Custom pickleball paddle manufacturing offers B2B buyers a unique opportunity to optimize performance, durability, and customization through advanced production techniques and premium materials. In short, choosing the right combination of manufacturing process and material—whether Carbon Fiber1, fiberglass, or a composite blend—ensures your paddles meet the specific needs of competitive play and brand differentiation.

In today's competitive sports equipment market, procurement managers and distributors face the dual challenge of balancing cost and performance while catering to the growing customization needs of teams and retailers. With advanced production techniques such as hot pressing, Cold Pressing2, and thermoforming, manufacturers can deliver paddles with precise weight distribution, superior impact resistance, and ergonomic comfort. In this article, we will provide a detailed technical guide on how to leverage various manufacturing processes and materials to create custom pickleball paddles that excel in every aspect—from power and control to aesthetics and durability.

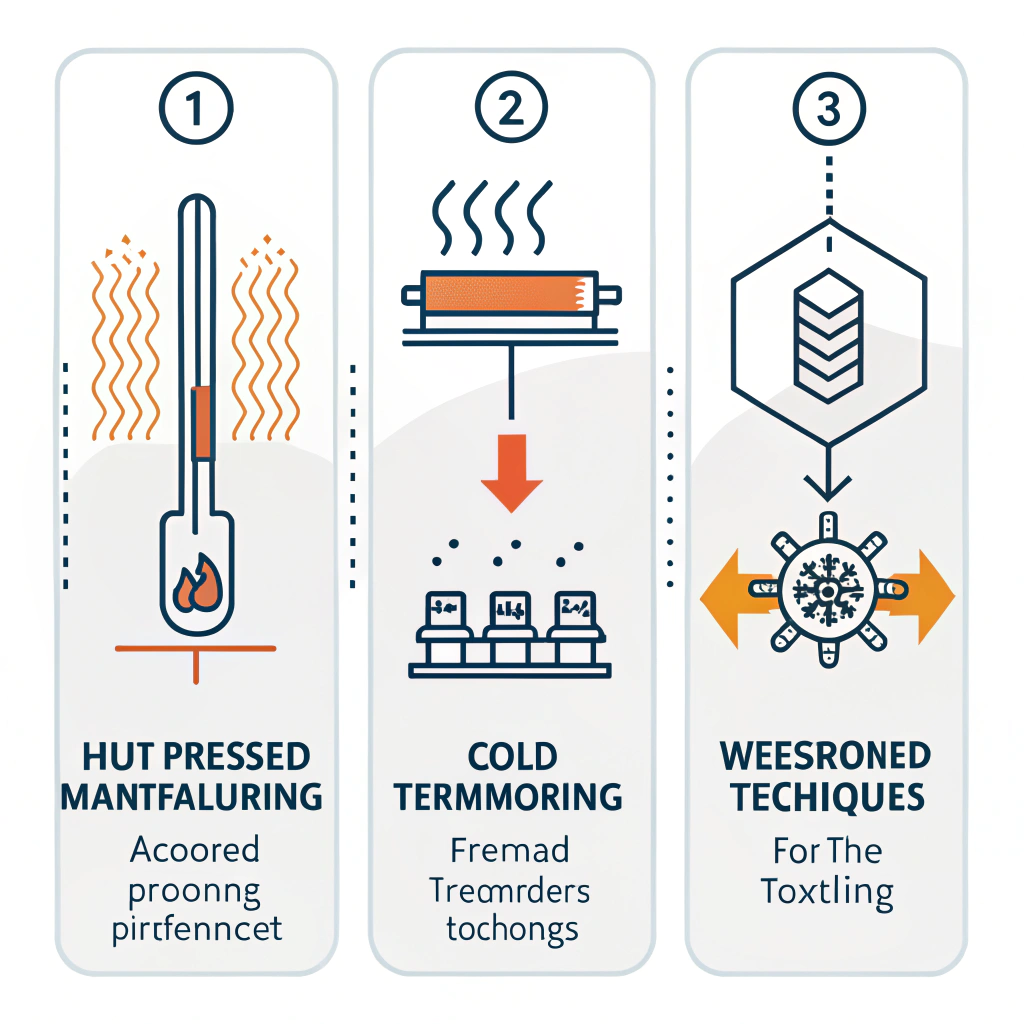

Custom pickleball paddles are built on a foundation of innovative production techniques. The three key processes—hot pressing, cold pressing, and Thermoforming3—each come with distinct benefits and trade-offs.

Hot pressing involves heating materials to a critical point and applying pressure to mold the paddle. This process is highly effective when a strong, durable paddle is required.

