Advanced production techniques are critical for ensuring high-performance custom pickleball paddles. In today’s competitive OEM1 market, partnering with an experienced manufacturer that leverages technologies such as hot pressing2, cold pressing3, and thermoforming4 is key to delivering durable, high-quality products.

Modern B2B buyers face mounting pressure to deliver sporting goods that not only meet regulatory standards but also exceed players’ performance expectations. Procurement managers, sports equipment distributors, and manufacturing decision-makers must navigate:

• Rapid changes in sports technology

• Increasing material complexity (e.g., various types of carbon fiber, fiberglass, and composite materials)

• The balance between peak performance, cost efficiency, and long-term durability

These realities set the stage for evaluating OEM manufacturers. The complexity of production processes means that selecting the right partner is a strategic decision affecting production scalability and end-product performance.

Quality custom pickleball paddles require a fine balance between performance material properties and precision engineering. Some common issues include:

-

Material Selection and Variability:

Different materials like 3K Carbon Fiber, 12K Carbon Fiber, and T300 Carbon Fiber5 deliver varying performance characteristics. The choice of material impacts paddle stiffness, rebound force, and overall durability. -

Production Process Complications:

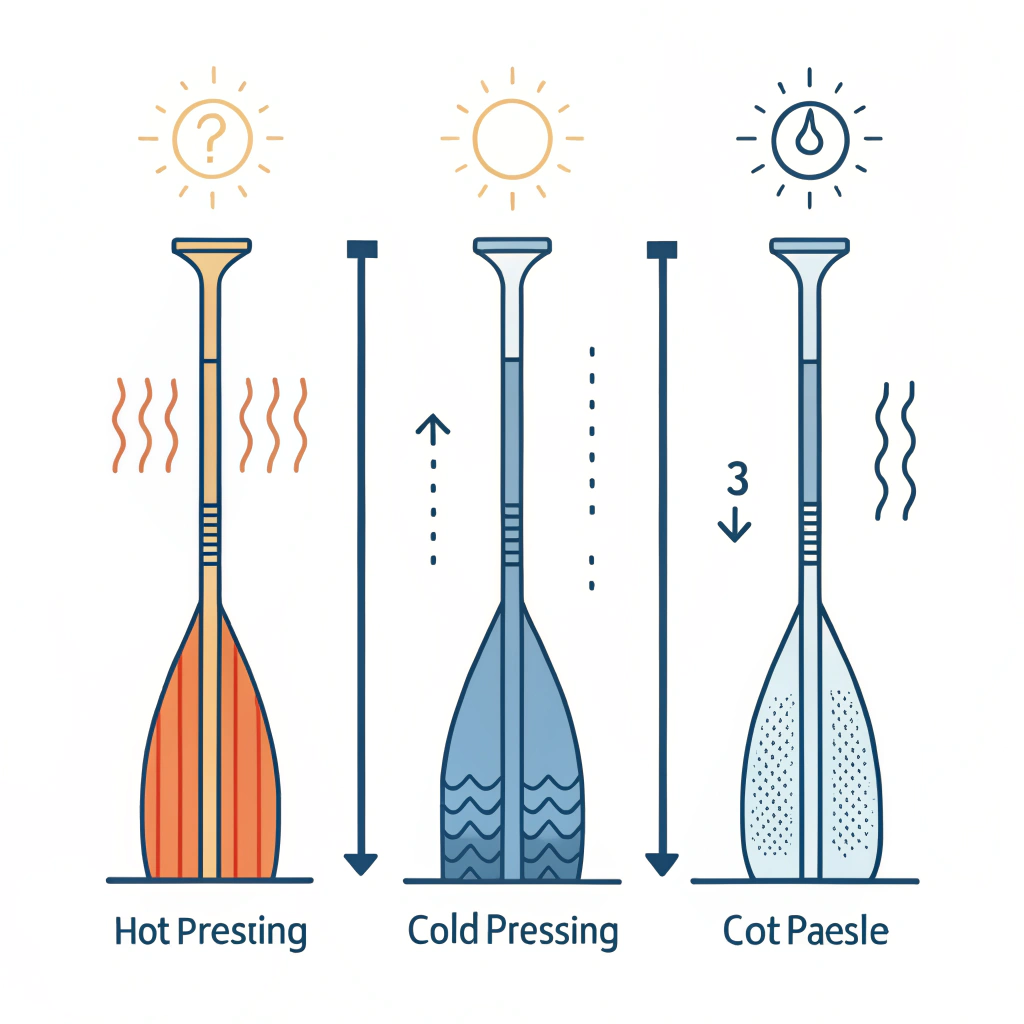

- Hot Pressing2: Offers high production efficiency and strong paddles; however, the high temperatures may also alter material properties that affect the paddle's feel.

