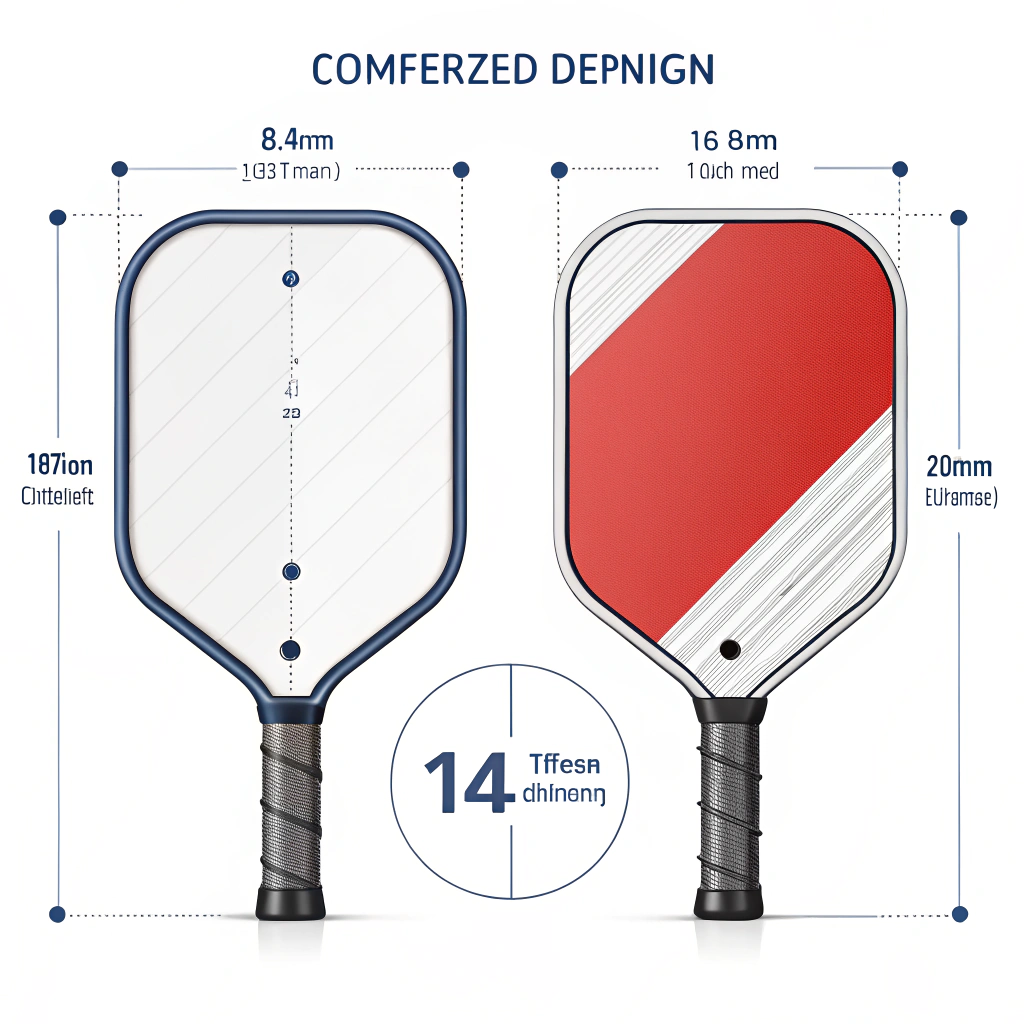

Quick Answer: A 16mm pickleball paddle typically offers enhanced durability and power due to its thicker core design, while a 14mm paddle delivers improved control and a softer feel. The best choice depends on the target market’s performance demands and production capabilities.

When choosing between paddle core thicknesses, the decision often boils down to balancing durability, power, and control. For B2B buyers in the sporting goods industry, understanding the technical differences between a 16mm paddle and a 14mm paddle is crucial. In this article, we closely compare these two paddle designs, focusing on their performance characteristics, manufacturing nuances, and production costs to help inform your procurement decision.

