Advanced pickleball paddles for 2025 are engineered using advanced materials and precise production techniques to deliver unparalleled performance, durability, and comfort for top-tier athletes while meeting stringent B2B procurement requirements.

In today’s competitive sports equipment landscape, selecting the right pickleball paddle requires engineers and procurement specialists to evaluate material properties, production processes, and technical performance. Advanced pickleball paddles are no longer just about a simple hit—they integrate the latest in carbon fiber1, fiberglass2, and Composite Technologies3 with optimized production processes such as hot pressing, cold pressing, and Thermoforming4. In this article, we will compare leading design approaches, discuss technical specifications, and outline the production techniques that define high-performance paddles for advanced players in 2025.

Advanced paddles are crafted from premium materials that balance power, control, and durability. At NEX Pickleball, we use several materials that provide distinctive performance benefits:

-

Carbon Fiber

- 3K Carbon Fiber: Known for its strength and flexibility, 3K carbon fiber offers high rebound force and excellent vibration reduction. It is incorporated in paddles where durability and responsiveness are priorities.

- 12K Carbon Fiber: With higher thread density, 12K carbon fiber results in a smoother surface, increased hardness, and exceptional durability. This makes the paddle ideal for competitive play that demands both power and resilience.

- T300 Carbon Fiber: Renowned for its tensile strength, T300 carbon fiber creates a well-balanced paddle that combines light weight with robust strength, ideal for players who demand precision and speed.

-

Fiberglass

- E-Glass Fiberglass: This material is used to achieve a balance between power and control. Its elastic properties contribute to a wider sweet spot, which enhances playability and ensures better ball control during high-speed exchanges.

-

Composite Materials

- Carbon Fiber & Fiberglass Composite: Combining the strengths of both materials provides a paddle that is light yet durable, offering excellent control without sacrificing power.

- Bamboo Core Composite: Known for being lightweight and highly impact-resistant, bamboo cores deliver an exceptional hitting feel with long-lasting performance.

- Honeycomb Core: Constructed from high-density polymers, honeycomb cores intensify shock absorption and reduce unwanted vibrations during play.

-

Core Materials

- Nomex Honeycomb Core5: This polymer-based core is engineered for outstanding shock absorption and stability under repeated high-impact stress.

- Aluminum Honeycomb Core: Offering balanced weight, aluminum cores provide both strength and precise control, catering to players who require a mix of power and finesse.

- Polymer Honeycomb Core: Valued for elasticity and reduced vibration, polymer cores are ideal for recreational players and advanced athletes alike.

Understanding the nuances of these materials is vital when assessing the optimal paddle design for your procurement needs. Manufacturers use rigorous testing to ensure that every paddle meets the highest standards of performance and durability.

