High-performance pickleball paddles combine advanced materials, precise production processes, and rigorous quality control to deliver products that meet both legal standards and competitive performance requirements. This article explains the critical steps—from material selection to production techniques—ensuring that procurement managers and product specialists can confidently evaluate and choose the right paddle for their market.

In today's competitive sports equipment market, businesses require paddles that not only meet official size and weight standards but also provide maximum performance. Manufacturers must focus on innovation, precision, and consistency to deliver paddles that satisfy both legal and competitive demands. For example, official guidelines state that the combined length and width must not exceed 24 inches and the handle length should be between 4” and 5.5”. Keeping these constraints in mind while delivering products that excel in playability is a complex challenge.

Procurement managers need paddles that can offer long-lasting durability, ergonomic design, and high-speed performance. In addition, the manufacturing process must be efficient and flexible enough to allow custom options such as unique grip sizes and branding. With many options available, the decision ultimately rests on identifying production processes and material choices that directly impact performance and compliance.

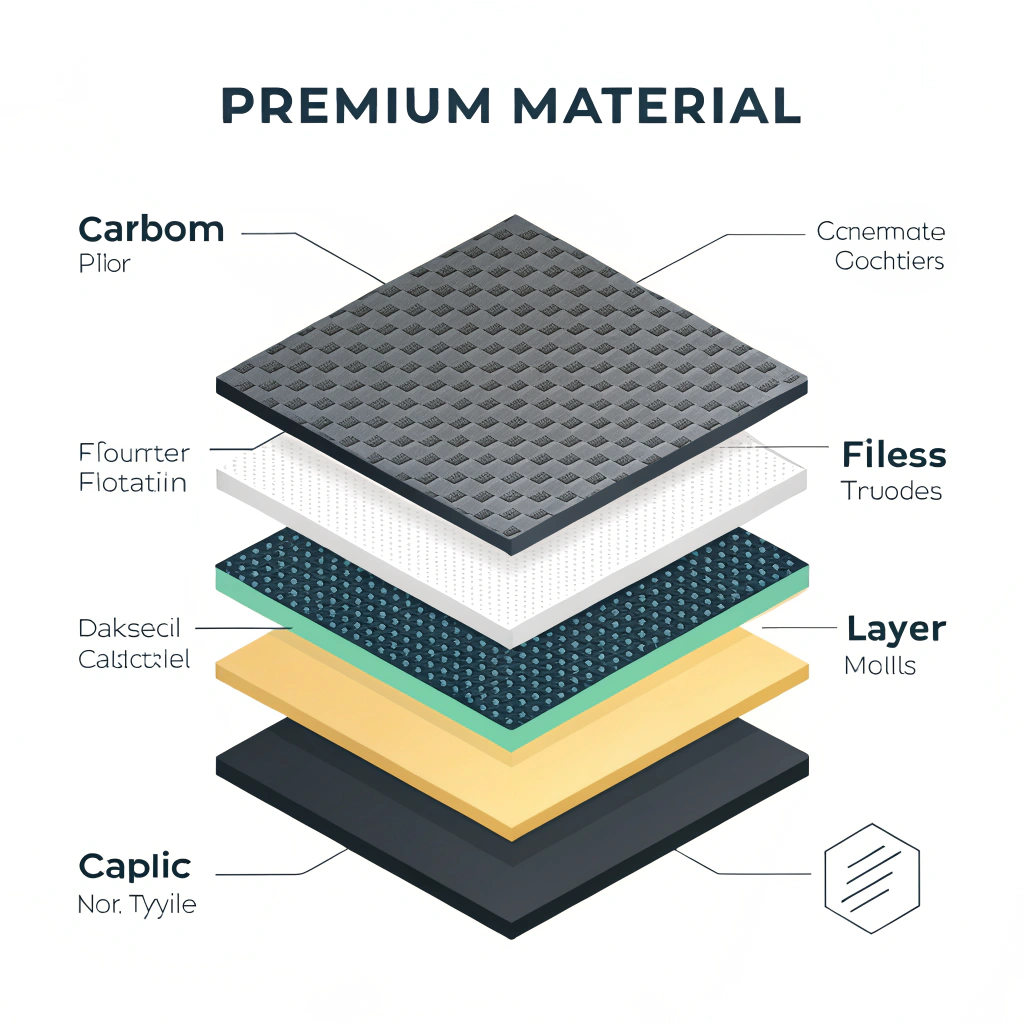

A key element in high-performance pickleball paddles is the selection of premium materials. Different materials guarantee various performance benefits:

- 3K Carbon Fiber1 provides strength and flexibility, ideal for paddles that require high rebound force. It reduces vibration and offers excellent durability.

