In brief, NEX Pickleball combines advanced production processes, premium materials, and rigorous quality control to deliver high-performance pickleball paddles that meet the demanding requirements of B2B buyers looking for exceptional quality, durability, and cost-effectiveness.

In today’s competitive sports equipment market, B2B procurement managers and wholesale distributors face significant challenges when evaluating suppliers for pickleball paddles. Reliable manufacturing, advanced production processes, and the use of high-performance materials are critical factors that can directly impact the success of their product lines. The key questions are: How do you ensure consistent product quality? Which production process best meets the needs of competitive play? And what materials offer the optimal balance of power, control, and durability?

For many in the sports equipment industry, making the right decision requires a detailed analysis of technical specifications, production methodologies, and material innovations. NEX Pickleball is uniquely positioned to address these challenges and provide a robust and flexible solution for various market needs.

Pickleball paddles are not a one-size-fits-all product. Each paddle’s performance is heavily influenced by the materials used and the production process employed. Some of the most critical aspects include:

- Material Consistency: The type of materials (e.g., various forms of carbon fiber1, fiberglass, or composite blends2) directly affects performance factors like power, control, and durability.

- Production Methods: Techniques such as hot pressing3, cold pressing4, and thermoforming5 each offer distinct advantages and limits. The choice of method influences the paddle’s texture, impact resistance, and overall feel.

For B2B buyers, understanding these elements helps in selecting a supplier who can consistently deliver products that meet stringent quality standards and performance requirements.

