The best equipment for pickleball combines high-performance design with advanced manufacturing processes—ensuring that paddles deliver exceptional power, control, and durability. At NEX Pickleball, our innovative approach using premium carbon fiber1 materials and optimized production processes such as hot pressing, cold pressing, and thermoforming has redefined what quality means in paddle manufacturing.

In an increasingly competitive sporting goods market, B2B purchasing managers face the challenge of selecting equipment that not only meets current performance demands but also provides long-lasting value and customization options. For pickleball, the paddle is the most critical component, and its performance hinges on material quality and production precision.

Manufacturers are now focusing on advanced materials like 3K Carbon Fiber2, 12K Carbon Fiber, and T300 Carbon Fiber to produce paddles that offer a superior balance of strength, flexibility, and responsiveness. Yet, material is only one side of the equation—the production process significantly influences the final product's properties. This article examines the technical benefits, manufacturing quality, and production methods that make our paddles the partner of choice for retailers and distributors.

Pickleball paddles manufactured with advanced materials deliver performance enhancements that are paramount in competitive play. Here, we explore the three types of carbon fiber used in our production:

- 3K Carbon Fiber2 – Known for its strength and flexibility, 3K carbon fiber lends itself to high rebound force paddles, ensuring durability and stable performance over long matches. This material reduces vibration and provides excellent control for rapid, dynamic play.

- 12K Carbon Fiber – With a higher thread density, 12K carbon fiber offers a smoother surface, increased hardness, and enhanced impact resistance. Ideal for competitive play, paddles using this material can handle high-speed impacts without sacrificing precision.

- T300 Carbon Fiber – A high-performance material recognized for its exceptional tensile strength, T300 carbon fiber is the ideal choice for paddles that require a balance of lightweight design and robust power.

By selecting the right carbon fiber, manufacturers can tailor the paddle characteristics to subtle performance requirements, directly impacting the player’s experience. The benefits include improved spin control, reduced vibration, and enhanced ball response—features that are fundamental in a high-performance sporting environment.

