Quick Answer: Pickleball’s rapid pace drives a need for cutting-edge equipment and innovative paddle design to enhance player agility, reaction time, and overall game performance – factors that in turn shape market trends and investment decisions in the sports equipment sector.

Introduction

Pickleball is rapidly emerging as a sport that appeals to diverse age groups and skill levels. The game’s fast pace is not just an exciting element for players; it also presents unique challenges and opportunities for equipment manufacturers and sports business managers. In a market where gameplay speed demands precise control, lightweight materials, and quick reaction response, the evolution of pickleball paddle design has become critical. Companies like NEX Pickleball are leading this movement by employing advanced production methods and innovative material usage to meet these challenges.

The game’s brisk tempo requires paddles that can endure quick strokes, rapid directional changes, and high-impact plays. For procurement managers and business development executives in the sports equipment sector, understanding the dynamics of pickleball pace is vital for making informed purchasing decisions and aligning product strategies with market trends.

Impact of Pickleball’s Fast Pace on Equipment Requirements

At the heart of pickleball’s growing popularity is its rapid gameplay. Unlike traditional racquet sports, where rhythm and sustained rallies may dominate, pickleball demands split-second decision-making and explosive movements for every shot. This rapid pace impacts paddle performance in several critical areas:

• Player Agility and Reaction Time: Fast gameplay requires paddles that allow for quick ball tracking and immediate response. The design must facilitate minimal vibration and optimal weight distribution, enabling players to adjust rapidly and maintain precision during play.

• Enhanced Ball Control: With the ball moving at high speeds and abrupt directional changes, even slight imperfections in paddle surface or weight can affect spin and control. Manufacturers must, therefore, innovate in surface treatments and material combinations to maximize control.

• Durability Under High Impact: Rapid gameplay and frequent high-impact strokes stress the paddle’s structure. This calls for using materials that not only boost performance but also ensure long-lasting durability under intense conditions.

The advancements in materials and production techniques have been driven by these very demands. For instance, the integration of carbon fiber1, fiberglass, and composite materials2 has been central to the recent improvements in paddle performance.

Materials Innovation: Carbon Fiber and Composite Technologies

In the pursuit of creating paddles that perfectly blend strength, lightness, and durability, manufacturers have turned to innovative materials. NEX Pickleball, renowned for its meticulous production processes, utilizes several high-performance materials, including:

-

Carbon Fiber – This group includes types such as 3K, 12K, and T300 carbon fibers.

- 3K Carbon Fiber offers a high rebound force with excellent durability, making it suitable for paddles that must absorb impact while providing a nimble response.

- 12K Carbon Fiber provides a smoother surface ideal for competitive play through its superior hardness and impact resistance.

- T300 Carbon Fiber is celebrated for its balanced performance, combining strength and lower weight for enhanced quickness during play.

-

Fiberglass – Known for delivering an excellent balance between power and control, fiberglass paddles come with a larger sweet spot and improved ball handling due to their flexibility.

-

Composite Materials – Combining different materials to capture their unique benefits, composite options include a blend of carbon fiber with fiberglass that provides a balanced mix of strength and weight reduction. Additionally, innovative core components like bamboo core composites and honeycomb cores minimize vibration and optimize impact absorption.

By integrating these materials, manufacturers ensure that each paddle is engineered with an eye toward both performance and longevity. This innovation is crucial when catering to the demands of high-speed gameplay, where even minor flaws in design or material can lead to performance lapses.

