Quick Answer: This guide explains how advanced production processes and high-performance materials like carbon fiber1, fiberglass, and innovative composite cores2 elevate pickleball paddle manufacturing. It outlines the advantages and trade-offs of techniques such as hot pressing, cold pressing, and Thermoforming3, providing clear comparisons to help B2B decision-makers choose the right partner for reliable, customizable, and top-performing pickleball equipment.

Pickleball is one of the fastest-growing sports globally, and the demand for high-performance equipment is rising rapidly in the B2B sports equipment sector. This article is designed for procurement and brand managers seeking precise technical insights and solid data. Our guide delves into modern manufacturing techniques and material choices that differentiate top-tier pickleball paddles. We break down the production methods, material properties, and design customizations that ensure durability, power, and control. By the end of this guide, you'll be equipped to make informed decisions for bulk purchasing and long-term business partnerships.

When selecting pickleball paddles for your business, the material composition is crucial. Each material brings unique benefits:

-

3K Carbon Fiber: Known for its strength and flexibility, this material offers high rebound force and excellent durability. It minimizes vibration, making it ideal for intense gameplay.

-

12K Carbon Fiber: With a higher thread density, this carbon fiber provides a smoother surface, increased hardness, and improved durability. It is particularly useful for competitive play due to its superior impact resistance.

-

T300 Carbon Fiber: Valued for its outstanding tensile strength, T300 strikes a perfect balance between weight and durability. It is a favorite among players looking for both performance and agility.

These carbon fiber types are typically chosen by manufacturers to ensure that paddles provide maximum performance under high-speed gameplay conditions.

Fiberglass paddles, especially those made from E-Glass Fiberglass, are known for offering a balanced mix of power and control. Their elasticity and tensile strength provide a generous sweet spot, ensuring excellent ball control without compromising durability.

Composite materials combine the strengths of different components:

-

Carbon Fiber and Fiberglass Composite: This mix harnesses the power of both materials, yielding paddles that boast enhanced strength, lightness, and flexibility.

-

Bamboo Core Composite: Bamboo cores are lightweight and highly impact-resistant, providing players with a crisp hitting feel that stands the test of time.

-

Honeycomb Core: Typically made from high-density polymer or pulp, honeycomb cores are engineered for superb shock absorption. This minimizes vibration, ensuring a consistent and comfortable playing experience even during prolonged use.

The core of a paddle plays a significant role in defining its control and stability:

-

Nomex Honeycomb Core: Constructed from durable polymers, these cores are built for longevity, absorbing shocks effectively for enhanced play stability.

-

Aluminum Honeycomb Core: These cores provide a balanced weight ideal for generating both power and precision.

-

Polymer Honeycomb Core: Known for its elasticity, polymer cores reduce vibration and deliver a softer, more controlled hit, favored especially among recreational players.

