipment to maintain consistency. - Ideal For: Producing paddles where precision and control over the hitting feel are prioritized.

-

- Description: Material is heated until soft, then formed using precision molds to achieve complex designs.

-

Advantages:

◦ Capability to create paddles with intricate designs and precise distribution of materials.

◦ Enhances product stability, a feature critical for tournament-level play.

◦ Offers potential for customization in paddle design, texture, and ergonomic grip. -

Disadvantages:

◦ Extended production time and higher equipment costs make this process suitable more for premium models.

◦ Requires significant expertise in mold design. - Ideal For: Custom, high-performance products targeting competitive players seeking design and performance enhancements.

Below is a comparison table for the three production processes:

| Production Process | Advantages | Limitations | Best Use Case |

|---|---|---|---|

| Hot Pressing | High efficiency, robust structure, superior impact resistance | Possible alteration of material properties, high equipment cost | Mass-produced durable paddles |

| Cold Pressing | Precise control over structure, preserves material properties, excellent tactile response | Longer production cycle, demands high precision equipment | Paddles emphasizing feel and control |

| Thermoforming | Intricate design capabilities, precise material distribution, stable structure | Longer production time, premium process with higher cost | Premium/custom paddle designs |

For tournament-level paddles where performance is measured in power, control, and durability, the choice of materials and production process is crucial. Here are some performance factors to consider:

-

Shock Absorption:

Paddles incorporating Nomex Honeycomb or Polymer cores are designed to reduce vibration during play, which minimizes player fatigue and improves overall control. This is particularly important for high-intensity matches where sustained performance is required. -

Weight Distribution:

Balancing weight and maintaining a consistent center of gravity can dramatically improve a player’s control and precision. Manufacturing processes like cold pressing and thermoforming offer enhanced control over weight distribution, allowing for paddles that feel responsive and balanced. -

Surface Texture and Grip:

The tournament paddle’s surface treatment is key for managing spin and ball control. Manufacturers invest in advanced texturing techniques to ensure that players can generate extra spin, especially during rapid passing or when employing strategic shots. -

Customization Options:

Many high-performance paddles now offer on-demand print services and customizable features. This includes variations in grip sizes, weight balance, and aesthetic design, providing an added value by aligning the paddles with personal or team branding needs.

For procurement managers, paying attention to these performance metrics alongside the technical differences in materials and production will ensure that the chosen paddle meets the rigorous demands of professional tournament play. Not only does this help improve player performance, but it also contributes significant competitive advantage in the marketplace.

When deciding on a pickleball paddle for competitive sports, consider the following points:

-

Performance Specifications:

Evaluate the paddle’s material and production process. Paddles made from 12K Carbon Fiber or high-density composites tend to offer a higher level of performance for power hitters, while those with fiberglass or carbon-fiberglass composites provide more control for precision players. -

Production Consistency and Quality:

Manufacturing techniques like cold pressing and thermoforming offer precision and consistency which is critical for tournament-level equipment. Given the higher costs, these methods are best suited for premium segments where small performance variations can result in significant advantages. -

Customization and Branding:

Custom paddle options such as on-demand print services allow you to cater to specific players or teams. In a competitive setting, personalized equipment can also be a strategic marketing tool for sports distributors and teams. -

Performance Testing and Data:

Look for partners like NEX Pickleball who provide thorough performance testing and quality control. Rigorous testing ensures that the paddle’s durability, tactile response, and impact resistance meet high-performance tournament expectations.

Below is a checklist summarizing the key decision factors:

| Decision Factor | Key Considerations |

|---|---|

| Material Selection | Carbon Fiber types vs. Fiberglass vs. Composites |

| Production Process | Efficiency (hot pressing) vs. Precision (cold pressing/thermoforming) |

| Customization Options | On-demand printing, grip size, weight distribution |

| Performance Testing & Quality | Vibration control, shock absorption, structural integrity |

After comparing the different material types and production processes, it becomes clear that for high-performance tournament play, selecting a paddle is not just about raw power but also involves precision in manufacturing and design. Paddles that use advanced carbon fiber resins and engineered cores tend to deliver a superior balance between control, durability, and performance. Meanwhile, production processes like cold pressing and thermoforming provide the precise specifications that can significantly enhance a player’s performance on the court.

For procurement managers evaluating options for tournament-grade equipment, it is recommended to:

• Prioritize products with rigorous performance testing and consistent quality control.

• Request technical datasheets highlighting materials and manufacturing details.

• Consider the customizability options as a value-add for team branding and differentiated experiences.

Taking these factors into account, you will be well positioned to procure paddles that not only meet professional standards but also offer a competitive edge in the market.

Q: What paddle do most pro pickleball players use?

A: Professional players often use paddles combining high-performance materials like carbon fiber and optimized core structures. Popular selections include models from brands such as JOOLA and Selkirk, which deliver a balance of power, control, and durability necessary for competitive play.

Q: What is the #1 rated pickleball paddle?

A: The top-rated pickleball paddle in current comparisons is often highlighted for its balance of power, spin, and control. However, the best choice depends on specific play styles, with options tailored for power hitters, control players, and overall value seekers consistently receiving high marks in performance reviews.

Q: Do more expensive pickleball paddles make a difference?

A: Higher-priced paddles typically use advanced materials like high-grade carbon fiber and incorporate precision manufacturing techniques. While these features do deliver improvements in power, control, and vibration reduction, the optimal paddle choice will match the player's specific performance needs rather than simply reflecting the price point.

-

carbon fiber: Read this article to understand the advanced properties, production methods, and performance benefits of carbon fiber in high-performance sporting goods. ↩ ↩

-

hot pressing: Explore detailed insights on the hot pressing process, its advantages in manufacturing rigidity and durability, and its role in large-scale production. ↩ ↩ ↩2

-

cold pressing: Learn about the cold pressing technique, including its impact on material properties preservation and how it enhances tactile response for precision equipment. ↩ ↩ ↩2

-

thermoforming: Discover how thermoforming enables the creation of intricate designs and custom specifications, offering benefits for premium and customized products. ↩ ↩ ↩2

-

Nomex Honeycomb: Understand the unique characteristics of Nomex Honeycomb cores, including their superior shock absorption and contribution to improved product durability. ↩ ↩