Pickleball paddle edge guards serve as a vital design element that not only protects your investment but also enhances performance. In essence, an effective edge guard solution can dramatically improve paddle durability and maintain the performance integrity of every manufactured unit.

In today’s competitive B2B sports equipment market, procurement and product development managers face the challenge of selecting the optimal edge guard design to withstand repeated impacts and provide longevity. The decision must balance material innovation, manufacturing process capabilities, and ultimate product performance. For managers evaluating edge guard solutions, understanding the core differences among various protection options is key to making an informed decision that aligns with both quality and cost targets.

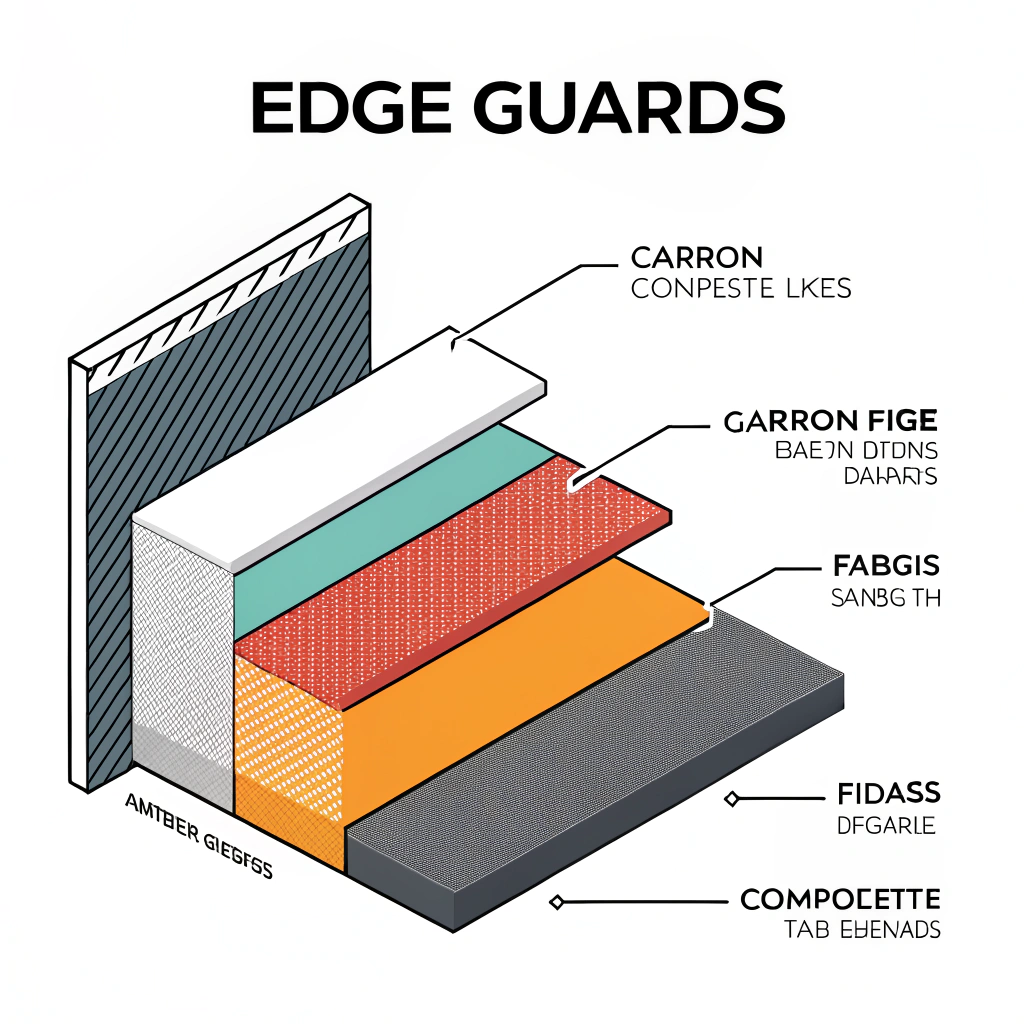

Edge guards are protective bands or layers incorporated into pickleball paddles primarily to shield vulnerable borders where structural failures often start. These guards prevent chipping, cracking, or delamination, which are common in high-impact sports. With enhanced durability and improved performance, edge guards contribute both to extended product lifespan and to maintaining a consistent hitting feel during play.

