A high-performance carbon fiber1 paddle is created through a series of meticulous production steps. In this article, we explore the detailed manufacturing processes for advanced pickleball paddles, focusing on the benefits and limitations of methods like hot pressing2, cold pressing3, and thermoforming4, as well as a deep dive into carbon fiber production.

For any B2B procurement manager or technical buyer in the sports equipment industry, understanding the manufacturing process behind pickleball paddles is critical. The combination of advanced material technologies and innovative production methods sets the foundation for products with unmatched durability, impact resistance, and precise performance. This article aims to provide a complete review of the processes used in making high-performance paddles, with special attention given to the production of carbon fiber reinforcements and the assembly techniques used in paddle construction.

Modern pickleball paddles require more than just a simple assembly process—they are a product of high engineering standards. The key challenges in producing these high-quality paddles include:

- Ensuring exact weight distribution and optimal balance for different playing styles.

- Achieving a precise and durable surface treatment that enhances ball control and reduces vibration.

- Maintaining consistent quality and performance using varied composite materials5 and core types.

- Integrating advanced production methods—such as hot pressing, cold pressing, and thermoforming—while controlling production costs and cycle times.

Procurement professionals must carefully consider these factors to ensure that their suppliers can deliver paddles that meet strict quality standards and performance expectations. Let’s break down the major production challenges and analyze how each process addresses them.

High-performance paddles manufactured by companies like NEX Pickleball rely on three primary production techniques. Each technique involves specific advantages and limitations that impact the final product quality.

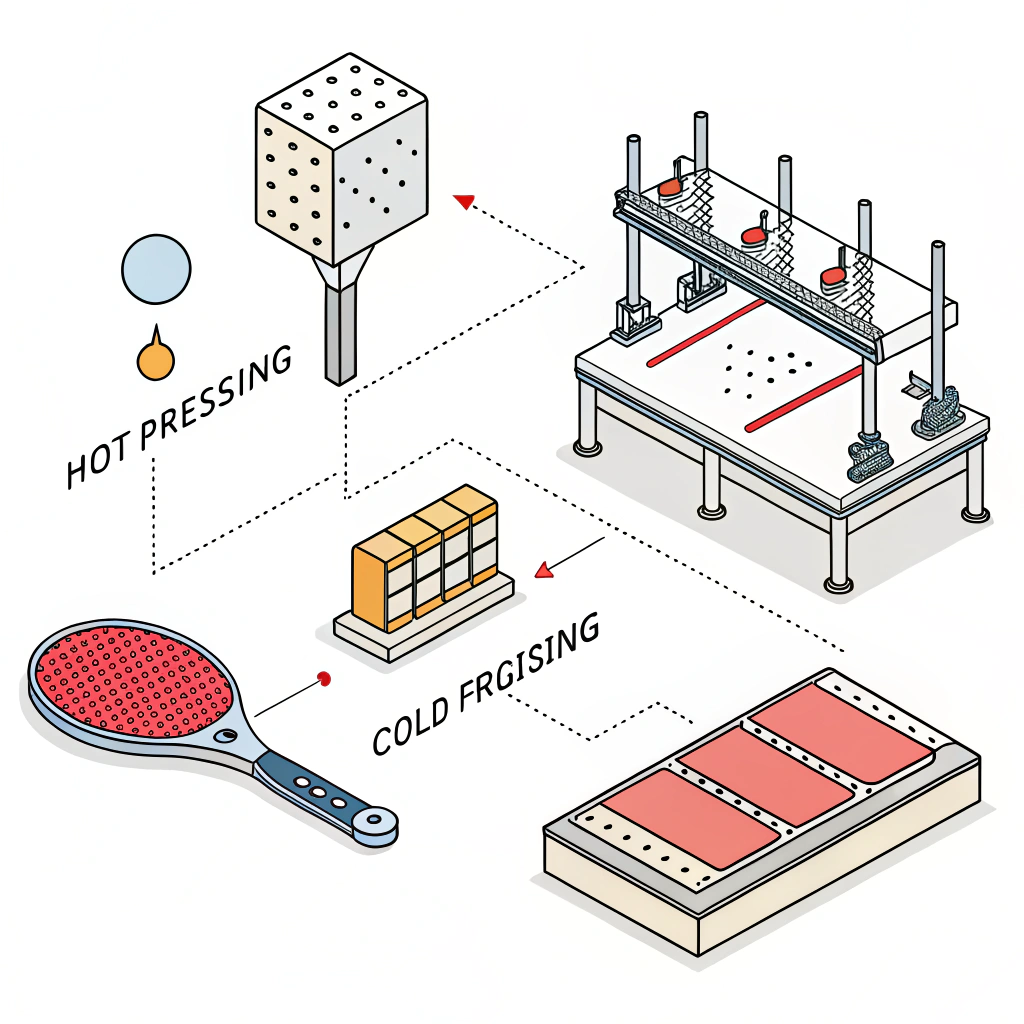

Hot pressing is a method where materials are heated and pressured simultaneously to form the structure of the paddle. This method is widely used due to its high production efficiency and reliability in producing durable products.

