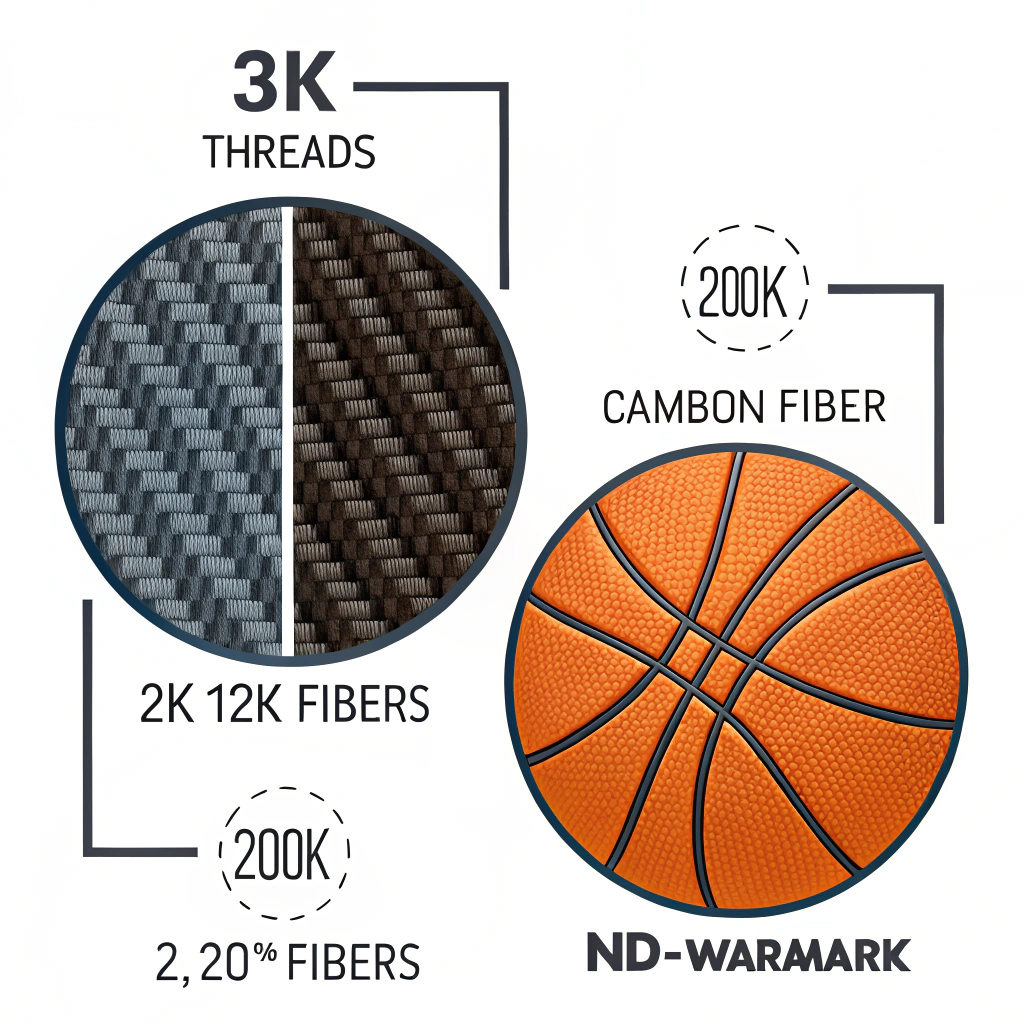

Achieving a high-performance pickleball paddle starts with selecting the right materials. In brief, 3K carbon fiber1 offers excellent strength, durability, and control for competitive play. However, differences in thread counts, such as between 3K and 12K carbon fiber2, and variations like T700 versus T300, can significantly influence paddle performance, production cost, and overall feel.

In today’s competitive sports equipment market, B2B purchasers and product managers must carefully evaluate the technical specifications and production processes behind high-performance pickleball paddles. At NEX Pickleball, our focus on advanced materials and manufacturing expertise has allowed us to achieve a superior balance between durability and performance. This article provides a detailed technical comparison of 3K carbon fiber against its counterparts and examines manufacturing methods that ensure consistent quality and performance.

