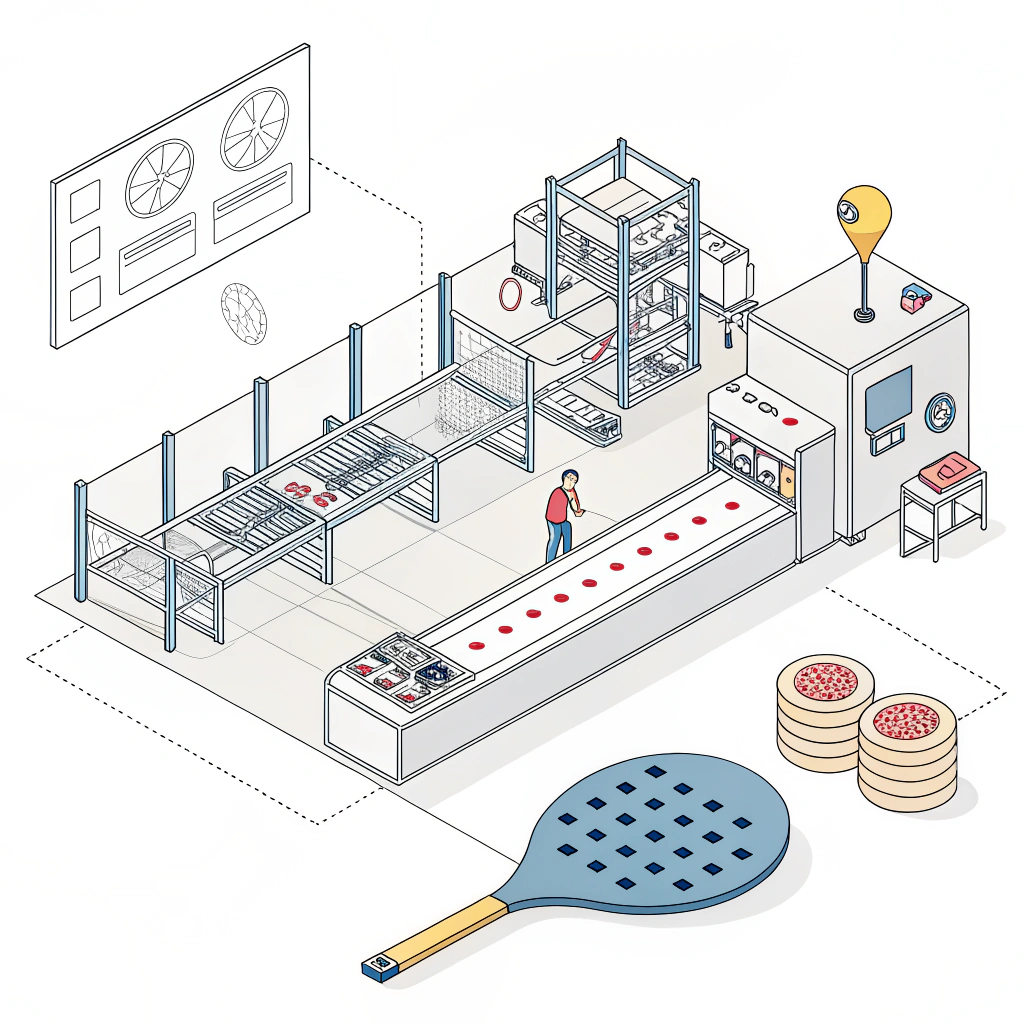

For procurement managers comparing Chinese pickleball manufacturers, the key is to evaluate both the advanced production technologies, such as hot pressing1, cold pressing2, and thermoforming3, and the premium materials used by suppliers to ensure that the paddles deliver superior performance and durability.

Chinese pickleball suppliers have emerged as leaders in the global market due to their ability to combine cutting-edge material science with innovative production techniques. With a wide variety of paddle materials such as different grades of carbon fiber4 (3K, 12K, T300), fiberglass, and various composite materials5, these manufacturers offer solutions tailored for competitive play as well as recreational needs. In this comparison guide, we look into the production processes, technological expertise, and quality control measures that help procurement managers make informed sourcing decisions.

