In brief, advanced pickleball paddle manufacturing hinges on the right blend of innovative production techniques, quality materials, and rigorous quality control—all of which are critical for OEM partners looking for durability, performance, and catering to custom designs.

In today’s competitive sports equipment industry, decision-makers evaluating production techniques need a comprehensive understanding of both materials and processes. This article outlines the technical aspects behind pickleball paddle OEM manufacturing1, with detailed insights into the benefits of advanced production processes and premium materials. With over a decade of experience in high-performance paddle production, our discussion aims to help procurement managers and product developers recognize the value of partnering with industry leaders like NEX Pickleball.

The challenge in manufacturing high-performance pickleball paddles lies in balancing multiple factors:

• Achieving optimal power, control, and durability in a single product.

• Selecting materials that offer the right characteristics for different levels of play.

• Adapting production techniques that guarantee both precision and repeatability while coping with high production volumes.

Manufacturing leaders must overcome issues such as maintaining consistent material properties, ensuring structural integrity, and meeting customer demand for customization. The need for speed, efficiency, and superior quality underpins every decision, from material sourcing to production process control.

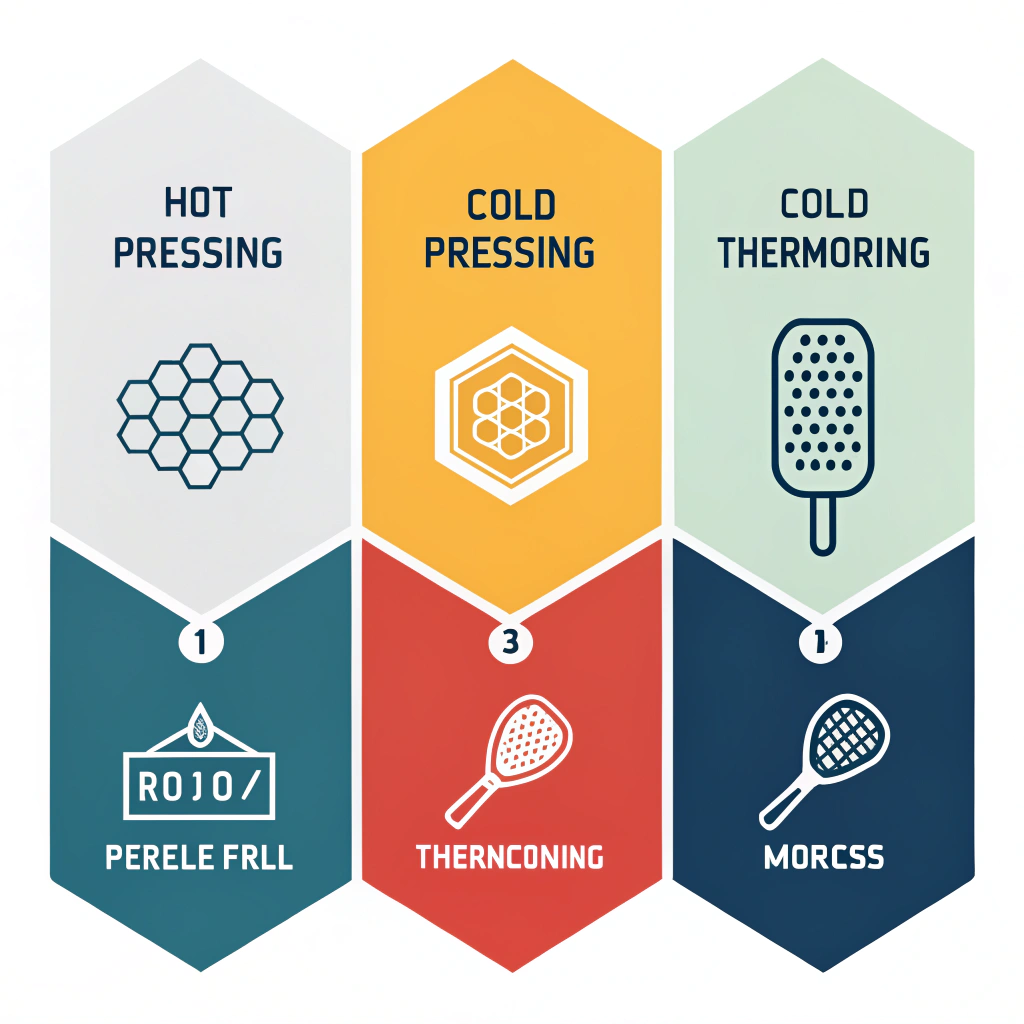

When evaluating production techniques, three main processes come to the forefront: hot pressing, cold pressing, and thermoforming2. Each of these processes has unique advantages and limitations that affect the final product quality.