Advantages:

- High Production Efficiency: The process is ideal for large-scale manufacturing.

- Structural Integrity: The applied heat helps in bonding the layers effectively, ensuring that paddles have excellent impact resistance.

- Impact Resistance: Paddles produced with hot pressing are strong and can endure high levels of force during intense play.

Disadvantages:

- Material Property Alteration: Heating can sometimes change the inherent properties of the materials, altering the paddle’s feel.

- High Equipment Investment: A significant setup cost is needed to maintain high-quality production standards.

Cold pressing uses mechanical pressure at room temperature to shape the paddle components. This method is particularly useful when precision in layering and material thickness is paramount.

Advantages:

- Precision Control: It allows manufacturers to achieve precise control over the paddle’s thickness and structure without affecting material properties.

- Enhanced Ball Feel: Since the material’s natural characteristics remain intact, players experience improved control and responsiveness.

- Flexibility in Design: This method is beneficial for designs that emphasize ball control and a perfect tactile experience.

Disadvantages:

- Longer Production Cycles: Compared to hot pressing, cold pressing can slow down overall manufacturing efficiency.

- Stringent Quality Requirements: High-quality, accurate pressure application is essential, which demands advanced equipment and monitoring systems.

Thermoforming involves heating the raw material until it softens, then forming it into a specific shape using precise molds. This process is ideal for creating paddles with intricate designs, including those with complex geometries.

Advantages:

- Intricate Design Capability: Thermoforming allows for the production of paddles with unique shapes that enhance both aesthetics and function.

- Material Distribution: It enables precise control over the distribution of the composite materials, ensuring the paddle remains balanced and stable.

- Enhanced Performance: Paddles produced via thermoforming often combine a high level of durability with a well-defined hitting surface.

Disadvantages:

- Longer Production Time: The process requires careful modulation of temperature and shape, which can extend production cycles.

- Higher Costs: The need for specialized molds and sophisticated equipment can drive up the production cost, making this method more suitable for premium paddle lines.

Manufacturing carbon fiber is a complex process that significantly contributes to a paddle’s overall performance. Not only is carbon fiber prized for its strength-to-weight ratio, but it also provides the rigidity needed for competitive play. Below is a detailed look at the two primary raw materials used to produce carbon fiber:

- Raw Material Preparation: The process begins with PAN (Polyacrylonitrile), which is spun to form precursor fibers.

- Stabilization: The precursor fibers undergo a stabilization phase, where controlled oxidation ensures that they do not melt during subsequent high-temperature processing.

- Carbonization: The stabilized fibers are then subjected to extremely high temperatures (typically around 1,000°C to 3,000°C) in an inert atmosphere. This step removes non-carbon elements, leaving nearly pure carbon fiber.

- Surface Treatment: Post-carbonization, surface treatments are applied to improve bonding properties with resins used in paddle manufacturing.

- Sizing: A final coating of sizing material is applied to further enhance the fiber’s compatibility with composite matrices.

- Raw Materials: Here, pitch produced from coal undergoes a refining process. This involves dry distillation and mesophase formation.

- Spinning: The refined pitch is spun into fibers.

- Heat Treatment: Similar to PAN-based carbon fiber, the spun fibers are subjected to high temperatures to remove impurities and promote the formation of a graphitic structure.

- Final Treatments: Surface treatments and sizing are applied to ensure quality integration with composite materials.

A simplified overview comparing both approaches is provided in the table below:

| Process Step | PAN-Based Carbon Fiber | Pitch-Based Carbon Fiber |

|---|---|---|

| Raw Material | Polyacrylonitrile (PAN) | Coal-derived pitch |

| Fiber Formation | Spinning of PAN fibers | Spinning after mesophase formation |

| Stabilization | Oxidation process | Refining and mesophase establishment |

| Carbonization | High-temperature treatment (1,000°C to 3,000°C) | High-temperature graphitization |

| Surface Treatment & Sizing | Applied to enhance resin bonding | Applied to improve composite integration |

The choice between types such as 3K Carbon Fiber, 12K Carbon Fiber, and T300 Carbon Fiber depends on the specific performance requirements. For instance, 3K Carbon Fiber balances strength and flexibility, while 12K Carbon Fiber offers a smoother surface and enhanced durability for competitive scenarios. T300 Carbon Fiber is ideal when a combination of power and lightweight features is needed.