Advanced Production Processes: Crafting High-Performance Paddles

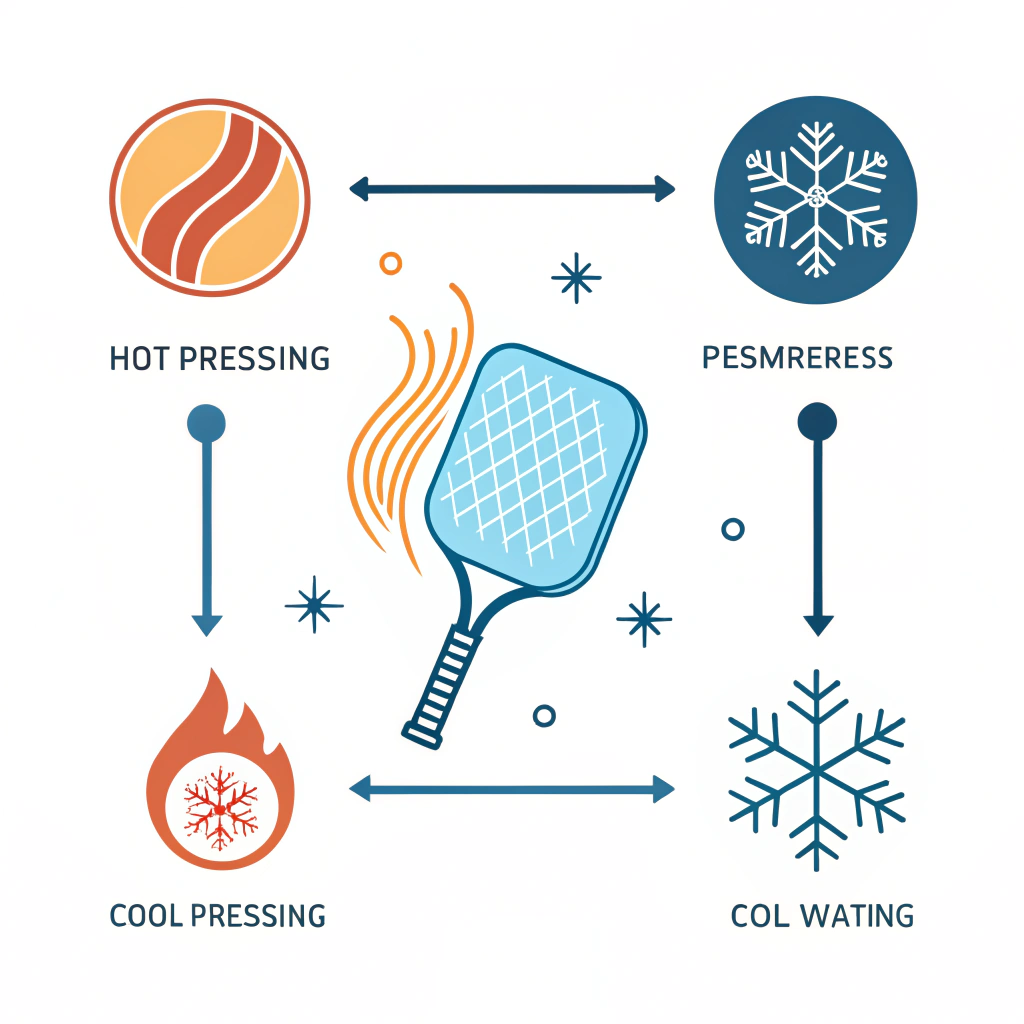

The production method is as significant as the materials used. At NEX Pickleball, three primary processes are employed to perfect paddle design: hot pressing3, cold pressing4, and thermoforming5. Each process offers its own set of advantages, tailored to meet the needs of rapid and competitive pickleball play.

Below is a comparative analysis of these production methods:

| Production Process | Advantages | Disadvantages |

|---|---|---|

| Hot Pressing | • High production efficiency • Produces paddles with excellent impact resistance • Ensures strong structural integrity | • Can alter some material properties affecting the paddle feel • High investment in equipment required |

| Cold Pressing | • Precise control over paddle thickness • Maintains inherent material properties for better control • Provides superior ball feel | • Longer production cycles • Requires sophisticated pressure control equipment |

| Thermoforming | • Allows for intricate paddle designs • Even material distribution enhances performance • Suitable for premium custom orders | • Extended production time • Higher costs associated with equipment and molds |

The selection of a production process often reflects the target market segment—whether prioritizing mass production with hot pressing or the need for high precision with cold pressing or thermoforming. These nuanced choices play a critical role in how production quality influences game performance, and they help slicers of the market align their procurement strategies with consumer expectations.

Market Trends and Competitive Edge in the Pickleball Sector

The increasing awareness and adoption of pickleball as a competitive sport have attracted significant attention from both manufacturers and investors. The pace of the game plays a crucial role in the following market dynamics:

-

Demand for High-Performance Equipment

Fast-paced gameplay drives players’ expectations for equipment performance. This in turn fuels demand for paddles engineered with innovative materials and manufacturing processes that can withstand the sport's intensity over time. -

Technological Innovation in Sports Equipment

Manufacturers are pushed to innovate constantly. The need to balance speed, control, and durability has led to breakthrough technologies in both material science and production methodologies. Companies like NEX Pickleball invest in research and development – ensuring that each paddle is not only responsive but also built to last. -

Shifting Consumer Preferences

With more players engaging in speedy, competitive play, consumer preferences are gravitating towards paddles that offer rapid recovery and precise control. This trend extends to both recreational players and those involved in professional competition, each demanding equipment that suits their specific needs.

