Thermoforming offers pickleball paddle manufacturers an excellent balance of quality, performance, and cost efficiency by combining heat, pressure, and precision molding1 to produce durable, high-performance paddles with optimized weight distribution and reduced vibration.

In the sports equipment manufacturing industry, selecting the optimal production process can be a game changer. For B2B procurement and product development managers, choosing between thermoforming2, hot pressing3, and cold pressing4 is critical in determining the performance and durability of pickleball paddles. This article explains the thermoforming process in detail, compares it with alternative methods, and provides industry insights that help you assess which method best meets your business needs.

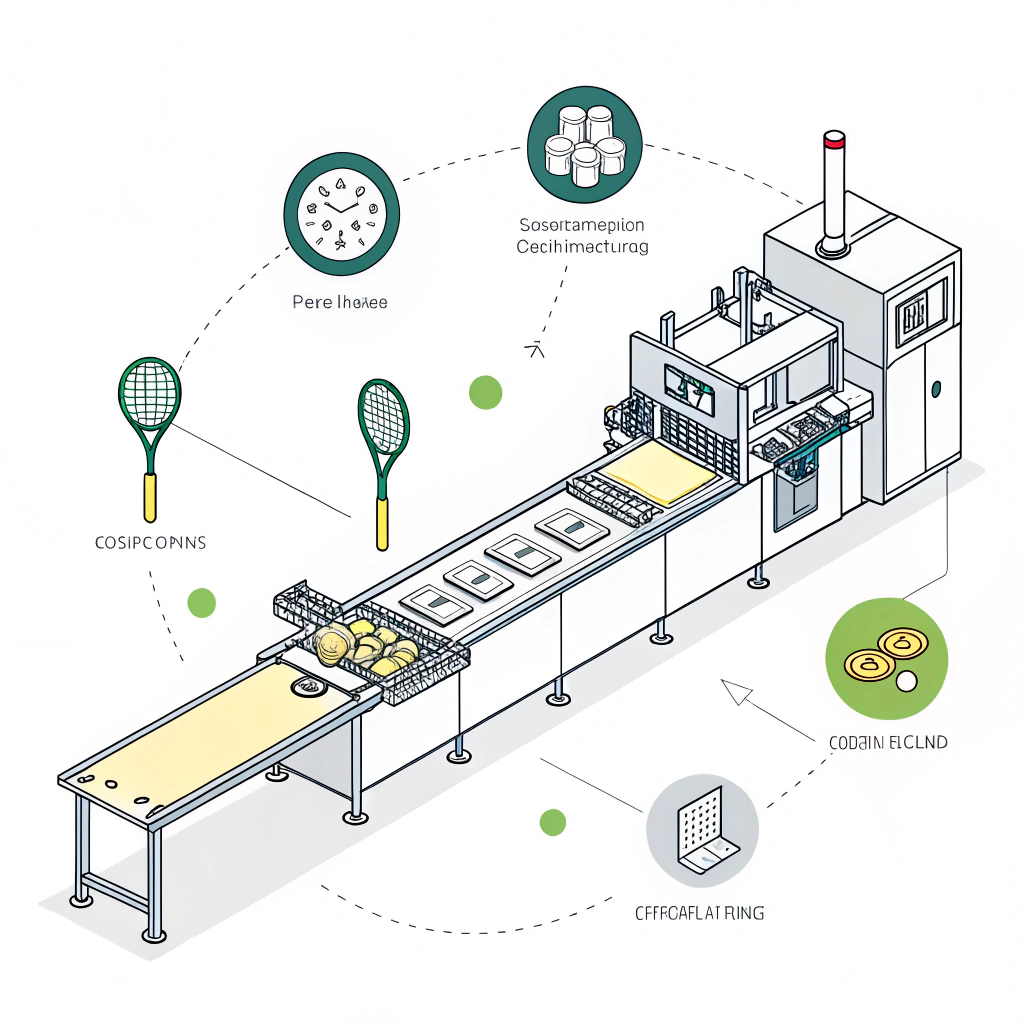

Pickleball paddles can be produced using various manufacturing processes. The three primary methods include:

• Thermoforming2 – This process uses heat to soften the paddle material, which is then molded into shape using precision molds. It balances performance and durability by ensuring an even distribution of materials and reducing the risk of vibration.