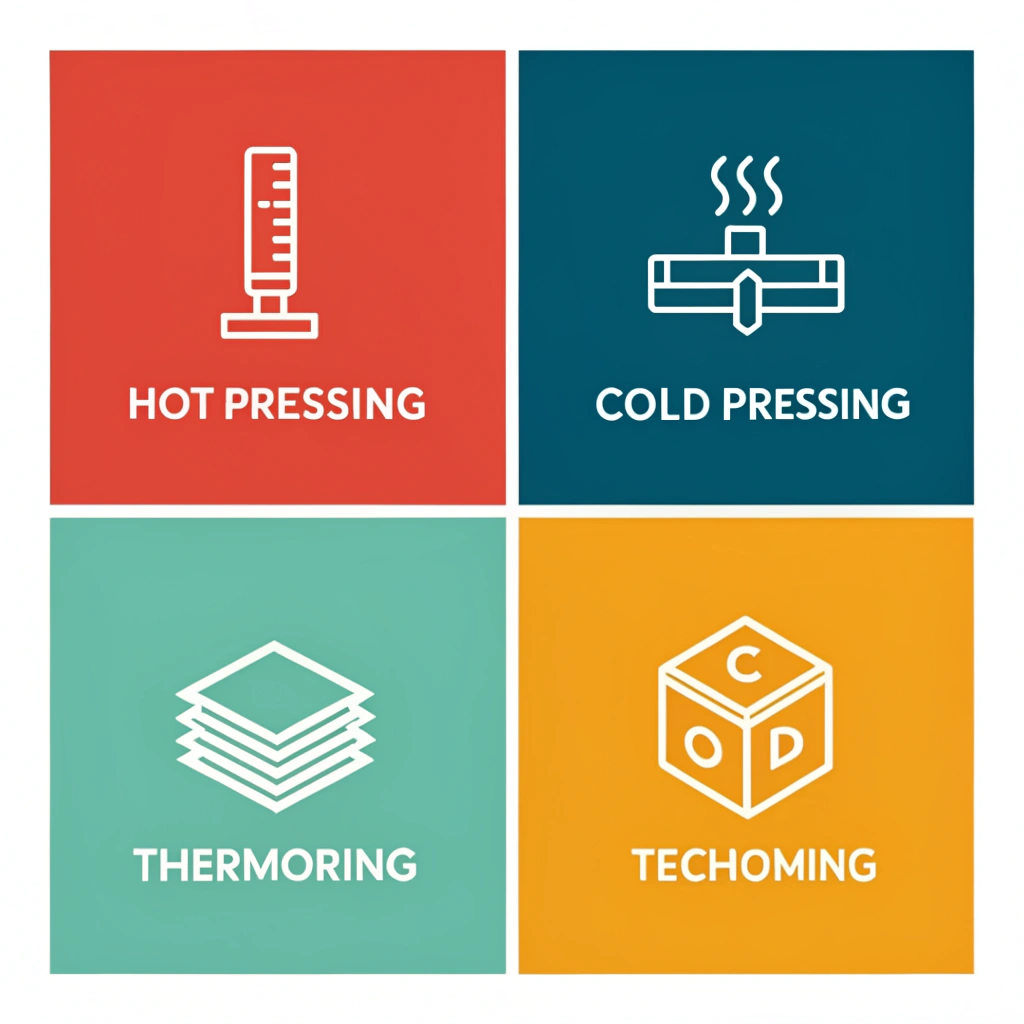

Understanding the manufacturing techniques is essential for assessing production efficiency and quality control. There are three primary production methods used in the manufacture of high-performance pickleball paddles:

Hot pressing involves heating paddle materials and applying significant pressure to mold them into shape. This process ensures the structural integrity of the product.

Advantages:

- Efficiency: High production efficiency makes hot pressing suitable for large-scale manufacturing.

- Strength: Produces robust paddles with excellent impact resistance.

- Structural Integrity: Maintains the shape and performance during high-impact usage.

Disadvantages:

- Material Alteration: High temperatures may modify some material properties, potentially affecting paddle feel.

- Equipment Investment: Requires sophisticated, high-cost machinery to maintain consistency.

In contrast, cold pressing employs mechanical pressure at room temperature. This preserves the original properties of the material.

Advantages:

- Precision: Allows for meticulous control over paddle thickness and structure.

- Material Preservation: Retains the inherent qualities of the materials, ensuring superior ball feel and responsiveness.

- Customization: Ideal for developing paddles tailored to specific play styles.

Disadvantages:

- Efficiency Trade-Off: Longer production cycles reduce overall manufacturing output.

- Equipment Demands: Requires highly precise and calibrated machinery.

Thermoforming uses heat to soften materials so that they can be molded into complex shapes using specially designed molds.

Advantages:

- Design Flexibility: Facilitates the creation of intricate designs and even material distribution, important for paddle balance.

- Stability: Enhances paddle performance by achieving optimal weight distribution.

- Premium Product Suitability: Best for high-performance paddles where design and detailed craftsmanship are paramount.

Disadvantages:

- Long Production Time: Generally slower than hot pressing.

- Higher Cost: Increased equipment and production costs justify its use primarily in premium models.

For decision-makers, understanding the central differences is key. The table below summarizes each process's advantages and disadvantages to aid your selection decisions based on production necessity and product performance requirements.

| Process | Advantages | Disadvantages | Ideal For |

|---|---|---|---|

| Hot Pressing | High production efficiency; excellent impact resistance; strong structural integrity | Potential alteration of material properties; high equipment investment | Large-scale manufacturing and high-performance paddles |

| Cold Pressing | Precise control over structure; preserves material properties; exceptional ball feel | Longer production cycles; requires high-precision machinery | Custom paddles and designs requiring precise control |

| Thermoforming | Intricate designs; maintains paddle stability; well-suited for premium materials | Longer production time; higher equipment costs | Premium, custom-made paddles and innovative designs |

For B2B procurement managers, customization is a critical factor. With on-demand print capabilities and a range of materials, NEX Pickleball offers extensive customization options.

Key Customization Capabilities Include:

- Custom Designs: Clients have the freedom to specify design elements like surface texture, weight distribution, grip size, and overall paddle aesthetics.

- Material Selection: Options for carbon fiber, fiberglass, composite, and various core types allow for products tuned to performance demands.

- Branding Opportunities: Bulk purchasing with custom print services ensures that paddles can carry an organization's branding, making them ideal for team uniforms, promotional events, or retail sales.