- Cold Pressing3: Provides precise control over paddle thickness, preserving the inherent material qualities but requires longer production cycles.

- Thermoforming4: Ideal for creating complex shapes but involves higher equipment costs and longer cycle times.

-

Cost Efficiency vs. Customization:

OEM manufacturers must balance cost with technological advantage. Custom designs, such as specialized grip sizes or custom printing for team branding, add layers of complexity to production planning.

At NEX Pickleball, we harness advanced production methods along with premium materials to address these challenges. Below is a detailed solution list that outlines our approach:

| Production Process | Advantages | Limitations | Ideal Use Case |

|---|---|---|---|

| Hot Pressing | - High efficiency - Superior impact resistance - Strong structural integrity | - Possible alteration of material's natural feel - Requires significant equipment investment | High-performance paddles for competitive use |

| Cold Pressing | - Precise thickness control - Preserves material properties - Excellent ball feel | - Longer production cycles - Demands precise pressure control equipment | Paddles where control and response are paramount |

| Thermoforming | - Accommodates complex designs - Ensures uniform material distribution - Enhances product stability | - Higher equipment costs - Longer production time | Premium custom paddles or limited edition designs |

Each process is paired with the best-suited materials. For instance:

• 3K and 12K Carbon Fiber: High strength and rebound properties – perfect when combined with hot pressing for top-level performance.

• Fiberglass (E-Glass): Offers elasticity and control, ideally used with cold pressing for a better touch.

• Composite Options: Products like Carbon Fiber & Fiberglass Composites ensure the best of both worlds, enhancing both power and control.

The integration of advanced materials with precision production processes is key. To deliver a product that stands out in an increasingly competitive market, we use:

-

Carbon Fiber Variants:

• 3K Carbon Fiber: Ideal for paddles needing a robust rebound effect despite its vibration-dampening ability.

• 12K Carbon Fiber: With a higher thread density, it promises enhanced surface smoothness and durability vital for high-impact matches.

• T300 Carbon Fiber: Balancing durability with a significant reduction in weight. -

Fiberglass Options:

Fiberglass, particularly E-Glass Fiberglass, provides flexibility and an extended sweet spot, facilitating improved ball control for players ranging from amateurs to professionals. -

Composite and Core Innovations:

Using combinations such as Carbon Fiber and Fiberglass or materials like Bamboo Core and Honeycomb cores (Nomex, Aluminum, Polymer) allows for tailor-made solutions that cater to specific performance attributes like shock absorption and impact resistance.

By synchronizing our production techniques with these material advantages, we overcome the common production challenges found in custom paddle manufacturing. For example:

• Hybrid Approaches:

Some designs employ a sequence of cold pressing followed by a light hot pressing phase. This dual-method approach secures both the natural material properties and structural integrity needed for high-performance paddles.

• Custom Process Calibration:

Our state-of-the-art equipment allows us to fine-tune pressure settings during cold pressing or control temperature profiles during thermoforming. This ensures any potential deviation in paddle performance is minimized, providing consistent, high-quality output.

Quality control is a pillar of NEX Pickleball’s operations. Every paddle, regardless of the technology employed, undergoes rigorous testing for:

• Weight Distribution: Ensuring ergonomics and balanced performance.

• Grip Design: Produced in various sizes to cater to a global audience with diverse requirements.

• Surface Treatments: Applications that enhance ball grip, spin, and overall accuracy during play.

Customization is another critical element. Our clients can choose:

- Specific material combinations to maximize paddle attributes.

- Unique designs and printing options that allow for team branding or personalized color schemes.

- Optimized core materials based on the desired level of shock absorption, impacting both comfort and longevity.

Such detailed customization combined with advanced production techniques means procurement managers receive a product tailored to their specific market needs—whether it be for local recreational leagues or international competitive tournaments.