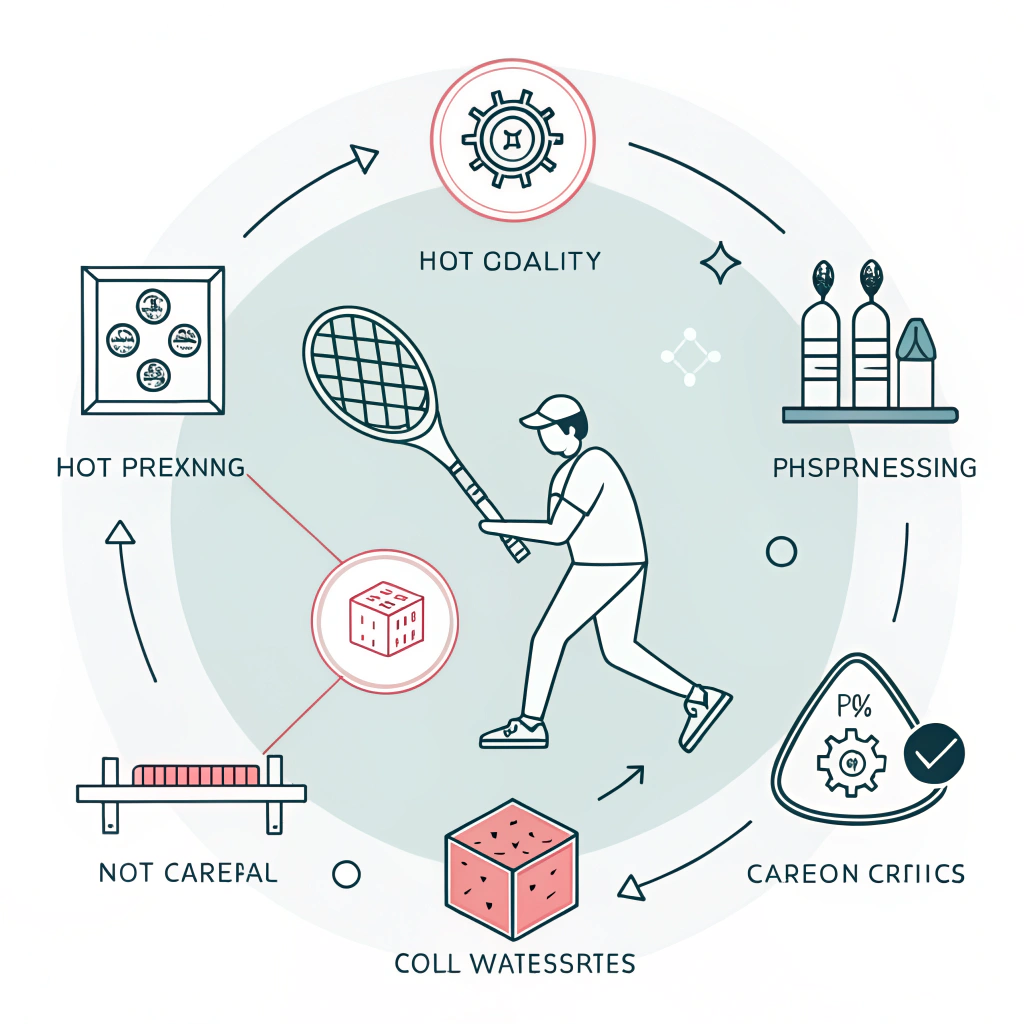

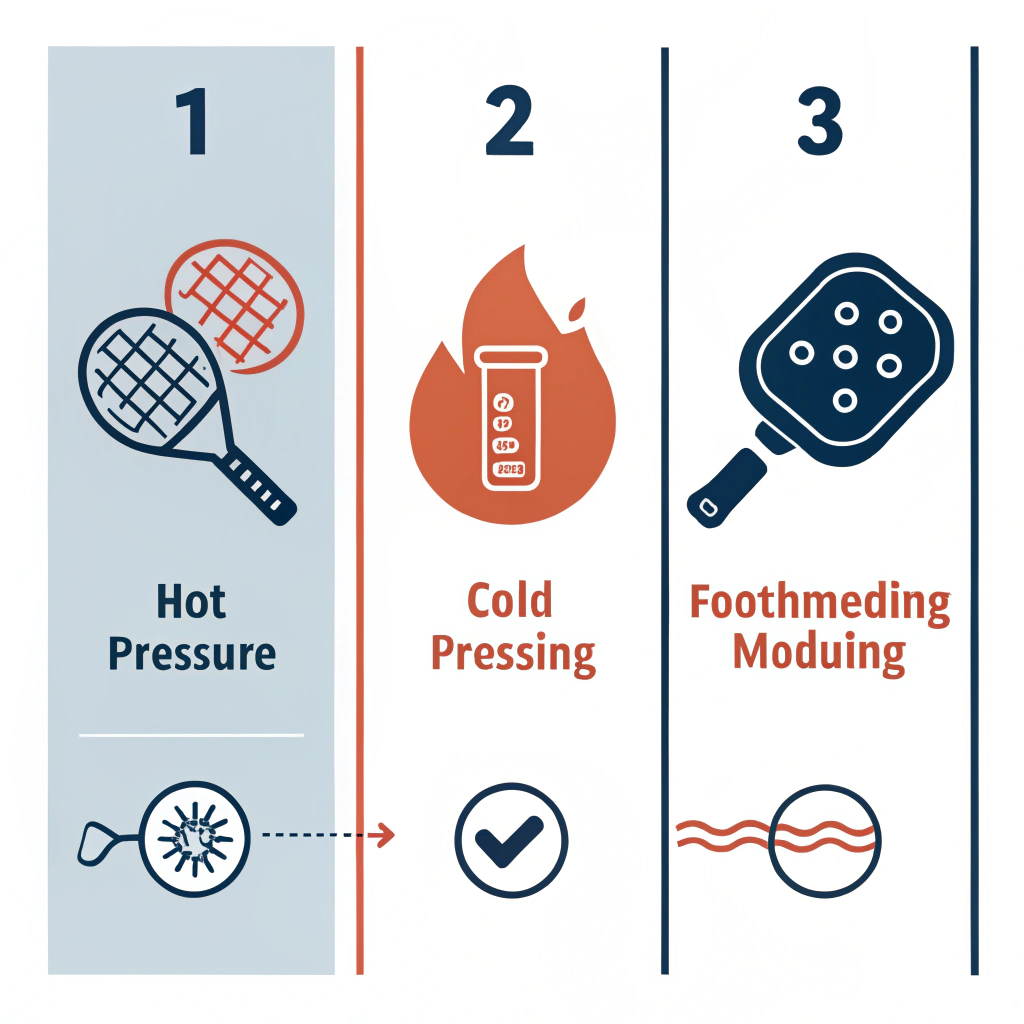

NEX Pickleball uses three main production processes, each tailored to meet specific performance and design requirements. These processes include:

-

- Involves heating materials and applying pressure to form the paddle.

- Ensures high structural integrity and strength, ideal for competitive play.

- Offers excellent production efficiency for bulk manufacturing but may alter certain material properties.

-

- Shapes the paddle at room temperature under controlled mechanical pressure.

- Maintains the material’s natural properties for better ball control and a responsive feel.

- Although more precise, this method has longer production cycles and requires high-quality equipment.

-

- Utilizes heat to soften materials before molding them into shape.

- Supports complex designs and intricate material distributions, resulting in optimal paddle balance and stability.

- Best suited for custom and premium paddle orders; however, the process is time-intensive and has higher equipment costs.

The table below provides a clear comparison of these processes:

| Production Process | Advantages | Disadvantages |

|---|---|---|

| Hot Pressing | High production efficiency; strong and durable paddles; excellent impact resistance | Potential alteration of material properties; high equipment investment |

| Cold Pressing | Preserves material integrity; offers precise control over paddle thickness and structure | Longer production cycles; demands precise pressure control equipment |

| Thermoforming | Capable of producing intricate designs; maintains paddle stability and balance | Time-consuming; higher cost due to specialized equipment |