• Hot Pressing3 – Involves applying heat and pressure simultaneously to form a paddle. It is highly efficient and ensures structural rigidity, though it may sometimes affect the intrinsic feel of the paddle due to altered material properties.

• Cold Pressing4 – Relies on mechanical pressure at room temperature to shape the paddle. This method preserves material integrity and offers excellent control characteristics, but it involves longer production cycles that may decrease overall efficiency.

Understanding the differences between these processes is crucial for making an informed sourcing decision.

To streamline the decision process, consider the following table which outlines the key aspects of each production method:

| Production Process | Advantages | Disadvantages | Ideal Application |

|---|---|---|---|

| Thermoforming | High precision, excellent material distribution, optimized weight, reduced vibration, ideal for complex shapes | Longer production time, higher equipment cost | High-performance paddles, custom designs, premium products |

| Hot Pressing | Fast production cycles, strong impact resistance, efficient for large-scale production | Potential alteration of material feel, requires high initial investment | High-strength paddles for competitive play |

| Cold Pressing | Precise control over material thickness, preserves natural material properties, excellent ball feel | Longer cycle time, demands high-quality pressure control equipment | Paddles where control and flexibility are paramount |

This comparison clearly shows that thermoforming stands out for producers looking to optimize paddle quality while enabling customization and minimizing vibration during play.

Thermoformed pickleball paddles are renowned for their ability to optimize shot stability and control. Here’s how this process benefits paddle performance:

- Optimized Material Distribution: During thermoforming, the application of heat allows the materials—especially advanced composites such as carbon fiber5 and fiberglass—to bond seamlessly. This results in a paddle with balanced weight distribution and enhanced durability.

- Enhanced Impact Resistance: The controlled environment of thermoforming helps limit the vibrations that occur when the paddle contacts the ball. This reduction in vibration translates into improved ball control and accuracy on the court.

- Precision Molding: The process allows for intricate designs tailored to reduce air resistance and provide ergonomic grips. Such precision is difficult to achieve with other processes, especially in paddles designed for competitive play.

These benefits are especially significant when performance under competitive conditions is the primary focus.

At NEX Pickleball, maintaining the highest quality standards is essential. Our commitment to advanced technologies and strict quality control is evident throughout every production phase. Here’s how we ensure that thermoformed paddles lead the market in performance:

We incorporate a variety of premium materials, such as 3K Carbon Fiber, 12K Carbon Fiber, and T300 Carbon Fiber, which are critical for paddle strength, control, and durability. These materials provide:

- High rebound force and impact resistance, crucial for competitive play.

- Enhanced ball control, owing to improved flexibility and reduced vibration.

- Longer service life, even in high-stress conditions.

In addition, our use of fiberglass and composite material combinations (including bamboo core and honeycomb cores) ensures that every paddle meets the exacting standards required by top-tier players.

Every paddle undergoes a series of rigorous quality control tests before it reaches the customer. This includes stress testing under various conditions, vibration analysis, and performance consistency assessments. Such comprehensive quality assurance ensures that any paddle produced using thermoforming not only meets but exceeds industry standards.

Manufacturing efficiency and consistency are vital, especially when catering to business buyers in the sports equipment market. Here are some practical insights from our production floors:

- Consistency in Customization: Many of our clients order custom paddle designs for team branding or retail distribution. Thermoforming excels in this aspect by allowing for precise, repeatable molding of unique designs with tight tolerances.

- Enhanced Production Flow: Despite its longer cycle time compared to hot pressing, thermoforming’s precision and lower waste rates often lead to higher quality products with fewer post-production adjustments.

