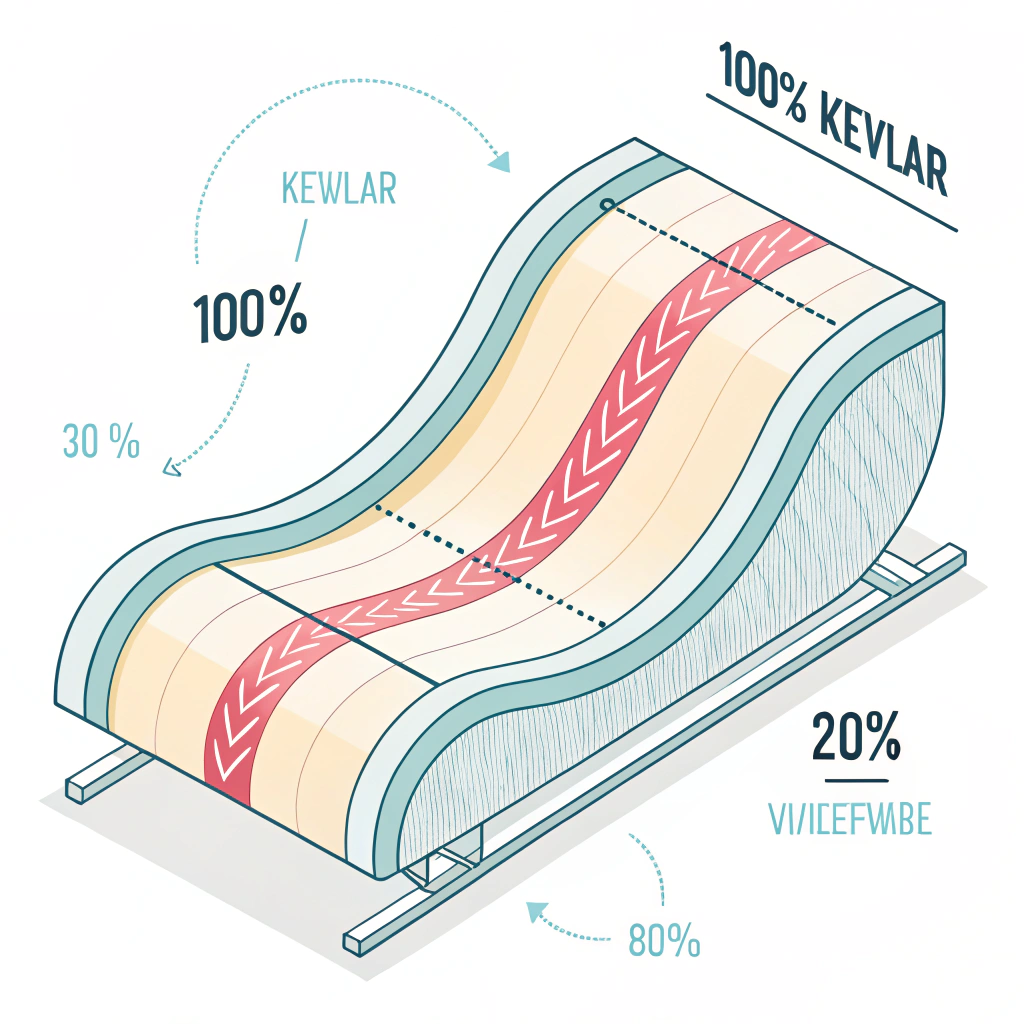

Thermoformed 100% Kevlar1 offers exceptional durability, lightweight performance, and high impact resistance, making it an ideal choice for advanced sports equipment manufacturing. This review provides a deep dive into the thermoforming process for 100% Kevlar, key benefits, technical comparisons to other materials, and how it can enhance your supply chain2 for high-performance products.