A high-performance edge guard must include:

• Resistant materials that balance stiffness and flexibility

• A design that complements the paddle’s overall weight distribution

• Compatibility with advanced manufacturing processes

• Customization capabilities for different target markets

For B2B buyers, adopting a robust edge guard solution can lead to fewer product returns and enhanced brand reputation, exciting factors that drive the competitive edge in manufacturing sports equipment.

Modern edge guards rely on an interplay of premium materials—Carbon Fiber, Fiberglass, and various Composite Materials1—combined with precise production techniques such as Hot Pressing2, Cold Pressing3, and Thermoforming4. Each combination delivers a unique balance of strength, flexibility, and production efficiency.

-

Carbon Fiber Variants

- 3K Carbon Fiber offers a robust design with excellent rebound and durability, reducing vibration during play.

- 12K Carbon Fiber is denser, offering a smoother, harder surface that can bear more intense impacts.

- *T300 Carbon Fiber5 promotes balanced performance with outstanding tensile strength, ideal for high-level competitive play.

-

Fiberglass

Fiberglass materials, like E-Glass Fiberglass, provide an excellent balance between power and control. With inherent flexibility and ball control, these materials contribute to a wider sweet spot on the paddle. -

Composite Materials

- Carbon Fiber and Fiberglass Composite: This blend optimizes strength and lightness.

- Bamboo Core Composite and Honeycomb Core variants offer lightweight designs with outstanding impact resistance.

The right material not only supports the functional requirements of the paddle but also ensures that the edge guard remains resilient to wear and tear.

