In short, selecting the right material and production process for pickleball paddles is a balancing act between performance, durability, and production efficiency. Advanced materials like 3K, 12K Carbon Fiber1, and T300 Carbon Fiber2 each offer distinct performance benefits, while alternative materials such as fiberglass and composite cores provide unique advantages. By understanding these differences and the intricacies of production processes like hot pressing, cold pressing, and thermoforming, B2B decision-makers can choose the optimal solution that meets both technical requirements and cost considerations.

For a purchasing manager or a product development lead in sports equipment distribution, choosing the right pickleball paddle material is not just a technical decision—it’s a strategic one. The selection process requires detailed comparisons between materials that determine key performance factors such as rebound force, vibration reduction, ball control, and overall durability. Meanwhile, production methods have a direct impact on production efficiency and quality control. Incorrect material selection or production inefficiencies can lead to issues in product performance, increased returns, and ultimately a negative impact on the brand’s reputation.

Many distributors face challenges such as:

• Balancing cost and performance when selecting premium material options.

• Aligning production methodologies with the quality requirements of high-performance competitive play.

• Adapting to evolving market demands with fast production cycles while maintaining strict quality standards.

It is crucial to demystify the specifics of each material approach and its production process to support sound procurement decisions.

Breaking down the technical options available can be approached from two main angles: the choice of materials and the selection of production processes. Below is an analysis of the most commonly used materials and the advanced production methods available for pickleball paddle manufacturing.

3K Carbon Fiber

– Known for its balance of strength and flexibility.

– Provides high rebound force and excellent durability while reducing unwanted vibration.

– Ideal for paddles used in fast-paced competitive games.

12K Carbon Fiber1

– Features a higher thread density which creates a smoother surface, greater hardness, and improved durability.

– Best suited for high-impact play scenarios where extreme strength is essential.

– Often selected for paddles demanding high performance in competitive settings.

T300 Carbon Fiber2

– Renowned for outstanding tensile strength with a balanced performance that combines both power and light weight.

– Suitable for diverse playing styles, ensuring reliable performance across varied game conditions.

Fiberglass paddles, such as those made from E-Glass Fiberglass, offer:

• Excellent elasticity and tensile strength.

• An expanded sweet spot which enhances ball control and provides a comfortable feel on impact.

• A more flexible alternative compared to carbon fiber, often preferred by players focusing on control and spin.

Composite paddles blend the best qualities of different materials. Advantages include:

• Combining carbon fiber and fiberglass results in paddles that optimize both power and ball control.

• Bamboo Core Composites deliver lightweight impact resistance while maintaining a solid hit feel.

• Honeycomb Core composites, constructed from either high-density polymer or pulp, offer exceptional vibration damping and shock absorption, extending paddle longevity.

The core component of the paddle is crucial for determining overall performance. Options include:

• Nomex Honeycomb Core4: Offers robust shock absorption and provides a stable, durable playing surface.

• Aluminum Honeycomb Core: Balances weight distribution to offer both power and precision.

• Polymer Honeycomb Core: Known for its elasticity and reduced vibration transmission. This makes it an excellent choice for players who value comfort during prolonged play.

