In today’s competitive sporting goods market, selecting the right manufacturing partner is crucial. NEX Pickleball offers factory-direct production1 with deep technical expertise and robust quality control, making us an ideal partner for sourcing high-performance pickleball paddles. In this article, we detail our advanced production processes, material innovations, and customization capabilities to help you make an informed sourcing decision.

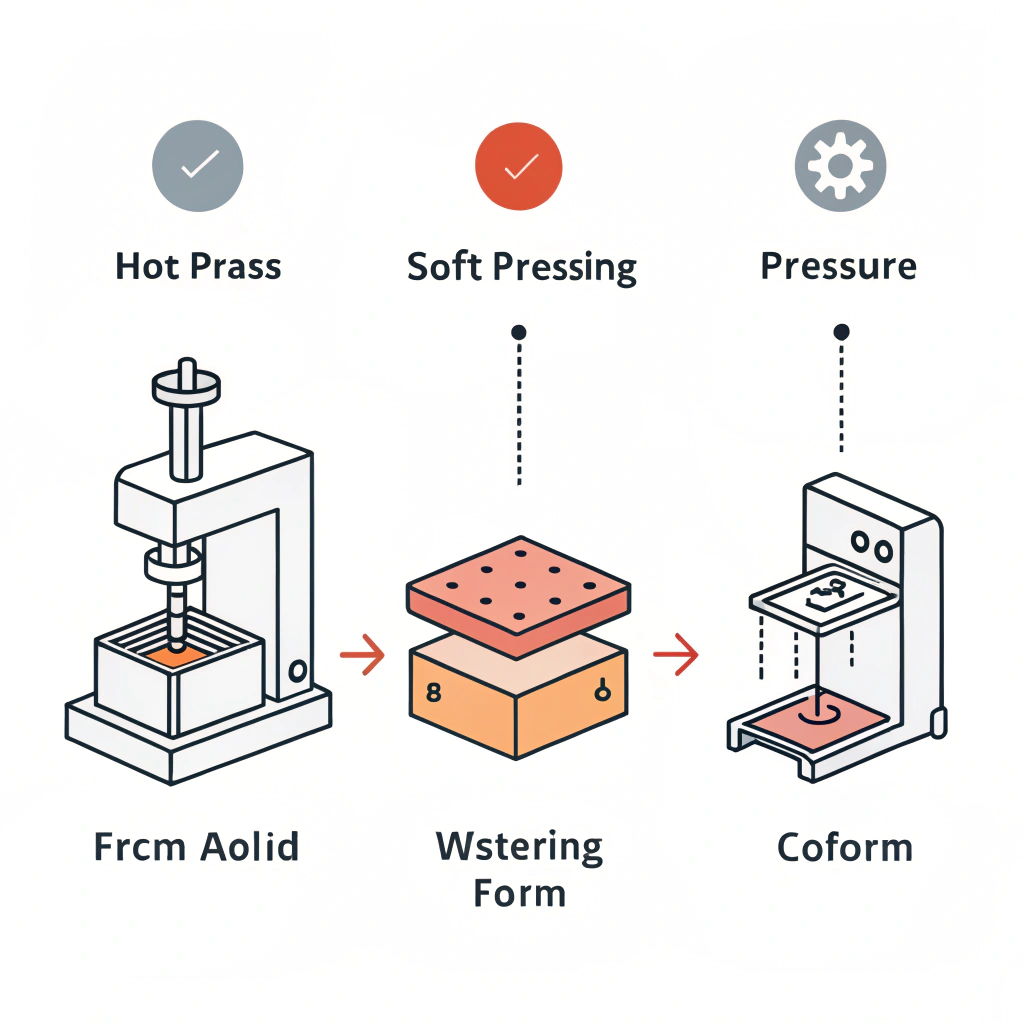

To meet the demands of professional and recreational players, NEX Pickleball employs three proven production techniques: hot pressing, cold pressing, and thermoforming2. Each process is carefully chosen based on product design requirements and desired performance characteristics. Here’s a quick breakdown of our processes:

-

Hot Pressing:

- Uses heat and pressure to achieve strong, durable paddles.

- Ideal for high-performance paddles where impact resistance is key.