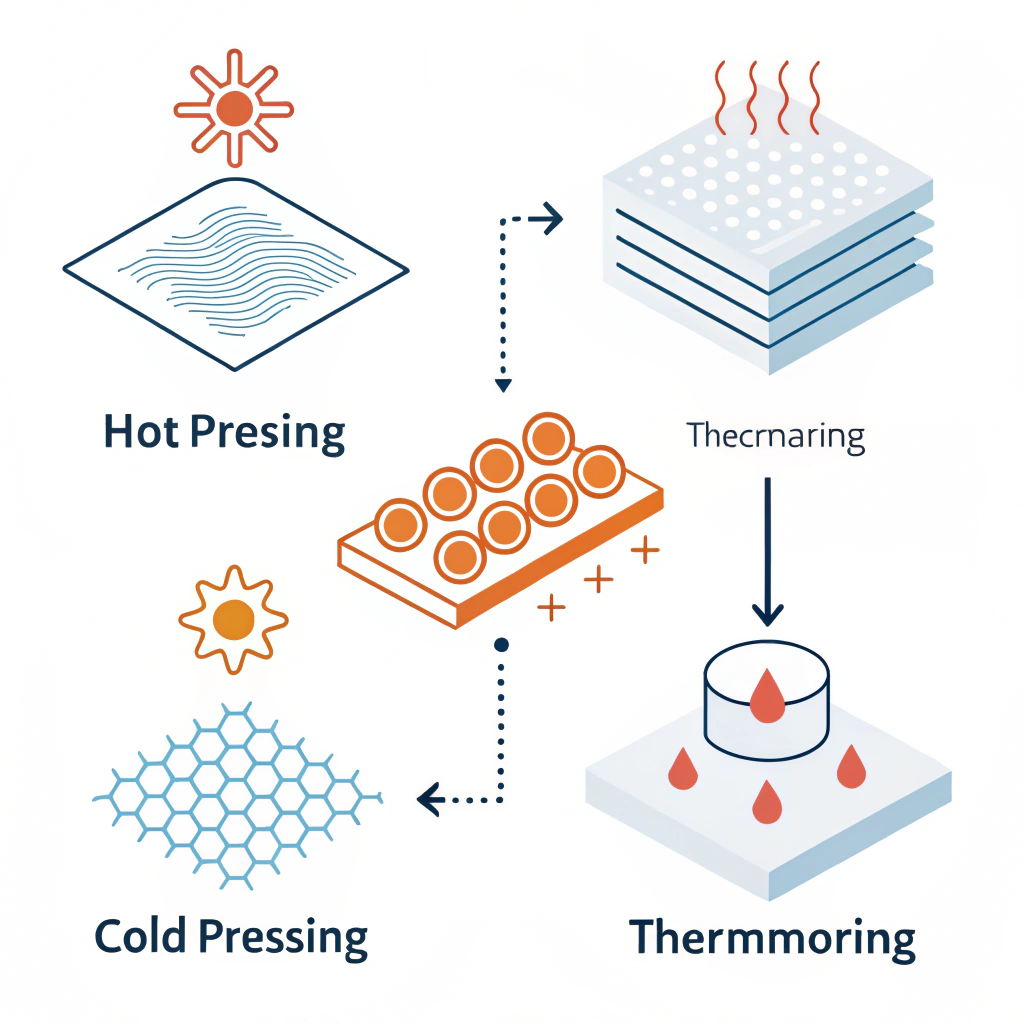

Material selection is only as effective as the production process that transforms it into a final product. At NEX Pickleball, we use three primary manufacturing methods, each with its advantages and limitations:

Hot pressing involves heating materials and applying pressure to achieve a unified, strong structure. This method is widely used for its efficiency and is capable of producing a high volume of paddles with uniform quality.

Advantages:

- High production efficiency suitable for large-scale manufacturing.

- Produces paddles with strong impact resistance and structural integrity.

- Ideal for meeting the demands of high-performance play.

Disadvantages:

- High investment in equipment is required.

- The process might slightly alter the material’s intrinsic properties, which could affect the paddle’s feel.

Cold pressing applies mechanical pressure at room temperature, preserving the natural characteristics of the paddle material. This technique ensures better control over the paddle’s thickness and maintains the material’s inherent flexibility.

Advantages:

- Superior control over dimensional properties, enhancing the paddle’s ergonomic design.

- Preserves the material properties for a more responsive ball feel.

- Fine-tunes the paddle's performance, suitable for precision control in competitive play.

Disadvantages:

- Longer production cycle compared to hot pressing.

- Requires precise pressure control mechanisms, which can demand significant quality assurance measures.

Thermoforming uses heat to soften materials which are then molded into complex shapes with precision. This process is particularly beneficial for paddles with intricate designs and varying thicknesses.

Advantages:

- Enables the creation of paddles with sophisticated shapes and uneven material distribution.

- Maintains the paddle’s structural stability and enhances overall performance.

- Suitable for high-performance and custom-made products.

Disadvantages:

- Longer production time and increased equipment costs.

- Best suited for premium product lines where performance and design intricacies justify the cost.

To summarize these production methods, the following table outlines the key factors to consider when selecting a manufacturing process for high-performance pickleball paddles:

| Production Method | Key Advantages | Limitations | Best Suited For |

|---|---|---|---|

| Hot Pressing | High efficiency; Strong impact resistance | High equipment investment; Possible material alteration | Large-scale manufacturing of high-strength paddles |

| Cold Pressing | Precise control; Preserves material properties | Longer production cycle; Requires precision equipment | Paddles requiring enhanced control and responsiveness |

| Thermoforming | Intricate design; Consistent performance | Increased production cost/time | Premium or custom-designed paddles |

Custom Manufacturing5 and Its Impact on Market Differentiation

Beyond material selection and production processes, customization plays a critical role in addressing the specific needs of diverse market segments. At NEX Pickleball, we offer custom design options that allow clients to specify paddle features such as design aesthetics, weight distribution, balance, grip size, and surface texture. This level of customization is essential for:

- Brand Differentiation: Retailers and distributors can offer exclusive paddle designs that resonate with their target demographic.

- Tailored Performance: Whether it’s for recreational play or competitive tournaments, custom paddles ensure that performance characteristics meet player needs.

- Enhanced End-User Experience: Custom grips and surface treatments enhance comfort and ball control, crucial for maintaining player endurance over long matches.

Such tailoring has become a key value proposition in B2B sporting goods relationships, where differentiated products can command premium pricing and foster brand loyalty. The strategic integration of custom manufacturing within our production model has allowed industry leaders to stay ahead of market trends and meet the evolving demands of competitive pickleball play.

