Quick Answer: NEX Pickleball stands out as a reliable manufacturing partner for bulk, custom pickleball paddles in China, offering advanced production processes and high-performance OEM/ODM Services1 for global distributors.

In today’s competitive sports equipment market, sourcing managers and procurement executives need a partner that not only excels in scale production but also provides customizable, high-quality Custom Pickleball Paddles2. With increasing demand for performance-driven paddles, it is essential to evaluate manufacturing partners that combine technical excellence with competitive pricing. NEX Pickleball, based in Jiaxing, Zhejiang, China, is one such partner renowned for its state-of-the-art production techniques and innovative material applications.

Procurement managers face several challenges when procuring pickleball paddles in bulk. The primary issues include:

• Ensuring the chosen manufacturer can consistently produce paddles with precise material properties such as optimal weight distribution, surface texture, and durability.

• Balancing cost considerations with high-performance requirements.

• Navigating the various production processes – such as hot pressing, Cold Pressing3 and thermoforming – to select a method that best meets performance and customization needs.

The increasing need for differentiation in the market has prompted sports equipment distributors and retail chains to seek manufacturing partners that can provide custom solutions, precise quality control, and flexible production cycles. These requirements further drive the need for detailed insights into production processes and material options.

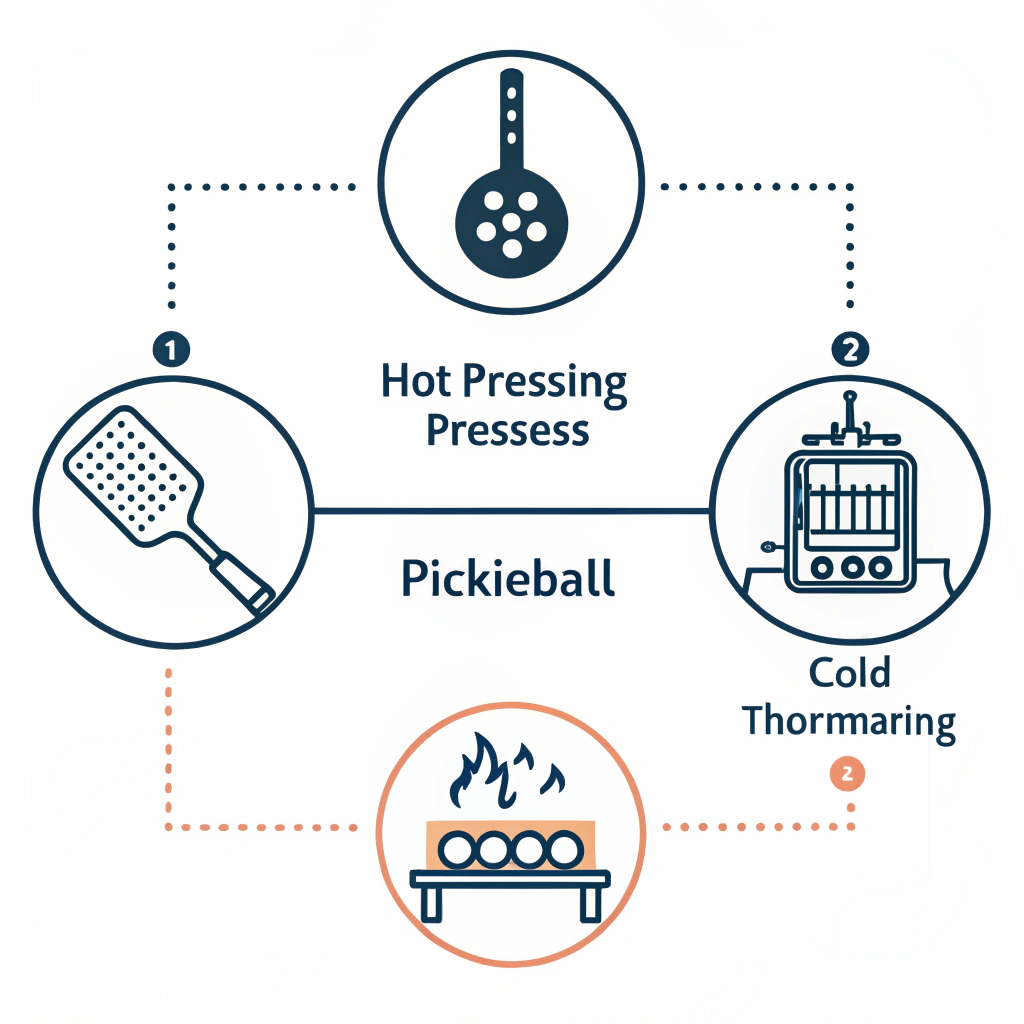

NEX Pickleball employs three main production processes. Each has its own technical merits and may be more suitable depending on your specific product requirements.

