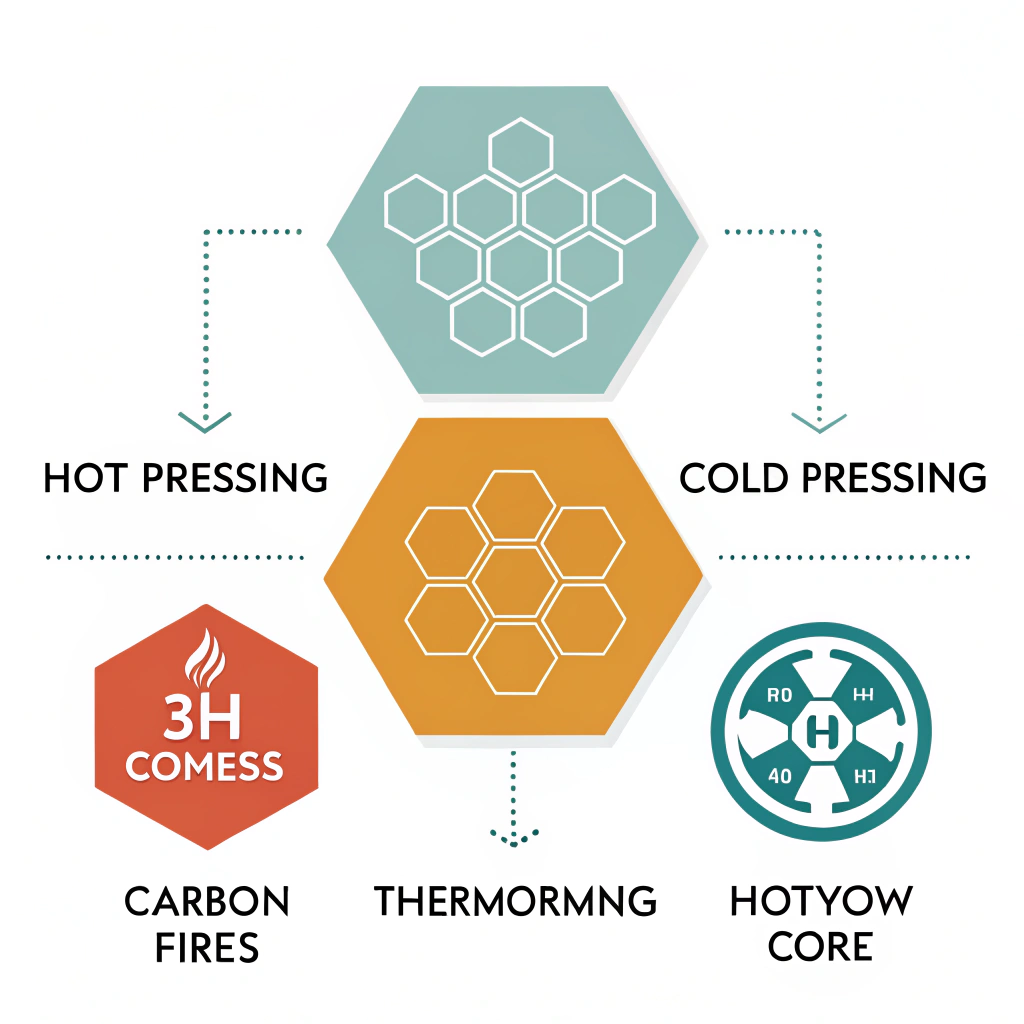

In choosing optimal materials and production techniques for manufacturing pickleball paddles, it is crucial to evaluate how each method and material impacts performance, durability, and cost efficiency. In this article, we compare advanced construction methods—hot pressing1, cold pressing2 and thermoforming3—along with various elite materials such as carbon fiber4 (3K, 12K, and T300), fiberglass, and specialized core composites. Our goal is to support B2B procurement managers and manufacturing leads in making informed decisions that suit both production needs and competitive market demands.