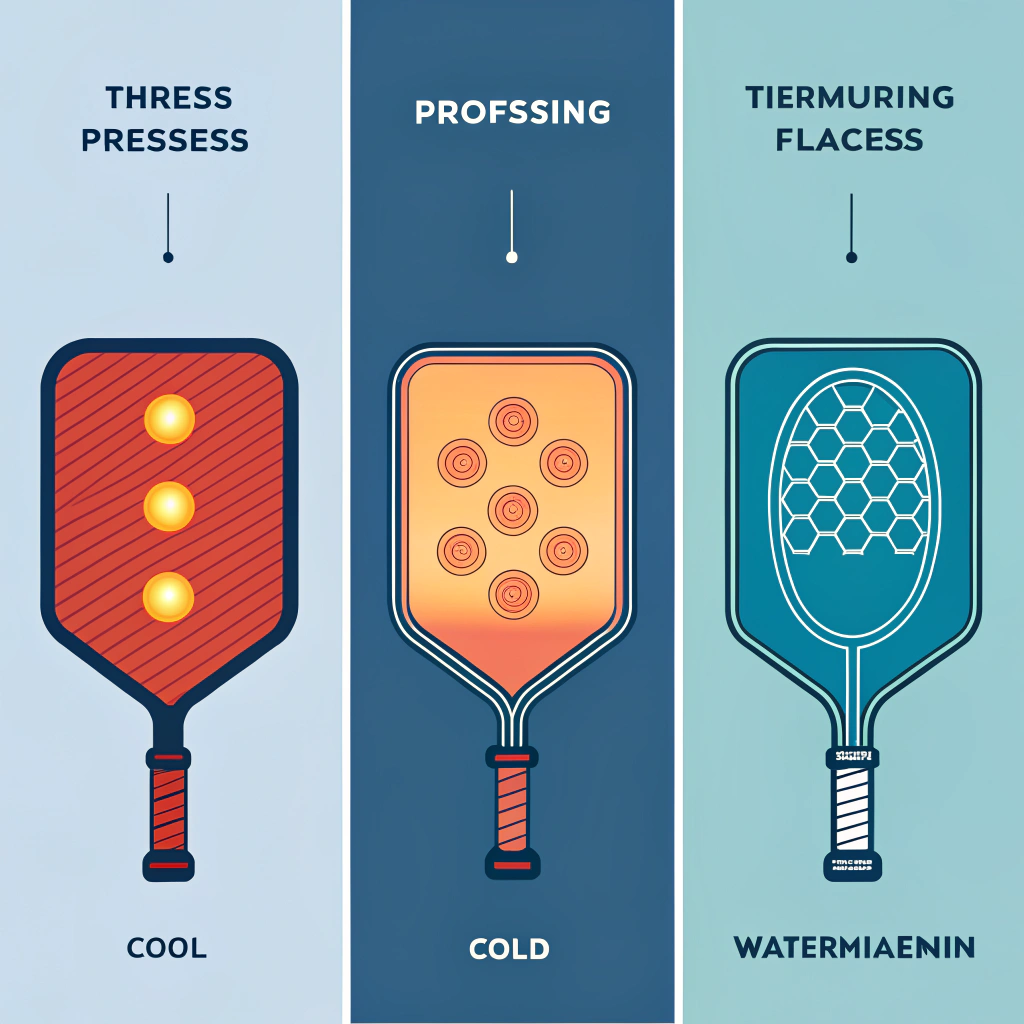

The production process is a key differentiator in achieving optimum performance for advanced pickleball paddles. At NEX Pickleball, our commitment to innovation is evident in our three main production techniques:

-

Hot Pressing

- Process: Materials are heated and pressed rapidly to form a durable paddle.

- Advantages:

- High production efficiency with strong, impact-resistant paddles.

- Maintains structural integrity during high-performance play.

- Disadvantages:

- Potential alteration of material feel.

- High capital equipment costs.

-

Cold Pressing

- Process: Materials are shaped at room temperature under high mechanical pressure.

- Advantages:

- High precision in control over paddle thickness and structure.

- Retains natural material properties for superior ball feel.

- Disadvantages:

- Slower production cycle which may affect scalability.

- Requires advanced equipment for consistent pressure control.

-

Thermoforming

- Process: Heating materials to a soft state and then forming them using molds.

- Advantages:

- Ability to create complex shapes with precise material distribution.

- Enhances paddle stability and performance.

- Disadvantages:

- Longer production time and higher costs.

- Most suitable for premium or custom paddle lines.

Below is a comparative table that summarizes these production processes:

| Process | Advantages | Disadvantages | Best For |

|---|---|---|---|

| Hot Pressing | High efficiency, strong impact resistance, robust design | Alters material feel, high setup cost | Large-scale production, durable paddles |

| Cold Pressing | Precise control over thickness, preserves natural properties | Longer cycle time, requires high-quality equipment | Paddles with superior control and feel |

| Thermoforming | Intricate design capability, precise material distribution | Higher investment, slower production cycle | Custom and premium paddle designs |

By comparing these processes, procurement managers can effectively assess the trade-offs in production efficiency, performance, and cost when choosing a paddle supplier.