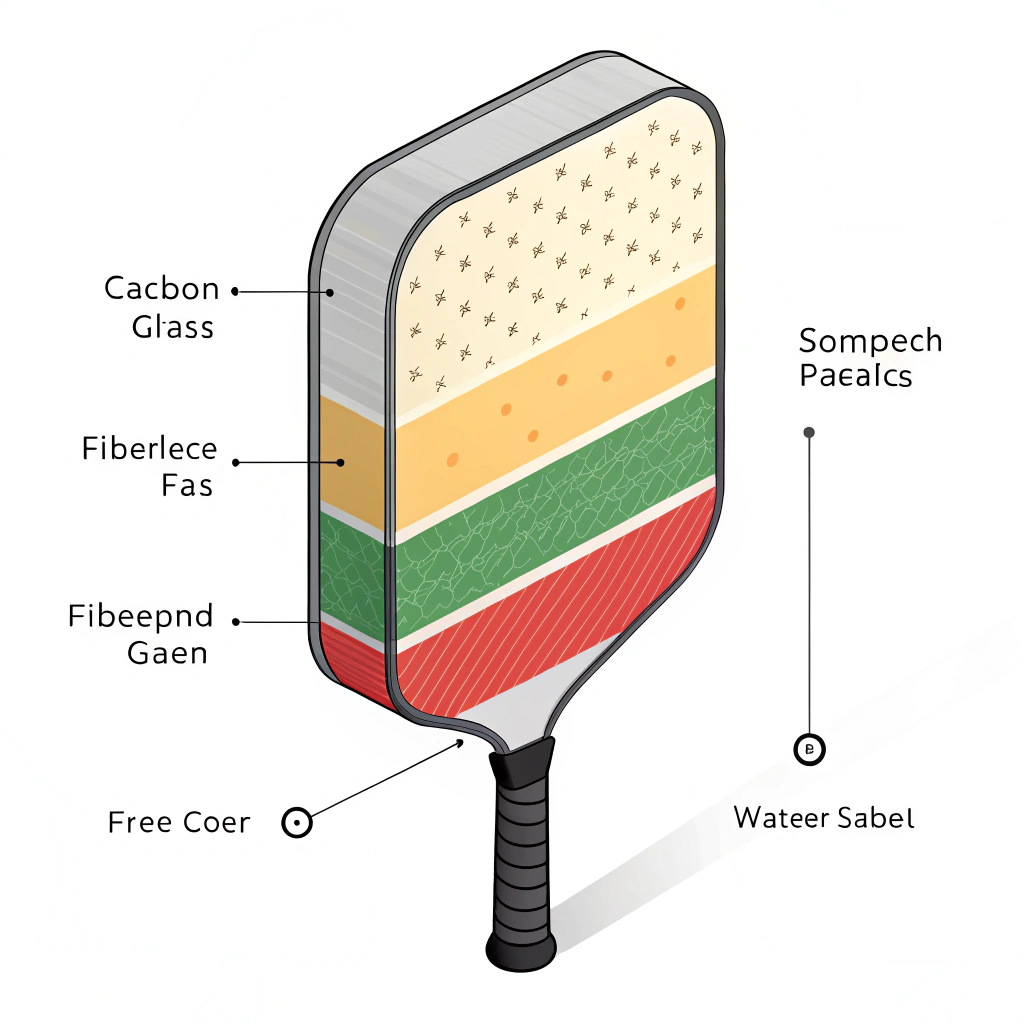

Many pickleball paddles are constructed using a sandwich method where the paddle’s core acts as the “meat” and the face layers act as the “bread.” The core materials, which include Nomex Honeycomb Core, Aluminum Honeycomb Core, and Polymer Honeycomb Core, play a crucial role in ensuring the paddle’s performance. Here’s how several components are integrated into a high-performance paddle:

- Nomex Honeycomb Core: Offers excellent shock absorption and stability.

- Aluminum Honeycomb Core: Provides a balanced weight for optimal power and control.

- Polymer Honeycomb Core: Excels at reducing vibrations, offering a comfortable hit sensation.

- Carbon Fiber Layers: Utilized for their strength and lightweight nature, forming the main facing surfaces.

- Fiberglass Options: Often used to provide enhanced flexibility and control, with materials like E-Glass Fiberglass ensuring a wider sweet spot.