- Advantages:

- High production efficiency suitable for large-scale orders.

- Results in paddles with excellent impact resistance and structural integrity.

- Enhances shock absorption properties which is essential for high-performance play.

- Disadvantages:

- The heat may slightly alter the raw material’s properties, potentially impacting the responsive feel.

- Requires significant investment in specialized equipment.

Cold Pressing2 shapes the paddle material at room temperature through mechanical pressure. This method preserves the natural material properties, maintaining the optimal ball feel and precise control.

- Advantages:

- Facilitates detailed control over paddle thickness and structural uniformity.

- Maintains inherent material properties for superior tactile feedback.

- Offers a controlled production environment, yielding paddles with excellent precision.

- Disadvantages:

- Longer production cycles due to meticulous process control.

- Demands high-quality equipment to ensure consistency.

Thermoforming3 involves heating the material until it reaches a pliable state before molding it over a custom-designed form. This process is especially favored for producing paddles with intricate designs and differing thickness distributions.

- Advantages:

- Accommodates complex shapes and detailed design features.

- Enhances paddle stability by allowing a precise distribution of materials.

- Ideal for premium or custom-made paddles that require fine-tuned performance.

- Disadvantages:

- Longer production time and higher equipment costs.

- Best suited to niche or high-value production lines rather than mass production.

Below is a comparison table summarizing the key factors associated with each manufacturing process:

| Process | Advantages | Disadvantages | Best Suited For |

|---|---|---|---|

| Hot Pressing | High efficiency, strong impact resistance, excellent structural integrity | Potential alteration of material feel, high equipment cost | High-performance and large-scale production |

| Cold Pressing | Precise control, maintains original material properties, enhanced responsiveness | Longer cycle times, requires precision instruments | Custom paddles where control and feel are prioritized |

| Thermoforming | Accommodates intricate designs, excellent material distribution | Longer production time, higher capital investment | Premium products, exclusive design editions |

The choice of materials is pivotal when it comes to producing a paddle that meets both performance and aesthetic criteria. Every material brings a unique combination of benefits to the final product. Here we examine the primary options:

Carbon Fiber is a cornerstone material in high-end pickleball paddles. Among the types used, each serves different performance goals:

-

3K Carbon Fiber:

Known for its flexibility combined with strength, 3K enables paddles to achieve high rebound force and durability. It minimizes vibration during play, making it ideal for players requiring quick response. -

12K Carbon Fiber:

With a denser thread configuration, this fiber offers a smoother surface finish and greater hardness. The increased impact resistance makes it suitable for competitive scenarios where longevity and strength are vital. -

T300 Carbon Fiber:

T300 provides a balanced combination of tensile strength and lightness. Its attributes contribute to paddles that are both robust and agile, serving both offensive and defensive playing styles.

Paddles constructed with fiberglass strike a balance between power and control, offering a wider sweet spot. Fiberglass is often favored for its flexibility and improved ball control. For example, E-Glass Fiberglass is chosen for its excellent elasticity and tensile strength, delivering an enhanced feel when striking the ball.

For a tailor-made approach, composite materials blend the attributes of different fibers:

-

Carbon Fiber and Fiberglass Composite:

This combination leverages the durability and stiffness of carbon fiber with the smoother ball control offered by fiberglass. It creates a paddle that excels both in power and responsive touch. -

Bamboo Core Composite:

Employing bamboo cores ensures the paddle retains a lightweight structure while absorbing impacts effectively. The natural resilience of bamboo supports long-lasting play and a clear hitting feel. -

Honeycomb Core:

Typically constructed from high-density polymers, a honeycomb core is designed for superior shock absorption. This configuration reduces vibrations and extends the lifespan of the paddle, offering stability during intense play.

The core material is critical because it directly affects the paddle’s hardness and vibration damping:

-

Nomex Honeycomb Core4:

Manufactured from durable polymers, Nomex is renowned for its exceptional shock absorption. It is a favorite for players looking for longevity combined with consistent performance. -

Aluminum Honeycomb Core:

Delivering a balanced combination of power and control, an aluminum core is often chosen for competitive paddles that require precise weight distribution. -

Polymer Honeycomb Core:

This core is popular for recreational paddles, providing a softer hit with reduced vibrations to improve comfort during extended play.

By carefully selecting the appropriate material for each section of the paddle, manufacturers can craft customized products that perfectly match the desired play style and performance level.

