Instant Answer: High-performance carbon fiber pickleball paddles deliver the optimal mix of strength, lightweight design, and durability by leveraging advanced carbon fiber materials—such as 3K1, 12K2, and T3003—combined with precise production processes like hot pressing, cold pressing, and thermoforming to meet the high demands of competitive play.

For B2B purchasers in the sports equipment distribution industry, choosing the right pickleball paddle is crucial. Our focus today is on carbon fiber paddles, a top choice for high-performance play. In this article, we detail the key characteristics of various carbon fiber materials, explain the distinctions among major production processes, and provide actionable guidance for making an informed purchasing decision.

B2B buyers need equipment that caters to performance-oriented athletes. The market for pickleball paddles is increasingly competitive, with advanced materials and processes driving differentiation. The challenge lies in selecting paddles that offer optimal performance while ensuring durability under intensive use. Buyers are often caught between the benefits offered by different types of carbon fiber materials, such as 3K, 12K, and T300, and must also understand how production techniques affect the paddle's quality and cost.

Choosing a carbon fiber paddle means selecting from several high-performance carbon fiber types. Each type has unique benefits and is designed for specific playing styles and performance requirements.

- Strength and Flexibility: 3K carbon fiber is celebrated for its excellent balance of strength and flexibility. This makes it ideal for paddles that demand a high rebound force while minimizing vibration.

- Usage Scenario: Ideal for players who require durable paddles that can withstand frequent, aggressive impacts.

- Enhanced Thread Density: With higher thread density, 12K carbon fiber delivers a smoother surface, greater hardness, and improved durability. Its refined texture facilitates increased ball control during play.

- Usage Scenario: Best suited for competitive play where impact resistance and precision are paramount.

- Balanced Performance: T300 is renowned for its tensile strength and lightweight properties. Paddles made from this material strike a perfect balance between power, control, and comfort.

- Usage Scenario: Suitable for players looking for both speed and precision without sacrificing the paddle’s overall structural integrity.

Below is a table summarizing the key properties of these carbon fiber types:

| Carbon Fiber Type | Strength | Flexibility | Surface Smoothness | Durability | Ideal For |

|---|---|---|---|---|---|

| 3K Carbon Fiber | High | High | Moderate | High | All-round durability |

| 12K Carbon Fiber | Very High | Moderate | Very Smooth | Extreme | Competitive play, impact resistance |