The core thickness of a paddle significantly influences its performance metrics:

- Impact Resistance: A thicker core can absorb shocks better, offering heightened durability during competitive, high-impact plays.

- Vibration Control: Paddle thickness plays a role in vibration dampening. Thicker paddles—like the 16mm design—tend to reduce vibration, which is critical for maintaining control.

- Player Feel and Control: Thinner cores, such as the 14mm design, provide a more responsive and softer feel, ideal for players emphasizing finesse and precision.

- Production Efficiency: The manufacturing process can vary depending on the paddle’s core thickness. Approaches such as hot pressing1, cold pressing, and thermoforming affect the consistency and cost of the final product.

This trade-off between durability and control is at the heart of the decision-making process for product managers and procurement specialists looking to develop a paddle line that meets specific market expectations.

Below is a detailed table comparing the 16mm and 14mm paddle designs on key performance and manufacturing parameters:

| Feature | 16mm Paddle | 14mm Paddle |

|---|---|---|

| Durability | Higher durability due to increased core thickness | Sufficient durability for recreational use |

| Impact Resistance | Superior impact absorption, ideal for competitive play | Good but may transfer more shock to the player |

| Vibration Control | Excellent vibration dampening, reducing player fatigue | Enhanced tactile feedback but can have increased vibrations |

| Player Feel | Provides a solid, powerful hit | Offers a softer, more controlled feel |

| Production Efficiency | Faster production with high-pressure methods (e.g., hot pressing1) | Typically requires longer cycle times (e.g., cold pressing) |

| Cost Factors | May incur higher material costs and equipment investment | Lower material cost and improved equipment longevity |

| Target Market | Competitive players prioritizing power and durability | Recreational players valuing control and comfort |

The production method chosen—such as hot pressing, Cold Pressing2, or Thermoforming3—plays a crucial role in the overall quality of the paddle. For instance:

-

Hot Pressing:

- Advantages: High production efficiency and strong impact resistance. Ideal for manufacturing 16mm paddles where structural integrity is paramount.

- Disadvantages: Some potential alteration in material feel due to high temperatures.

-

Cold Pressing:

- Advantages: Better control over the paddle's thickness and material properties, preserving a more natural ball feel that is essential for 14mm paddles.

- Disadvantages: Longer production cycles and a need for precise pressure regulation.

-

Thermoforming:

- Advantages: Allows for intricate designs and precise material distribution, which can benefit both 16mm and 14mm paddles by optimizing balance and power.

- Disadvantages: Increased production time and higher equipment costs, making it best suited for premium or custom designs.

These processing decisions directly impact the end product’s performance characteristics and cost structure. Manufacturers must weigh these factors carefully to ensure that the paddle meets the expectations of both high-level competitive players and the recreational market.

Understanding the performance differences between the 16mm and 14mm paddles is essential for making an informed procurement choice. Here are the key points:

-

Power vs. Control:

- The 16mm paddle is engineered for players who demand explosive power and durability. Its thicker core provides a more rigid hit, which is beneficial in high-velocity competitive play.

- The 14mm paddle, on the other hand, is optimized for control. It offers a softer hit, giving players the ability to maneuver shots with greater precision. This design is more suited for recreational play or scenarios where finesse is preferred over raw power.

-

Impact Absorption and Vibration Reduction:

- With a higher core thickness, the 16mm design can absorb shocks more effectively, reducing vibrations that may lead to player fatigue.

- While the 14mm paddle may transmit a slightly higher amount of vibration, its enhanced responsiveness provides a beneficial feedback loop that some players find advantageous for quick adjustments during play.

-

Cost and Production Considerations:

- Producing a 16mm paddle may require a higher upfront investment, particularly if leveraging hot pressing1 due to faster cycle times and robust equipment. This can be cost-effective if targeting a competitive market with a willingness to pay a premium for performance.

