Pickleball paddle construction relies on a combination of advanced materials engineering1 and specialized production processes. In simple terms, the integration of state‐of‐the‐art manufacturing techniques with premium materials creates paddles that deliver optimal performance, durability, and playability.

In today’s competitive sports equipment market, engineering managers, product development specialists, and procurement decision-makers are looking for technical insights into how pickleball paddles are manufactured. At NEX Pickleball, we break down the intricacies of production processes—from material selection to structural design—to help you understand how our high-performance paddles are built and how these methods can influence your own manufacturing or product selection.

The performance of a pickleball paddle is largely determined by the quality and composition of its materials. High-end paddles employ a mix of carbon fiber, fiberglass, and various composite materials2. Each material has unique characteristics that contribute to either power, control, or durability.

- 3K Carbon Fiber: Offers strength and flexibility, lending exceptional durability while reducing vibration.

- 12K Carbon Fiber: Features a higher thread density for a smoother surface, increased hardness, and improved impact resistance. This option is ideal for competitive play where extreme performance is needed.

- T300 Carbon Fiber: Known for its high tensile strength, T300 provides a careful balance between lightness and durability, making it a popular choice for balanced performance.

- Fiberglass: Provides a perfect equilibrium between power and control. Its elasticity and broader sweet spot ensure excellent ball manipulation.

- Composite Materials: By blending carbon fiber with fiberglass, or incorporating materials like bamboo core or honeycomb structures, paddles achieve an optimized mix of strength, weight, and flex. For instance, a carbon fiber and fiberglass composite can deliver both power and control, appealing to a wide range of players.

The core of a pickleball paddle plays a critical role in determining its overall performance. Common core materials include:

- Nomex Honeycomb Core: Offers outstanding shock absorption and long-term durability.

- Aluminum Honeycomb Core: Strikes an excellent balance between weight and performance.

- Polymer Honeycomb Core: Provides enhanced elasticity and minimizes vibration, ideal for players seeking a softer hitting feel.

Each of these material decisions impacts factors such as weight distribution, structural integrity, and the tactile feedback during play. The proper combination of materials and core types is essential in crafting a paddle that meets the rigorous demands of modern pickleball.