3K carbon fiber is widely recognized for its robust strength and controlled flexibility, making it a popular choice for competitive paddle design. In contrast, 12K carbon fiber2 utilizes 12,000 threads per strand instead of 3,000, resulting in a fabric that is often more flexible but may trade off some rigidity for enhanced shock absorption. Below is a table that summarizes the critical differences between these materials:

| Feature | 3K Carbon Fiber | 12K Carbon Fiber |

|---|---|---|

| Thread Count per Strand | 3,000 | 12,000 |

| Strength & Rebound Force | High strength with excellent rebound control | Increased flexibility; may offer softer impact |

| Durability | Excellent impact resistance | Smooth surface; potentially less rigid structure |

| Vibration Dampening | Effective vibration reduction | Superior flexibility can enhance shock absorption |

| Best Suited For | Competitive play with a focus on precision and durability | Designs prioritizing flexibility and controlled rigour |

With these characteristics in mind, the choice between 3K and 12K carbon fiber often depends on the desired balance between impact resistance and material flexibility. For businesses targeting elite players or markets with high-performance demands, 3K carbon fiber’s robust properties make it a strong candidate for producing consistent and reliable paddles.

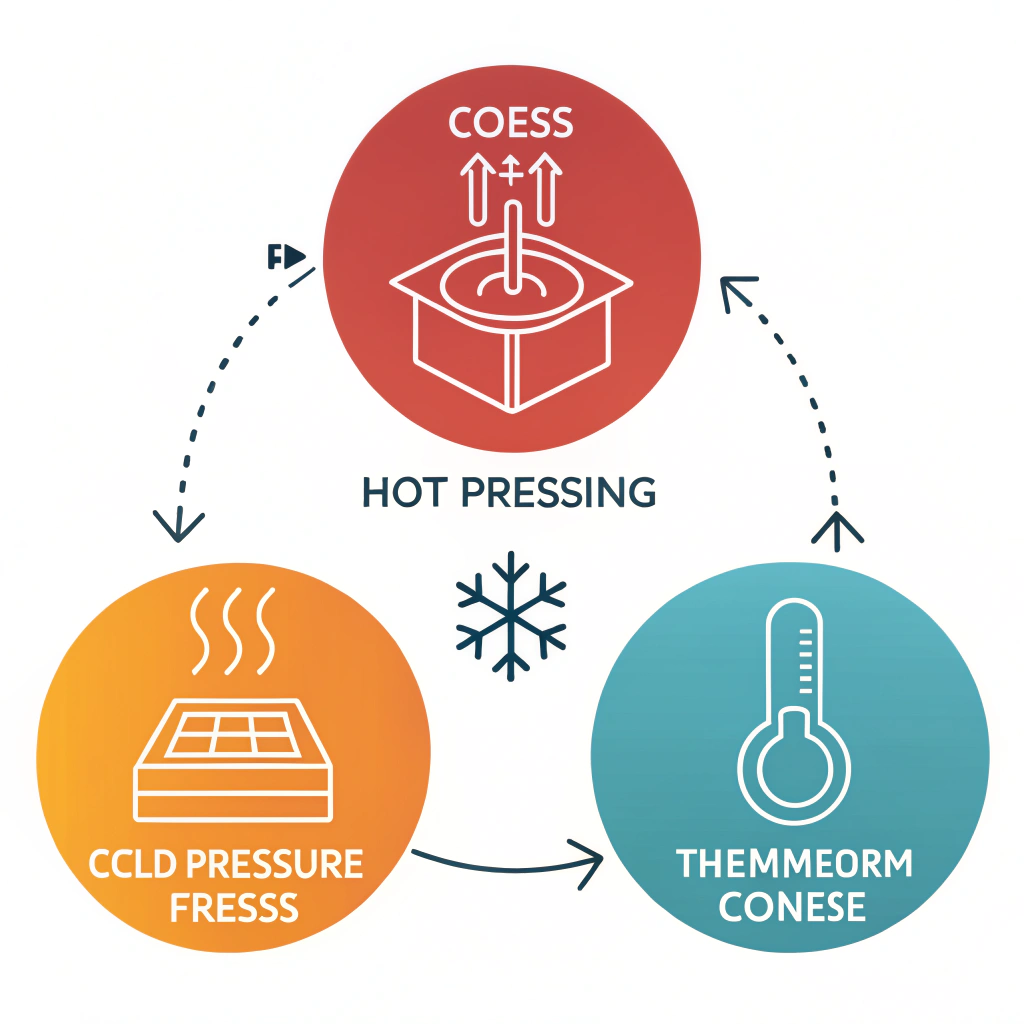

In addition to material selection, the production process plays a key role in achieving the desired paddle performance. At NEX Pickleball, we employ state-of-the-art manufacturing techniques to optimize the characteristics of our paddles. The main production processes include Hot Pressing3, cold pressing, and Thermoforming4—each offering distinct advantages:

-

Hot Pressing3

Hot pressing utilizes heat and pressure to form the compound structure of the paddle. Its benefits include high production efficiency, improved impact resistance, and robust structural integrity. However, high temperatures may slightly alter material properties, impacting the tactile feel of the paddle. -

Cold Pressing

Cold pressing is employed to maintain the material’s innate properties by shaping the paddle at room temperature under controlled mechanical pressure. This method excels at preserving flexibility and control, though it tends to involve longer production cycles and requires precise pressure regulation. -