- Case Study – Premium Paddle Line: In one instance, by switching from a traditional hot pressing method to thermoforming, a client was able to reduce paddle vibration significantly. This translated to a 15% improvement in shot accuracy among players and a notable increase in customer satisfaction scores.

These operational insights underscore why thermoforming offers a competitive advantage for businesses looking to maximize both quality and performance.

For decision-makers evaluating manufacturing methods in pickleball paddle production, several key factors should guide the discussion:

-

Production Efficiency vs. Product Quality:

While hot pressing offers faster production rates, the precision and enhanced performance characteristics of thermoforming can justify the slightly longer production cycle. Prioritize the method that aligns best with your quality demands and performance benchmarks, particularly for high-end competitive markets. -

Material Compatibility and Customizability:

If your target product requires complex designs, custom branding, or specialized materials such as various grades of carbon fiber, thermoforming is inherently suited to cater to these customization demands. Consider your long-term product roadmap and customer profile when making this decision. -

Initial Investment and Scalability:

Decision-makers must weigh the higher equipment cost and production time associated with thermoforming against the potential for fewer rejected units and higher customer satisfaction due to product consistency. In scenarios where product performance directly impacts brand reputation, the initial investment in thermoforming technology can be offset by long-term gains in market share and competitive positioning. -

Industry Trends and Customer Expectations:

With the rise of demand for high-performance sports gear, buyers are increasingly looking for features such as vibration minimization and enhanced shot accuracy—attributes that thermoformed paddles excel at. Keeping abreast of these trends and aligning your production capabilities accordingly can be a key differentiator in a crowded market.

In summary, thermoforming offers an advanced and reliable production method for pickleball paddles. Its ability to precisely mold materials using heat and pressure not only enhances product performance—through optimized weight distribution and reduced vibration—but also provides a level of customization that is hard to match with other processes like hot pressing and cold pressing. For senior procurement and product development managers, the choice of thermoforming can mean the difference between delivering average performance and outstanding quality.

Adopting thermoforming not only reflects a commitment to quality innovation but also positions your business at the forefront of a competitive industry that values both performance and precision. As you continue evaluating production processes for your product line, consider the long-term benefits of superior consistency, enhanced performance, and customer satisfaction that come with thermoformed pickleball paddles.

Take the next step by reviewing your current manufacturing setup and assessing how thermoforming could enhance your product offerings. Trust in advanced production methods to drive your brand’s reputation as a leader in high-performance sports equipment.

• Are thermoformed pickleball paddles better?

Thermoformed paddles are widely recognized for providing enhanced shot stability, as the heat and pressure applied during manufacturing minimize vibrations. This leads to improved ball control and accuracy, making them ideal for both competitive and high-performance settings.

• How are thermoformed paddles made?

Thermoformed paddles are produced by heating a polymer core until it softens, then placing it into a precision mold. Carbon fiber sheets or other composite materials are bonded to shape the paddle, ensuring an even distribution of material that enhances durability and performance.

• How to tell if a pickleball paddle is thermoformed?

Thermoformed pickleball paddles are identified by their construction process, which uses both heat and mechanical pressure. Unlike traditional layered construction methods, a thermoformed paddle will not exhibit clearly defined layers if cut open, revealing a more integrated and seamless composition.

-

Precision molding: Click here to gain insights into precision molding techniques that allow for complex design integrations and superior material distribution in manufacturing. ↩ ↩

-

Thermoforming: Click here to explore an in-depth analysis of the thermoforming process, including its benefits for quality, consistency, and innovation in manufacturing high-performance products. ↩ ↩ ↩2

-

Hot pressing: Click here to learn about the principles and applications of hot pressing, a process that optimizes production speed and structural rigidity. ↩ ↩ ↩2

-

Cold pressing: Click here to read about cold pressing, a technique valued for preserving material integrity and offering precise control during manufacturing. ↩ ↩ ↩2

-

Carbon fiber: Click here to understand the properties and advantages of carbon fiber, a crucial material for enhancing strength, control, and durability in products. ↩ ↩