NEX Pickleball leverages advanced production techniques and premium materials to deliver high-performance pickleball paddles that meet the rigorous demands of competitive play. In short, our paddles are produced using cutting-edge methods such as hot pressing1, cold pressing, and thermoforming2, combined with materials like various types of carbon fiber3, fiberglass, and tailored composite cores. This approach ensures exceptional durability, optimal power, and precise control for players at all levels while positioning our company as a reliable partner for B2B procurement.

In today’s competitive sports equipment market, procurement managers seek partners that provide not only consistent quality but also the technological know-how to produce products meeting the highest standards. At NEX Pickleball, reliability is built on the expertise in both material selection and production methodology. We combine premium resources with state-of-the-art manufacturing processes to create paddles that stand up to intense gameplay and long-term use.

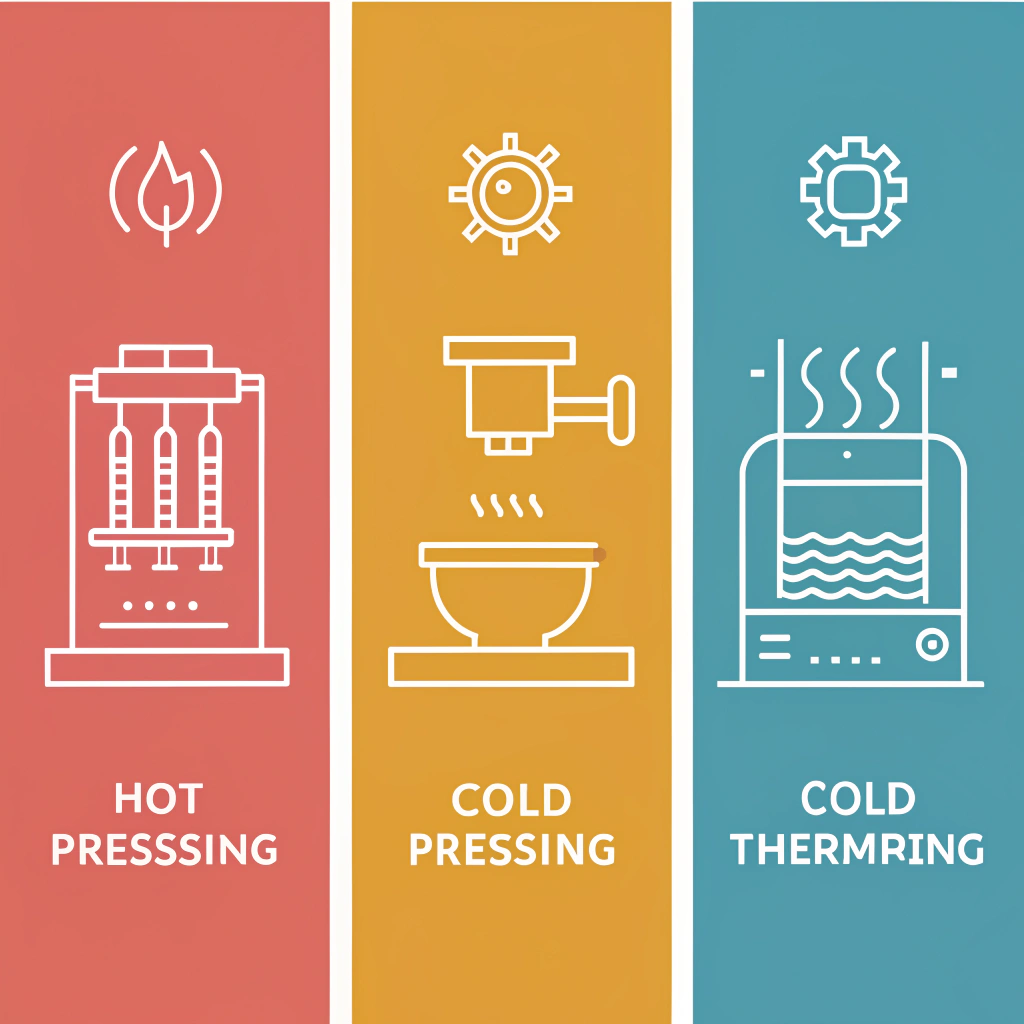

Our paddle manufacturing is rooted in three primary production techniques:

- Hot Pressing: Ideal for creating high-strength paddles rapidly, maintaining structural integrity.

- Cold Pressing: Employed when precise control over paddle thickness and material properties is paramount.