Hot pressing involves heating the materials and applying pressure to form robust paddles. This technique is particularly favored for high-performance paddles where structural integrity and strength are paramount.

• Advantages:

- High production efficiency: Ideal for large-scale manufacturing.

- Enhanced impact resistance: Produces strong paddles that withstand intense play.

- Maintained structural integrity: Essential for competitive use.

• Disadvantages:

- Potential alteration of material properties: Excessive heat can affect the paddle’s feel.

- High equipment investment: Requires specialized machinery.

Cold Pressing3 shapes materials at ambient temperatures under mechanical pressure, which is essential for designs needing precise control over the paddle structure.

• Advantages:

- Precision and control: Retains the material's inherent properties for optimal responsiveness.

- Superior ball feel: Maintains elasticity and ensures a more controlled hit.

- Flexible customization: Suitable for paddles requiring specific thickness and grip designs.

• Disadvantages:

- Longer production cycles: Lower efficiency compared to hot pressing.

- Demanding precision: Requires high-quality equipment and precise pressure calibration.

Thermoforming4 uses controlled heating to soften the material before molding it into a paddle shape. This process is ideal for achieving intricate designs and tailored material distribution.

• Advantages:

- Intricate design capability: Perfect for premium, custom-made products.

- Stable structural performance: Ensures even material distribution for balanced weight.

- Versatile material use: Compatible with high-performance materials like carbon fibers.

• Disadvantages:

- Increased production time: More time is needed to achieve the desired shape.

- Higher equipment costs: Investment in molds and specialized machinery is required.

The following table summarizes the key aspects of each production process:

| Production Process | Advantages | Disadvantages |

|---|---|---|

| Hot Pressing | High efficiency, strong impact resistance, robust structure | May alter material feel, high equipment investment |

| Cold Pressing | Precise control, better ball feel, flexible customization | Longer cycles, demands precise machinery |

| Thermoforming | Intricate design, stable performance, versatile material compatibility | Longer production time, higher production costs |

Quality and performance in pickleball paddles are not just about the production process; the choice of materials plays a central role. NEX Pickleball utilizes premium materials:

• Carbon Fiber5 Options:

- 3K Carbon Fiber: Known for its strength and flexibility, offering high rebound force and excellent vibration reduction.

- 12K Carbon Fiber: Boasts a higher thread density, providing a smoother surface and extreme impact resistance—a key for competitive play.

- T300 Carbon Fiber: Balances tensile strength with lightweight properties, ideal for balanced performance.

• Fiberglass (E-Glass Fiberglass): This material is selected for its elasticity and excellent ball control, making it ideal for paddles requiring a wider sweet spot and durability.

• Composite Materials:

- Carbon Fiber and Fiberglass Composite: Combines the benefits of both materials to achieve a balanced mix of power, control, and light weight.

- Bamboo Core Composite: Provides a lightweight core that enhances impact resistance and offers a crisp hitting feel.

- Honeycomb Core Composites (Nomex, Aluminum, Polymer): Each type of core delivers tailored shock absorption and stability. For instance, Nomex Honeycomb Core offers excellent durability, while Polymer Honeycomb Core reduces vibration and enhances elasticity for comfortable play.

Choosing the right material is crucial depending on your target market—whether it is high-level competitive players or casual recreational players. NEX Pickleball ensures every paddle is engineered with optimal weight distribution, ergonomic grip design, and surface treatments to enhance ball grip, spin, and precision.

For a procurement executive evaluating potential partners, quality control is non-negotiable. At NEX Pickleball, rigorous testing protocols are in place to ensure each paddle meets high standards of strength, durability, and performance. Our multi-step quality assurance process includes:

• Material Testing: Every batch of carbon fiber, fiberglass, and composite material undergoes strict testing to verify tensile strength and flexibility.

• Process Validation: Each production process (hot pressing, cold pressing, thermoforming) is continuously monitored to ensure consistency in paddle construction.

• Ergonomic Design Reviews: Paddles are tested for optimal weight distribution and grip ergonomics, crucial for reducing player fatigue and enhancing performance.