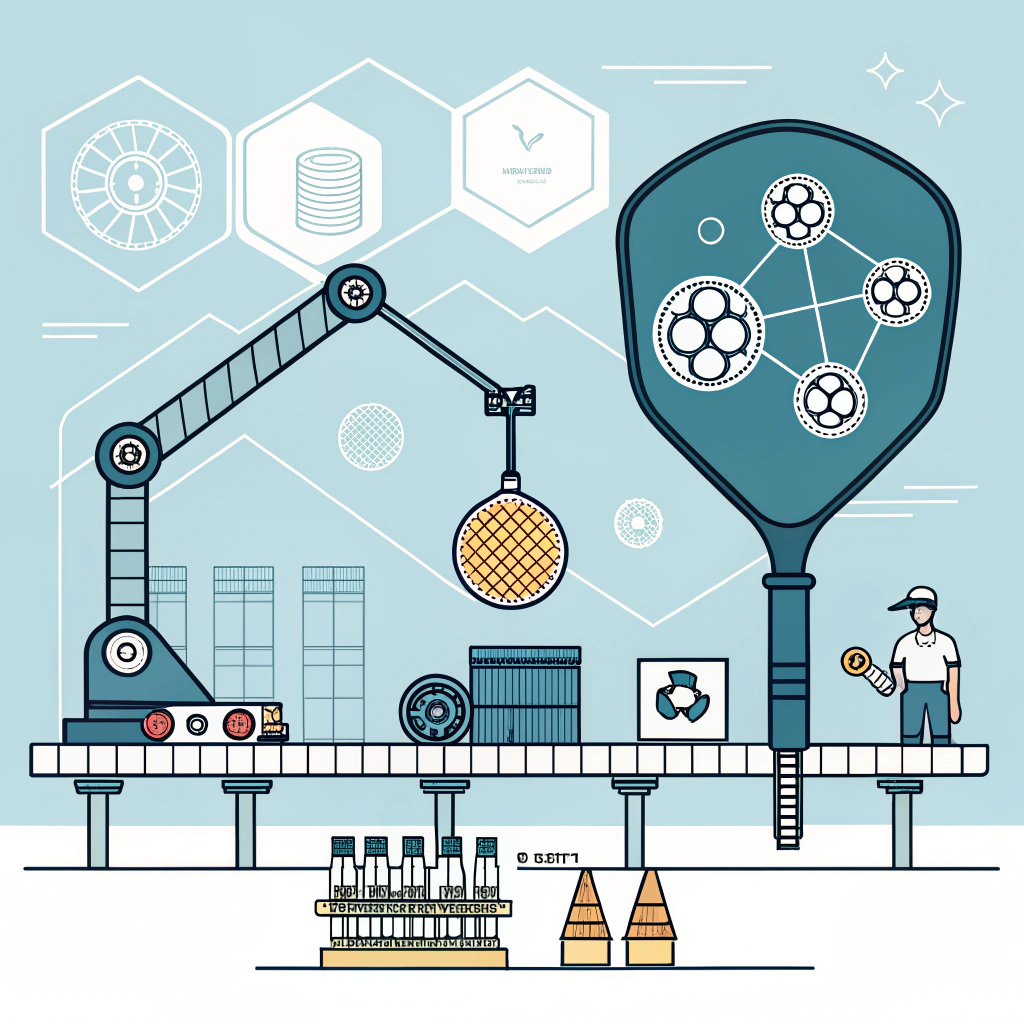

NEX Pickleball prides itself on being a leading manufacturer that partners with brands like Joola and Selkirk to deliver elite paddles. Our commitment to quality and innovation is reflected in:

- Rigorous Quality Testing: Every paddle undergoes intensive performance tests to ensure optimal weight distribution, balance, and surface treatment designed for enhanced grip and ball spin.

- Customizable Solutions: We offer on-demand paddle printing and design customizations, providing clients with the ability to modify paddle specifications such as weight, balance, grip size, and even external aesthetics for branding opportunities.

- Consistent Production Standards: By utilizing advanced production techniques, we minimize production variability and ensure that every paddle meets high durability and performance metrics, crucial for B2B buyers and competitive players.

- State-of-the-Art Technologies: From hot pressing to thermoforming, our processes exploit the latest technological advancements. This commitment ensures that paddles not only serve as sports equipment but also as reliable, high-performance tools for competitive play.

Our superior engineering practices are backed by a strong quality control regime. This ensures that advance players receive a product with predictable performance on every hit—a factor that is critical when these paddles are used in competitive tournaments or in sports clubs with high usage.