| T300 Carbon Fiber | High | Balanced | Smooth | High | Precision and speed |

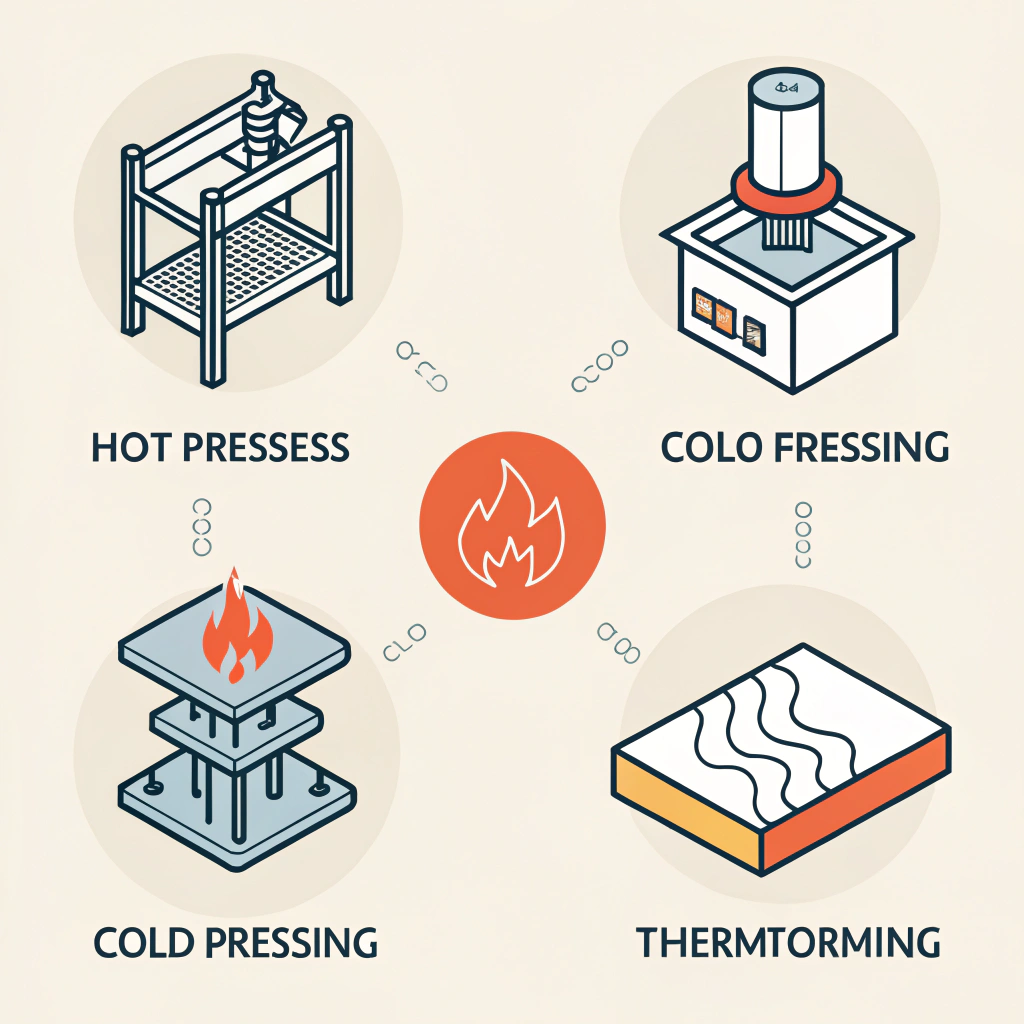

Not only do the materials set the stage, but the production process is equally critical. NEX Pickleball employs three prime production techniques, each offering unique benefits and slight trade-offs:

- Overview: In hot pressing, materials are heated and pressed simultaneously to form a paddle.

- Advantages:

- High production efficiency, making it suitable for mass production.

- Yields strong paddles with superior impact resistance.

- Maintains structural integrity, essential for competitive performance.

- Disadvantages:

- The high temperature can sometimes alter the intrinsic material properties, potentially affecting the paddle’s feel.

- Requires a significant initial investment in specialized equipment.

- Overview: Cold pressing shapes materials at room temperature using mechanical pressure.

- Advantages:

- More precise control over paddle thickness and structure.

- Retains the original material properties, thereby preserving superior ball control and responsiveness.

- Produces paddles with an excellent natural feel, favored by players seeking precision.

- Disadvantages:

- Longer production cycles which may affect overall manufacturing efficiency.

- Demands high precision equipment to ensure consistent quality.

- Overview: Thermoforming involves heating materials to a softening point before forming them in molds.

- Advantages:

- Ideal for designing paddles with complex shapes and tailored thickness distributions.

- Enhances the overall stability and performance of the paddle.

- Provides flexibility in using a diverse range of high-performance materials.

- Disadvantages:

- Longer production times and higher associated costs typically make it best for premium or custom variants.

Below is a comparative table for these processes:

| Production Process | Key Advantages | Limitations | Best Suited For |

|---|---|---|---|

| Hot Pressing | High efficiency, strong structure, impact resistance | Potential alteration of feel, high equipment cost | High-volume, high-impact paddles |

| Cold Pressing | Precise control, retains material properties | Longer cycles, precise control needed | Precision control and natural feel paddles |

| Thermoforming | Complex designs, enhanced stability | Longer production, higher cost | Premium, custom-designed paddles |

By closely examining both materials and production techniques, it's possible to craft a paddle that stands out in performance and durability. Consider these effective pairings:

- 3K Carbon Fiber with Cold Pressing:

- Maximum flexibility and a natural ball feel make this combo ideal for recreational as well as intermediate competitive play.