• Customization Flexibility: Clients can specify design details such as paddle weight, balance, grip size, and even on-demand print services, which is a defining feature for OEM/ODM Services.

Our capacity to offer customized options is particularly beneficial for businesses looking to promote unique branding or tailored performance specifications. This flexibility allows for personalized design, ensuring that each order meets both aesthetic and functional requirements.

For sourcing executives and procurement managers evaluating bulk manufacturing partners for your sports equipment lineup, consider the following action points when working with NEX Pickleball:

-

Evaluate Material Options:

Understand your target market's needs. For competitive play, carbon fiber variants like 12K or T300 might be ideal, whereas players seeking a broader contact area may benefit from fiberglass or composite materials. -

Assess Production Techniques:

Choose between hot pressing, cold pressing, or thermoforming based on your requirements for production efficiency, cost sensitivity, and the tactile feel of the finished product. Ask the manufacturer to provide data or samples that highlight the differences. -

Confirm Quality Assurance Processes:

Request detailed documentation on quality control measures. NEX Pickleball's rigorous testing protocols ensure every paddle meets high durability and performance standards. -

Explore Customization Capabilities:

If your brand values uniqueness, ensure the manufacturer offers customizable printing options along with tailored paddle specifications, which can strengthen your market proposition. -

Engage in Pilot Testing:

Before a full-scale order, consider ordering a pilot batch. This ensures that product specifications, including material performance and manufacturing consistency, align with your business needs.

The dynamic sports equipment market is witnessing a shift towards performance-enhancing designs and materials. Today’s players demand more than just durability—they require a blend of control, power, and ergonomic comfort. This evolving trend emphasizes the need for manufacturers that not only produce volume but also innovate in material sciences and design.

NEX Pickleball’s focus on advanced production methods like thermoforming and cold pressing aligns with these market expectations. Moreover, their expertise in using high-performance Carbon Fiber, Fiberglass, and cutting-edge composite materials underlines their commitment to innovation. This focus positions them as a key player amid rising competition.

Procurement managers should consider the broader supply chain implications, including lead times, cost consistency, and after-sales support. Collaborating with a partner that provides scalability and consistent quality assurance, such as NEX Pickleball, can significantly streamline your inventory management and reduce operational risks.

In conclusion, selecting the right manufacturing partner for your Custom Pickleball Paddle needs involves a multi-faceted evaluation of production processes, material choices, and quality assurance protocols. NEX Pickleball offers a compelling solution with its advanced production techniques, diverse material portfolio, and comprehensive quality control processes. By integrating actionable steps into your sourcing strategy, you can ensure that the final product not only aligns with your cost requirements but also delivers on performance and durability.

For sports equipment distributors and B2B sourcing teams, a partnership with NEX Pickleball offers both reliability and innovation. As the market continues to evolve, aligning with manufacturers who emphasize technical excellence, quality control, and flexibility in customization will be paramount in maintaining a competitive edge.

People Also Ask

• Who makes the best pickleball paddles in China?

Answer: NEX Pickleball is a leading manufacturer in China known for its advanced production processes and high-quality materials. With extensive experience in crafting high-performance paddles using techniques like hot pressing, cold pressing, and thermoforming, NEX Pickleball is a trusted choice among industry professionals.

• What company makes the best pickleball paddles?

Answer: While many companies offer quality pickleball paddles, leading manufacturers such as JOOLA and Selkirk compete in the market. NEX Pickleball, however, stands out for its customizable options, strict quality control, and large-scale production capabilities that meet B2B requirements, making it an excellent choice for bulk orders and OEM/ODM services.

• Are Selkirk pickleball paddles made in China?

Answer: Selkirk & Selkirk LABS paddles are designed and quality-controlled in the USA, yet some components or assembly steps may originate from China. This mixed production approach is common in the industry to balance high-quality American design with the efficiency of Chinese manufacturing.

-

OEM/ODM Services: Click to learn about the tailored manufacturing and design solutions that allow brands to customize products to their specific market needs. ↩

-

Custom Pickleball Paddles: Click to discover how custom-designed paddles can enhance brand identity and performance in competitive sports. ↩

-

Cold Pressing: Click to explore the process of cold pressing, a technique that shapes materials at ambient temperatures for precision manufacturing. ↩ ↩2

-

Thermoforming: Click to understand how thermoforming uses controlled heat to create intricately molded products with diverse material applications. ↩

-

Carbon Fiber: Click to delve into the properties of carbon fiber, a high-performance material known for its strength, light weight, and durability in competitive equipment. ↩