Modern pickleball paddle manufacturing demands precision and innovation. Chinese suppliers, including leading players like NEX Pickleball, combine advanced processes such as hot pressing, cold pressing, and thermoforming to produce paddles that meet the high standards required by the global sports equipment market. By using diverse materials, these manufacturers discuss several production challenges and solutions that are critical for B2B buyers.

Hot pressing is a method widely used for producing high-impact, durable paddles. In this process, materials are heated and pressed into shape, producing paddles with robust structural integrity. The advantages include:

- High Production Efficiency: Ideal for bulk manufacturing.

- Exceptional Impact Resistance: Ensures paddles sustain high-performance demands.

- Structural Integrity: Delivers products that can withstand intense play.

However, hot pressing also has its drawbacks:

- Material Alteration: The heating process can slightly change material properties, affecting paddle feel.

- High Equipment Investment: Requires significant capital expenditure.

For paddles that require a delicate balance of control, cold pressing is an excellent option. This process involves shaping the paddle materials at ambient temperature using precise mechanical pressure, which helps maintain the intrinsic properties of the materials.

- Enhanced Ball Feel: Provides players with better touch and control.

- Precise Thickness Control: Allows manufacturers to fine-tune the paddle’s structure.

- Maintaining Material Integrity: Keeps the original properties intact to optimize performance.

The challenges related to cold pressing include:

- Longer Production Cycles: It can be less efficient compared to hot pressing.

- Demand for High-Quality Equipment: Ensures that pressure is consistently controlled throughout the process.

Thermoforming brings versatility to the manufacturing process by heating materials to a softening point before molding them into the final paddle shape. This method is particularly suited for producing paddles with intricate designs and exact material distribution, which is essential for advanced and custom paddle designs.

- Intricate Design Capabilities: Allows for unique shapes and optimized performance elements.

- Material Distribution: Ensures even thickness and consistency across the paddle.

- Ideal for Premium Products: Often used for custom-made paddles that need detailed performance specifications.

Key disadvantages of thermoforming include:

- Longer Production Time: The method requires more time due to the additional steps involved.

- Higher Equipment Costs: Investment in specialized machinery is necessary.

To further facilitate the comparison between these processes, here’s a detailed table outlining their core strengths and limitations:

| Production Process | Advantages | Limitations | Best Suited For |

|---|---|---|---|

| Hot Pressing | High efficiency; strong impact resistance; sturdy build | Material alteration; high equipment costs | Large-scale manufacturing of high-durability paddles |

| Cold Pressing | Precise control; preserves material properties; excellent ball feel | Longer production cycle; requires precise machinery | Paddles requiring exact control and delicate design |

| Thermoforming | Intricate design; even material distribution; ideal for custom orders | Slower cycle time; higher cost investment | Premium and custom-designed paddle products |

This comparison table serves as a quick reference for procurement managers weighing their options between speed, cost, and performance in production technologies.