One of the standout features in modern pickleball paddle manufacturing is the opportunity for extensive customization. B2B customers can specify a range of features during the design process. This level of customization not only boosts performance but also enables strong market branding and team identity. Here are the critical customization options available:

Procurement managers can choose to upload custom images, logos, or text designs for the front and back of the paddle. This personalization allows teams or retailers to align the product with their branding strategy. Custom color selections are also available for additional parts like the edge guard, grip tape, and band.

The overall performance of a paddle is strongly influenced by its weight distribution. By adjusting the composition of materials—for example, incorporating a bamboo core composite or an aluminum honeycomb core—manufacturers can fine-tune the paddle’s balance. This enables an optimal mix of agility and power, tailored to the specific demands of high-level play.

The ergonomic design of the paddle, including grip size options, surface textures, and handle shapes, plays a significant role in user comfort. Ensuring that the grip suits different hand sizes enhances control during play. Our production techniques, particularly cold pressing, allow for precise control over these dimensions, thereby improving comfort and performance.

Quality control is paramount in our manufacturing process. Every paddle undergoes rigorous testing to ensure it meets the highest standards of strength, flexibility, and performance consistency. Techniques like detailed pressure control during cold pressing or precision temperature regulation during thermoforming guarantee that the final product is both durable and reliable.

For procurement managers, the key decision often revolves around balancing enhanced performance features with cost efficiency. Here’s a closer look at addressing this challenge:

-

Production Process Trade-offs:

- Hot pressing may be more cost-effective for large-scale production but can slightly alter material properties.

- Cold pressing, while delivering superior control, involves longer cycle times and higher precision costs.

- Thermoforming offers unmatched design capabilities for premium custom orders yet requires more time and investment.

-

Material Choices and Their Impact on Performance:

- Carbon Fiber variants generally yield high-performance paddles but come at a premium cost.

- Fiberglass options provide excellent ball control and larger sweet spots which may suit a broader range of players.

- Composite materials enable a customizable balance between performance and price, making them appealing to both competitive and recreational markets.

-

Customization vs. Standardization:

Customization brings substantial branding benefits, but it requires additional design iterations and quality control measures. Manufacturers must work closely with B2B clients to understand the specific performance and aesthetic requirements, ensuring that customization does not compromise the paddle's overall functionality. -

Ergonomic and Quality Considerations:

Balancing the ergonomic features—like grip size, weight distribution, and surface texture—while meeting rigorous testing standards is crucial. This comprehensive approach not only ensures player comfort but also extends the product's lifespan, thus providing value for both the retailer and the end-user.

Custom pickleball paddle manufacturing represents an intersection of innovative engineering, material science, and design creativity. By leveraging advanced processes like hot pressing, cold pressing, and thermoforming, manufacturers can produce paddles that are both high-performing and highly customizable. With premium materials such as various carbon fiber grades, fiberglass, and composite cores at your disposal, you are empowered to meet the exacting standards of competitive play and brand differentiation.

For procurement managers and sports equipment distributors, the technical nuances detailed in this guide serve as a roadmap to making informed decisions. When evaluating your next order of custom pickleball paddles, consider how the manufacturing process and material choices will impact performance, durability, and cost. Engage with experienced manufacturers who offer transparent quality control and customization options tailored to your market needs.

Take the next step by reaching out for a detailed consultation and sample evaluation. With the proper technical and strategic insights, you can confidently source paddles that not only match your performance criteria but also elevate your brand presence in a competitive market.

People Also Ask

-

Can I design my own pickleball paddle?

Yes, you have the option to create a custom paddle design by uploading your own images, logos, or text. Manufacturers like us provide design assistance and allow you to choose custom colors for various paddle components, ensuring a fully personalized product that meets your branding requirements. -

Which company makes the best pickleball paddles?

While several top brands are available in the market, our expertise in advanced production techniques and premium material selection positions us among the leading manufacturers. Our commitment to consistent quality control and customization makes our paddles a preferred choice for competitive performance and tailored branding.

-

Carbon Fiber: Reading this article will provide insights into the advanced properties, variants, and manufacturing benefits of carbon fiber, a critical material for high-end sports equipment. Back ↩

-

Cold Pressing: Learn about the cold pressing technique and its role in maintaining material integrity and achieving precise control in manufacturing. Back ↩ ↩2

-

Thermoforming: Discover how thermoforming processes enable the creation of complex and intricately designed products, offering customization and precision in molding materials. Back ↩ ↩2

-

Nomex Honeycomb Core: Explore the exceptional shock absorption and durability benefits of Nomex honeycomb cores, important for performance and longevity in sports equipment. Back ↩