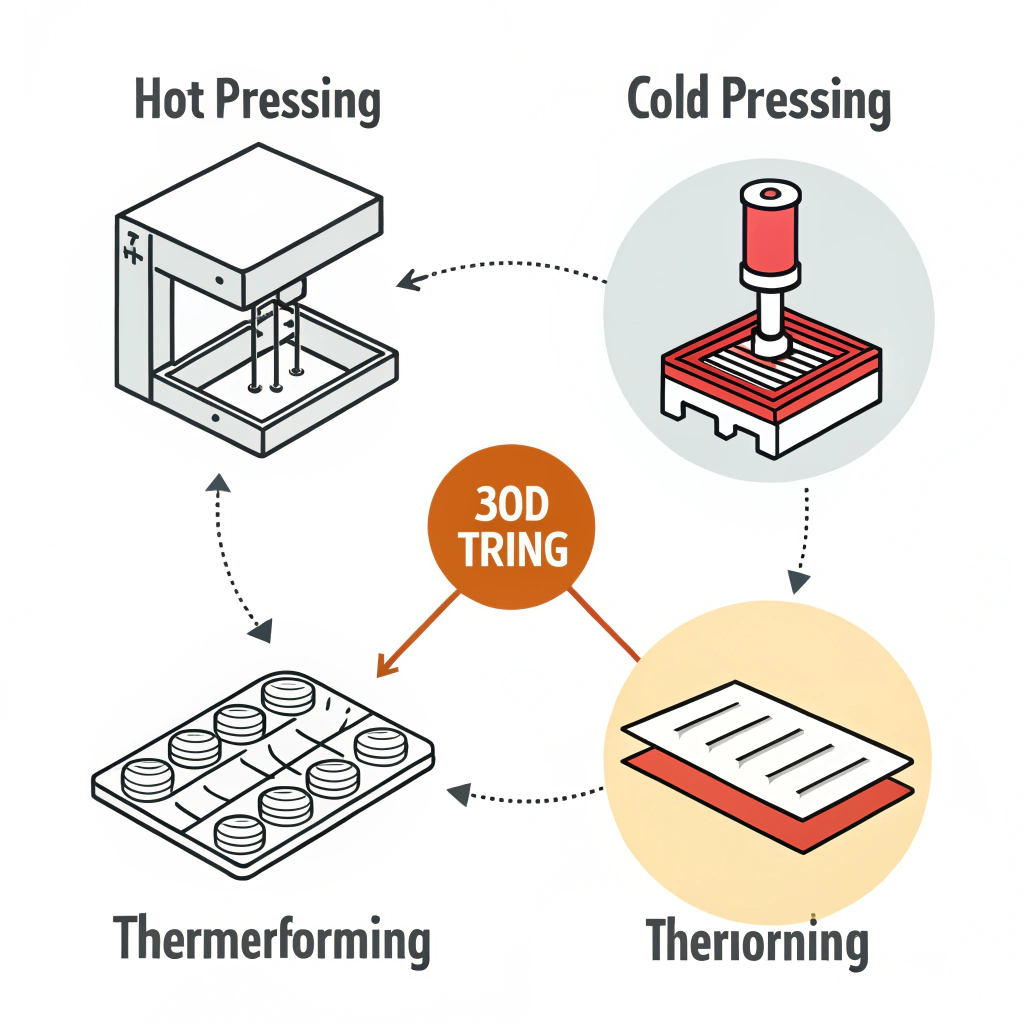

The production process chosen for manufacturing edge guards has a significant impact on the final product’s quality:

• Hot Pressing2:

This process involves heating and applying pressure to shape the materials. It results in a strong, durable edge guard capable of high impact resistance. The high production efficiency of hot pressing is attractive for large-scale manufacturing, though the process may alter some material properties affecting the paddle’s feel.

• Cold Pressing3:

By shaping materials at room temperature under significant pressure, cold pressing results in precise control over thickness and structure, preserving the inherent characteristics of the raw material. Its application makes for a better “ball feel” and more refined edge guard design, ideal for paddles that require precision.

• Thermoforming4:

Thermoforming involves heating the material to a softening point before molding it into a desired shape. This method is particularly suitable for complex designs and ensures exact material distribution. Premium paddles benefit from thermoforming despite the higher equipment cost and longer production time.

These processes offer their unique advantages and drawbacks. B2B decision-makers must evaluate which technology fits their production volume, quality control standards, and customization needs.

When comparing edge guards to other protection options—such as over-molded materials or surface coatings—a clear differentiation emerges based on several core factors. The table below provides a quick overview of comparative attributes:

| Feature | Edge Guards | Over-Molding/Coatings | Key Considerations |

|---|---|---|---|

| Durability | High impact resistance | Moderate; prone to wear | Edge guards add extra mechanical protection |

| Weight Distribution | Optimized for balance | May add unwanted bulk | Proper design maintains paddle feel |

| Customization Level | High (materials & design) | Limited customization | Options for branding and specific performance |

| Manufacturing Complexity | Moderate integration | Lower integration skills | Edge guards rely on advanced production methods |

| Production Efficiency | Depends on process | Generally high | Hot pressing can offer high efficiency |

| Cost | Higher initial investment | Lower upfront, higher maintenance | Investment vs. longevity trade-off |

The edge guard solution not only focuses on protecting the paddle’s design but also supports enhanced performance through better material integration and precision manufacturing.

A successful edge guard solution requires a comprehensive approach that combines material expertise with tailored manufacturing processes. Here are some critical strategies to consider when integrating edge guards into your product portfolio:

-

Evaluate Material Compatibility:

Ensure that the chosen edge guard materials blend seamlessly with the main paddle structure. For instance, pairing carbon fiber-based edge guards with a polymer honeycomb core can help sustain both power and vibration reduction. -

Process Alignment with Production Goals:

Decide if high volume production or premium custom production is the priority. For high-volume production, Hot Pressing2 may yield economic benefits, while Thermoforming4 might be better suited for premium, high-performance paddles that demand intricate designs. -

Customization for Market Differentiation:

Leverage the ability to customize edge guards. Using design techniques that support custom branding or incorporating advanced materials like T300 carbon fiber can create a competitive differentiation in the market. -

Quality Assurance and Rigorous Testing:

With any integrated design element, strict quality control is necessary. Every batch should undergo rigorous testing for impact resistance, durability, and user comfort. Statistical quality data and real-world testing feedback can drive continuous improvement. -

Factory Collaboration and Expertise:

Engage with manufacturing partners who possess the technical expertise in materials science and production processes. For example, as a manufacturer with experience in serving high-performance brands like Joola and Selkirk, NEX Pickleball ensures that every production process from cold pressing to thermoforming meets stringent quality standards.