This detailed analysis allows procurement managers to better evaluate the manufacturing processes that contribute to a paddle’s overall performance and suitability for competitive markets.

The choice of material is one of the primary drivers for performance in pickleball paddles. NEX Pickleball leverages a range of premium materials to meet various market demands, including:

-

Carbon Fiber Varieties:

- 3K Carbon Fiber: Known for its high strength and flexibility, typically used where high rebound force is desired. It also reduces vibration and enhances durability.

- 12K Carbon Fiber: With a higher thread density, 12K offers a smoother finish, increased hardness, and superior impact resistance, making it well-suited for intense competitive play.

- T300 Carbon Fiber: Valued for its excellent tensile strength, T300 provides a balanced combination of strength and lightweight characteristics.

-

Fiberglass:

- Offers a balanced mix of power and control. The use of E-Glass Fiberglass ensures enhanced elasticity and tensile strength, contributing to a wider sweet spot and improved ball handling.

-

Composite Materials:

- Carbon Fiber and Fiberglass Composite: This blend provides the perfect balance between power and precision, making it an ideal choice for players requiring both aspects.

- Bamboo Core Composite: Utilized for its lightweight and impact-resistant properties; it offers a quick, responsive feel.

- Honeycomb Cores: Whether made of high-density polymers or pulp, these cores provide excellent shock absorption, reducing vibration and adding durability.

The variety of materials used allows NEX Pickleball to customize paddles to specific performance criteria and player preferences. Each option provides unique advantages that directly translate into improved on-court performance and player satisfaction.