Thermoforming4

Thermoforming involves heating the material to a softening point before molding it into detailed shapes. It allows for intricate geometrical designs and a well-distributed structure. This process is ideal for premium, custom-made paddles but comes with a higher cost and longer production time.

The application of these manufacturing techniques ensures that each paddle maintains a consistent weight distribution, ergonomic grip design, and surface texture that meets strict quality control standards. Robust production processes not only enhance paddle performance but also enable us to offer custom design options—essential for meeting the varied needs of large-scale distributors and sports equipment retailers.

Comparative Analysis: T300 (3K) vs. T700 carbon fiber5

Technical advancements in carbon fiber technology continue to influence high-performance sports equipment. In the realm of pickleball paddles, a comparison between T300 (3K Carbon Fiber) (a common form of 3K carbon fiber) and T700 carbon fiber5 reveals important differences that affect performance:

| Aspect | T300 (3K Carbon Fiber) | T700 Carbon Fiber |

|---|---|---|

| Tensile Strength | High tensile strength, ideal for balanced play | Approximately 40% higher tensile strength than T300, offering more power in impact scenarios |

| Density | Optimized for lightweight yet strong design | Slightly denser, resulting in increased weight but higher durability |

| Material Composition | Standard carbon fiber composition | Higher carbon content and lower nitrogen levels, enhancing performance quality |

| Application Focus | Best for players requiring an optimal mix of power and control | Suitable for competitive players who need enhanced strength for high-impact play |

| Performance Impact | Provides excellent control and stable rebound | Greater energy transfer and impact resistance can boost competitive advantage |

This table illustrates that while T300 carbon fiber (often synonymous with traditional 3K carbon) offers a well-rounded performance for most players, T700 carbon fiber5 presents compelling benefits for scenarios that demand extra power and durability. B2B buyers must weigh these factors carefully, as the slight increase in weight might be acceptable given the enhanced tensile strength.