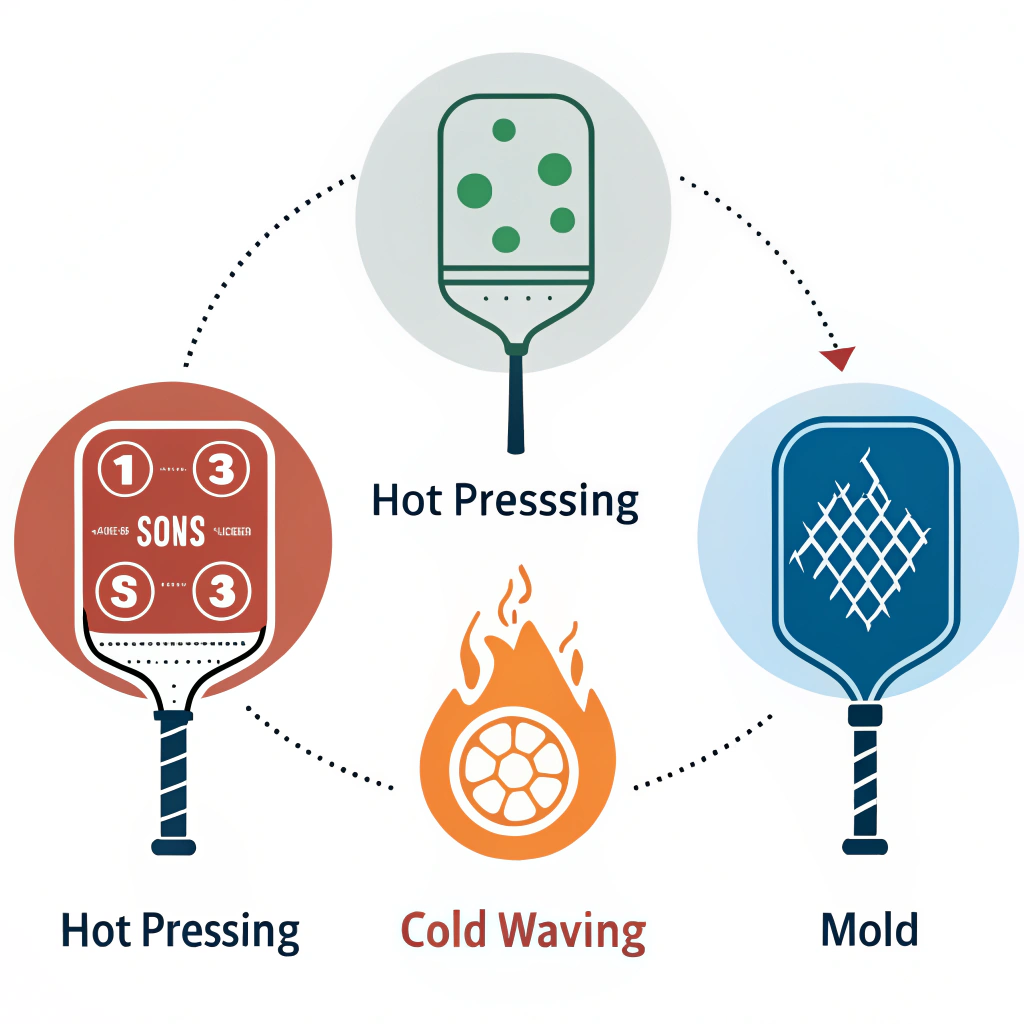

Choosing the correct production technique is just as important as selecting the right material. At NEX Pickleball, we use three main production processes. Each method introduces its own set of advantages and limitations that directly impact the final product quality.

| Production Process | Advantages | Disadvantages |

|---|---|---|

| Hot Pressing | • High production efficiency suitable for large-scale manufacturing. • Results in sturdy paddles with excellent impact resistance. • Maintains structural integrity through high-temperature treatment. | • Potential alteration of some material properties, affecting the paddle's natural feel. • High investment required for specialized equipment. |

| Cold Pressing | • Allows for precise control over paddle thickness and structure. • Retains the inherent properties of the material, improving flexibility and playability. • Ensures excellent ball feel and responsiveness. | • Slower production cycle, which might hinder large-scale manufacturing. • Requires refined pressure control, demanding high precision equipment. |

| Thermoforming5 | • Enables production of intricate designs with exact material distribution. • Maintains paddle stability, enhancing overall performance. • Perfect for custom-made paddles and premium product lines. | • Longer production time and higher cost due to complex molds. • Best suited for premium product segments rather than mass-market production. |

The table above summarizes the major trade-offs each process presents. Each method is valuable in its own right and must be chosen based on product requirements and market positioning.

To address the common challenges faced by procurement managers and product developers, it is helpful to adopt a solution-oriented methodology. Below is a checklist and guidance for making informed decisions regarding material and production process selection.

• Determine the primary use of the paddle. For instance, high-impact competitive play often benefits from 12K Carbon Fiber1 for its superior hard-wearing properties, while recreational play may prefer the ball control provided by fiberglass.

• Evaluate the importance of reducing vibration. If minimizing shock and enhancing stability is key, a Nomex Honeycomb Core4 or Polymer Honeycomb Core can be ideal.

• Weigh the cost implications of high-performance materials against expected product life and durability.

• Consider that while T300 Carbon Fiber2 may have a higher upfront cost, its balanced weight and strength might reduce long-term expenses associated with product failures and returns.

• Examine production efficiency: Hot pressing may offer cost benefits for large-scale production, while Thermoforming5 can enhance custom product appeal albeit at higher manufacturing costs.

• Choose hot pressing when high throughput and consistent durability are required.

• Opt for cold pressing if product feel and precision are prioritized.

• Consider Thermoforming5 for products requiring complex shapes and precise balancing, particularly in niche or premium segments.

| Decision Criteria | What to Consider | Options Recommended |

|---|---|---|

| Performance Demand | Power, speed, vibration damping, and ball control | 12K Carbon Fiber, Fiberglass, Composite |

| Cost Efficiency | Budget constraints versus long-term durability expectations | Hot Pressing, Aluminum Honeycomb Core |

| Production Scale | Order volumes and process efficiency | Hot Pressing for mass production; Cold Pressing for precision builds |

| Customization Needs | Ability to offer unique, tailored solutions | Thermoforming and Custom Composite Options |

Taking the time to complete such an evaluation ensures that the final product aligns with both market demands and technical specifications.