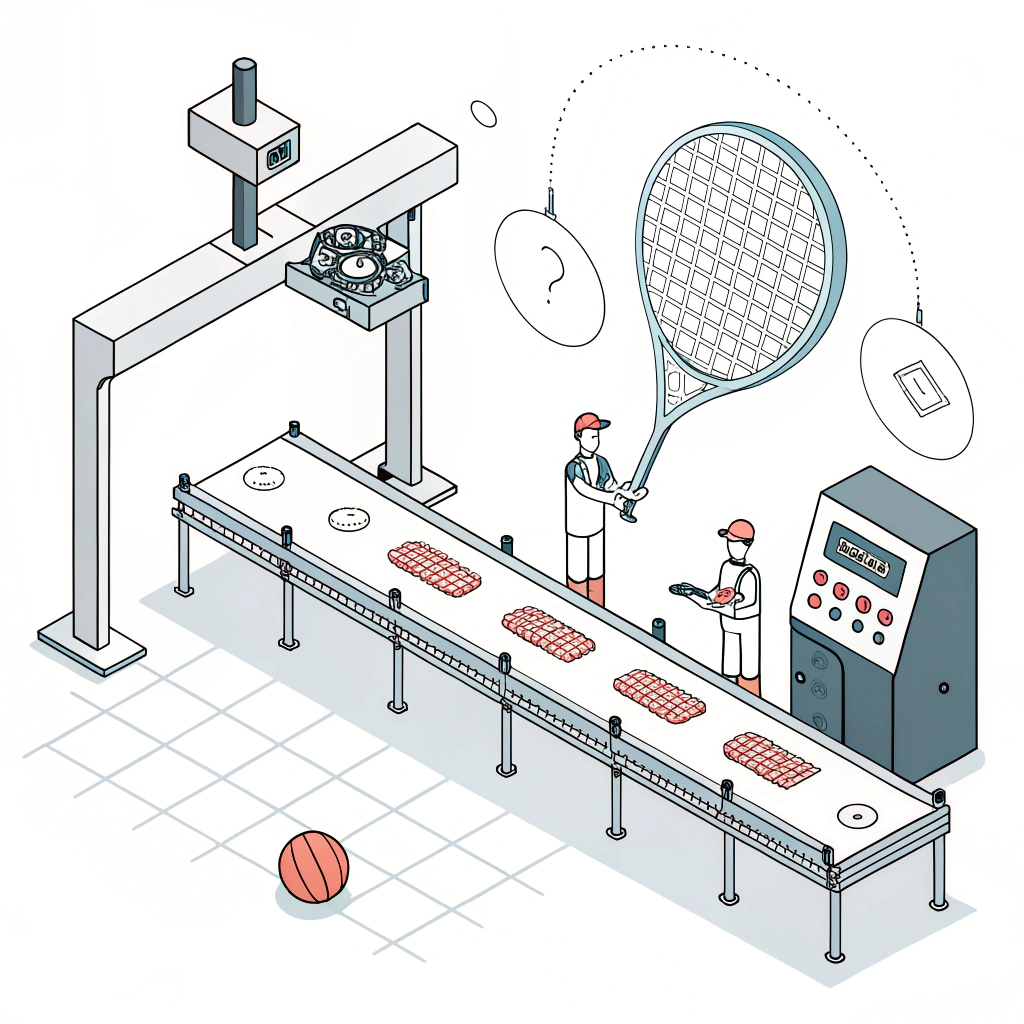

For B2B buyers, reliability and consistency across bulk orders are paramount. NEX Pickleball’s manufacturing processes incorporate advanced quality control measures and flexible production techniques, including:

-

Rigorous Testing Procedures: Every paddle undergoes strict quality checks to ensure that it meets the highest standards of strength, flexibility, and durability.

-

Custom Manufacturing Options: Clients have the opportunity to tailor paddle specifications such as design, weight, balance, and grip size. This level of customization ensures that the products exactly match the end-users’ needs, whether for individual distribution or team branding.

-

On-Demand Print Services: Our innovative on-demand printing service allows for personalized branding options, elevating the product’s appeal for various markets and promotional events.

The strategic combination of modern manufacturing techniques, premium materials, and customization capabilities helps NEX Pickleball stand out as a dependable and innovative supplier in the sports equipment sector.

-

Assess Material Compatibility:

- Evaluate whether the supplier’s range of materials (carbon fiber, fiberglass, composite materials) aligns with your market requirements.