This level of customization not only enhances performance tailored to specific play styles but also empowers businesses to maintain a unique market identity. The ability to produce paddles with selecting advanced materials and manufacturing processes guarantees that you, as a distributor or brand manager, receive consistent quality and supporting data for product claims in competitive environments.

At the heart of advanced pickleball paddle manufacturing is rigorous quality control. With every paddle undergoing extensive testing for strength, flexibility, and durability, manufacturers ensure that performance and longevity are never compromised.

Testing includes:

- Impact Resistance Analysis: Evaluating how different materials and core types absorb shocks during high-speed gameplay.

- Vibration Reduction: Ensuring that design elements and material properties work in concert to minimize unwanted vibrations.

- Ergonomic Studies: Verifying that grip sizes and paddle weight distributions meet ergonomic standards to maximize player comfort and performance.

These measures affirm that every paddle delivered meets the high standards necessary for both competitive play and recreational use. In an industry where precision matters, our testing protocols ensure that you consistently offer products that exceed customer expectations.

When evaluating pickleball paddle suppliers, consider the following critical points:

-

Performance-Centric Materials: Ensure that the paddles incorporate advanced materials like carbon fiber and premium composites tailored for specific gameplay needs. Each material provides unique performance benefits that cater to different levels of play and playing styles.

-

Adaptive Manufacturing Processes: Choose suppliers who employ multiple production techniques—hot pressing for maximum durability, cold pressing for precision, and thermoforming for premium designs. This diversity in manufacturing ensures that product lines can be adjusted according to market demand.

-

Customization Capabilities: Customization options are a significant selling point. From branding opportunities to tailored paddle specifications, being able to choose aspects such as weight, balance, and grip design can directly influence customer satisfaction and market differentiation.

-

Quality Control and Testing: Look for thorough quality testing protocols. A robust testing regimen ensures that each paddle meets performance guarantees, reducing the risk of product recalls and enhancing overall customer trust.

-

On-Demand Production and Scalability: Evaluate a supplier’s ability to scale production and offer rapid turnaround times. In today's fast-paced market, being able to adapt to sudden large orders or design modifications is crucial for maintaining a competitive edge.

By understanding these elements, you will be better equipped to make a decision that not only meets performance standards but also strengthens your business portfolio in the sports equipment market.

In conclusion, high-performance pickleball paddles demand a perfect marriage of innovative materials, precise manufacturing processes, and comprehensive quality control. Whether you are considering the robust benefits of carbon fiber in its various forms, the nuanced control offered by cold pressing, or the intricate designs possible through thermoforming, each factor plays a crucial role in product performance and market success.

For B2B partners, selecting a supplier that understands both the technical specifications and the broader market dynamics is essential. NEX Pickleball, with its commitment to technological advancement, customization, and rigorous testing, stands out as a reliable partner in the quick-evolving sports equipment manufacturing industry. We encourage you to evaluate these factors carefully to ensure that your purchasing decision maximizes performance, reliability, and business growth.

Embrace the advanced production techniques and material innovations discussed in this guide to drive your business forward in an increasingly competitive marketplace.

People Also Ask

Q1: What are the benefits of using carbon fiber in pickleball paddles?

A1: Carbon fiber, including variants like 3K, 12K, and T300, offers high strength, improved durability, and reduced vibration. It enhances paddle performance by providing superior rebound and control, making it ideal for fast-paced competitive play.

Q2: How do different production processes affect paddle performance?

A2: Production processes such as hot pressing, cold pressing, and thermoforming impact paddle performance by influencing factors like structural integrity, material preservation, design flexibility, and overall product durability. Each method has its advantages, making them suitable for specific production and performance needs.

Q3: What customization options are available for pickleball paddles?

A3: Customization options include selecting materials (carbon fiber, fiberglass, composites), core types (Nomex, aluminum, polymer honeycomb), design elements (weight distribution, grip size, surface texture), and on-demand print services for branding purposes. These options enable tailored solutions for both performance and market differentiation.

-

carbon fiber: Click to read an in-depth article on the engineering properties, manufacturing benefits, and performance enhancements provided by carbon fiber in sports equipment production. ↩ ↩

-

composite cores: Click to learn about composite cores, their material composition, and how combining different materials can optimize performance, durability, and weight in paddle design. ↩ ↩

-

Thermoforming: Click to explore the thermoforming process, its role in achieving complex shapes, and its importance in premium product manufacturing. ↩ ↩ ↩2

-

Hot Pressing: Click to understand how hot pressing works, including its impact on material properties, production efficiency, and structural integrity in large-scale manufacturing. ↩ ↩

-

Cold Pressing: Click to discover the benefits and challenges of cold pressing, and how preserving material integrity results in superior tactile response in custom sports equipment. ↩ ↩