For sports equipment procurement managers seeking to invest in high-performance pickleball paddles, a detailed side-by-side comparison of materials, production processes, and performance characteristics is essential. Below are the key recommendations based on our analysis:

-

Evaluate Material Composition:

- Consider paddles utilizing 12K Carbon Fiber if your priority is endurance and hard-hitting performance.

- Opt for fiberglass composites if control and a larger sweet spot are more crucial for your customer base.

-

Align Production Process with Product Positioning:

- If rapid production and large-scale supply are essential, then paddles made via hot pressing are the best fit.

- For niche markets demanding customized feel and improved ball control, paddles manufactured using cold pressing or thermoforming may be preferable.

-

Leverage Customization Opportunities:

- Utilize on-demand print services to incorporate team branding, which enhances both the market appeal and personalized value of the product.

- Custom options in grip size and weight cater to different playing styles and ergonomic requirements—an essential factor in high-performance sports.

-

Consider Core Material Specifications:

- Nomex Honeycomb Core paddles are ideal when durability and shock absorption are top priorities.

- Polymer Honeycomb Core can offer a softer feel for players who are more sensitive to vibrations.

The following table summarizes these key factors for quick reference:

| Key Factor | Recommendation | Ideal For |

|---|---|---|

| Material | 12K Carbon Fiber / Fiberglass / Composite | High-performance play vs. balanced control |

| Production Process | Hot Pressing / Cold Pressing / Thermoforming | Scale production vs. custom premium designs |

| Core Material | Nomex Honeycomb / Polymer Honeycomb | Superior durability vs. enhanced comfort and reduced vibration |

| Customization | On-demand Printing, Custom Grip & Weight | Tailored branding and ergonomic design |

Our experience in using advanced procedures and premium material selection sets NEX Pickleball apart in the B2B market. By understanding your product requirements and matching them with the right process and material, you'll be well-positioned to supply paddles that meet the highest standards of modern competitive play.

In conclusion, advanced pickleball paddles for 2025 are revolutionizing the game by integrating innovative materials with state-of-the-art production techniques. For procurement managers, key decision drivers include material composition, production process, and the potential for product customization. By understanding these technical parameters and aligning them with market demands, businesses can confidently select paddles that enhance both performance and brand reputation.

I encourage you to review these technical insights and compare them with your procurement criteria to determine the best match for your customers. Engaging directly with suppliers who maintain strict quality control and continuous innovation, like NEX Pickleball, will ensure that your purchasing decision supports both short-term performance and long-term reliability.

People Also Ask

Q1: What are the best pickleball paddles in 2025?

A1: The best pickleball paddles in 2025 are those that integrate advanced materials like 12K carbon fiber and composite structures, combined with precision manufacturing processes such as hot pressing, cold pressing, and thermoforming. These paddles offer superior power, control, and durability, making them ideal for competitive play.

Q2: Which pickleball paddle hits the hardest?

A2: While paddle hardness can depend on design and material composition, paddles built with robust carbon fiber structures—such as those featuring 12K carbon fiber—have been noted for delivering exceptional power. Many advanced models focus on maximizing impact resistance to ensure a harder hit without compromising control.

Q3: What paddle do most pro pickleball players use?

A3: Many pro pickleball players favor paddles that balance power and control; for example, models similar to JOOLA Perseus are popular among professionals. These paddles feature a control design with ample power and spin capabilities, ensuring optimal performance during high-level competitive play.

-

Carbon Fiber: Click to explore detailed insights about carbon fiber’s properties, including its strength-to-weight ratio and vibration damping capabilities, which are essential for high-performance sports equipment. ↩

-

Fiberglass: Click to delve into the advantages of fiberglass in sports equipment, such as its elasticity and ability to balance power with control. ↩

-

Composite Technologies: Click to learn how composite technologies combine multiple materials for enhanced performance and durability, offering a tailored balance of strength, weight, and control. ↩

-

Thermoforming: Click to understand the thermoforming process, including its ability to produce complex geometries and how it enhances material distribution for premium paddle design. ↩

-

Nomex Honeycomb Core: Click to read about the engineering behind Nomex honeycomb cores, focusing on their shock absorption, stability, and role in high-impact sports gear. ↩