- The 14mm paddle, often manufactured with processes like cold pressing, might result in lower production costs. This can be advantageous for targeting a broader market segment or satisfying cost-sensitive procurement strategies.

When determining the optimal paddle thickness for your product lineup, several strategic factors must be taken into account:

-

Market Demand:

Evaluate whether your primary market consists of competitive players who prefer a stiffer, more robust paddle or recreational players who value a lighter, more controlled feel. -

Cost Efficiency:

Align your production processes with your financial targets. Higher production efficiency with hot pressing1 may favor a 16mm design, while longer cycles from cold pressing may be justifiable for a 14mm model if it meets market demand for precision and smooth playability. -

Customization and Material Options:

Consider the benefits of offering customizable options such as different core materials (Nomex4, Aluminum, Polymer) or composite designs5 that blend the best attributes of both paddle thicknesses. Customization can be an excellent way to address niche market requirements while balancing overall production costs.

A strategic decision matrix comparing quality, production cost, and target customer profile will help align your product offerings with market expectations. Many successful manufacturers use data-driven insights combined with customer feedback to continuously refine their paddle designs.

Studies and customer performance data from paddle manufacturers have shown the following trends:

- Players in competitive settings report a lower incidence of hand fatigue and bounce inconsistency with 16mm paddles due to their superior shock absorption and reduced vibrations.

- Recreational players often opt for 14mm paddles because the lower core thickness enhances tactile feedback and provides a more intuitive control during play.

Integrating these insights into your product development strategy can lead to improved customer satisfaction and a stronger market position.

In conclusion, both 16mm and 14mm pickleball paddles offer distinct advantages tailored to different playing styles and market segments. The 16mm paddle excels in delivering power, durability, and vibration control, making it the ideal choice for competitive play. Conversely, the 14mm paddle is preferred for its enhanced control, smoother feel, and potential cost benefits, which suit recreational environments where finesse is valued.

For decision-makers in the sporting goods sector, the critical steps are:

- Evaluate your target customer’s priorities—power and durability versus control and comfort.

- Balance production efficiency and material costs based on your chosen manufacturing process.

- Consider offering a range of products, including customizable options, to cater to various market segments.

Making an informed choice based on these criteria can drive customer satisfaction and product performance in the competitive sporting goods market.

-

What are the performance differences between a 16mm and a 14mm pickleball paddle?

The 16mm paddle typically provides greater durability, power, and improved vibration control, making it suitable for competitive play. In contrast, the 14mm paddle offers a softer, more controlled feel which is ideal for recreational players. -

How do manufacturing processes affect the quality of 14mm vs. 16mm paddles?

Manufacturing methods such as hot pressing, cold pressing, and thermoforming influence the structural integrity and performance. For instance, hot pressing used in 16mm paddles boosts efficiency and impact resistance, while cold pressing in 14mm paddles enhances precision and ball feel. -

Which paddle thickness is better for competitive play?

Competitive players generally prefer the 16mm paddle because its thicker core delivers enhanced power, superior shock absorption, and reduced vibration, all of which are crucial for high-intensity matches.

-

hot pressing: Click to read an article detailing how hot pressing improves production efficiency and enhances the structural integrity of sporting goods. ↩ ↩ ↩2 ↩3 ↩4

-

Cold Pressing: Click to read more about cold pressing techniques and how they allow for greater control over material properties in precision manufacturing. ↩ ↩

-

Thermoforming: Click to explore how thermoforming enables intricate product designs and optimized material distribution in the manufacturing process. ↩ ↩

-

Nomex: Click to learn about Nomex, its unique properties, and why it's a valuable core material in high-performance products. ↩ ↩

-

composite designs: Click to understand composite designs and how blending different materials results in products that balance power, control, and cost-effectiveness. ↩ ↩