- 12K Carbon Fiber features a higher thread density, resulting in a smoother surface and enhanced hardness. This type is perfect for competitive play due to its superior impact resistance.

- T300 Carbon Fiber combines outstanding tensile strength with a lightweight design, ensuring a balanced performance that is critical for fast-paced games.

Fiberglass2 Paddles

Fiberglass offers a balance between power and control. It provides:

- A wider sweet spot,

- Enhanced durability,

- Greater ball control structure.

Using E-Glass Fiberglass, paddles can achieve exceptional elasticity and tensile strength, making them especially suitable for players needing excellent ball feel and control.

Combining different materials can lead to improvements in both performance and durability:

- Carbon Fiber and Fiberglass Composite leverages the strengths of both materials, offering an ideal balance of strength, lightness, and flexibility.

- Bamboo Core Composite provides a lightweight platform with high impact resistance, delivering a clear and crisp hitting feel.

- Honeycomb Core utilizes high-density polymers or pulp, ensuring superior shock absorption and reduced vibration, which is essential for prolonged play.

The core material influences overall paddle characteristics, such as rigidity, ball control, and vibration reduction. Common cores include:

- Nomex Honeycomb Core: It is known for exceptional shock absorption and long-lasting performance.

- Aluminum Honeycomb Core: This provides balanced weight, enhancing both power and control.

- Polymer Honeycomb Core: Offers better elasticity and a comfortable hitting experience, often preferred by recreational enthusiasts.

An informed decision regarding material selection is crucial to meet both performance standards and official paddle regulations.

The manufacturing process significantly affects the final quality of the paddle. At NEX Pickleball, we employ three main production methods, each with its own unique attributes:

This method involves applying heat and pressure simultaneously to fuse the materials into a solid paddle:

- Advantages:

- High production efficiency, making it suitable for large-scale manufacturing.

- Produces strong, durable paddles that excel in impact resistance.

- Ensures structural integrity, which is essential for competitive play.

- Disadvantages:

- High temperatures may affect some material properties, potentially altering the paddle’s feel.

- Requires significant investment in specialized equipment.

Cold pressing is a technique where materials are shaped under controlled mechanical pressure at room temperature:

- Advantages:

- Offers precise control over paddle thickness and structural integrity.

- Preserves the natural properties of the materials, providing better control and flexibility.

- Results in an excellent ball feel and immediate response upon impact.

- Disadvantages:

- A longer production cycle compared to hot pressing, which may reduce overall efficiency.

- Demands high-precision equipment to maintain consistent quality.

In thermoforming, the material is heated to a softening point and then moulded into the desired shape:

- Advantages:

- Enables the creation of paddles with complex designs and precise material distribution.

- Maintains paddle stability by ensuring uniform fitting of each component.

- Suitable for high-performance materials and premium custom designs.

- Disadvantages:

- Involves longer production times and higher associated costs.

- Best utilized for specialized production or limited-edition products.

Below is a summary table clearly contrasting these three key production methods:

| Production Process | Advantages | Disadvantages |

|---|---|---|

| Hot Pressing | High efficiency; strong, durable paddles; excellent impact resistance | Potential alteration of material feel; high equipment cost |

| Cold Pressing | Precise control; preserves material properties; excellent ball feel | Longer cycle time; requires high-precision machinery |

| Thermoforming | Complex designs; uniform material distribution; maintains stability | Longer production time; higher cost and complexity |

The choice of production process depends on the desired balance between production efficiency, product quality, and cost-effectiveness. Manufacturers like NEX Pickleball strategically select and sometimes combine these processes to achieve optimal paddle quality.

Meeting industry standards is not just about performance; it is also about legal compliance and market regulations. Official paddle specifications dictate critical dimensions and weights:

- The combined length and width of the paddle must not exceed 24 inches.

- The handle length should be between 4 to 5.5 inches.

- The weight should ideally fall within 6.5 to 9.5 ounces.

While these strict guidelines ensure fair play in tournaments, manufacturers need to implement rigorous quality control measures:

- Precision Testing: Each paddle undergoes extensive testing to confirm that dimensions and weights are within standard limits.

- Performance Verification: Tests related to vibration, rebound force, and grip surface quality are conducted to ensure optimal performance.

- Material Integrity Checks: Continuous tests on the carbon fiber, fiberglass, and composite structures guarantee durability and effective energy transfer during play.