- Thermoforming2: Used for producing intricate design details while preserving even material distribution.

In parallel with these processes, a wide variety of high-quality materials is used:

- Carbon Fiber3: Including 3K, 12K, and T300 types, each with distinct benefits.

- Fiberglass: Offering a balance between power and control.

- Composite Materials4: Such as combinations of carbon fiber and fiberglass, bamboo core composites, and honeycomb cores designed for impact resistance.

- Core Materials: Including Nomex honeycomb, aluminum honeycomb, and polymer honeycomb cores that enhance both durability and performance.

Understanding the strengths and limitations of each production process is crucial for procurement managers making their sourcing decisions. Below is a comparative analysis table that highlights the key aspects of hot pressing, cold pressing, and thermoforming.

| Production Technique | Advantages | Disadvantages | Typical Applications |

|---|---|---|---|

| Hot Pressing | - High production efficiency with robust impact resistance. - Suitable for high-volume manufacturing. - Ensures strong structural integrity. | - May cause alteration in material properties affecting paddle feel. - Requires significant initial investment in machinery. | Large-scale production of high-strength paddles for competitive sports. |

| Cold Pressing | - Provides precise control over paddle thickness and structure. - Maintains material properties for enhanced control and flexibility. - Superior ball-feel and responsiveness. | - Longer production cycles than hot pressing. - Demands high precision equipment and consistent pressure control. | Paddles that require exact specifications for improved trajectory control and fine-tuned performance. |

| Thermoforming | - Suitable for creating complex paddle designs with precise material distribution. - Enhances paddle stability and overall performance. - Ideal for premium or custom models. | - Requires longer processing times. - Involves higher equipment costs. | Customized and premium product lines where design intricacy and performance precision are critical. |

Carbon Fiber3 paddles are known for their strength and responsiveness. Among them, we use three types:

- 3K Carbon Fiber: Its balance of strength and flexibility makes it ideal for paddles designed to offer high rebound force with reduced vibration.

- 12K Carbon Fiber: Provides a smoother paddle surface with increased hardness and durability, suitable for aggressive competitive play.

- T300 Carbon Fiber: Recognized for its remarkable tensile strength while keeping the overall weight low, offering a balanced mix of power and agility.

These variants allow our clients to choose paddles that best suit their performance and durability requirements, ensuring that whether the focus is on power or precision, there’s an option available in our product lineup.

Fiberglass provides an alternative to carbon fiber, particularly for paddles where flexibility and ball control are prioritized. Our E-Glass Fiberglass material ensures:

- Excellent elasticity that aids in providing superior ball control.

- A wider sweet spot, making these paddles more forgiving during off-center hits.

The combination of fiberglass with other materials often yields paddles that are versatile and well-rounded, balancing power with an enhanced touch.

The use of hybrid composite materials further pushes the performance envelope:

- Carbon Fiber and Fiberglass Composites combine the advantages of both materials to yield paddles that optimize strength, lightness, and flexibility.

- Bamboo Core Composites provide a natural feel with high resilience, ideal for absorbing shocks and enhancing the overall hitting experience.

- Honeycomb Cores (Nomex, aluminum, and polymer variants) are engineered to maximize shock absorption while reducing vibration, contributing to prolonged paddle life and a comfortable experience during extended play.

These options allow for tailored customization, which is vital to meet the specific demands and branding requirements of sports equipment distribution businesses.

One of the critical aspects of any successful B2B partnership is a robust quality control system. At NEX Pickleball, every paddle undergoes rigorous testing to ensure consistency in performance. Our quality checks address:

- Material Integrity: Verifying the properties of carbon fiber, fiberglass, and composite materials.

- Production Precision: Ensuring the paddle’s weight distribution, ergonomic grip, and surface texture meet the specified standards.

- Durability Testing: Simulated game conditions to ensure the paddle withstands long-term use without significant degradation in performance.

In addition to quality assurance, we offer extensive customization options that are a key advantage for businesses looking to differentiate their products. Clients can specify:

- Paddle shape

- Weight distribution

- Grip size and design

- Custom surface treatments for enhanced ball spin and accuracy

This flexibility has made our production facility a preferred OEM production5 for well-known brands like Joola and Selkirk, underscoring the trust placed in our manufacturing expertise.

When looking for a reliable B2B supplier for pickleball paddles, several factors need to be evaluated:

- Manufacturing Capabilities: Do they use advanced production techniques such as hot pressing, cold pressing, and thermoforming?

- Material Excellence: Are the materials (carbon fiber types, fiberglass, composites) state-of-the-art and suited for high-performance requirements?

