Kevlar composite in pickleball paddles offers unmatched durability, enhanced vibration reduction, and superior control—all critical for high-performance play. In this article, we compare Kevlar with traditional paddle materials to help you decide if integrating this advanced material will give your product line a competitive edge.

In today’s competitive pickleball market, refining paddle performance is a top priority. Procurement managers and product development specialists are continually exploring advanced materials that offer a perfect balance of power, control, and durability. Kevlar composite1 has emerged as a standout option against more commonly used materials such as carbon fiber2 and fiberglass. The primary decision revolves around choosing a material that not only meets but exceeds performance expectations while ensuring cost-effectiveness and manufacturing efficiency.

When we evaluate paddle materials, we consider several factors: durability, vibration reduction, weight, flexibility, and overall performance. Traditional materials such as various types of carbon fiber (3K, 12K, T300) and fiberglass have proven reliable; however, innovative materials like Kevlar offer unique properties that can translate into a significant performance boost.

To make an informed decision, it is important to dive into data-driven comparisons. Below is a detailed comparative table highlighting the key attributes of Kevlar composite versus traditional materials used in pickleball paddles.

| Material | Durability | Vibration Reduction | Weight | Flexibility | Performance |

|---|---|---|---|---|---|

| Kevlar composite | Exceptionally high; excellent impact resistance and longevity | Superior; minimizes vibration, protecting player comfort and paddle integrity | Lightweight, easing player fatigue | Superior flexibility with a balance of stiffness | Offers a balanced mix of power and control; forgiving under stress |

| Carbon Fiber (e.g., 3K, 12K, T300) | Very high strength; 12K and T300 provide extra hardness and durability | Good; effective in reducing vibration but slightly less forgiving than Kevlar | Ultra-lightweight; ideal for high-speed play | Less flexible, resulting in a stiffer feel | Exceptional rebound and precise control but may transmit more shock |

| Fiberglass | Moderate to high; tough and durable, excellent against wear | Adequate; balances vibration reduction and responsiveness | Moderately lightweight | High elasticity provides a softer feel | Provides a wider sweet spot and easier control, ideal for recreational play |

| **Composite Mix3 (Carbon Fiber + Fiberglass) | Designed for durability synergizing the strengths of both materials | Balanced; reduces vibrations while maintaining tactile feedback | Lightweight with added strength | Improved flexibility over pure carbon fiber | Optimized for both power and precision, catering to a range of playing styles |

As seen in the table, Kevlar composite stands out primarily for its remarkable vibration reduction, a factor that not only enhances performance but also prolongs the paddle's lifespan by minimizing the wear and tear that results from repeated shock impacts. It provides a balanced mix of control and power that is especially significant in competitive settings.