For experienced technical professionals in the sports equipment manufacturing industry, the primary challenge lies in balancing performance characteristics with manufacturing efficiency. On one hand, materials and processes determine the paddle’s power, control, vibration dampening, and overall durability. On the other, the choice of production method directly impacts cost structures and production cycles.

Key considerations include:

- Production efficiency versus customization potential

- Trade-offs between material strength and natural feel

- Cost implications of high-performance materials and manufacturing technologies

These factors are pivotal when deciding between different production techniques and material compositions. The correct combination not only meets modern performance metrics but also delivers reliability for high-demand competitive and commercial applications.

Below is a comparative table summarizing the three primary manufacturing processes used for high-performance pickleball paddles:

| Production Process | Advantages | Disadvantages | Typical Applications |

|---|---|---|---|

| Hot Pressing | - High production efficiency - Excellent impact resistance - Strong structural integrity |

- Alters some material properties - Requires significant capital investment in specialized equipment |

Suitable for large-scale production where strength is paramount |

| Cold Pressing | - Precise thickness and structure control - Maintains original material properties - Superior ball feel and responsiveness |

- Longer production cycles - High reliance on precision equipment |

Ideal for premium product lines emphasizing control and finesse |

| Thermoforming | - Intricate designs possible - Uniform material distribution - Enhanced paddle stability and performance |

- Longer production times - Higher equipment costs |

Best for custom-made paddles and boards requiring advanced design features |

This table illustrates that each technique offers unique benefits depending on the desired balance between performance, production speed, and customization capabilities. For instance, while hot pressing ensures a robust product ideal for high-impact play, cold pressing offers finer control—both critical for meeting different market demands.