The selection of surface and core materials, coupled with production techniques like thermoforming, produces paddles with distinct performance profiles. For example, paddles made with thermoforming can have complex designs where injected foam around the perimeter improves shock absorption without compromising the overall stability of the carbon fiber faces.

Manufacturers can also combine different materials to create a composite paddle that delivers both power and control. A hybrid design may incorporate both carbon fiber and fiberglass, ensuring that the paddle has strength while also offering the flexibility needed for precise ball control.

When evaluating potential suppliers or considering in-house production processes, B2B buyers should consider the following checklist for advanced paddle manufacturing:

-

Quality Control Standards:

Ensure that every paddle undergoes rigorous testing procedures. Advanced techniques such as thermal imaging and stress analysis should be in place to maintain consistent quality. -

Technology Integration:

Verify that the supplier utilizes modern production techniques like hot pressing, cold pressing, and thermoforming. The ability to produce custom designs that meet specific performance criteria is a key factor. -

Material Transparency:

Suppliers should clearly disclose the types of materials used, including detailed descriptions of carbon fiber variants (3K, 12K, T300) and core materials. This transparency allows for accurate assessment of the paddle’s potential performance. -

Scalability:

The production capabilities should match your procurement needs. Assess the supplier’s ability to maintain performance consistency during large-scale runs. -

Cost Efficiency:

Consider the balance between production methods and overall cost. While techniques like thermoforming offer design advantages, they may incur higher costs. Analyze whether the added performance benefits justify the premium.

| Checklist Item | Key Considerations |

|---|---|

| Quality Control | Rigorous testing, consistent performance, certification |

| Technology Integration | Adoption of hot pressing, cold pressing, thermoforming |

| Material Transparency | Detailed specifications on carbon fiber and composite types |

| Scalability | Ability to maintain quality at high production volumes |

| Cost Efficiency | Balance between advanced methods and production costs |

Using this checklist, procurement managers can make an informed decision on whether their supplier’s manufacturing processes align with performance goals and budgetary constraints.

For B2B buyers in the pickleball equipment industry, the ability to evaluate a supplier’s technical prowess and production capabilities is critical. Understanding the intricacies of carbon fiber manufacturing and the related production processes offers a competitive edge in selecting the right partner.

Based on the above analysis, the following steps are recommended:

- Review detailed supplier documentation on material sourcing and production methods.

- Visit manufacturing facilities if possible to observe production techniques in operation.

- Request sample products to validate performance claims through real-world testing.

- Evaluate the balance between innovation in production techniques and overall cost efficiency.

By taking these actions, procurement managers can ensure that the purchased paddles not only meet but exceed performance expectations, supporting both high-level competitive play and everyday durability.

Q: How is carbon fiber made step by step?

A: Carbon fiber is produced by first spinning precursor fibers, usually made from PAN (Polyacrylonitrile). These fibers are stabilized through oxidation before being carbonized at very high temperatures in an inert atmosphere, followed by surface treatment and sizing to enhance bonding with composite resins. Alternatively, pitch-based carbon fiber involves processing coal-derived pitch through refining, mesophase formation, and spinning before similar high-temperature treatment.

Q: How are paddles made?

A: Paddles are typically made by fusing layers of materials with a chosen production method. For example, thermoforming involves heating the materials to shape them, fusing the facing layers, and integrating a core (such as nomex or polymer honeycomb) with additional foam injection around the edges. This construction ensures enhanced power, stability, and durability.

Q: How are pickleball paddles constructed?

A: Traditional pickleball paddles are constructed using a sandwich method. The core material acts as the central layer (or “meat”), while the paddle faces, which can be made from materials like carbon fiber or fiberglass, form the outer “bread”. This combination allows for optimized power, enhanced control, and reduced vibration during play.

-

carbon fiber: Read the external article to understand the advanced material properties, production techniques, and benefits of using carbon fiber in high-performance sports equipment. ↩ ↩

-

hot pressing: Discover the process of hot pressing, a method that uses simultaneous heat and pressure to bond materials, enhancing structural integrity and production efficiency. ↩ ↩

-

cold pressing: Explore how cold pressing employs mechanical pressure at room temperature to maintain the natural material properties, ensuring precision and improved tactile performance. ↩ ↩

-

thermoforming: Learn about thermoforming, a shaping technique involving heat-softened materials molded into complex designs, which optimizes both aesthetics and functionality. ↩ ↩

-

composite materials: Click here to learn about how composite materials combine different substances to achieve superior strength, durability, and design flexibility in manufacturing. ↩ ↩