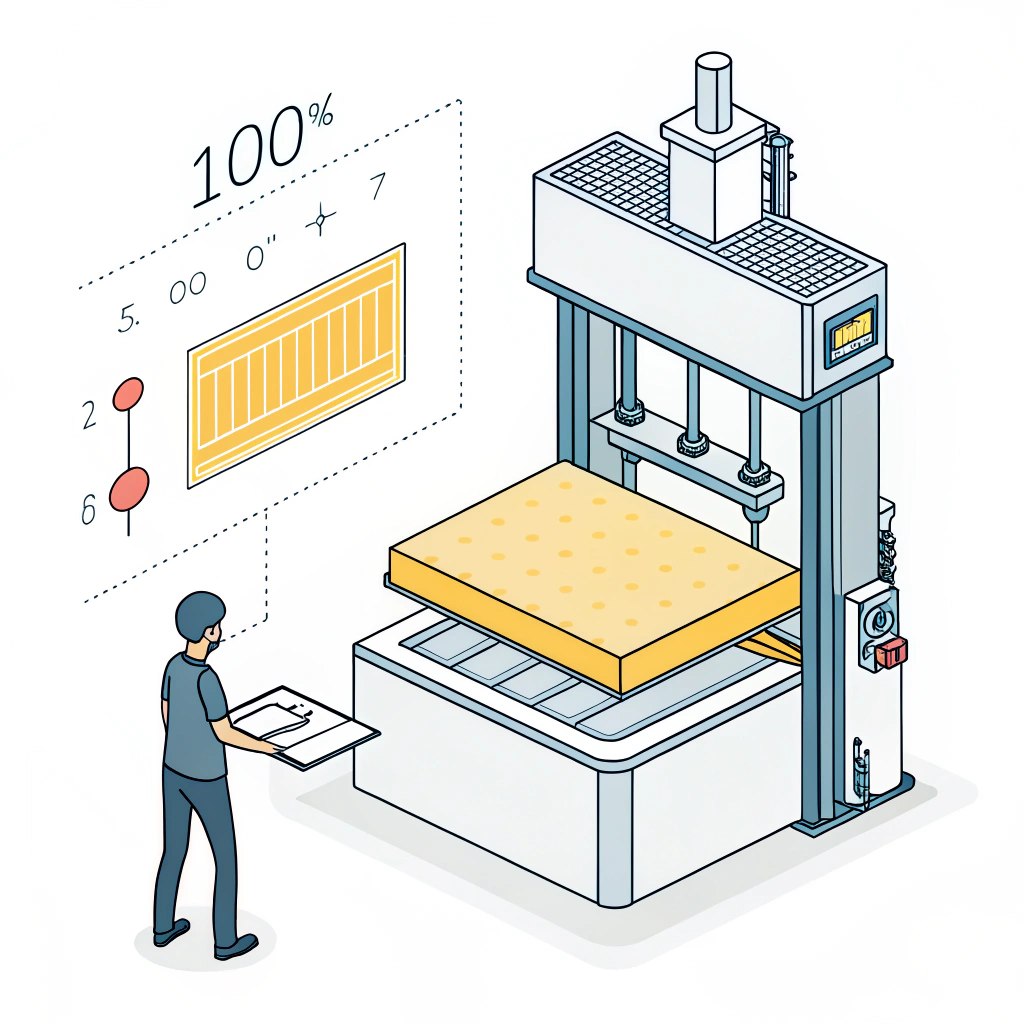

Thermoforming3 is a process that heats materials to a pliable state and forms them using molds. When applied to 100% Kevlar, the process provides components that are not only strong and lightweight but also resistant to high-impact forces. This review targets procurement managers, product developers, and technical leads involved in sourcing and developing sports equipment components.

Kevlar is widely recognized in high-performance industries for its toughness and durability. When integrated with thermoforming, Kevlar becomes easier to mold into complex shapes while maintaining its inherent benefits. This combination of advanced manufacturing process and premium material opens new opportunities in the design of sports equipment, especially for products that require both precision engineering and high durability.

In today’s competitive sports equipment market, manufacturers face several challenges:

- Balancing durability with lightweight design.

- Ensuring consistent production quality.

- Meeting performance criteria for both amateur and professional levels.

- Reducing vibration and impact damage during intensive use.