- Consider the specific benefits of each material type relative to your target customer segments.

-

Compare Production Process Capabilities:

- Understand the advantages and limitations of hot pressing, cold pressing, and thermoforming as they impact product performance.

- Use detailed comparisons (such as the table above) to match production capabilities with your quality and quantity needs.

-

Review Quality Assurance Protocols:

- Confirm that the manufacturer implements rigorous quality control measures including standardized testing and certification processes.

- Request documented data and case studies that showcase consistent product performance over time.

-

Explore Customization Options:

- Look for suppliers offering customization services, from paddle design to on-demand printing, which allows for flexible product differentiation and branding.

- Engage in discussions about pilot orders to test the customization process before committing to large-scale orders.

-

Analyze Cost-Effectiveness:

- Consider both the upfront costs and the long-term value. While advanced processes like thermoforming may incur higher production costs, they often yield premium products that justify a higher price point.

- Balance the need for quality with competitive pricing to ensure optimal return on investment.

NEX Pickleball has built a strong reputation in the market by not only providing high-performance pickleball paddles but also by ensuring that each batch maintains consistent quality. Several industry leaders, including renowned brands like Joola and Selkirk, have benefited from our manufacturing expertise when they outsource production. The strategic advantage comes from:

- Advanced production techniques that secure a balance between efficiency and precision.

- A robust mix of premium materials that enhance paddle performance in terms of power, control, and durability.

- A commitment to innovation with customizable options which appeals to diverse market segments from professional athletes to recreational players.

Such factors collectively underscore why NEX Pickleball is considered a trusted partner in the wholesale sports equipment market. For procurement managers, partnering with a supplier who offers this level of technical depth and quality assurance can streamline bulk orders while ensuring customer satisfaction.

In the competitive landscape of sports equipment, the selection of a reliable pickup paddle manufacturer is critical. NEX Pickleball’s blend of innovative production methods, diverse material options, and stringent quality control measures makes it a compelling choice for B2B buyers. By understanding the technical nuances and production capabilities detailed in this article, decision-makers can better evaluate suppliers based on performance reliability, customization flexibility, and cost-effectiveness.

We encourage procurement managers and wholesale distributors to leverage this detailed insight when reviewing potential suppliers. Taking the time to align your quality and performance needs with the right manufacturing partner will ensure that your retail channels continue to offer products that meet and exceed consumer expectations.

For more details on how NEX Pickleball can become your trusted partner in high-performance pickleball paddle manufacturing, get in touch with us today.

Q: What is the best pickleball paddle manufacturer?

A: NEX Pickleball stands out as a leading manufacturer by utilizing advanced production processes, such as hot pressing, cold pressing, and thermoforming, combined with premium materials like 3K, 12K, and T300 carbon fiber. This blend of innovation and rigorous quality control makes them an excellent choice for high-performance, reliable pickleball paddles.

Q: What material pickleball paddle is best?

A: Experts widely consider carbon fiber to be the best material for pickleball paddles due to its superior strength, durability, and lightweight properties. NEX Pickleball uses multiple grades of carbon fiber—including 3K, 12K, and T300—to tailor performance, ensuring an optimal balance of power, control, and responsiveness suitable for competitive play.

-

carbon fiber: Click to learn about the properties and manufacturing advantages of carbon fiber materials that contribute to lighter and stronger sports equipment. ↩

-

composite blends: Click to discover how composite blends combine different materials to achieve an optimal balance between power, control, and durability in sports equipment. ↩

-

Hot Pressing: Click to explore how hot pressing techniques enhance material bonding and structural integrity in high-performance manufacturing. ↩ ↩2

-

Cold Pressing: Click to understand the benefits of cold pressing in preserving the natural qualities of materials, resulting in superior control and responsiveness. ↩ ↩2

-

Thermoforming: Click to read about thermoforming processes and how heat-based molding creates intricate and durable designs in manufacturing. ↩ ↩2