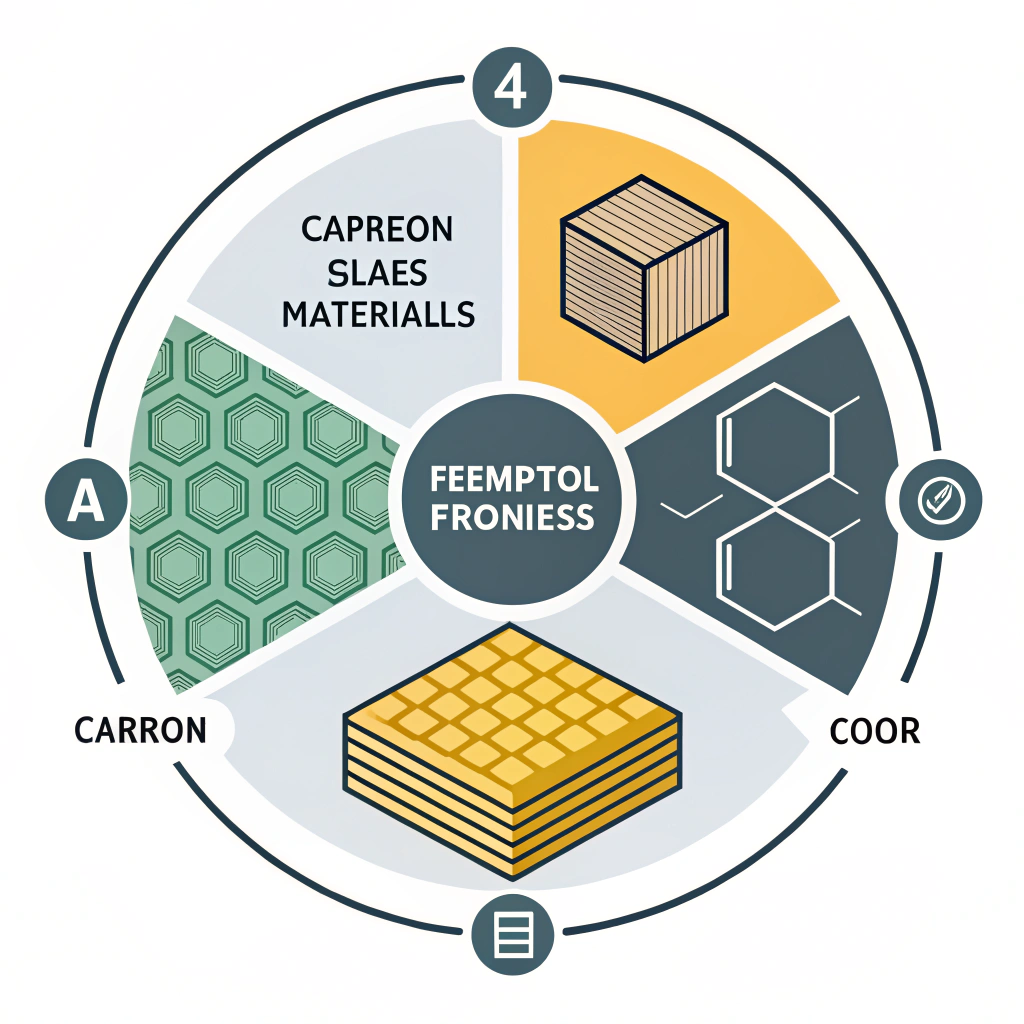

Carbon fiber4 remains a top choice for many high-performance paddles. Its variations, such as 3K, 12K, and T300, cater to different performance and durability requirements:

- 3K Carbon Fiber: Known for its flexibility and strength, it offers a high rebound force and excellent vibration reduction. Its balance of durability and performance makes it a pragmatic option for competitive play.

- 12K Carbon Fiber: With a higher thread count, this variant results in a smoother surface finish and added hardness. It is critical for producing paddles with greater impact resistance, making it highly suitable for high-level athletes.

- T300 Carbon Fiber: This high-performance material is celebrated for its outstanding tensile strength and low weight. Its balanced performance attributes enhance both power and control, making it effective in competitive environments.

While many manufacturers opt for carbon fiber, fiberglass is another popular material. The main benefits include:

- Enhanced ball control, thanks to its greater flexibility.

- A wider sweet spot, which improves playability.

Moreover, composite materials mix the strengths of various components. For example:

- Carbon Fiber and Fiberglass Composite: This combination offers both the strength of carbon fiber and the control advantages of fiberglass.

- Bamboo Core Composite: Known for its lightweight properties and impact resistance, it guarantees a crisp hitting feel.

- Honeycomb Core Variants: Utilizing high-density polymers, these cores improve shock absorption, reducing paddle vibration while intensifying durability.

The core of the paddle is integral to its overall performance. Different core materials affect the paddle’s hardness, vibration damping, and impact resistance:

- Nomex Honeycomb Core5: Renowned for its exceptional shock absorption and stability, it is ideal for players seeking long-lasting durability.

- Aluminum Honeycomb Core: With a balanced weight distribution, this material provides a mix of power and precision, making it versatile for various play styles.

- Polymer Honeycomb Core: This core type emphasizes elasticity and comfort, often preferred by recreational players and beginners due to its reduced vibration and smoother feel.

To further assist in decision-making, the following table contrasts material behaviors when paired with different production techniques:

| Material Category | Hot Pressing | Cold Pressing | Thermoforming |

|---|---|---|---|

| Carbon Fiber (3K, 12K, T300) | - Provides solid performance - High structural rigidity |

- Maintains surface finish integrity - Balances strength with finesse |

- Allows for custom design integration - Uniform material spread |

| Fiberglass | - Durable and robust - Suitable for large-scale runs |

- Superior ball feel - Enhanced control and flexibility |

- Achieves intricate shapes for performance tuning |

| Core Materials (Nomex, Aluminum, Polymer) | - High shock absorption with Nomex - Durable impact characteristics |

- Retains material softness and natural feel - Precise control over paddle weight |

- Stable production of complex designs - Enhanced vibration reduction properties |

This comparative analysis assists in aligning material selection with the desired production technique, ensuring a balanced approach to performance quality and manufacturing efficiency. Choosing the right material and process can directly influence the paddle’s operational lifespan and its performance metrics on the court.