Hot pressing is a widely used method for its production efficiency and the robust quality of the finished paddle.

• Advantages:

- High production efficiency suited for large-scale manufacturing.

- Results in paddles with excellent impact resistance and structural integrity.

- Ideal for high-performance proportions in competitive play.

• Disadvantages: - Alters some inherent material properties, which might affect the paddle’s “feel.”

- Involves high capital investment in equipment.

This process is all about delivering precision. The use of room temperature pressure enables greater control over the paddle’s thickness and structure.

• Advantages:

- Maintains the original material properties for better ball response.

- Delivers precise control over paddle design elements.

- Offers a superior ball feel which is appreciated by players at all levels.

• Disadvantages: - Lower throughput compared to hot pressing.

- Demands high-quality equipment for consistent pressure control.

Thermoforming2 allows manufacturers to achieve intricate designs, ensuring the precise distribution of materials.

• Advantages:

- Allows for the creation of paddles with complex geometries.

- Ensures uniform material distribution for improved product stability.

- Suitable for applications requiring high-performance features and a premium finish.

• Disadvantages: - Longer production time and higher equipment costs.

- Generally used for custom or premium product orders.

Below is a summary table comparing these production methods:

| Production Process | Advantages | Disadvantages |

|---|---|---|

| Hot Pressing | High efficiency; excellent impact resistance; strong structural integrity | Alters material properties; high capital investment |

| Cold Pressing | Precise control; retains natural material feel; excellent responsiveness | Slower production cycle; requires precise equipment |

| Thermoforming | Complex designs possible; uniform material distribution; premium finish | Longer production time; higher equipment costs |

Material selection is just as important as the production process. The performance and durability of a pickleball paddle often depend on the type of materials used. Here we delve into the components used in high-quality paddle manufacturing:

Carbon fiber is favored for its strength and lightweight properties. NEX Pickleball utilizes various types:

- 3K Carbon Fiber: Offers a flexible yet robust structure, delivering high rebound force while reducing vibration.

- 12K Carbon Fiber: With a denser thread structure, it provides a smoother hitting surface, increased hardness, and remarkable impact resistance.

- T300 Carbon Fiber: Balances tensile strength with reduced weight, making it perfect for competitive play where performance consistency is crucial.

These different grades ensure that manufacturers can tailor the paddle performance to the specific needs of different player profiles. Each type of carbon fiber supports enhanced power, precision, and durability.

Fiberglass paddles provide an excellent balance between power and control. They deliver:

- A wider sweet spot for improved ball contact.

- Enhanced durability with a degree of elasticity that supports better ball control.

- E-Glass Fiberglass is primarily used for its elasticity and tensile strength, making it ideal for players that require a softer yet controlled paddle feel.

The innovative use of composite materials has allowed manufacturers to combine the strengths of individual components. For instance:

- Carbon Fiber and Fiberglass Composite: Offers a hybrid solution, merging the control of fiberglass with the strength of carbon fiber.

- Bamboo Core Composite: Features a light-weight structure paired with high impact resistance, ideal for a clear and responsive hitting feel.

- Honeycomb Core: Provides superior shock absorption while ensuring minimal vibration, enhancing overall paddle stability.

These materials are not only chosen for their individual benefits but also for how they complement the structural performance of the paddle.

The core of the paddle plays a significant role in determining its performance and user experience. Understanding the type of core materials used can help illustrate why some paddles last longer and perform better.

Nomex Honeycomb Core5

Manufactured from durable polymers, this core type stands out for:

- Superior shock absorption.

- Long-lasting durability.

- Excellent stability for competitive play.

Offers a balanced weight with a combination of power and precision:

- Provides strong control while maintaining a light paddle weight.

- Highly respected for delivering a mix of strength and finesse.

