Edgeless Pickleball Paddles offer a direct, expansive hitting surface that enhances ball feel, improves control, and delivers a larger sweet spot. This innovative design is transforming paddle performance in the market, making it an attractive solution for upscale sports clubs and premium retailers.

The evolution from traditional edged paddles to edgeless designs is driven by the desire to improve game performance. Conventional paddles have defined edges that often limit the effective playing area. In contrast, removing these boundaries creates an uninterrupted surface. This design change leads to better ball contact, more predictable spin, and increased control, particularly on finesse shots such as dinks and drops.

Edgeless pickleball paddles introduce several benefits, including:

- Enhanced Ball Feedback: Without sharp edges, players experience a more uniform and responsive surface that translates into improved touch and control.

- Larger Sweet Spot: The absence of boundaries allows for a larger effective hitting area, which can be crucial for precision shots during fast-paced plays.

- Simplified Manufacturing Process: With the removal of edge-forming stages, some edgeless designs can potentially streamline production steps, reducing the chances of defects along the paddle periphery.

- Aesthetic Appeal: The continuous surface presents a modern and sleek look, aligning with high-performance branding and premium product positioning.

When evaluating these benefits, decision-makers in product development can consider how an edgeless design might offer a competitive edge over more traditional paddle options.

Decision-makers in the sports equipment industry need to evaluate performance, durability, and cost efficiency. Below is a detailed comparison between traditional edged paddles and edgeless paddles:

| Feature | Traditional Paddles | Edgeless Paddles |

|---|---|---|

| Hitting Surface | Defined edges may alter ball contact | Uninterrupted surface improves ball feel |

| Sweet Spot | Limited by frame constraints | Larger sweet spot offers enhanced control |

| Manufacturing Process | Multiple steps to form and finish edges | Streamlined production with fewer finishing steps |

| Durability | Edges are often reinforced but can wear out | Requires careful protection as edges cannot be easily replaced |

| Aesthetic Design | Classic design with visible boundaries | Modern, sleek appearance with a continuous surface |

This comparison table highlights that while the edgeless design brings notable performance enhancements, success relies on careful consideration of material selection and manufacturing processes.