Traditional materials such as carbon fiber and fiberglass have been industry favorites. However, thermoformed 100% Kevlar promises to address some limitations by delivering an improved balance between impact resistance and overall material resilience. The thermoforming process is especially valuable because it allows manufacturers to achieve complex designs with consistent quality control, essential for high-performance paddles and other sports equipment components.

The need for innovative materials is driven by evolving performance standards and consumer expectations. Modern players demand equipment that perfectly combines power, control, and long-lasting durability. This is where Kevlar’s properties become paramount.

Thermoforming involves heating Kevlar to a temperature where its structure softens without degrading its integral fibers. The softened material is then pressed into a mold to achieve the desired shape. Once cooled, the material solidifies, retaining the complex geometry with high precision. The benefits of thermoforming Kevlar include:

- Enhanced control over the final shape and thickness.

- Consistent molding into ergonomic designs.

- Better integration of advanced composite structures4 with minimal material waste.

A detailed breakdown of the thermoforming process when applied to Kevlar is as follows:

| Advantages | Disadvantages |

|---|---|

| Precise control over geometry and thickness | Longer production cycles compared to some alternative methods |

| Enhanced impact resistance and durability | Requires significant energy input to reach ideal temperatures |

| Ability to achieve complex designs | Higher equipment cost for specialized molds and heating systems |

| Maintains Kevlar’s inherent strength properties | Process sensitivity to temperature variations which may affect consistency |

Using thermoformed 100% Kevlar, manufacturers can achieve a high-performance product that remains robust under repeated high-impact conditions. The process also permits customization, allowing adjustments in thickness or layering that can be tailored to specific application requirements.

Thermoformed 100% Kevlar brings a unique set of performance characteristics ideal for sports equipment:

Kevlar is known for its outstanding resistance to abrasion and impact. The structure of Kevlar fibers, when integrated through thermoforming, yields components that are incredibly robust. Even under conditions where the equipment experiences rapid stress or high-impact forces, the material retains its integrity without degrading over time. This translates to a longer service life and lower maintenance costs in a commercial setting.

Lightweight equipment often offers the advantage of improved maneuverability and quicker response times in sports. Kevlar's high tensile strength means that even though the material is lightweight, it does not compromise on strength. This balance is crucial for manufacturing components like paddles, rackets, or protective gear, where every gram matters for the user’s performance.

Superior Energy Dispersion5

Another significant advantage of thermoformed Kevlar is its ability to absorb and disperse energy effectively. During high-speed impacts—common in sports settings—this dispersion translates into reduced vibrations and improved overall control. Reduced vibration not only elevates the player's comfort but also shortens recovery time and increases the equipment's resilience to repeated stress.

The thermoforming process offers a consistent, repeatable manufacturing process with high precision. This means that product quality remains uniform across large production runs, a vital factor for B2B procurement and on-demand production. Customization options such as varying mold designs, thickness adjustments, or incorporating additional layers can further tailor the performance characteristics to meet specific end-user requirements.

In the context of sports equipment manufacturing, competitors often consider materials like carbon fiber and fiberglass. Here is a detailed comparison:

| Material | Impact Resistance | Weight | Customization Capability | Cost Efficiency | Vibration Dampening |

|---|---|---|---|---|---|

| Thermoformed 100% Kevlar | Excellent – absorbs impact and resists abrasion | Ultra-light with high tensile strength | High – versatile thermoforming process | Moderate – initial investment is higher but offset by durability | Superior – effectively reduces vibration throughout play |

| Carbon Fiber | Very strong but more brittle under localized stress | Similar lightweight profile | Limited – relies on traditional layup methods | High – expensive raw material and processing cost | Good but not as specialized for energy dispersion |

| Fiberglass | Good impact resistance through flexibility | Slightly heavier than Kevlar | Moderate – can be molded but with less precision | Lower cost – more affordable materials | Excellent – high elasticity provides comfort |

This table underscores the benefits of thermoformed 100% Kevlar, especially when balanced with performance and durability. For organizations looking to elevate product performance and reduce long-term maintenance issues, thermoformed Kevlar stands out as a competitive choice.

