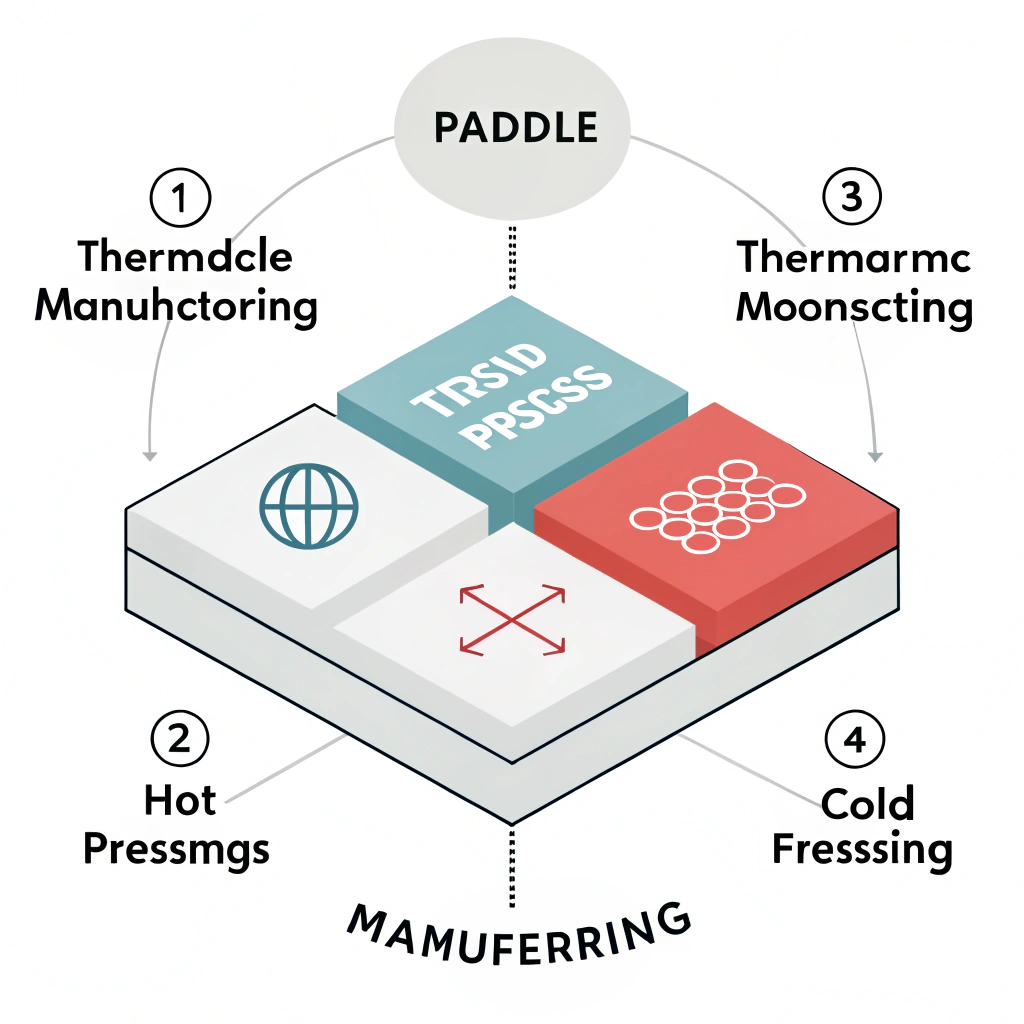

Thermoforming, a process that leverages heat and pressure to shape high-performance materials, plays a crucial role in modern pickleball paddle production. In this article, we explore how thermoforming contributes to the design of intricate, durable, and high-performing paddles, comparing it with traditional methods like hot pressing1 and cold pressing2 to help you make an informed manufacturing decision.