Breakdown of Advanced Manufacturing Processes1

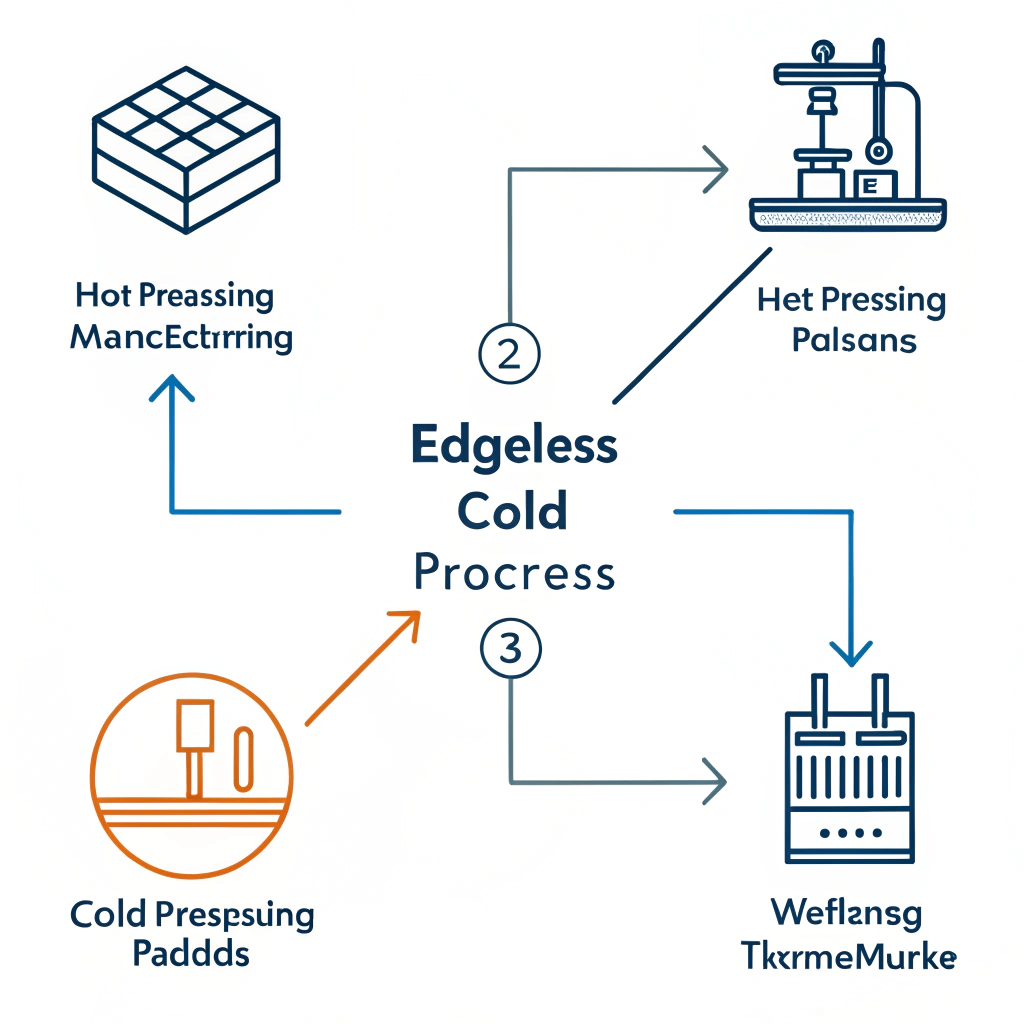

At the heart of edgeless designs is a refined manufacturing approach that leverages advanced technologies. NEX Pickleball, a reputed manufacturer with deep technical expertise, relies on three primary production processes: hot pressing, cold pressing, and thermoforming. Manufacturers often combine these techniques with cutting-edge composite materials2 like carbon fiber and fiberglass. For instance, carbon fiber types such as 3K, 12K, and T300 can be integrated to optimize both strength and flexibility, while resilient core materials like Nomex Honeycomb Core and polymer honeycomb provide essential shock absorption.

Hot pressing involves heating materials and applying pressure to form a consolidated paddle structure. This method can yield paddles with excellent impact resistance and consistent strength. The advantages of hot pressing include:

- High production efficiency suitable for large-scale manufacturing.

- Strong paddles with superior durability.

- Consistent structural integrity, crucial for high-performance design.

However, hot pressing might alter some of the material’s tactile properties, which requires balancing between performance and feel.

Cold pressing processes materials at room temperature, maintaining inherent material qualities. This technique allows for:

- Increased precision in thickness and layout.

- Enhanced ball feel and responsiveness due to preserved material properties.

- Greater control in the paddle's final design.

The main drawback is a slower production cycle, making it less ideal for mass production unless balancing strict quality requirements.

Thermoforming heats materials until they soften and then shapes them using molds. It is critical for producing paddles with:

- Intricate and ergonomic designs.

- Thorough material distribution that improves overall stability.

- Capability to integrate multiple composite materials seamlessly.

Despite its advantages, thermoforming is more time-consuming and entails higher equipment costs. It is best suited for premium or custom orders where performance is non-negotiable.

Each process has its pros and cons, depending on the intended market segment and performance specifications. Manufacturers often combine these techniques with cutting-edge composite materials like carbon fiber and fiberglass.

Implementing an edgeless design means rethinking material combinations to ensure longevity and performance. Here are some key material aspects to consider:

-

Composite Materials: Leveraging a mix of carbon fiber and fiberglass ensures that the paddle maintains its power without compromising control. Composites allow manufacturers to fine-tune the paddle’s overall weight and responsiveness.

-

Core Technologies: Whether using Nomex Honeycomb5, aluminum honeycomb, or polymer honeycomb cores, each offers unique benefits:

- Nomex Honeycomb Core: Excellent for shock absorption and long-term durability.

- Aluminum Honeycomb Core: Provides balance between power and control.

- Polymer Honeycomb Core: Enhances elasticity and reduces vibrations during intense play.

-

Surface Treatments: The edge-free surface requires specialized coatings and treatments to reduce wear while maintaining high performance. For example, advanced surface lamination can protect the paddle while enhancing grip and spin control.