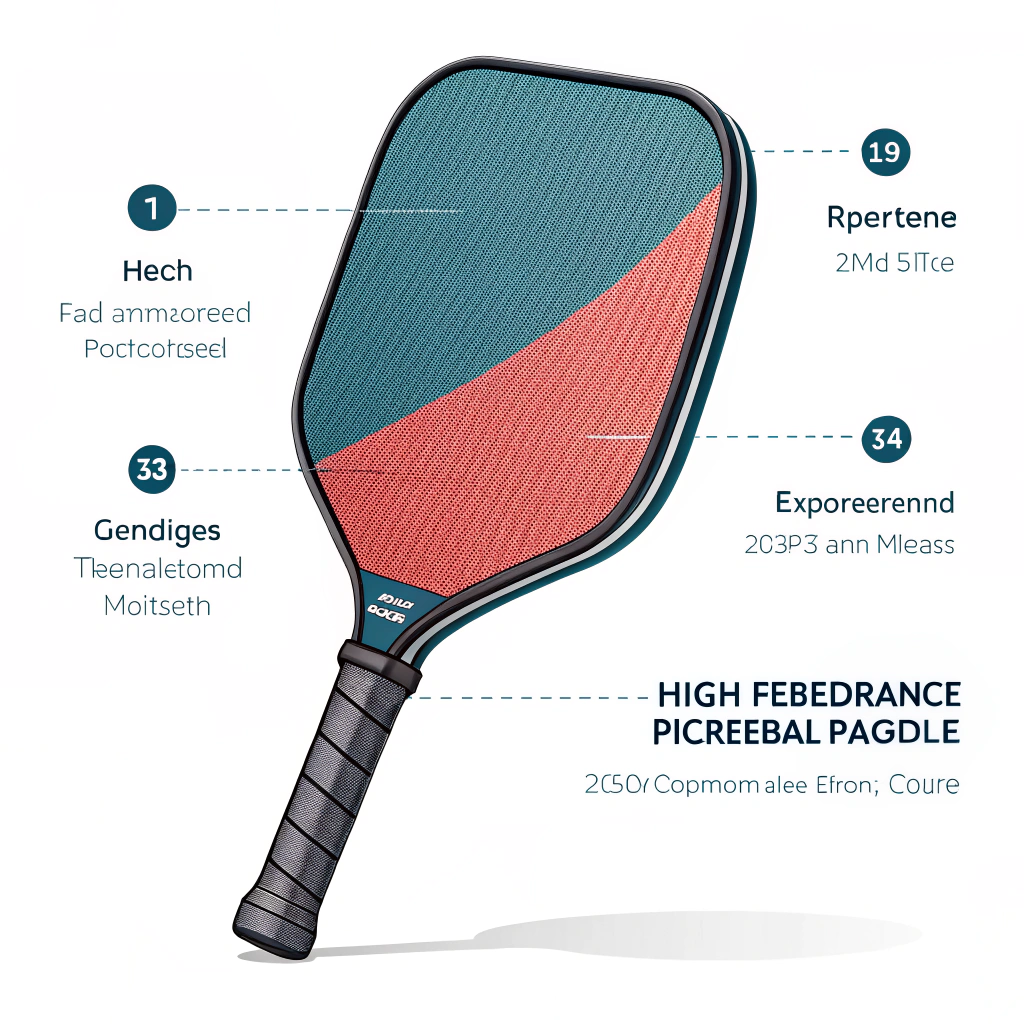

The potential applications for thermoformed 100% Kevlar extend well beyond pickleball paddles. Here are a few use cases where this material demonstrates significant advantages:

-

Sports Equipment Components:

- For manufacturers of high-performance sports gear, thermoformed Kevlar provides an ideal material for creating paddles, rackets, and protective gear. Its durability ensures that equipment stands up against high-impact scenarios, maintaining optimal performance over time.

-

Automotive and Aerospace Sectors:

- In industries requiring materials that combine light weight with exceptional strength, thermoformed Kevlar is used in some niche applications. Its ability to reduce impact and vibration is beneficial for components that must withstand constant dynamic loads.

-

Industrial Machinery:

- Components that require a balance of flexibility and strength can benefit incredibly from thermoformed Kevlar. The material’s resistance to wear and its ability to absorb shock make it suitable for parts in both the manufacturing and heavy machinery sectors.