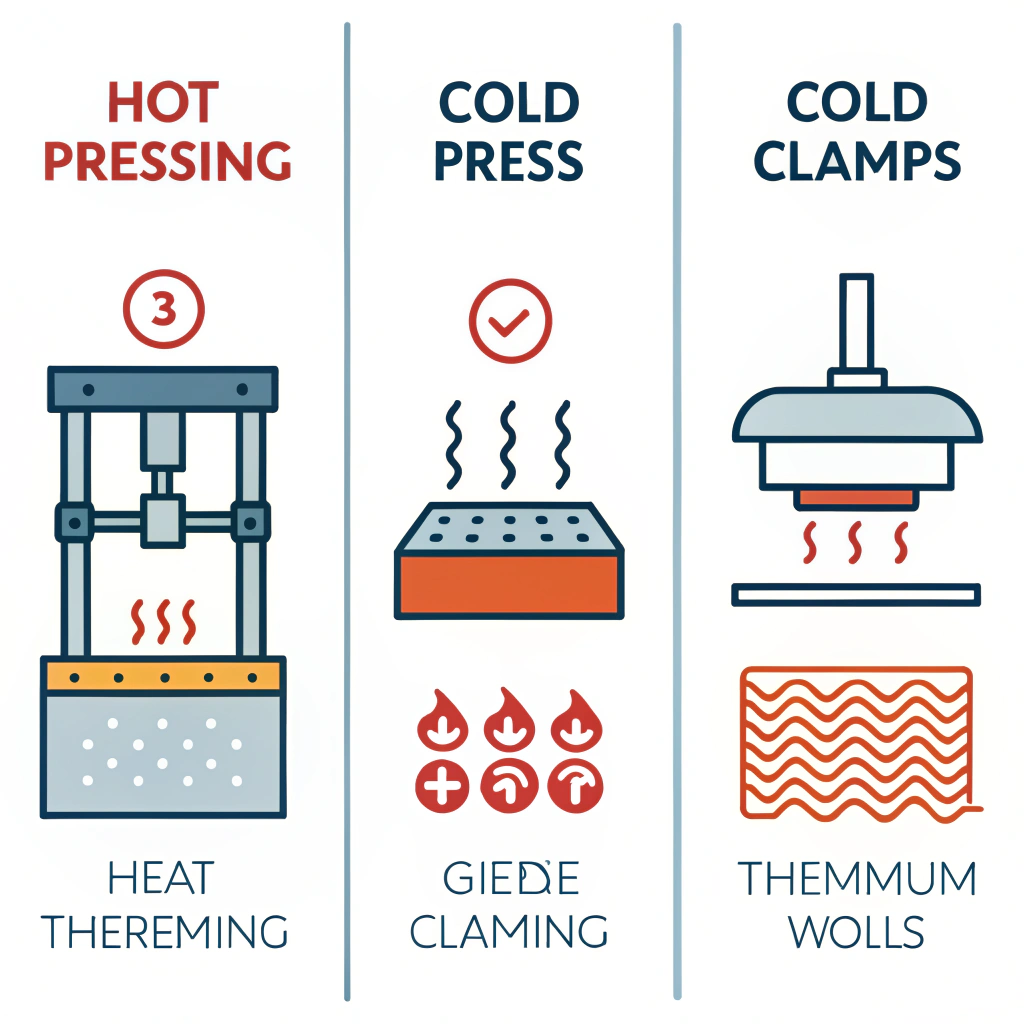

Manufacturing advanced pickleball paddles involves three main production methods, each with its distinct advantages and limitations. Understanding these processes gives crucial insights into production efficiency, product consistency, and customizability—key factors for careful procurement decisions.

Hot pressing involves applying heat and pressure simultaneously to shape the paddle components.

Key advantages include:

- High Production Efficiency: Suited for large-scale manufacturing.

- Enhanced Impact Resistance: Results in a robust paddle with outstanding durability.

- Structural Integrity: Ensures that paddles withstand high-performance uses.

However, it also has limitations:

- Material Alteration Risks: Excessive heat can change some material properties, affecting the paddle’s feel.

- High Equipment Investment: Requires specialized and expensive equipment.

This process shapes the paddle material at room temperature using mechanical pressure, ideal for designs demanding precise control.

Advantages of cold pressing include:

- Precision: Offers meticulous control over paddle thickness and structure.

- Material Preservation: Maintains original material properties, ensuring better control and flexibility.

- Superior Ball Feel: Enhances responsiveness and overall playability.

Cold pressing isn’t without its challenges:

- Longer Production Cycles: Typically slower than hot pressing, which may impact efficiency.

- Demanding Equipment: Needs very accurate pressure control for consistent results.

Thermoforming utilizes heat to soften the material, followed by molding into the desired shape.

This process is highly beneficial for:

- Complex Designs: Allows creation of paddles with intricate shapes and precise material distribution.

- Stability Maintenance: Limits deformation, ensuring a stable, high-performance product.

- Customization: Particularly suited for premium and custom-made paddles.

The disadvantages include:

- Extended Production Time: Requires more time compared to hot pressing.

- Higher Equipment Costs: Generally more expensive due to sophisticated mold designs and heating systems.

The following table provides a clear comparison of these three production methods:

| Production Process | Advantages | Limitations |

|---|---|---|

| Hot Pressing | - High efficiency - Robust impact resistance - Strong structural integrity | - Possible material property alteration - High initial equipment cost |

| Cold Pressing | - Precise control over structure - Retains material properties - Superior tactile ball feel | - Longer production cycles - Requires precise equipment |

| Thermoforming | - Accommodates complex designs - Maintains paddle stability - Ideal for custom paddles | - Extended production time - Higher production costs |

Each manufacturing process offers unique benefits that can be matched to specific design goals. For instance, companies looking to scale production might favor hot pressing, while those aiming for unique, high-performance designs may invest in thermoforming.

High-performance pickleball paddles are not simply mass-produced items; they represent the culmination of intense research, testing, and customization. At NEX Pickleball, we understand that different players and organizations have unique needs. This is why our paddle design incorporates factors such as weight distribution, ergonomic grip design, and surface texture considerations.