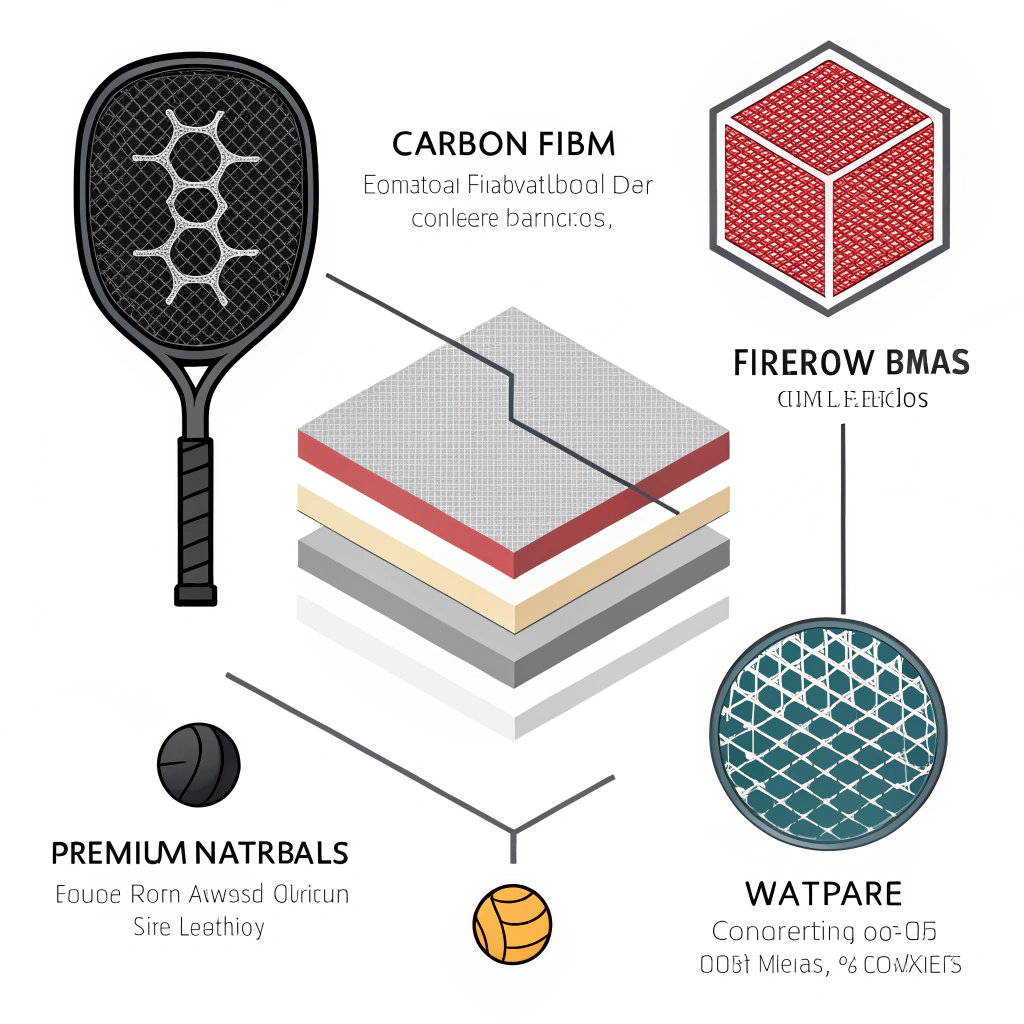

The choice of raw materials is a cornerstone of production quality. Premium carbon fiber stands out due to its exceptional strength-to-weight ratio and performance characteristics. Let’s review the different types:

- 3K Carbon Fiber:

Renowned for its balance between strength and flexibility, 3K carbon fiber provides a high rebound force while reducing vibration. - 12K Carbon Fiber:

Offers a smoother surface with greater hardness, making it a top choice for competitive play where extreme impact resistance is vital. - T300 Carbon Fiber:

Known for its tensile strength, this option is ideal for paddles that require both endurance and a lightweight structure.

In addition to carbon fiber, fiberglass is also utilized for its superior elasticity and ball control properties. This material tends to generate a wider sweet spot while maintaining durability, meaning it is particularly effective in paddles designed for versatile play styles.

Composite materials further enhance performance by combining the benefits of multiple materials. Blends such as carbon fiber with fiberglass create paddles that offer an ideal mix of flexibility, strength, and performance balance. Other composites like Bamboo Core and Honeycomb Core provide unique advantages, such as improved impact resistance and vibration damping, important attributes for long-term durability.

For B2B procurement, reliability and consistency are paramount. Manufacturers like NEX Pickleball implement rigorous quality control measures across every production process, ensuring that each paddle is tested for strength, flexibility, and correct weight distribution. With such detailed attention to quality, procurement managers can be confident in the performance of the finished products—be they for recreational players or competitive athletes.