Manufacturers must optimize the interplay between these materials to achieve a top-tier edgeless paddle that meets the performance demands of competitive players and upscale clientele.

While edgeless paddles offer clear performance benefits, they come with certain maintenance challenges. One key issue is the vulnerability of the uncovered edges. With no traditional protective frame, players and clubs should consider the following:

- Edge Protection: The application of edge tape is highly recommended on edgeless paddles, especially to prevent core exposure. Once the core material is visible, the paddle's overall playability and durability may be compromised.

- Regular Inspection: Instituting a routine inspection protocol helps detect early wear and tear, allowing for timely interventions before damage escalates.

- User Education: Educate players on the proper handling and storage of edgeless paddles to extend their lifespan.

Implementing these protective measures can ensure that the superior performance features are not undermined by practical wear and damage over time.

From a product development perspective, comparing edgeless paddles against traditional models reveals trade-offs in production scalability and cost. Although edgeless designs might initially incur higher production costs due to specialized techniques and material treatments, these costs can be mitigated by:

- Streamlined Production Steps: Reducing or eliminating certain finishing processes associated with edge creation.

- Customization Potential: Offering bespoke services can justify higher price points. Upscale clubs and retailers are often willing to pay a premium for paddles that meet precise performance and aesthetic guidelines.

- Brand Differentiation: Emphasizing the innovative design and technological advancement of edgeless paddles can help secure a competitive market position. This differentiation not only appeals to high-performing athletes but also to discerning club managers and procurement leads seeking long-term value.

To assist in decision-making, companies should also conduct trials and performance studies that quantify the advantages in real-game conditions. Data from such studies can be tabulated and shared with stakeholders to support the investment in an edgeless production line.

Edgeless pickleball paddles represent a significant shift from traditional designs by offering improved ball contact, a larger sweet spot, and a modern aesthetic. However, success in adopting this innovation depends on several key factors:

- Selecting the right composite materials to balance strength and flexibility.

- Choosing an appropriate manufacturing process that aligns with both production capabilities and performance goals.

- Implementing protective measures to safeguard the paddle’s integrity over its lifespan.

- Leveraging data-driven insights from field tests to support production investments.

For product development managers and procurement leads, carefully weighing these technical and economic factors will enable informed decisions. The investment in edgeless technology can lead to enhanced player satisfaction and market differentiation, paving the way for a robust retail portfolio.

By staying at the forefront of manufacturing innovation, companies like NEX Pickleball continue to push the envelope, ensuring products that meet the high standards demanded by competitive sports today.

People Also Ask

What is the advantage of an edgeless pickleball paddle?

Edgeless pickleball paddles offer enhanced feel and control due to their continuous hitting surface. This design results in better feedback from the ball, allowing for more precise control on delicate shots and an overall improved playing experience.

Are edgeless pickleball paddles legal?

Yes, edgeless pickleball paddles are legal. Several manufacturers offer these paddles, and many are approved by governing bodies such as USA Pickleball, ensuring that they meet regulatory requirements and competitive standards.

How do you protect the edges of the edgeless paddle?

The best practice to protect an edgeless paddle is to use edge tape. Since these paddles lack traditional frames, once the edge is worn down and the core material is exposed, the paddle's performance may decline. Regular maintenance and careful handling are recommended to prolong its usability.

-

Advanced Manufacturing Processes — Click to read about state-of-the-art manufacturing methodologies that streamline production, improve quality, and drive innovation in competitive industries. ↩

-

cutting-edge composite materials — Click to explore comprehensive insights on modern composite materials and how they revolutionize product performance by enhancing strength-to-weight ratios and overall durability. ↩

-

Cold Pressing — Click to learn more about cold pressing techniques, their benefits in preserving material properties, and their applications in precision manufacturing. ↩

-

Thermoforming — Click to discover detailed information on thermoforming processes, including their role in creating complex shapes and designs with superior material consistency. ↩

-

Nomex Honeycomb — Click to understand the advantages of using Nomex honeycomb structures in products, focusing on shock absorption, durability, and performance optimization. ↩