By maintaining these robust quality control processes, manufacturers not only ensure compliance but also build trust with B2B procurement managers over the long term.

Today’s B2B buyers value customizability and detail-oriented manufacturing. At NEX Pickleball, the capability to offer custom paddle options—ranging from design tweaks to custom grip sizes and weight distributions—allows us to meet specific customer demands. This aspect is especially crucial for sports teams, retail brands, and distributors that seek to differentiate their products in a competitive marketplace.

- Tailored Designs: Customers can choose specific paddle shapes and aesthetics to enhance brand recognition.

- Optimal Weight Distribution: Adjustments in the core and composite materials ensure the paddle suits different playing styles, from power hitters to precision players.

- Ergonomic Grip Sizes: Custom grip and handle designs cater to a wide variety of hand sizes, ensuring comfort and reducing the risk of injury.

- On-Demand Print Services: Allows for personalized branding elements, such as logos and color schemes, that help teams and retailers stand out.

For procurement managers, the ability to source a product that can be easily customized translates into greater market agility and an edge in competitive scenarios. A strategic focus on customization not only meets immediate product needs but also opens the door for innovative product developments.

Several studies in the sports equipment industry indicate that well-manufactured paddles using premium techniques and materials can significantly enhance game performance. Here are some key insights:

- Enhanced Durability: Paddles built with a combination of 12K Carbon Fiber and Polymer Honeycomb Core have shown improved impact resistance, reducing the frequency of replacements.

- Player Comfort: Adjustable grip sizes and ergonomically designed handles contribute to lesser fatigue and a more enjoyable playing experience, directly correlating with sustained player performance.

- Market Adaptation: Customized paddles that adhere to official dimensions and performance benchmarks are more likely to be approved for tournament play, ensuring a broader market acceptance.

Data collected from competitive matches illustrates that paddles optimized with advanced production techniques like cold pressing tend to deliver superior control and consistency over time. These real-world examples become invaluable benchmarks for B2B procurement decisions.

Manufacturers and brands that back their products with performance tests and quality control certifications establish themselves as reliable partners in the industry. This data-driven approach is essential for procurement managers who balance cost, quality, and compliance in their purchase decisions.

To summarize, the key components in selecting high-performance pickleball paddles include:

- Rigorous Material Selection: Opt for advanced materials such as 3K, 12K, and T300 Carbon Fiber combined with high-quality core materials.

- Optimized Production Processes: Understand the benefits and challenges of hot pressing, cold pressing, and thermoforming to align with performance and manufacturing demands.

- Strict Quality Control: Ensure that each paddle meets regulatory dimensions, weight specifications, and performance standards.

- Customizable Options: Leverage on-demand print services and tailored design solutions to meet unique B2B requirements.

- Data-Driven Decisions: Utilize performance benchmarks and real-world testing data to support procurement choices.

For procurement managers and product specialists, partnering with a manufacturer like NEX Pickleball means gaining access to high-performance, compliant, and customizable pickleball paddles that meet the rigorous demands of modern competitive play. A well-informed decision on material selection and production techniques has a direct impact on the success of your sports equipment lineup.

We encourage you to evaluate your procurement processes and explore how advanced manufacturing solutions can provide a competitive edge in the dynamic pickleball market.

-

What makes a legal pickleball paddle?

Legal pickleball paddles must adhere to size guidelines where the combined length and width, including any edge guard and butt cap, do not exceed 24 inches, and the handle length must remain within the specified range. There is no limitation on paddle thickness. -

What are the official pickleball paddle specs?

Official specifications dictate a handle length between 4 and 5.5 inches with a grip circumference of 4 to 4.5 inches. Additionally, the paddle generally weighs between 6.5 and 9.5 ounces, and the overall paddle size must fall within the prescribed dimensions. -

What pickleball paddles are allowed in tournaments?

Approved pickleball paddle lists include models that meet both legal size and performance requirements. These lists often contain key details such as model names, manufacturer information, and specific release dates to ensure compliance for competitive play.

-

3K Carbon Fiber: Reading this article will help you understand its role in enhancing paddle strength and flexibility. ↩

-

Fiberglass: This article explains how fiberglass materials balance power and control to optimize paddle performance. ↩

-

Composite Materials: Explore how combining various materials improves durability and performance in advanced paddle manufacturing. ↩

-

Hot Pressing: Discover how hot pressing methods contribute to high production efficiency and robust paddle structure. ↩

-

Thermoforming: Learn about thermoforming techniques and their benefits in achieving complex designs and uniform material distribution. ↩