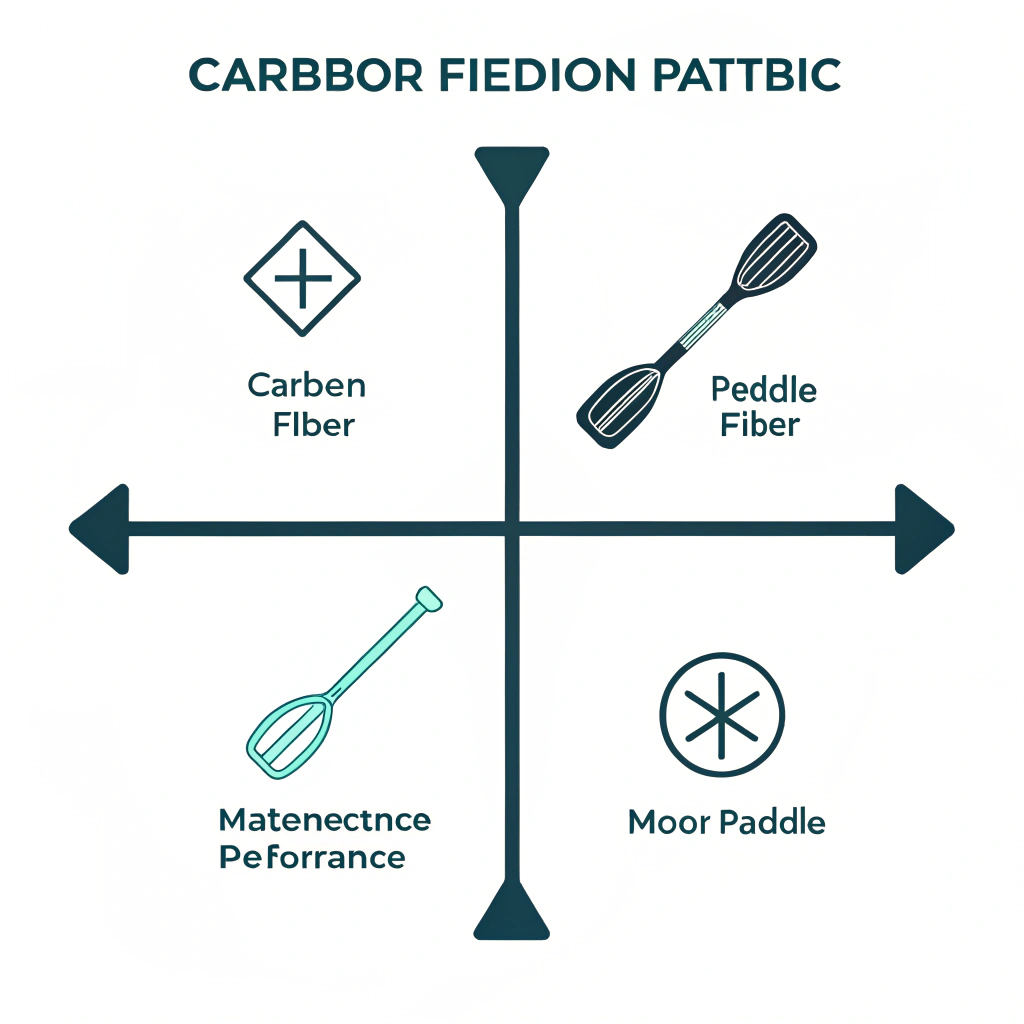

When making purchasing decisions, it is important to consider not only the raw material differences but also how manufacturing processes affect the final product. For example:

• Rebound Force and Vibration Damping: A paddle made with 3K carbon fiber processed through cold pressing may offer superior ball control due to a preserved material feel, which is critical for precision in competitive play.

• Structural Integrity and Durability: Paddles crafted with 12K carbon fiber using hot pressing can provide a durable solution that absorbs shock well, making them ideal for environments where high-impact play is frequent.

• Customizability: Thermoforming enables the production of paddles with complex shapes and ergonomic designs. This allows manufacturers to offer tailored solutions that cater to both amateur and professional athletes, meeting diversified market needs.