- Maximizes production efficiency for bulk orders.

-

Cold Pressing:

- Applies mechanical pressure at room temperature to retain precise material properties.

- Provides enhanced control and better "feel" for players.

- Suitable for designs where precision and thickness control are critical.

-

Thermoforming:

- Involves shaping materials via molds after heating them to a softening point.

- Enables the creation of complex paddle designs with accurate material distribution.

- Offers premium quality though it requires longer production cycles.

At NEX Pickleball, we blend traditional methods with modern material science to produce paddles that cater to varied playing styles and competitive needs. Our materials portfolio includes:

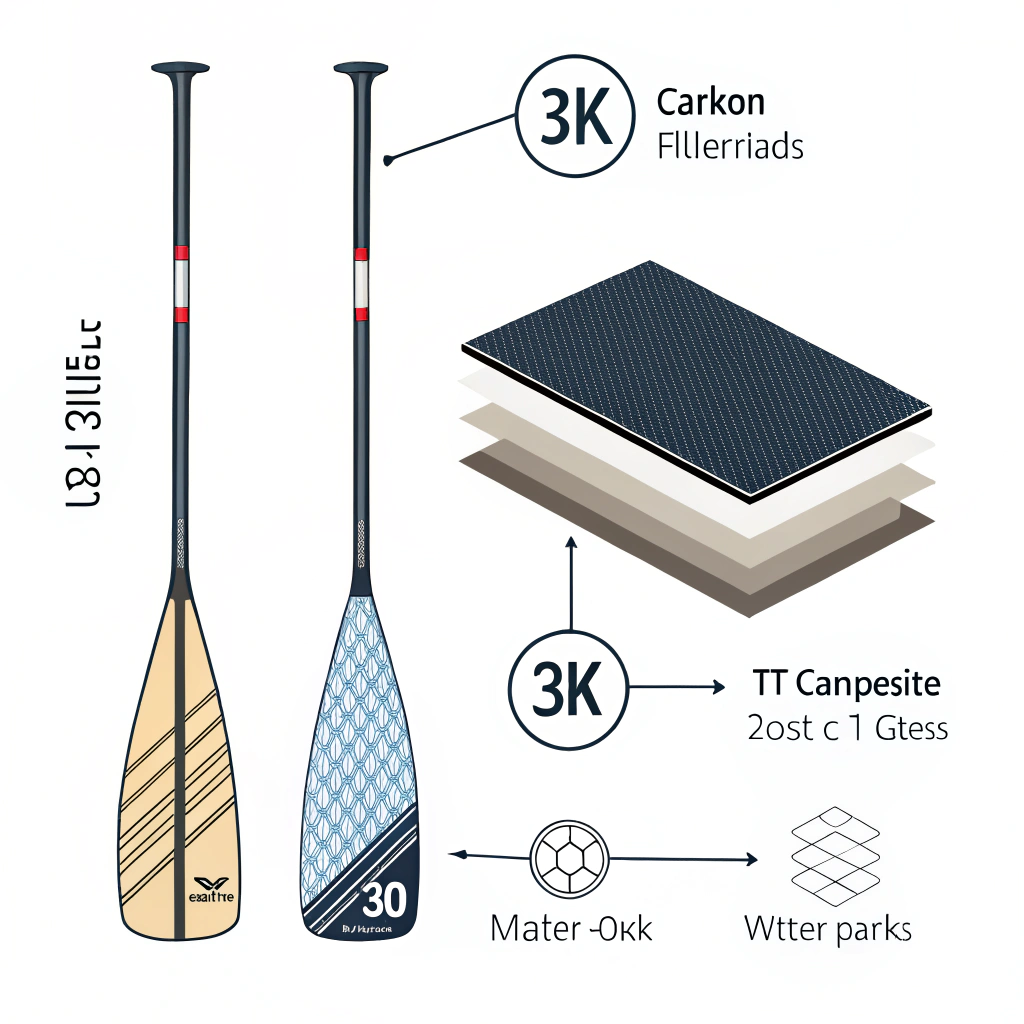

We use several types of carbon fiber, each providing unique performance benefits:

- 3K Carbon Fiber: Known for its strength and flexibility, this material offers a high rebound force with excellent durability and reduced vibration.