Clients can specify:

- Design Preferences: Custom shapes, colors, and graphic designs for branding.

- Weight and Balance: Adjustments to the distribution for enhancing power or control.

- Grip Sizes and Textures: Options tailored to individual hand sizes for improved handling.

- Material Combinations: Choices ranging from premium carbon fiber types to diverse composite integrations.

By allowing such customization, manufacturers not only meet individual or team requirements but also foster innovation within the sports equipment sector. This level of personalization also ensures that higher levels of quality control are maintained through rigorous testing and evaluation protocols.

Quality control remains paramount in ensuring that each paddle meets the high standards expected by competitive players and recreational enthusiasts alike. At our facilities:

- Material Quality Checks: Each batch of raw materials undergoes strict inspection for consistency.

- Rigorous Testing: Paddles are tested for performance characteristics like rebound force, vibration damping, and impact resistance.

- Iterative Feedback: Continuous feedback from play-testing helps refine production techniques and material application.

- Precision Engineering: Advanced production techniques such as hot pressing, cold pressing, and thermoforming are calibrated to ensure uniformity and reliability in each product.

These measures are essential in building trust with procurement decision-makers, ensuring that the production system delivers on its promise of performance and durability.

The insights gained from understanding the materials and production processes extend real value to the sports equipment manufacturing sector. By analyzing and adopting the right combination of manufacturing techniques, companies can:

- Enhance Product Performance: Optimize paddles to provide targeted benefits like increased power, better control, or reduced vibration.

- Improve Production Efficiency: Choose processes that best align with their production volumes and custom design requirements.

- Drive Innovation: Implement advanced materials and customize production techniques to stay ahead of market trends.

- Reduce Costs: By selecting the optimal production process, companies can balance upfront investments with long-term returns, ensuring competitive product pricing.

For engineering managers and product development specialists, the ability to dissect each production stage—and understand its impact on the final product—empowers them to make informed decisions regarding vendor selection, process improvements, and innovation strategies.

In conclusion, the manufacturing processes used in pickleball paddle production are a blend of material science, advanced engineering, and precise manufacturing techniques. From carbon fiber variants and composite materials to processes such as hot pressing, cold pressing, and thermoforming, each element contributes to a paddle’s overall performance. For procurement decision-makers, the key is understanding which combination of materials and processes aligns best with their performance requirements and production efficiency needs.

As the demand for high-performance sports equipment grows, staying informed about production techniques and material innovations will be vital. Evaluating production efficiencies and material properties can drive decisions that not only enhance product quality but also lower lifecycle costs.

We encourage procurement professionals to further inquire about customized paddle options, detailed production protocols, and quality control measures. These discussions will undoubtedly support strategic decisions that foster both innovation and cost efficiency in product development.

Q: Why do some pickleball paddles have a hole in them?

A: The holes are intentionally designed to help improve the paddle’s aerodynamic profile. By reducing swing weight and enhancing spin on the ball, they allow for a more efficient power transfer.

Q: Does an expensive pickleball paddle really make a difference?

A: Yes. The performance differences between paddles stem from hundreds of attributes, including material quality, weight, shape, craftsmanship, and the technology used in production. These factors collectively impact control, power, and durability.

Q: Why is the diadem vice paddle illegal?

A: According to USAPA regulations, the presence of holes in a paddle is prohibited. This restriction is in place to maintain fairness and performance consistency in sanctioned pickleball competitions.

-

advanced materials engineering: Learn about the integration of novel materials and cutting-edge processes that drive performance improvements and durability in high-end products. ↩

-

composite materials: Discover how combining different materials creates a synergy that enhances strength, reduces weight, and optimizes performance outcomes. ↩

-

Hot Pressing: Understand the process of applying heat and pressure simultaneously to achieve superior structural integrity and production efficiency in manufacturing. ↩

-

Cold Pressing: Explore how cold pressing preserves inherent material properties, offering enhanced precision and maintaining optimal control and flexibility. ↩

-

Thermoforming: Delve into the thermoforming process and how it enables the creation of complex, customized shapes while maintaining high stability and performance. ↩