For manufacturing leads and procurement managers, several practical factors need to be considered that extend beyond raw performance metrics:

- Production Volume Needs: High-volume orders may favor techniques like hot pressing due to their efficiency even if it occasionally compromises finer material properties. Conversely, niche markets or custom orders might embrace cold pressing or thermoforming.

- Customization Capabilities: Thermoforming is excellent for custom orders. Since its design flexibility permits complex paddle shapes, manufacturers can cater to personalized designs for sports organizations, corporate branding, or high-end product lines.

- Equipment Investment and Cycle Time: Although advanced processes such as cold pressing or thermoforming might require higher investment and longer cycle times, they also allow for premium quality and better control. Assessing total production costs relative to end-user pricing is vital for maintaining market competitiveness.

- Quality Control and Testing: Regardless of the chosen material or process, incorporating rigorous testing phases is crucial. In our production model at NEX Pickleball, each paddle is meticulously tested for balance, vibration absorption, and durability. This ensures that high-performance standards are met even as the production volume scales.

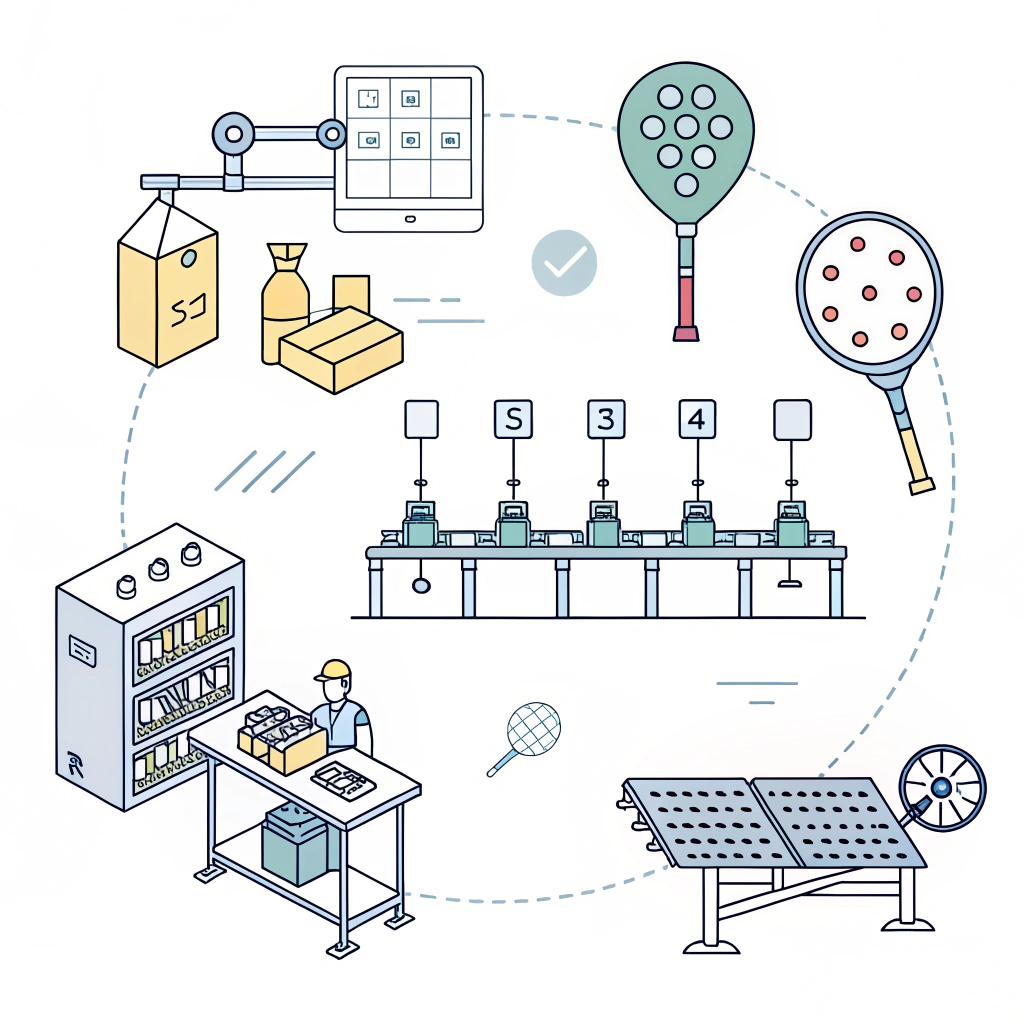

At NEX Pickleball, our approach integrates advanced production techniques with stringent quality control protocols to deliver high-performance paddles. Our extensive experience with OEM manufacturing for reputable brands like Joola and Selkirk necessitates constant innovation in both materials and processes.

Our manufacturing process includes:

- Rigorous Testing: Each paddle offers optimized weight distribution and ergonomic grip design, critical for both competitive sports and casual play.

- Customization Flexibility: We provide on-demand printing services, allowing clients to customize paddle surface designs, thereby enhancing branding opportunities.

- Streamlined Production Cycles: By combining hot pressing for bulk runs with cold pressing for specialty paddles, we achieve a balance between production speed and bespoke quality.

This hybrid approach ensures that whether you seek a cost-effective solution or a premium customized product, NEX Pickleball remains a reliable manufacturing partner. Our expertise with processes like hot pressing, cold pressing, and thermoforming further supports the technical demands of modern pickleball leagues and sports equipment providers.