Favored by recreational players, this core is known for:

- Enhanced elasticity.

- Reduced vibration for a more comfortable playing experience.

Below is a simplified comparison of core materials:

| Core Material | Benefits | Ideal For |

|---|---|---|

| Nomex Honeycomb Core | Excellent shock absorption; high durability | Competitive play; high-impact situations |

| Aluminum Honeycomb Core | Balanced weight; good for power and control | Players needing a mix of precision and strength |

| Polymer Honeycomb Core | Superior elasticity; reduced vibration | Recreational and beginner players |

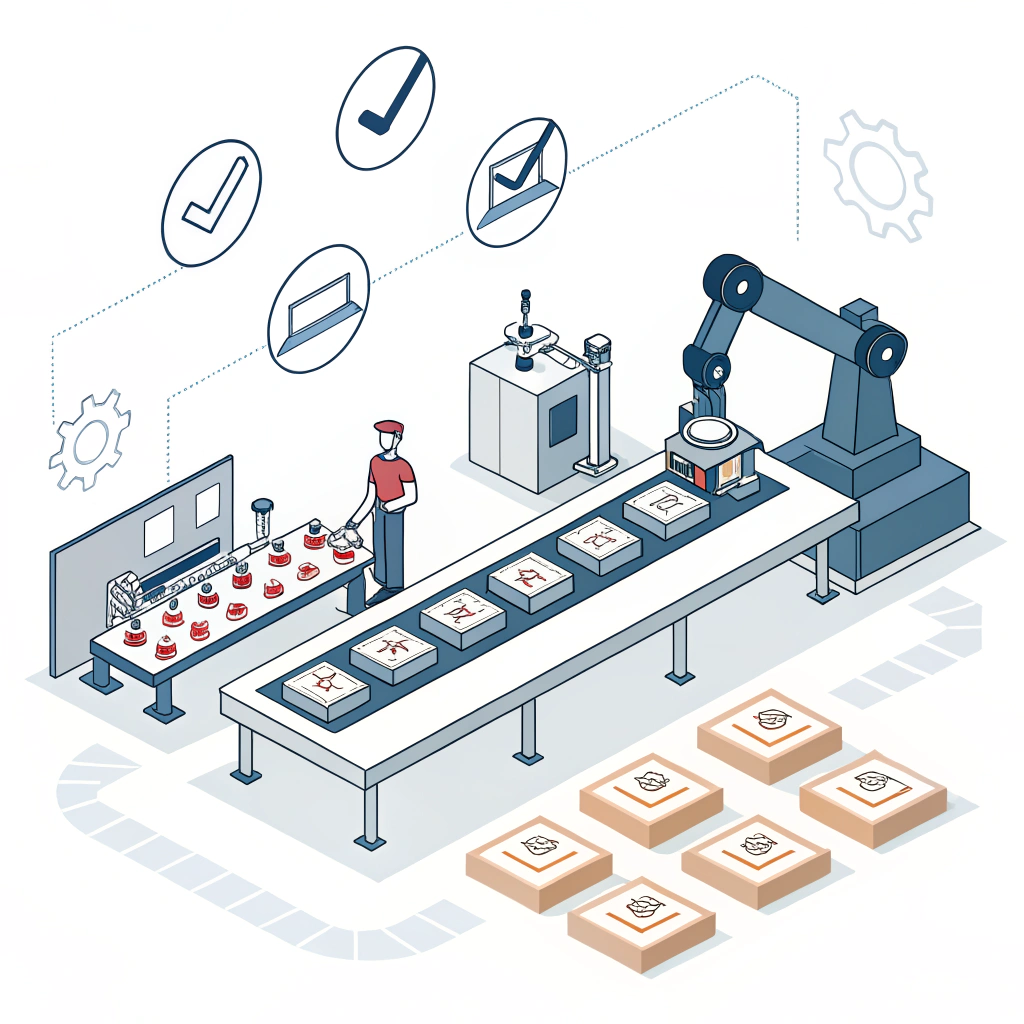

In B2B relationships, ensuring quality is of paramount importance. At NEX Pickleball, every paddle undergoes rigorous testing to ensure that it meets the strict standards required for performance and durability. Our commitment to quality includes:

• Precision measurement of weight distribution for optimal balance.