- 12K Carbon Fiber: With a high thread density for a smoother surface, it provides superior hardness and durability, suitable for extreme impact resistance.

- **T300 Carbon Fiber3: Offers a balanced mix of strength and weight, perfect for competitive paddles needing a harmonious balance between power and control.

- E-Glass Fiberglass: This material delivers excellent elasticity, tensile strength, and improved ball control. Ideal for players seeking a wider sweet spot without compromising durability.

Our composite designs combine multiple materials to optimize paddle performance:

- Carbon Fiber and Fiberglass Composite: Merges the benefits of both materials for exceptional strength, lightness, and flexibility.

- Bamboo Core Composite: Provides a lightweight structure with high impact resistance, ensuring long-lasting play without sacrificing precision.

- Honeycomb Core: Constructed from high-density polymers, honeycomb cores excel at shock absorption and reduce vibration.

The core of the paddle is where performance differences are most pronounced. We offer:

- **Nomex Honeycomb Core4: Made of durable polymer, perfect for shock absorption and long-lasting stability.

- Aluminum Honeycomb Core: Delivers a balanced mix of weight, power, and fine control for precision strikes.

- Polymer Honeycomb Core: Known for its superior elasticity and vibration reduction, ideal for enhancing comfort during play.

When evaluating manufacturing partners, procurement managers must focus on both the technical and commercial aspects of production. Below is a comparison table summarizing our production processes along with material benefits:

| Process/Material | Key Advantage | Industry Application | Considerations |

|---|---|---|---|

| Hot Pressing | High production volume with excellent durability | High-performance paddles in competitive settings | Potential alteration of material “feel” |

| Cold Pressing | Precision control over paddle thickness | Premium tour-level designs, custom orders | Longer production cycle |

| Thermoforming | Complex design capabilities with stable structure | Customized high-end paddles and boutique products | Higher production costs, longer lead times |

| 3K Carbon Fiber | Strength with flexibility | Recreational to competitive play | Balancing stiffness and rebound control |

| 12K Carbon Fiber | Superior hardness and smooth surface | Extreme impact-resistant, high-level competition | Increased cost for premium performance |

| T300 Carbon Fiber | Balanced weight and strength | All-rounder paddles for diverse playing styles | Requires precise production conditions |

| E-Glass Fiberglass | Enhanced ball control and durability | Recreational players focused on precision | May offer less power compared to carbon fibers |

| Composite (Carbon Fiber & Fiberglass) | Optimal balance of power and control | Versatile match strategies, both casual and competitive | Complex production process management |

| Nomex/Aluminum/Polymer Honeycomb Cores | Tailored performance based on player preference | Varying from durability to high feedback and comfort | Customization necessary to meet specific needs |

This table highlights that our commitment to precision engineering and customized production solutions is designed to match various usage scenarios—whether your focus is on competitive performance or recreational play. We ensure that every detail, from the material properties to the chosen production technique, aligns with the specific requirements of your market segment.

For a procurement manager, quality and consistency are paramount. At NEX Pickleball, our quality control processes include:

-

Rigorous Testing:

Every paddle undergoes multi-stage testing for strength, flexibility, and durability. We use both automated systems and manual inspections to check for material defects and structural integrity. -

Precision Engineering:

Our production line integrates advanced machinery calibrated to strict tolerances. This precision ensures that every paddle meets our high standards before it reaches the market. -

On-Demand Customization:

We provide OEM and ODM services5 that allow you to tailor aspects such as paddle weight, grip size, balance, and design patterns. By offering a customized approach, we align closely with your unique market requirements and branding needs. -

Factory-Direct Pricing:

By cutting out middlemen, NEX Pickleball offers competitive pricing on bulk orders while maintaining superior product quality. This significantly benefits distributors looking to secure reliable, factory-direct sports equipment.

These stringent quality checks coupled with our efficient production process ensure that you receive the optimal balance between cost and high-quality performance. Our dedication to innovation and exemplary production standards positions us as a leader in the sports gear manufacturing industry.