Quality control is as important as the initial design. Every paddle produced at NEX Pickleball undergoes rigorous testing to validate performance metrics, including impact resistance, vibration reduction, and overall durability. Laboratory tests and real-world play scenarios provide valuable data enabling us to fine-tune our production processes continuously.

For example, scientific studies on carbon fiber properties have demonstrated that paddles made with 12K Carbon Fiber possess greater hardness and impact resistance—attributes quantifiable through stress tests and comparative performance metrics. Such data not only confirm our material choices but also offer B2B buyers concrete evidence of our products’ superior performance in rigorous competitive conditions.

Implementing a robust quality assurance program ensures that every paddle matches the precise specifications required for high-level competitive play. This scientific approach to quality and performance has allowed NEX Pickleball to develop strong, long-term relationships with partners across the global sporting goods market.

When evaluating pickleball equipment, purchasing managers should consider the following action points:

- Material Quality: Prioritize paddles manufactured with high-grade carbon fibers such as 3K, 12K, or T300 Carbon Fiber. These materials offer a mixture of durability, enhanced performance, and precise control.

- Production Process: Understand the production method behind the paddle design. Whether it’s hot pressing for efficiency, cold pressing for precision, or thermoforming for intricate designs, the process directly impacts overall performance and cost.

- Customization Capabilities: Look for manufacturers that offer custom manufacturing solutions. Being able to tailor the paddle design to target market segments provides a significant competitive edge.

- Quality Assurance: Assess the manufacturer’s quality control protocols. Reliable testing procedures ensure that the paddles will perform consistently under competitive conditions.

- Supply Chain Integration: Consider manufacturers known for timely production and efficient supply chain management. This ensures that large orders can be met without delays, a critical factor in maintaining market competitiveness.

By aligning these key considerations, B2B purchasing managers can make an informed decision that maximizes return on investment and customer satisfaction. NEX Pickleball’s commitment to cutting-edge production technology and rigorous quality assurance provides the transparency and reliability that discerning buyers seek.

In today’s competitive sporting goods landscape, the performance of pickleball equipment hinges on the careful integration of advanced carbon fiber materials and meticulously managed production processes. With our comprehensive understanding of material properties and precision manufacturing, NEX Pickleball offers products that set new benchmarks in durability, performance, and customization.

Our in-depth analysis highlights the advantages of using 3K Carbon Fiber, 12K Carbon Fiber, and T300 Carbon Fiber in high-performance paddles. Whether through hot pressing for efficiency, cold pressing for a natural feeling, or thermoforming for intricate designs, our production processes ensure that each paddle meets the highest standards of craftsmanship.

For B2B purchasing managers looking to invest in superior sporting goods equipment, the decision should weigh both immediate performance benefits and long-term strategic advantages. NEX Pickleball stands as a reliable partner, offering customized solutions, robust quality control, and a commitment to excellence that drives competitive advantage in an ever-evolving market.

We invite you to explore our range of advanced pickleball paddles and discover how our expertise can meet your business needs. Engage with our team for detailed technical insights and customized product solutions that empower your portfolio and satisfy your market’s demands.

What is the best equipment for pickleball?

High-performance pickleball equipment is not just about specialized shoes or paddle bags—it is fundamentally about the paddles themselves. Paddles made from advanced carbon fiber1 materials (such as 3K Carbon Fiber, 12K Carbon Fiber, and T300 Carbon Fiber) and produced through optimized methods like hot pressing, cold pressing3 or thermoforming4, deliver the essential balance of power, control, and durability necessary for competitive play.

-

carbon fiber: Click to learn about the fundamental properties of carbon fiber and its benefits in creating lightweight, strong, and durable sports equipment. ↩ ↩ ↩2

-

3K Carbon Fiber: Click to explore detailed insights into 3K Carbon Fiber, including its structural advantages and suitability for enhancing performance in sporting goods. ↩ ↩ ↩2

-

Cold Pressing: Click to understand the cold pressing manufacturing process, its impact on preserving material properties, and its relevance in producing precision sports equipment. ↩ ↩ ↩2

-

Thermoforming: Click to read more about the thermoforming process, how heat is used to shape materials, and why this method is essential for custom-designed, high-performance products. ↩ ↩ ↩2

-

Custom Manufacturing: Click to discover how custom manufacturing strategies enable tailored product designs that meet specific market needs and drive competitive advantage in B2B environments. ↩ ↩