The fast pace of the game reinforces the importance of quality and consistency in the manufacturing process. As the sport grows in popularity, a reliable supply chain and timely production become as critical as the paddle’s design itself. Business decision-makers must consider both the competitive edge that advanced paddle technologies deliver and the broader market potential of pickleball.

Our Perspective and Strategic Recommendations

Given these trends, procurement managers in the sports equipment market should consider the following strategies when evaluating the pickleball market:

• Invest in Products with Technological Advancements:

Look for manufacturers that emphasize innovative materials like advanced carbon fiber and composite designs. Such technologies are often linked to enhanced performance and durability, providing a tangible competitive advantage.

• Prioritize Customizable Options:

Custom paddle options allow adjustments in terms of design, weight, balance, and grip size. These features are not only beneficial for achieving peak game performance but also offer tailored solutions that cater to professional and recreational players alike.

• Align Procurement with Production Capabilities:

Understanding the nuances of manufacturing processes is crucial. Whether it’s the high efficiency of hot pressing or the precision of cold pressing and thermoforming, aligning procurement decisions with these capabilities ensures that product expectations are met consistently.

• Monitor Market Trends and Consumer Feedback:

Stay updated with trends in player preferences. Rapid feedback and agile response to market demands can help in fine-tuning the procurement strategy, ensuring that business decisions remain relevant and forward-thinking.

Our experience at NEX Pickleball, where we serve as OEM partners for renowned brands such as Joola and Selkirk, gives us a unique advantage in anticipating the needs of the international sports community. By integrating constant technological innovation and rigorous quality control, we are well-positioned to help businesses and sports facilities respond to the high demands of pickleball’s vibrant and rapidly evolving market.

Conclusion

Pickleball’s fast pace is a double-edged sword—it challenges traditional design and production methods while simultaneously offering a massive opportunity for market growth. By embracing advanced materials, refined production processes, and an in-depth understanding of game dynamics, manufacturers can offer paddles that not only meet the rigorous demands of the sport but also set a new benchmark in performance and durability.

For procurement executives and business development professionals, the insights presented here underscore the importance of aligning equipment investments with evolving market trends. The rapid game pace presents a unique value proposition: high-performance paddles not only improve the playing experience but also unlock new avenues for business growth in a competitive sports market.

By prioritizing quality, innovation, and responsive design, you can ensure that your products or facilities are well-equipped to meet the dynamic needs of pickleball enthusiasts. As the sport continues to surge globally, keeping pace with its evolution is essential for staying ahead in a competitive market.

People Also Ask

Q1: How does pickleball’s fast pace influence equipment design?

A1: The rapid gameplay of pickleball demands paddles with precise weight distribution and minimal vibration. Manufacturers use advanced materials and innovative production methods to ensure paddles are both durable and responsive, thus catering to quick reaction times and enhanced ball control.

Q2: What are the key materials used in high-performance pickleball paddles?

A2: High-performance paddles typically employ a range of materials, including various types of carbon fiber (such as 3K, 12K, and T300), fiberglass for greater flexibility, and composite materials that combine the benefits of both. These materials are selected to provide an optimal balance of strength, lightness, and durability.

Q3: Which production process best supports the durability and performance of pickleball paddles?

A3: Each production process has its merits. Hot pressing offers high efficiency and solid impact resistance; cold pressing allows for precise control and preservation of material properties; while thermoforming is ideal for intricate, premium designs. The choice depends on balancing production needs with desired performance outcomes.

-

carbon fiber provides detailed insights into its high strength-to-weight ratio, durability, and applications in high-performance sports equipment—vital for understanding material innovations. ↩

-

composite materials explain how combining different substances can create a material that leverages the strengths of each component, enhancing durability and performance. ↩

-

hot pressing covers the method’s rapid production and structural benefits, offering a deeper look at its impact on manufacturing efficiency and product durability. ↩

-

cold pressing outlines how this process preserves material properties for better control and ball feel, ideal for applications requiring precision. ↩

-

thermoforming details this versatile molding process, its ability to create complex designs, and its role in producing premium sports equipment. ↩