A step-by-step implementation outline might look like this:

- Material Selection and Testing

- Prototype Design and Process Simulation

- Pilot Production with Quality Audits

- Feedback Integration from Product Testing

- Full-Scale Rollout and Continuous Improvement

These strategies, combined with in-depth process comparison, can help streamline decision-making for B2B buyers looking to optimize the design and performance of their pickleball paddles.

Consider a scenario where a sports equipment manufacturer was evaluating several edge protection solutions. Initially, the company faced challenges with paddle durability, especially under high-frequency use in competitive settings. After a comparative review, the following steps were taken:

• A rigorous material review was conducted. The team tested various combinations of carbon fiber and fiberglass composites to assess which safeguarded the paddle border without compromising the ball feel.

• Multiple production processes, including hot pressing and thermoforming, were trialed on sample batches. Each method was evaluated on criteria such as production speed, consistency in quality, and overall durability.

• A standardized quality assurance protocol was developed. This protocol thoroughly tested the edge guard’s performance under simulated conditions, addressing issues such as impact absorption, material degradation, and color retention for branded paddles.

• The final choice was a combination of T300 carbon fiber integrated through precision thermoforming, which delivered exceptional rigidity with minimal added weight. This choice resulted in a product that met the rigorous demands of competitive play while staying within budget.

This real-world scenario underscores the importance of combining technical insights with strategic production choices. It reiterates how edge guards, as a seemingly small component, play an outsized role in the overall performance and longevity of pickleball paddles.

In summary, a well-engineered edge guard is not just an accessory on a pickleball paddle—it is a central feature that can define the product's durability, performance, and market competitiveness. B2B buyers should:

• Conduct thorough comparative evaluations of material options and manufacturing processes.

• Leverage the detailed analysis provided by industry experts to refine product design.

• Consider customization options that align with both performance requirements and brand identity.

• Invest in advanced production methods to ensure that protective designs meet high-quality benchmarks.

By integrating these strategies and continuously striving for innovation, companies can reduce production risks, enhance product lifespan, and ultimately offer superior performance to the end user.

For procurement managers and product developers aiming to stay ahead in the highly competitive sports equipment market, edge guard innovation is an essential step. A careful balance of material science and manufacturing precision can yield paddles that not only survive intense play but also deliver outstanding user experiences, fostering customer loyalty and enhancing competitive positioning.

People Also Ask

Q1: What are the benefits of using edge guards in pickleball paddles?

A1: Edge guards protect the paddle’s vulnerable borders from chipping and cracking, leading to extended durability, improved impact resistance, and a consistent hitting feel. Their design is critical for maintaining overall performance, especially under repetitive, high-impact play.

Q2: How do different manufacturing processes impact the performance of edge guards?

A2: Production processes like hot pressing, cold pressing, and thermoforming affect the edge guard’s integration and performance. Hot pressing offers efficiency and high impact resistance, cold pressing ensures precision and material integrity, while thermoforming provides the opportunity for complex designs and precise material distribution.

Q3: What are the best materials for designing durable paddle edge guards?

A3: Durable edge guards typically use premium materials such as various types of Carbon Fiber (3K, 12K, T300), Fiberglass, and advanced composite materials. The choice depends on desired attributes, balancing strength, weight, and overall impact resistance to meet specific performance and durability requirements.

-

Composite Materials: This resource explains the advantages of using composite materials in sports equipment, including their strength, durability, and lightweight properties that enhance overall product performance. ↩ ↩

-

Hot Pressing: Click here to explore the benefits and limitations of using heat and pressure in manufacturing processes to achieve high impact resistance and production efficiency in sports equipment. ↩ ↩ ↩2 ↩3

-

Cold Pressing: Learn more about how applying pressure at room temperature helps preserve material integrity while allowing for precise control over thickness and structure in production processes. ↩ ↩ ↩2

-

Thermoforming: Reading this article will help you understand how heating materials to a pliable state before molding them allows for complex designs and precise material distribution, vital for producing high-performance sports equipment. ↩ ↩ ↩2 ↩3

-

T300 Carbon Fiber: Discover the properties of T300 carbon fiber and why its superior tensile strength makes it ideal for high-performance sports applications, ensuring a balance of rigidity and weight reduction. ↩ ↩