Understanding Thermoforming3 in Pickleball Paddle Production

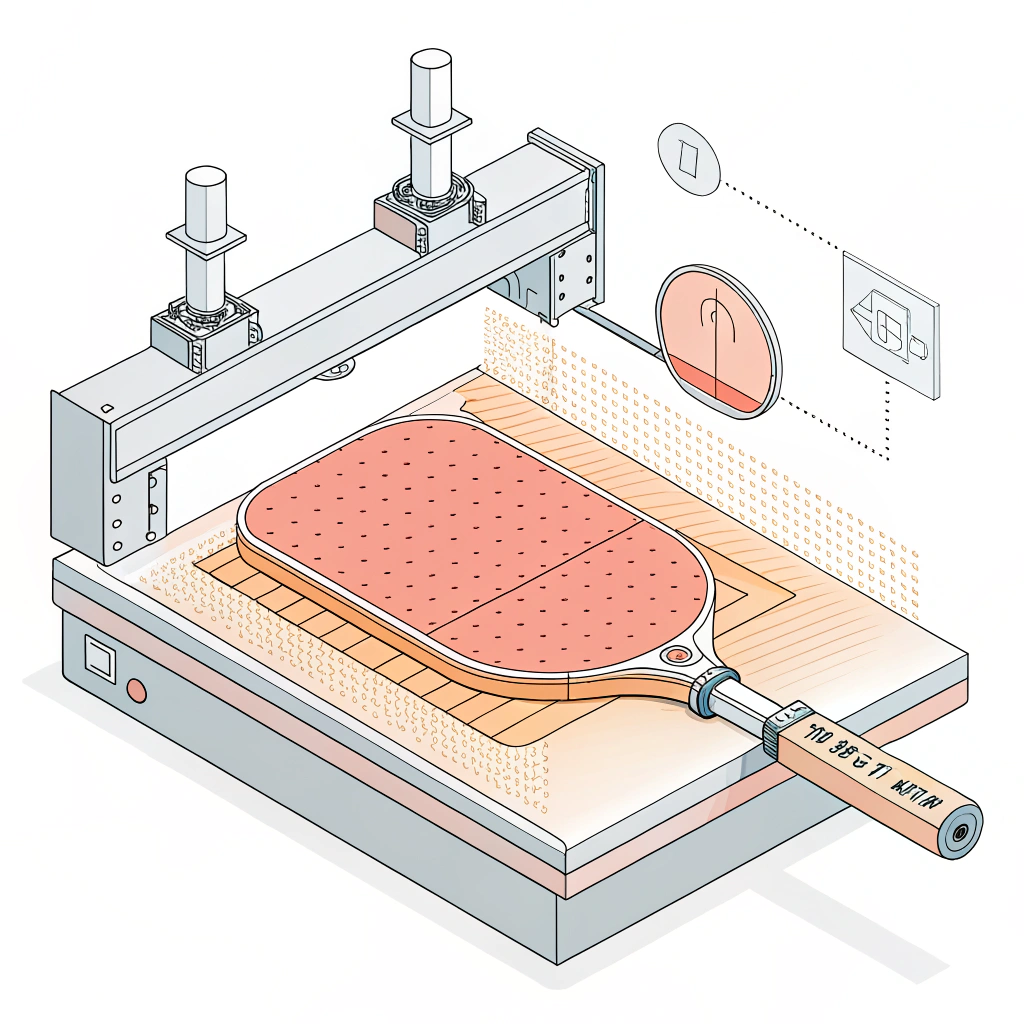

Thermoforming involves heating a plastic or composite sheet until it becomes pliable, then molding it into a precise, pre-designed shape before cooling. This method is particularly valuable for high-performance pickleball paddles where complex shapes and exactly distributed materials are needed. The process ensures that every paddle has uniform material distribution and excellent surface detail—key factors in achieving optimal control, power, and durability in the final product.

Compared to other techniques, thermoforming provides a unique advantage in allowing customized paddle designs. With advanced molding technology, manufacturers can integrate detailed ergonomic grips and sophisticated face textures that cater to both professional and recreational players. This level of control over the shape and structure is what sets thermoformed paddles apart.

To better understand thermoforming, it is essential to compare it with other prevalent production processes—hot pressing and cold pressing.

Hot pressing uses heat combined with mechanical pressure to compress materials into a solid form. This process is known for its speed and efficiency in mass-production environments:

-

Advantages:

- Rapid production cycles.