• Thorough testing protocols that simulate real-game impacts.

• Customization options where clients can specify design, grip size, and paddle composition.

By offering custom paddle solutions, manufacturers can create unique products that resonate with end users while aligning with brand requirements. This is particularly important for retail distribution where branding and personalization add significant market value.

Using advanced technology and quality control checklists, the manufacturing process becomes more predictable and reliable. For instance, automated inspection systems can significantly reduce the incidence of defective products while ensuring that each paddle meets predefined performance criteria. These systems provide real-time feedback, allowing production lines to adjust parameters swiftly, ensuring product consistency.

For decision-makers considering manufacturing partnerships, several key factors should be evaluated:

- Production technique compatibility with desired paddle characteristics.

- Material quality and suitability for targeted performance outcomes.

- The flexibility of the manufacturing process to deliver custom designs.

- Efficiency of quality control systems within the OEM manufacturing partner.

By weighing these factors and having a transparent understanding of each aspect, procurement managers and product developers can make informed decisions. The following actionable recommendations can serve as a checklist when reviewing potential manufacturing partners:

• Request detailed documentation on production processes including hot pressing, cold pressing, and thermoforming.

• Inquire about the specific types of materials used, and request samples or performance data if available.

• Analyze quality control systems and testing protocols to ensure long-term product reliability.

• Verify customization capabilities that can cater to specific market demands or branding strategies.

• Calculate the cost-benefit ratio of capital investment versus production quality and output speed.

These recommendations not only pave the way for choosing the right manufacturing partner but also support a long-term strategy for achieving consistent product excellence.

In summary, the world of pickleball paddle manufacturing demands a well-rounded approach that integrates advanced production techniques with premium materials and rigorous quality control. Every element, from the selection of carbon fiber or fiberglass to the decision of employing hot pressing, cold pressing, or thermoforming, plays a crucial role in defining the final product’s quality and performance.

For B2B partners seeking to elevate their product offerings, a thorough comparison of these production processes and materials can help in establishing clear criteria for selection. Our industry insights and technical breakdown provide the necessary framework to make strategic procurement decisions.

As you move forward with your manufacturing partner evaluation, consider the detailed technical insights and data-driven comparisons provided here. By exploiting innovation and technology in your production processes, you can ensure that your pickleball paddles are not only competitive in terms of performance but also excel in durability and customizability.

NEX Pickleball remains committed to delivering high-performance OEM solutions that meet the evolving demands of the sports equipment industry. We invite you to connect with us to explore how our expertise and state-of-the-art manufacturing capabilities can empower your business to achieve new heights in product excellence.

People Also Ask

-

What are the main production processes used in pickleball paddle manufacturing?

The primary production methods include hot pressing for high efficiency and structural strength, cold pressing for precise control and material retention, and thermoforming for complex designs and premium material distribution. -

How do different materials like carbon fiber and fiberglass affect paddle performance?

Different materials provide unique advantages—carbon fiber (including variants like 3K, 12K, and T300) ensures high strength, reduced vibration, and light weight, while fiberglass offers a larger sweet spot and excellent elasticity for superior ball control. -

What benefits do custom paddle manufacturing solutions offer in a B2B context?

Custom manufacturing allows for tailored paddle designs that meet specific performance and branding requirements, ensuring product excellence through precise material selection, controlled production processes, and rigorous quality checks.

-

OEM manufacturing: Read to gain insight into the strategic partnerships and production methodologies that define Original Equipment Manufacturer processes, enhancing supply chain efficiency and product consistency. ^Return ↩

-

Thermoforming: Explore how thermoforming techniques are used to mold materials into complex and precise shapes, leading to innovative product designs and improved performance. ^Return ↩ ↩2

-

Carbon Fiber: Understand the benefits of carbon fiber in manufacturing, including its light weight, high strength, and impact on product durability and efficiency in high-performance applications. ^Return ↩

-

Composite Materials: Delve into the world of composite materials to discover how combining different substances can optimize product performance, improve strength, and reduce manufacturing limitations. ^Return ↩

-

Honeycomb Core: Learn about honeycomb core structures and their role in providing superior shock absorption, improved stability, and enhanced weight distribution critical for high-performance products. ^Return ↩