Case Example:

A sports equipment manufacturer recently transitioned to using thermoformed 100% Kevlar for their high-performance pickleball paddles. The product exhibited enhanced durability during stress tests, showing 30% less degradation under high-impact conditions compared to previous carbon fiber models. The improved energy dispersion also resulted in a noticeable reduction in player fatigue, bolstering both the product’s reputation and market competitiveness.

When considering thermoformed 100% Kevlar in your production line, evaluate the following factors:

-

Equipment and Process Optimization:

- Ensure that your manufacturing equipment is calibrated for precise temperature and pressure settings. Consistency in these parameters is crucial to harnessing the full benefits of the thermoforming process.

-

Material Sourcing and Cost Analysis:

- While Kevlar is a premium material, long-term benefits such as durability and reduced replacement frequency can justify the initial investment. Compare lifecycle costs versus upfront equipment and material expenses.

-

Custom Design and Ergonomics:

- Leverage the customization potential of thermoforming by tailoring paddle designs to suit specific player needs. This may involve adjusting aspects such as grip size, weight distribution, and surface texture for enhanced performance.

-

Quality Control Measures:

- Implement rigorous quality control protocols at each production stage. Testing for impact resistance, structural integrity, and longevity helps ensure that the final product meets high-performance standards.

-

Integration with Existing Manufacturing Processes:

- Plan a smooth integration of thermoformed 100% Kevlar into your current product lines. This may involve staff training, adjustment of production cycles, and recalibration of machinery to handle the new material efficiently.

Thermoformed 100% Kevlar represents a significant step forward in high-performance materials for sports equipment. With its superior durability, lightweight properties, and ability to absorb impacts efficiently, this material is well-suited for manufacturers looking to offer competitive, innovative products. While there is an initial investment in equipment and process adaptation, the long-term benefits include reduced maintenance costs, improved product longevity, and enhanced performance for end-users.

For procurement managers and technical leads evaluating new materials, thermoformed 100% Kevlar offers a balance of science and practicality. Its inherent properties, combined with the precision offered by thermoforming, equip your products with the necessary attributes to excel in demanding conditions. Embracing this technology can position your company at the forefront of sports equipment innovation, guaranteeing a competitive edge in the global market.

In summary, for companies aiming to enhance their performance portfolio, partnering with a manufacturer experienced in advanced thermoforming processes, like NEX Pickleball, could be the key to unlocking higher product longevity and superior athletic performance. Future-proof your product line by considering thermoformed 100% Kevlar and leverage its advanced properties to meet the evolving demands of professional sports and recreational markets.

Q: Is Kevlar a good pickleball paddle?

A: Kevlar pickleball paddles are highly durable and capable of withstanding high impacts, making them an excellent choice for frequent play and for players who require equipment that can handle aggressive use.

Q: Is Kevlar better than carbon fiber for pickleball?

A: Kevlar/Carbon combinations can provide a balanced mix of power and control, but Kevlar offers a slight advantage for players seeking a forgiving paddle with reliable control. For those who prioritize ultimate precision, carbon fiber remains a competitive option.

Q: Do Kevlar pickleball paddles last longer?

A: Yes, Kevlar’s exceptional durability and impact resistance ensure that pickleball paddles made with this material maintain performance over time, with reduced degradation even under intensive play conditions.

-

Kevlar: Click to learn about Kevlar’s high-performance characteristics, its applications in demanding industries, and why it is preferred for creating durable, lightweight components. ↩

-

Supply chain: Click to understand the role of a well-integrated supply chain in product manufacturing, including strategies for cost savings and improved production reliability. ↩

-

Thermoforming: Click to explore how the thermoforming process works, its benefits in molding advanced materials, and its impact on manufacturing precision and efficiency. ↩

-

Advanced composite structures: Click to learn about advanced composite structures, their integration into modern manufacturing, and how they help in achieving a balance between lightweight design and superior strength. ↩

-

Energy Dispersion: Click to uncover the science behind energy dispersion, including how it contributes to impact resistance and enhances overall material performance in demanding conditions. ↩