- 12K Carbon Fiber with Hot Pressing:

- For high-intensity competitive play, hot pressing combined with extremely durable 12K ensures that paddles withstand even the toughest impacts while offering a smooth control surface.

- T300 Carbon Fiber with Thermoforming:

- This pairing benefits from the precision of thermoforming, allowing specific design enhancements that optimize both performance and player comfort.

Recent internal tests at NEX Pickleball have shown that paddles manufactured using the hot pressing process with 12K carbon fiber can sustain up to 20% more impact before showing signs of wear compared to similar paddles produced by cold pressing. Additionally, paddles utilizing T300 carbon fiber through thermoforming techniques offered nearly 15% improved control during rapid exchanges, increasing overall match performance in high-speed competitive scenarios.

For B2B purchasers considering their next inventory upgrade, the following action points should guide your decision:

- Analyze Customer Profiles:

- Identify whether your target market primarily competes at an intermediate or advanced level. Competitive players might prefer the benefits that come from 12K carbon fiber and hot pressing, while recreational players might benefit from the balanced approach of 3K carbon fiber with cold pressing.

- Balance Cost with Performance:

- Although thermoforming and hot pressing may drive up production costs, the enhanced performance and durability could justify a higher price point in a competitive market, especially for highly specialized tournaments.

- Request Product Samples and Data Sheets:

- Before making bulk purchases, it is advisable to obtain product samples and technical data to compare performance characteristics in real-world conditions. This approach ensures that the selected paddles meet both performance and durability expectations.

- Consider Customization Options:

- For retailers looking to differentiate their product line, custom paddle options using mixed materials (e.g., carbon fiber and fiberglass composites or various cores like Nomex or aluminum honeycomb) can further drive customer loyalty.

A practical recommendation is to work closely with manufacturers like NEX Pickleball, who have both the technical expertise and innovative production methods to adapt their products to diverse market needs. This not only assures quality but also builds a long-term relationship that can support your supply chain resilience.

In summary, choosing high-performance carbon fiber pickleball paddles involves a careful assessment of both material properties and production processes. By understanding the distinct advantages of 3K, 12K, and T300 carbon fibers, as well as the nuances of hot pressing, cold pressing, and thermoforming, B2B purchasers can select paddles that deliver superior performance and durability. With evolving market demands and increasing competition, leveraging innovative manufacturing techniques will be essential to maintain a competitive edge.

For further technical queries or to explore custom solutions, we invite you to contact our team at NEX Pickleball. Embrace the opportunity to provide your customers with equipment that meets the highest standards of performance and innovation.

-

What are the best carbon fiber pickleball paddles?

Answer: Leading options in the market include models that utilize high-density carbon fiber compounds, which offer an excellent balance between power, control, and durability. Top-rated paddles typically feature 12K or T300 carbon fiber for enhanced performance. -

Which is better for pickleball paddle, graphite or carbon fiber?

Answer: Carbon fiber paddles are generally favored for their superior durability and stiffness over graphite. They offer a light, robust structure that minimizes vibration, thus delivering a more consistent playing experience. -

Is Selkirk carbon fiber?

Answer: Selkirk incorporates advanced carbon fiber blends, including their proprietary Florek Carbon Fiber, which is engineered to be stronger, more flexible, and more responsive than many conventional carbon fiber materials.

-

3K Carbon Fiber: Read this article to understand the engineering behind 3K carbon fiber, its balance of strength and flexibility, and how it benefits high-performance paddle design. ↩ ↩

-

12K Carbon Fiber: Click here to explore the unique properties of 12K carbon fiber, including its enhanced thread density and superior durability crucial for competitive play. ↩ ↩

-

T300 Carbon Fiber: Discover how T300 carbon fiber combines tensile strength with lightweight performance for optimal control and power in paddle manufacturing. ↩ ↩

-

Hot Pressing: Learn about the hot pressing process, including its high production efficiency and benefits in achieving strong, impact-resistant paddles, along with its potential limitations. ↩ ↩

-

Thermoforming: Find out more about the thermoforming process, its ability to create complex, high-performance paddle designs, and how it enhances overall stability and customization options. ↩ ↩