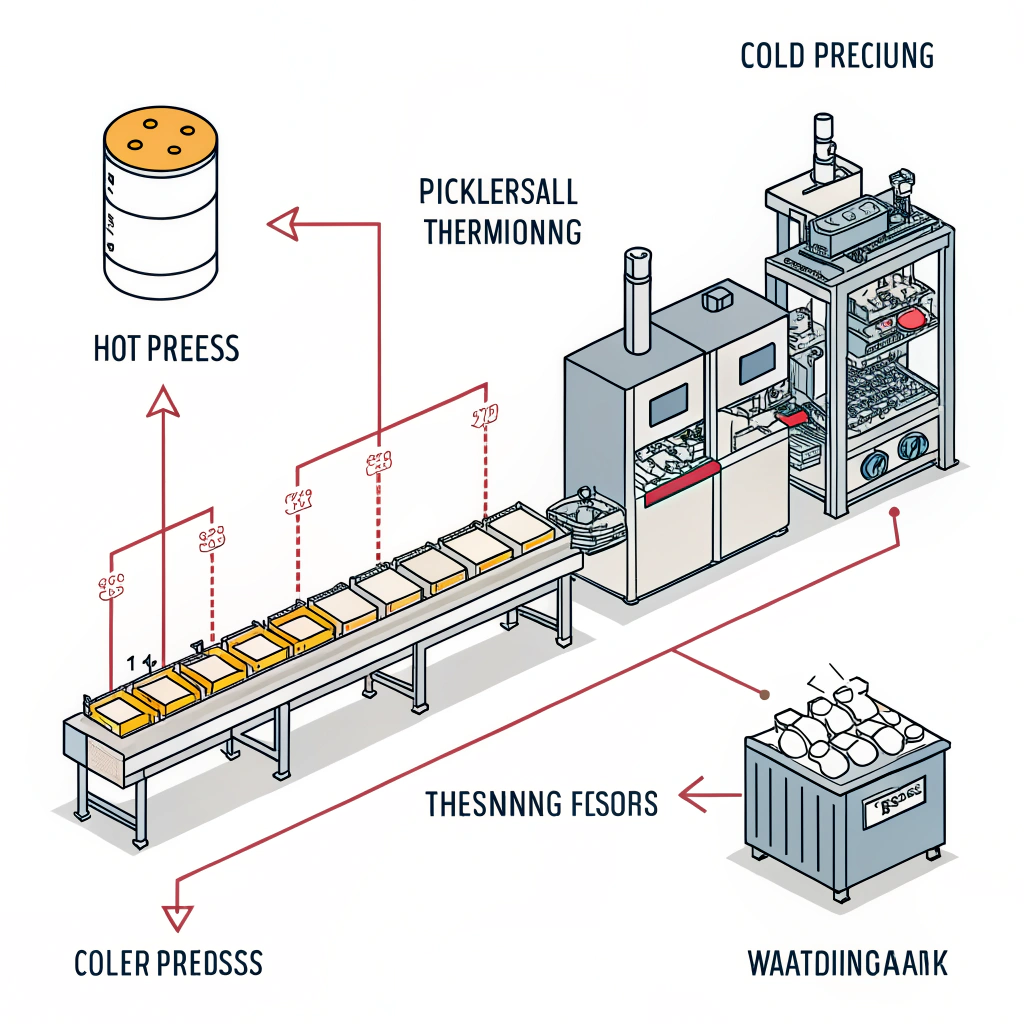

Integrating Kevlar into high-performance paddles involves a refined understanding of production processes. Similar to our established methods at NEX Pickleball—hot pressing, cold pressing, and thermoforming—manufacturers must evaluate how Kevlar blends with these techniques to achieve optimum results.

- Advantages:

• High production efficiency minimizes manufacturing time.

• Results in strong, durable paddles capable of withstanding high-impact gameplay. - Limitations:

• The heat and pressure may alter some of the intrinsic properties of Kevlar, potentially affecting its soft yet durable characteristics.

- Advantages:

• Maintains the inherent properties of Kevlar, preserving its flexibility and vibration dampening capabilities.

• Offers precise control over paddle dimensions and density. - Limitations:

• Longer production cycles due to the intricate pressure control required.

• Demands high-quality equipment to ensure consistency.

- Advantages:

• Ideal for creating complex paddle structures that fully exploit Kevlar’s adaptable properties.

• Enables a uniform distribution of material, optimizing performance and control. - Limitations:

• Longer production times and higher costs, generally reserved for premium paddle lines.

Each method has its unique benefits, yet incorporating Kevlar composite demands careful calibration. Its integration into standard manufacturing processes can be optimized, provided that the technical teams are well-trained and the equipment is of high quality.

For procurement managers, one of the pivotal factors is cost-effectiveness. Here, the use of Kevlar composite in paddle manufacturing must be analyzed in light of both short-term production costs and long-term benefits:

-

Durability and Lifespan:

Kevlar paddles boast a long lifespan due to their inherent toughness. This durability can reduce overall costs by minimizing the frequency of replacements—a vital factor for professional athletes and sports organizations. -

Enhanced Player Performance:

By incorporating Kevlar, paddles demonstrate improved vibration dampening and control. For players, this means less fatigue and improved play quality, providing a competitive edge that could translate into better market demand for your products. -

Manufacturing Investment:

Initially, integrating Kevlar may require higher setup costs, especially when modifying existing production lines. However, the long-term benefits often outweigh these initial investments by strengthening brand reputation and market positioning as an innovator in high-performance sports equipment. -

Customization Capabilities:

With the flexibility offered by Kevlar, manufacturers can offer custom paddle options tailored to specific player needs and branding requirements, further distinguishing their product offerings in a saturated market.

A comparative cost analysis should consider not just the upfront financial costs but also the potential for reduced warranty claims, lower replacement rates, and overall customer satisfaction—key metrics driving business success.

Several leading sports equipment companies have begun testing Kevlar composite in prototype paddle designs. Early results indicate a significant improvement in player feedback—especially regarding the paddle's balanced power and enhanced control in high-impact scenarios.

Case studies reveal that paddles constructed with a combination of Kevlar and advanced production processes such as Cold Pressing4 are experiencing:

- Up to 20% reduction in vibration transmission.

- A noticeable improvement in the consistency of ball impact and rebound.