Below is an integrated decision matrix that helps simplify the process:

| Key Metric | 3K Carbon Fiber (T300) | 12K Carbon Fiber | T700 Carbon Fiber |

|---|---|---|---|

| Rebound Force | High and consistent | Moderate with higher elasticity | Very high with superior energy transfer |

| Weight | Lightweight | Lightweight/mid-range | Slightly heavier |

| Impact Resistance | Excellent | Good, with enhanced shock absorption | Superior impact resistance |

| Manufacturing Flexibility | Suitable for cold and hot pressing | Best with hot pressing | Suitable with high-end processes like thermoforming |

| Ideal Use Case | Competitive play requiring balance | Recreational to competitive use with softer feel | High-stakes competitive scenarios needing extra strength |

When discussing production efficiency and cost-effectiveness, it is important for B2B buyers to balance technical superiority with scalable manufacturing processes. NEX Pickleball leverages its experience as a leading manufacturer—and even as an OEM for brands like Joola and Selkirk—to streamline production without compromising on quality. Our integration of advanced production processes ensures that every paddle delivered meets strict durability and performance standards while remaining cost-effective for bulk orders.

Consider a scenario where a sports retail chain decided to upgrade its product line to include paddles for a rising customer base of competitive players. The procurement team was initially inclined towards paddles using a standard composite material. However, after a detailed technical evaluation, they pivoted to consider 3K carbon fiber paddles manufactured through ultra-precise cold pressing techniques.

Key outcomes included:

• Enhanced ball control and improved angular stability during play.

• Reduced vibration losses that led to a more comfortable playing experience.

• Positive market reception as players reported better tactile feedback, leading to increased brand loyalty.

The factory’s flexible production approach allowed customization in paddle grip size and design, further differentiating the product in a highly competitive market. This case underscored the importance of aligning raw material selection with the manufacturing process, ultimately delivering a product that exceeded end-user expectations in both performance and durability.

In summary, while 3K carbon fiber offers balanced performance with excellent durability and control for pickleball paddles, it is essential to understand its comparative advantages against materials like 12K and T700 carbon fiber. Our detailed comparison and analysis demonstrate that the optimal choice depends on the targeted market segment:

• For competitive play requiring precise control and durability, 3K carbon fiber processed with cold pressing is an ideal solution.

• For products where enhanced flexibility or smoother surface textures are paramount, 12K carbon fiber may be preferred.

• When maximum tensile strength and energy transfer are needed, T700 carbon fiber5 offers significant benefits despite a slight weight trade-off.

B2B decision-makers should use this technical insight to guide their specifications and production planning. By partnering with experienced manufacturers like NEX Pickleball—who excel in leveraging advanced materials and manufacturing techniques—distributors and retailers can secure a competitive edge in the high-performance sports equipment market. We recommend further consultation with our technical sales team to explore custom solutions and detailed performance testing tailored to your market needs.

What is the difference between 3K and 12K carbon fiber paddle?

The primary distinction lies in the thread count; 3K carbon fiber uses 3,000 threads per strand while 12K carbon fiber uses 12,000 threads, resulting in a fabric that is typically more flexible. This flexibility can lead to a softer impact and enhanced shock absorption, whereas 3K maintains a balance of strength and precise rebound control.

What is the difference between T700 and 3K carbon fiber?

T700 carbon fiber offers roughly 40% higher tensile strength than the standard 3K (T300) carbon fiber. Additionally, T700 is slightly denser, which may result in a heavier paddle, and it features a higher carbon content with lower nitrogen levels. This composition enhances overall durability and power transfer, making T700 ideal for competitive environments that demand maximum performance.

-

3K carbon fiber: Read the article to explore the properties, manufacturing benefits, and overall performance characteristics that make 3K carbon fiber ideal for high-performance paddles. ↩ ↩

-

12K carbon fiber: Understand the distinct structural properties of 12K carbon fiber and its impact on flexibility, shock absorption, and overall paddle performance. ↩ ↩ ↩2

-

Hot Pressing: Discover how the hot pressing manufacturing process uses heat and pressure to form composite materials for enhanced impact resistance and structural integrity. ↩ ↩ ↩2

-

Thermoforming: Gain insights on thermoforming techniques that allow for intricate molding of materials into ergonomic designs suitable for high-performance sports equipment. ↩ ↩ ↩2

-

T700 carbon fiber: Learn about T700’s enhanced tensile strength and composition compared to traditional 3K fibers, offering improved durability and energy transfer. ↩ ↩ ↩2 ↩3 ↩4