- Quality Assurance & Customization: Does the supplier enforce strict quality control and offer customizable options?

- Experience and Track Record: Is the supplier a proven partner to reputable brands in the industry?

| Decision Factor | NEX Pickleball's Strengths | Competitor Considerations |

|---|---|---|

| Manufacturing Processes | Utilizes hot pressing, cold pressing, and thermoforming for varied product needs. | Some competitors may use only one or two methods. |

| Material Variety | Offers multiple carbon fiber types, fiberglass, composites, and modern core materials. | Limited material options can restrict product performance. |

| Quality Control | Rigorous testing and quality checks to ensure consistency and durability. | Varies significantly between manufacturers. |

| Customization Capabilities | Flexible design and customization, inclusive of custom print options. | May lack advanced customization or on-demand printing. |

| Industry Experience | OEM production for top brands like Joola and Selkirk. | Competitors may not have the same industry pedigree. |

The table not only consolidates technical differences but also highlights why partnering with a manufacturer like NEX Pickleball can streamline supply chain decisions while ensuring product excellence.

For procurement managers and business development executives, selecting the right supplier involves not only evaluating current capabilities but also anticipating future trends in equipment manufacturing. Here are some actionable insights:

- Evaluate Scalability: Ensure that the supplier can handle both large-scale orders and custom, low-volume batches without compromising on quality.

- Focus on Customization: With basketball and other sports moving towards personalized branding, having the flexibility to customize paddles is a competitive advantage.

- Prioritize Consistency and Quality: Given the rapid pace of sports equipment innovations, a rigorous quality control process ensures that every paddle meets high performance and safety standards.

- Assess Technological Adoption: Suppliers that invest in modern production techniques are more likely to adapt to new market trends and technologies, keeping your product offerings at the fore of innovation.

- Long-Term Partnerships: With long-term reliability being pivotal, choose a partner who not only meets current technical requirements but is also positioned to support future product development and market expansion.

By addressing these factors upfront, companies can reduce risks, ensure better product consistency, and optimize cost-effectiveness across the supply chain.

Selecting the right B2B partner for pickleball paddle manufacturing goes beyond mere cost considerations. It is essential to balance technical sophistication, material selection, production flexibility, and proven quality control. NEX Pickleball stands out in the competitive landscape due to our:

- Diverse advanced production techniques—hot pressing, cold pressing, and thermoforming.

- Wide range of high-performance materials that allow customization to meet varying market demands.

- Stringent quality assurance processes ensuring every paddle conforms to premium standards.

- Established track record as a trusted OEM production5 for leading brands like Joola and Selkirk.

Procurement managers can feel confident that partnering with NEX Pickleball not only guarantees excellent product performance but also opens opportunities for innovation and market expansion. With our capabilities in on-demand printing and custom paddle fabrication, we are well-equipped to handle both standard bulk orders and specialized requests.

When making your supplier decision, consider the complete value proposition. It is not just the cost per unit but the long-term benefits of product longevity, brand differentiation, and consistency in performance that will ultimately drive your market success.

Q: What is the best pickleball paddle manufacturer?

A: While market opinions vary, leading manufacturers like Joola, Selkirk, CRBN, and Gearbox are frequently cited for their premium quality. NEX Pickleball, as an OEM partner to brands such as Joola and Selkirk, offers advanced production techniques and high-quality materials that position it as a strong choice for businesses seeking reliable, high-performance pickleball paddles.

Q: Are Paddletek paddles made in China?

A: Not all pickleball paddles are made in China. For instance, brands like Paddletek and Engage manufacture their paddles in the USA using domestically sourced materials. In contrast, NEX Pickleball is based in China, utilizing advanced manufacturing techniques and premium materials to produce paddles that meet rigorous international standards.

-

hot pressing: Read more to understand how high-temperature compression techniques contribute to the production of robust, high-strength components. ↩

-

thermoforming: Discover the benefits of using heat to shape and mold materials for intricate, precision-engineered designs. ↩ ↩2

-

carbon fiber: Learn about the properties and applications of carbon fiber in enhancing performance and reducing weight in high-demand sporting equipment. ↩ ↩2 ↩3

-

Composite Materials: Explore the advantages of hybrid materials that combine the strengths of different fibers to deliver superior durability and performance. ↩

-

OEM production: Uncover insights on Original Equipment Manufacturing and how partnering with experienced OEMs can drive consistency, innovation, and quality in product sourcing. ↩ ↩2