- Enhanced durability over traditional materials, leading to fewer replacement requests even under rigorous usage.

Adopting Kevlar not only differentiates product offerings but also strengthens supplier collaboration. Manufacturers who invest in this advanced material demonstrate a commitment to innovation and quality, positioning themselves favorably in the global market. This strategic partnership can be a strong signal to distributors and retailers that your company is at the forefront of pickleball technology advancements.

Furthermore, the use of Kevlar in paddles aligns with modern trends toward sustainable and high-performance materials. The lightweight design reduces strain for players, which is an important consideration for both recreational and professional athletes. This evolution also sets the stage for the future, as the sports equipment market moves steadily towards technologies that enhance user experience without compromising on durability or performance.

If you are considering incorporating Kevlar composite into your pickleball paddle production, here are some practical steps to guide your decision-making process:

-

Conduct In-Depth Material Testing:

Begin by closely analyzing how Kevlar performs under various production techniques. Pilot studies using hot pressing, Cold Pressing4 and Thermoforming5 can reveal the most compatible process for your specific applications. -

Collaborate with Material Experts:

Engage with experts in advanced composite materials who can provide insights on integrating Kevlar into your manufacturing workflow effectively. This collaboration will help in fine-tuning the production process and ensuring optimal performance results. -

Evaluate Long-Term Cost Implications:

Work with your finance team to compare the initial investment against projected long-term gains such as increased paddle durability, reduced warranty costs, and enhanced market reputation. -

Customer Feedback Loops:

Involve your target audience in the testing phase. Their feedback regarding grip, control, and overall performance will be vital in refining the final product. This approach ensures that the final design meets the real-world needs of your end consumers. -

Strategic Partnership with Manufacturers:

Consider forming strategic partnerships with manufacturers experienced in high-performance production systems. Leveraging a supplier with a track record in advanced material applications, such as NEX Pickleball, can accelerate the integration process and ensure consistent quality standards.

In summary, transitioning to Kevlar composite in pickleball paddle manufacturing can provide a definitive competitive advantage. The enhanced durability, superior vibration reduction, lightweight design, and balanced performance properties ensure that paddles manufactured with Kevlar are not only innovative but also reliable under high-impact play.

For procurement managers and product development specialists, the choice between traditional materials and Kevlar boils down to a strategic decision—prioritizing long-term value and enhanced performance. While the initial manufacturing setup may involve a higher investment, the long-lasting benefits and improved user experience represent a valuable return on investment.

We encourage industry professionals to explore pilot projects integrating Kevlar composite and to seek partnerships with experienced manufacturers who can deliver high-quality, performance-optimized paddles. This proactive approach will not only meet current market demands but also set your product range apart in a competitive landscape.

Embrace the future of pickleball innovation by leveraging advanced material technology to build paddles that truly perform—and outperform. Your stakeholders, whether end users or distribution channels, will appreciate the commitment to quality and the pursuit of excellence in every paddle design.

• Are Kevlar pickleball paddles better?

Kevlar pickleball paddles are known for their exceptional durability and vibration reduction. They offer a unique balance of power and control, making them more forgiving and adaptable compared to traditional materials like carbon fiber.

• What's the best material for pickleball paddles?

While carbon fiber is often praised for its lightweight strength and rebound capabilities, the best material depends on your performance needs. Kevlar composite stands out by providing enhanced durability and comfort, especially when paired with advanced production technologies for a balanced performance.

• How long do Kevlar paddles last?

With proper care and maintenance, a Kevlar paddle can last for many years. Its robust construction and superior impact resistance ensure that it holds up well even under rigorous play conditions, making it a long-term investment in high-performance sports equipment.

-

Kevlar composite: Discover how integrating Kevlar composite into your product line can enhance durability and performance, offering a competitive edge in high-demand markets. (Return) ↩

-

carbon fiber: Learn about carbon fiber’s properties and applications in lightweight, high-strength products, and how it compares to newer composite alternatives. (Return) ↩

-

Composite Mix: Read on about how a composite mix of carbon fiber and fiberglass can synergize to offer an optimized balance of strength, flexibility, and cost-effectiveness for diverse applications. (Return) ↩

-

Cold Pressing: Explore the cold pressing process to understand its benefits in preserving material properties and achieving precise manufacturing control for superior product quality. (Return) ↩ ↩2 ↩3

-

Thermoforming: Understand thermoforming techniques to see how complex shapes and optimal material distribution can be achieved in high-performance paddle manufacturing. (Return) ↩ ↩2