Customization plays a vital role in catering to specific demands. Businesses can specify design preferences, including paddle weight, grip size, balance, and even aesthetic details. This ability to offer tailored solutions makes Chinese pickleball manufacturers a strong contender in the global B2B arena.

When deciding between suppliers, procurement managers often consider more than just product quality. Technology expertise, production capacity, and cost efficiency are equally important. Here’s how production technologies compare from a technological and financial perspective:

| Key Factor | Hot Pressing | Cold Pressing | Thermoforming |

|---|---|---|---|

| Production Volume | High volume production | Moderate volume production | Low to moderate volume production |

| Capital Investment | High (advanced equipment needed) | Moderate (precision machinery required) | High (specialized molds and heaters) |

| Scalability | Excellent scalability | Limited by process precision | Limited by production cycle |

| Precision Control | Consistent, but may alter materials | High precision and preservation | High but complex to maintain |

| Suitability for Custom Orders | Standard designs primarily | Some customization allowed | Highly customizable and premium |

This table further assists procurement managers in making strategic decisions aligned with market trends and business objectives.

For organizations looking to invest in high-performance pickleball paddles, understanding the nuances of manufacturing processes and material choices is fundamental. When evaluating potential suppliers, key questions include:

- What production process aligns best with the intended product quality and volume needs?

- Does the supplier offer flexibility in customization to target niche market segments?

- How robust and consistent is the supplier’s quality control methodology?

- What are the long-term cost implications of the chosen manufacturing technology?

As performance-focused businesses streamline their sourcing strategies, they increasingly look for partners who not only meet current technical standards but are also capable of evolving with market demands. Chinese pickleball manufacturers are well-positioned to facilitate such transitions, offering scalable and innovative solutions that provide excellent return on investment.

In conclusion, Chinese pickleball manufacturers stand out in the B2B market thanks to their advanced production processes, high-quality materials, and robust quality control standards. For procurement managers, the decision-making process should involve a thorough analysis of:

- Production techniques and their impact on product durability and feel.

- Material choices that align with the desired performance outcomes.

- Customization capabilities to meet specific branding and regulatory needs.

- Cost efficiency balanced with the need for precision and quality.

By carefully comparing factors like production method, technological investment, and operational scalability, businesses can partner with suppliers that enhance product performance while optimizing overall costs. The insights provided in this article offer a practical framework for evaluating Chinese pickleball suppliers, thereby supporting strategic sourcing decisions in an increasingly competitive market.

For those ready to advance their procurement strategies, the next step is to initiate detailed discussions with potential suppliers, request product samples, and review performance certifications that back up quality claims. Strategic partnerships with manufacturers that embody technological excellence and production consistency are essential for staying competitive in today’s dynamic sports equipment market.

People Also Ask

Q: What is the best Chinese brand pickleball paddle?

A: While several brands offer high-quality options, DinkPickleball is recognized as a leading manufacturer in China. Their paddles are well-regarded for optimal performance, built using premium materials and advanced technologies. However, procurement managers should compare technical specifications and production processes—including those of NEX Pickleball—to choose the supplier that best aligns with their business needs.

-

Hot pressing: Click to read about the process and benefits of applying heat and pressure in manufacturing, which ensures product durability and performance. Back to hot pressing ↩

-

Cold pressing: Click to learn how ambient temperature shaping maintains material properties and enhances product precision, crucial for quality control. Back to cold pressing ↩

-

Thermoforming: Click to explore how heating materials to a soft state before molding allows for intricate and customizable designs in production. Back to thermoforming ↩

-

Carbon fiber: Click to understand the material's exceptional strength-to-weight ratio and why it is vital for high-performance products. Back to carbon fiber ↩

-

Composite materials: Click to discover how blending different materials can provide the best balance of strength, flexibility, and durability in manufacturing. Back to composite materials ↩