- Produces strong, high-impact resistant paddles.

-

Disadvantages:

- Potential alteration to the material's inherent properties.

- Requires significant capital investment in specialized equipment.

Cold pressing shapes materials at room temperature under controlled pressure. This method preserves the original properties of the materials, making it preferable for certain paddle designs:

-

Advantages:

- Enhanced precision in controlling paddle thickness and structural integrity.

- Retains material properties, leading to superior ball feel and responsiveness.

-

Disadvantages:

- Longer cycle times compared to hot pressing, reducing overall efficiency.

- Demands precise mechanical control to achieve consistency.

In comparison, thermoforming is distinct in that it harnesses heat to create a malleable state in the material before molding:

-

Advantages:

- Ability to form intricate designs and distribute advanced materials evenly.

- Excellent for customizing ergonomic features and aesthetic finishes.

- Provides enhanced control over complex paddle geometries.

-

Disadvantages:

- It is a time-intensive process compared to hot pressing.

- Requires the right balance of heat and pressure, demanding well-calibrated machinery.

Below is a comparative table that succinctly outlines the differences:

| Process | Key Advantages | Key Disadvantages | Suitable For |

|---|---|---|---|

| Hot Pressing | High production efficiency; strong, durable results | Potential alteration of material properties; high capital cost | Mass production with high impact requirements |

| Cold Pressing | Precise thickness control; preserves natural material feel | Longer production cycle; requires precision in pressure control | Designs needing delicate handling and superior ball feel |

| Thermoforming | Intricate design capabilities; excellent material distribution | Longer cycle time; high equipment calibration needs | Custom, premium, and high-performance paddles |

Thermoforming enables the creation of paddles that boast detailed geometric designs. These designs are not only aesthetic but also serve functional purposes—improving grip ergonomics and enhancing the ball control. For example, design features such as texturized surfaces and specially shaped cores can be incorporated directly into the paddle during the thermoforming process. This means that each paddle can be tailored to specific playing styles, whether for fast-paced competitive play or recreational use.

One of the most significant benefits of thermoforming is its ability to achieve homogenous material distribution. This is particularly important for paddles made from composites like Carbon Fiber4 and Fiberglass, as well as various core materials like Nomex Honeycomb5, Aluminum Honeycomb, and Polymer Honeycomb. With thermoforming, manufacturers can ensure that both the face and the core materials are evenly distributed, which leads to a consistent performance profile across the entire paddle.

Through the controlled application of heat and pressure during thermoforming, the bonds between different layers—such as composite face materials and core structures—can be strengthened. This improved lamination reduces the risk of delamination or core crushing, common issues in paddle production. By maintaining a robust structural integrity, thermoformed paddles exhibit a longer lifespan and more reliable performance, even under high stress during play.

With the increasing demand for customization in sports equipment, thermoforming allows for on-demand production services. Clients can specify design parameters such as paddle weight, balance, grip size, and even custom branding elements. For instance, NEX Pickleball employs advanced thermoforming techniques to deliver paddles that meet individualized specifications while maintaining high industry quality standards.

NEX Pickleball, a leader in high-performance pickleball paddle manufacturing, leverages advanced thermoforming, among other processes, to produce premium paddles. The company uses a blend of 3K, 12K, and T300 Carbon Fiber along with composite materials to tailor paddles for both competitive and recreational play. Each step of the production process, including thermoforming, is meticulously controlled to ensure that the final product exhibits:

- Optimal weight distribution

- Ergonomic grip design

- Enhanced impact resistance

By focusing on precise process control, NEX Pickleball minimizes common issues such as core crushing and delamination. Rigorous testing protocols ensure every paddle meets the highest standards of durability and performance. Clients benefit from customized paddle options, whether they need paddles for a sports team, a retail chain, or specialized promotional events.

For manufacturers contemplating thermoforming as their preferred process for pickleball paddle production, several key factors must be taken into account:

Precise control over temperature and pressure is essential during the thermoforming process. Fluctuations can lead to material inconsistencies, which might compromise paddle performance. It is advisable to invest in reliable machinery that offers fine-tuned control to achieve consistent, reproducible results.