In conclusion, while the choice between hot pressing, cold pressing, and thermoforming each presents distinct advantages and limitations, the optimal selection for your business will depend on your specific production goals, target market segment, and budget constraints. By understanding the core material characteristics—whether it is 3K/12K/T300 carbon fiber, fiberglass, or various core materials—and pairing them with the appropriate production technique, you can achieve both high performance and cost efficiency.

Our comparative analysis shows that:

- High-volume manufacturers may lean towards hot pressing for its efficiency, while high-performance and custom markets benefit more from cold pressing and thermoforming.

- The integration of advanced materials like carbon fiber variants and specialized composites can significantly boost paddle longevity and playability.

- Rigorous quality control and flexible customization options are essential components in staying ahead of industry trends and customer expectations.

We encourage decision-makers to carefully analyze their production requirements, compare material performance metrics, and factor in long-term operational costs. Ultimately, selecting the right blend of material and technique will position your product portfolio both competitively and sustainably. Whether your focus is on innovation, customization, or mass production, an informed strategy will drive enhanced performance on the court and robust market success.

How are pickleball paddles constructed?

Pickleball paddles are typically constructed using the sandwich method, where a central core (such as Nomex, aluminum, or polymer honeycomb) is enclosed between two face layers. This construction method ensures optimal shock absorption, strength, and control during play.

What wood is best for pickleball paddles?

While wood is less common in high-performance paddles, some traditional paddles use wood like maple, birch, or pine. Lighter woods offer improved maneuverability, whereas denser woods provide more stability and power.

-

hot pressing: Reading this article will provide insights into how hot pressing uses heat and pressure to mold materials for enhanced durability and production efficiency. Back ↩

-

cold pressing: Reading this article will explain how cold pressing preserves material properties with precise control, a key factor in premium manufacturing processes. Back ↩

-

thermoforming: Reading this article will detail how thermoforming enables the creation of complex shapes with uniform material distribution, supporting advanced customization. Back ↩

-

carbon fiber: Reading this article will offer insights into carbon fiber and its variants, illustrating differences in strength, weight, and performance crucial for high-performance products. Back ↩ ↩2

-

Nomex Honeycomb Core: Reading this article will elaborate on the unique shock absorption and durability properties of Nomex Honeycomb Core, which are essential for ensuring long-lasting product performance. Back ↩