Numerous case studies underscore the benefits of our advanced production methods. For example, by transitioning to a hybrid process combining cold pressing with a controlled phase of hot pressing, one of our clients observed:

• A 15% improvement in paddle durability during high-impact testing.

• Enhanced player feedback on ball control and paddle responsiveness.

• Reduced production wastage, contributing to a 10% decrease in overall manufacturing costs.

These results not only illustrate performance gains but also demonstrate the economic benefits—lower production costs and higher market competitiveness.

Below is an overview of how advanced production methods compare with traditional processes:

| Parameter | Traditional Methods | Advanced Techniques at NEX Pickleball |

|---|---|---|

| Product Durability | Moderate | High |

| Control & Responsiveness | Good | Excellent |

| Production Efficiency | Variable (depends on method) | Consistent across processes |

| Customization Flexibility | Limited | Extensive |

| Cost Efficiency | Moderate (higher wastage) | Better with reduced material loss |

This comparison table reinforces our commitment to both quality and cost-effectiveness, two factors that are paramount for B2B decision-makers looking for a long-term OEM partner.

For procurement managers evaluating OEM partners for high-performance custom pickleball paddles, our data-driven approach offers several strategic insights:

-

Adopt a Tailored Material Strategy:

Select paddles based on the intended player profile. For high-impact competitive play, a combination of 12K or T300 carbon fiber with a Nomex honeycomb core is ideal. For recreational players, fiberglass-enhanced paddles might offer a better balance of control and comfort. -

Evaluate Production Flexibility:

Ensure that the partner has the capability to alternate between production processes like cold pressing and thermoforming to cater to different product specifications. This flexibility directly correlates with the ability to scale production cost-effectively. -

Prioritize Quality Assurance:

Look for OEM partners with rigorous quality control measures that include thorough testing of weight distribution, structural integrity, and grip optimization. Consistency in these areas leads to product reliability and customer satisfaction. -

Consider Customization Capabilities:

A manufacturer offering on-demand printing and customized design options will add value through branding and tailored product experiences for team sports and retail distribution.

In summary, leveraging advanced production techniques such as hot pressing, cold pressing, and thermoforming, along with careful material selection, is vital to manufacturing high-performance custom pickleball paddles. At NEX Pickleball, we pride ourselves on precision engineering, quality control, and the flexibility to meet diverse client needs. Our integrated approach significantly enhances the paddle's performance, durability, and overall gameplay experience, making us a strategic partner for B2B procurement managers and distributors.

For companies seeking a reliable OEM manufacturer with a proven track record in innovative production processes and material excellence, exploring a partnership with NEX Pickleball is a strategic move towards long-term supply chain efficiency and market competitiveness.

We invite you to request further details on our advanced production techniques, schedule a visit to our facility, or explore custom design options that best suit your market needs. Your next step towards a successful collaboration begins here.

-

Who makes the best pickleball paddles in China?

While there are several manufacturers in China, high-performance OEM providers like NEX Pickleball and similar industry leaders leverage advanced production techniques and premium materials to craft paddles that meet competitive standards. -

Are Selkirk pickleball paddles made in China?

Selkirk paddles have their design and quality control processes managed in the USA, though some components may originate from China. Hence, while parts of their manufacturing involve Chinese resources, the final assembly and quality assurance are conducted in the USA. -

What is the best pickleball paddle manufacturer?

Determining the best manufacturer depends on factors such as material quality, production techniques, and customization capabilities. Leading brands like Joola, Selkirk, CRBN, and Gearbox dedicate significant resources to producing premium paddles, and many OEM partners in China offer competitive, high-performance paddle solutions.

-

OEM: Discover how Original Equipment Manufacturers integrate production, quality assurance, and supply chain management to meet B2B requirements. ↩ ↩

-

Hot Pressing: Learn about hot pressing technology, its benefits, and its impact on production efficiency and product integrity. ↩ ↩ ↩2

-

Cold Pressing: Explore cold pressing processes, which offer precision control in thickness and preserve material properties for superior product performance. ↩ ↩ ↩2

-

Thermoforming: Understand thermoforming, a manufacturing technique used to create complex shapes through controlled heating and molding processes. ↩ ↩ ↩2

-

T300 Carbon Fiber: Read about T300 Carbon Fiber, a high-performance composite material known for its optimal balance between light weight and durability in high-end applications. ↩ ↩