The choice of materials significantly impacts the outcome of thermoformed paddles. Premium composites such as high-performance carbon fiber and advanced core materials require proper handling to optimize their properties. Manufacturers must ensure that the selected materials are compatible with the thermoforming process to prevent any degradation during production.

While thermoforming offers unparalleled customization and intricate design capabilities, it tends to have longer production cycles compared to hot pressing. Businesses should weigh this trade-off based on their volume demands and the importance of customization for their target market. For high-end, customized paddles, the benefits of thermoforming often outweigh the slower throughput.

Given the technical nature of thermoforming, implementing a rigorous quality control process is imperative. Regular testing and calibration of equipment help in ensuring that each paddle achieves the desired performance standards. This quality assurance is critical to maintain the reputation of the manufacturer and meeting the expectations of professional and serious recreational players.

Although thermoforming equipment and process control systems may require a higher initial investment, the long-term benefits in terms of product performance, reduced defect rates, and enhanced customer satisfaction can justify these costs. Manufacturers should conduct thorough cost-benefit analyses to align their production strategies with market demands and financial goals.

Thermoforming stands out as a versatile and powerful production method for creating high-performance pickleball paddles. Its capability to form intricate designs, provide uniform material distribution, and ensure enhanced structural integrity makes it an ideal choice for manufacturers targeting the premium sports equipment market. While it requires precise control over production variables and may have a longer cycle time compared to processes like hot pressing, the benefits in terms of product quality and customization are significant.

For B2B professionals, especially manufacturing engineers and procurement managers in the sports equipment sector, adopting thermoforming can lead to competitive advantages by:

- Enhancing product performance and durability.

- Offering customizable designs that meet specific player needs.

- Reducing long-term production defects related to delamination and core crushing.

A balanced approach could involve integrating thermoforming with other methods like hot and cold pressing, depending on the specific product requirements and production volumes. Manufacturers can leverage hybrid production strategies to optimize both efficiency and quality, ensuring that the final product meets the high expectations of modern pickleball enthusiasts.

If you are in the decision phase of evaluating production processes for pickleball paddles, carefully consider the trade-offs between production speed, customization, and material performance. Advanced thermoforming techniques, as exemplified by NEX Pickleball’s manufacturing approach, can offer a superior product that not only meets but exceeds the demands of competitive play.

Q: What is the thermoforming process of pickleball?

A: Thermoforming in pickleball involves heating a plastic or composite sheet until it becomes pliable, then molding it into the desired shape before cooling it down. This process results in a lightweight yet sturdy paddle that offers excellent control and power.

Q: What does it mean for a pickleball paddle to be thermoformed?

A: A thermoformed pickleball paddle is constructed using a combination of heat and pressure. The process molds the paddle’s shape and, when combined with techniques like foam injection for the core, results in a paddle without clearly defined layers—unlike the traditional sandwich method.

Q: What causes core crushing in pickleball paddles?

A: Core crushing occurs when the paddle's core loses its rigidity and compresses excessively, often due to issues like improper bonding or overuse. This, along with delamination—where the layers begin to separate—can negatively affect the paddle's feel and consistency, signaling it may be time for a replacement.

-

Hot Pressing: Click to explore hot pressing techniques that combine heat and mechanical pressure for rapid mass production while balancing material integrity and production speed. ↩ ↩

-

Cold Pressing: Click to understand cold pressing methods that shape materials at room temperature, ensuring high precision and preservation of material properties in specialized applications. ↩ ↩

-

Thermoforming: Click to learn how thermoforming uses heat and pressure to convert materials into complex, pre-designed shapes, enhancing customization and performance in manufacturing processes. ↩ ↩

-

Carbon Fiber: Click to delve into the properties and applications of Carbon Fiber, a high-strength composite essential for manufacturing lightweight yet durable high-performance products. ↩ ↩

-

Nomex Honeycomb: Click to examine Nomex Honeycomb structures, their characteristics, and why they are favored for enhancing the strength and performance of composite materials in industrial applications. ↩ ↩