Our hands-on experience in manufacturing professional-grade pickleball equipment stands out as a key differentiator. Here are a few examples of how our practices have translated into success for our partners:

-

Enhanced Playability for Tournaments:

Using our advanced thermoforming process along with high-performance 12K Carbon Fiber has resulted in paddles that offer superb control and power, meeting the rigorous demands of competitive play. This is crucial for tournaments where precision and durability are non-negotiable. -

Customization Leading to Market Expansion:

Several distributors have leveraged our custom paddle options to launch exclusive branded lines. By specifying parameters like core type and grip design, they have successfully captured niche markets and enhanced their competitive edge. -

Consistent Quality in Bulk Orders:

Our reliable quality control and production efficiency have ensured that large-scale orders maintain consistent performance and quality. This has proven valuable in maintaining recurring business relationships with major distributors worldwide.

For procurement managers and sourcing specialists, the following key actions are recommended:

-

Assess Material and Process Alignment:

Evaluate your target market’s performance expectations and compare them with the available paddle materials and production processes. Our detailed product matrix helps you decide whether a carbon fiber or composite solution best fits your needs. -

Leverage Customization as a Market Differentiator:

Consider the advantage of custom paddle options. Personalized product features can significantly influence purchasing decisions among players, giving your products an edge over standard offerings. -

Evaluate Cost and Lead-Time Efficiency:

Understand the trade-offs between production techniques. While thermoforming offers premium design options, it might have longer lead times compared to hot pressing. Factor these into your sourcing timeline and inventory planning. -

Prioritize Quality Control:

A robust quality management system not only guarantees product performance but also reduces returns and enhances customer satisfaction. Our commitment to comprehensive testing ensures that you receive a consistent product quality every time. -

Factory Direct Partnership Benefits:

Direct engagement with our manufacturing facility means transparent production monitoring, cost savings, and tailored product services. This strategic advantage can enhance your competitive pricing in the market.

By carefully matching your business requirements with our production strengths, you can secure a reliable manufacturing partner committed to maximizing your market success.

In summary, NEX Pickleball stands as a robust manufacturing partner for your sports equipment needs. Our in-depth technical expertise – ranging from advanced production processes like hot pressing, cold pressing, and thermoforming, to varied material innovations such as 3K, 12K, and T300 Carbon Fiber – ensure that you have access to high-quality, customizable, and durable pickleball paddles. For procurement managers seeking solid, factory-direct partnerships with a reliable manufacturer, our comprehensive production and quality assurance methods offer clear benefits that translate into both performance and economic advantages.

We encourage you to review our technical specifications, request samples, and discuss how our customization options can cater specifically to your product strategy. Contact us today to learn more about our offerings and take the next step in optimizing your sports equipment supply chain.

Q: What brand of pickleballs are used in tournaments?

A: Tournaments often use specially designed pickleballs like the ONIX Dura Fast 40, known as the “tournament ball” for its patented design and optimized performance with two sizes of holes for enhanced play.

Q: What is a good pickle ball set?

A: A good pickleball set includes high-quality paddles, a premium bag, and quality balls. There are notable sets such as SLK NEO 2.0, GoSports GS1, Friday Original, Hoverphenix Pickleball Net Set, Amazin' Aces 4-pack, and Helium 2-Pack for Kids that stand out in the market.

Q: Is there a quality difference in pickleball balls?

A: Yes, outdoor pickleball balls, for instance, have thicker plastic and smaller holes compared to indoor balls, making them heavier. This design ensures that outdoor balls are less affected by wind and more durable, but also gives them a different play characteristic compared to indoor balls.

-

factory-direct production: Read the article to understand how bypassing intermediaries can reduce costs, enhance supply chain transparency, and improve product quality for large-scale orders. ↩

-

thermoforming: Click here to learn about the thermoforming process, which uses heat to mold materials into complex shapes, offering designers flexibility in creating custom products. ↩

-

T300 Carbon Fiber: Explore the benefits of T300 Carbon Fiber, a material known for its balanced strength-to-weight ratio, making it ideal for competitive sports equipment. ↩

-

Nomex Honeycomb Core: Learn more about Nomex Honeycomb Core, a critical material technology that enhances shock absorption and stability, contributing to the overall performance of high-quality paddles. ↩

-

OEM and ODM services: Discover how OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) services allow you to customize products, ensuring that design and production meet your exact business needs. ↩