At NEX Pickleball, our commitment to quality and performance drives our material and production decisions:

• We use advanced techniques, incorporating a mix of premium carbon fiber options and robust core materials to achieve paddles that exceed industry standards.

• Our state-of-the-art production processes, whether it be hot pressing for mass production or cold pressing for detailed control, allow us to consistently deliver high-performance paddles.

• Rigorous testing and continuous refinement of design ensure that every paddle meets the stringent requirements of competitive play.

Our process not only guarantees performance but also leverages cost efficiencies that benefit our global B2B partners. By choosing the right material combination and production method, we enable our clients to offer products that stand out in a competitive market.

Adopting a holistic approach when evaluating paddle materials and manufacturing processes can lead to several competitive advantages:

• Innovation: Regularly reviewing new production techniques and emerging material technologies allows companies to stay ahead. For example, advances in composite materials and hybrid production processes continue to push the envelope in paddle performance.

• Quality Assurance: Rigorous quality control protocols must be established. Every batch of paddles should undergo stringent testing to verify that they meet performance targets such as vibration damping, impact resistance, and ergonomic comfort.

• Customization and Flexibility: In the B2B market, flexibility is key. Offering customizable paddle options regarding design, weight, and grip size can cater to a varied customer base. This responsiveness to customer needs builds trust and long-term relationships.

• Market Differentiation: By clearly differentiating products based on technical specifications and performance data, businesses can position themselves strongly against competitors. This differentiation becomes a critical selling point in pitches and product negotiations.

• Data-Driven Decisions: Use data and test results to drive product development. For example, conducting side-by-side comparisons of paddle models produced via different processes can reveal subtle improvements in performance that directly translate into competitive advantages.

In summary, selecting the optimal pickleball paddle material and production process hinges on a careful comparison of performance features, cost implications, and production scalability. Here are the key takeaways:

• Material Selection: Choose between various types of carbon fibers (3K, 12K, T300), fiberglass, and specialized composite or core materials based on the intended use and performance requirements.

• Production Process: Understand the trade-offs between hot pressing, cold pressing, and Thermoforming5. Each process offers unique benefits associated with efficiency, precision, and quality.

• Holistic Evaluation: Develop a decision checklist that assesses performance needs, cost efficiency, and production scalability. Data-backed analysis combined with industry insights leads to informed procurement decisions.

• Customization and Innovation: Embrace technology-driven customization to meet the diverse needs of global markets. Continuous innovation ensures product differentiation and long-term customer satisfaction.

For industry leaders looking to enhance their sports equipment portfolio, these considerations offer a roadmap for selecting paddle materials that align with market demands and quality standards. Leveraging our extensive experience at NEX Pickleball, we are uniquely equipped to support your success with high-performance paddles engineered through advanced production methodologies.

Take these insights into account when planning your next procurement or product development strategy. By doing so, you can secure a competitive edge in the growing pickleball market.

-

What are the main differences between various carbon fiber types used in pickleball paddles?

Answer: Different carbon fiber types such as 3K, 12K, and T300 offer distinct benefits. For example, 3K fiber is valued for its balance of strength and flexibility, 12K fiber provides a smoother surface and higher durability for intense play, while T300 fiber is noted for its high tensile strength and lightweight performance. -

What are the advantages of using fiberglass in pickleball paddle manufacturing?

Answer: Fiberglass offers excellent elasticity and a wider sweet spot, resulting in better ball control and a comfortable feel. It is especially useful in paddles where flexibility is as important as power, making it a strong option for players seeking improved control during play. -

How does the hot pressing production process impact the performance of pickleball paddles?

Answer: The hot pressing technique improves production efficiency by using high temperatures and pressure to form a durable paddle structure. Although it can slightly alter material properties, it ensures strong impact resistance and excellent structural integrity, which is crucial for high-performance competitive play.

-

12K Carbon Fiber: Click to learn how the higher thread density of 12K Carbon Fiber results in a smoother surface, greater hardness, and improved durability—key factors for high-impact competitive play. ↩ ↩ ↩2 ↩3

-

T300 Carbon Fiber: Click to explore the benefits of T300 Carbon Fiber, renowned for its outstanding tensile strength and balanced performance that combine power with a lightweight design. ↩ ↩ ↩2 ↩3

-

Composite Materials: Click to discover how composite materials blend the strengths of various components to optimize performance, offering benefits in power, control, and vibration damping. ↩ ↩

-

Nomex Honeycomb Core: Click to understand how the Nomex Honeycomb Core provides robust shock absorption and stability, contributing to a durable and high-performance playing surface. ↩ ↩ ↩2

-

Thermoforming: Click to read about the thermoforming process, which enables the production of intricate paddle designs through precise material distribution, ideal for custom, premium products. ↩ ↩ ↩2 ↩3 ↩4