Pickleball Paddle Manufacturer and factory in China – the ideal partner for high-performance, innovative, and scalable production solutions.

This article explains why selecting a pickleball paddle manufacturer in China, particularly a partner like NEX Pickleball, is a smart decision. We dive into our advanced production techniques, robust material choices, and the precision that brings your paddles to market faster and more reliably than ever before.

China has long been known as a global manufacturing hub. For sports equipment such as pickleball paddles, partnering with a reputable Chinese manufacturer offers several benefits:

• Economies of scale that lower costs

• Advanced production technologies and training

• Consistent quality control and strict adherence to international standards

• Flexibility in customization and high-volume production

At NEX Pickleball, our Jiaxing-based factory combines established expertise with technical innovation, making us one of the leading manufacturers for both OEM1 and private label partnerships. This advantage means that as the pickleball market evolves, your business will always have a reliable production partner who is prepared to scale production while maintaining premium quality.

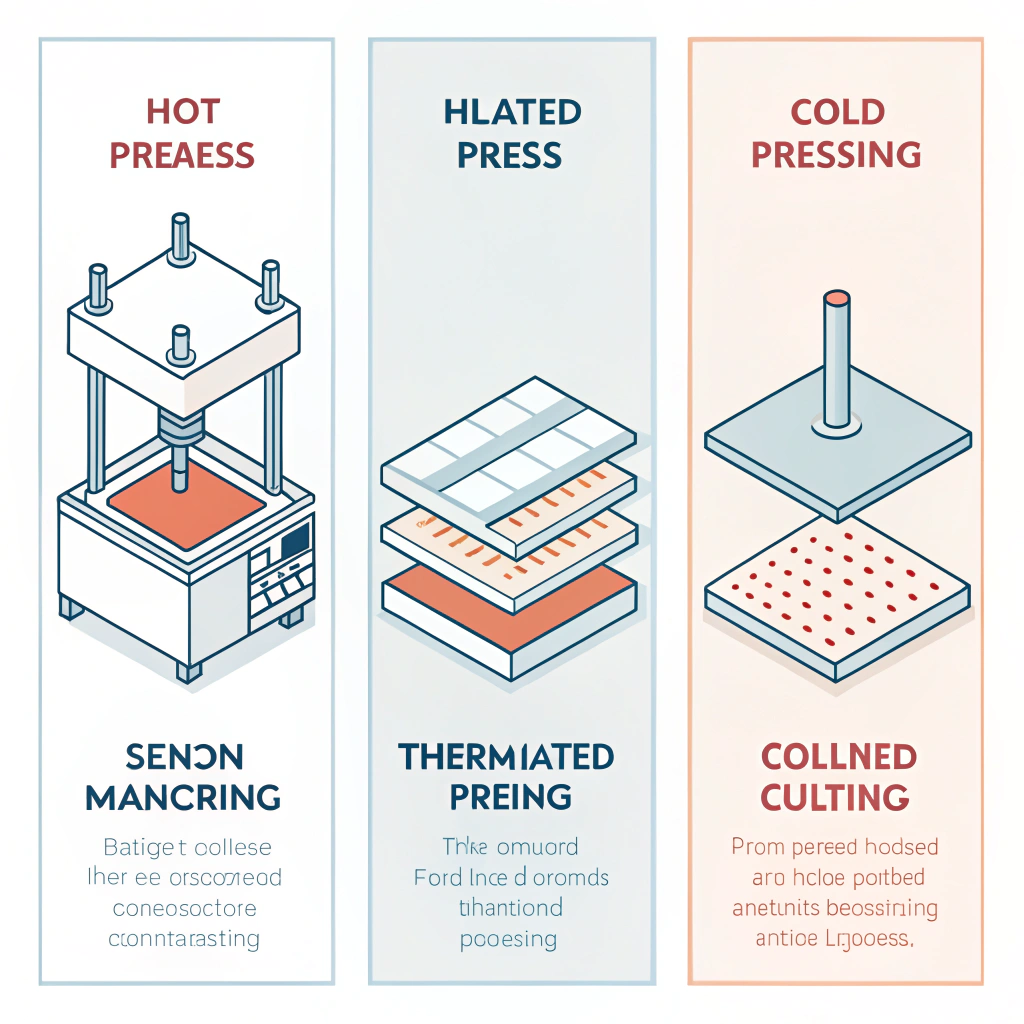

At NEX Pickleball, we use three primary manufacturing processes that each cater to different performance needs and product design specifications:

Hot pressing is our go-to process when producing paddles that require high impact resistance and robust structural integrity. In this method, materials are heated and pressed under high pressure:

- Advantages:

- High production efficiency

- Produces paddles with excellent impact resistance

- Ensures a structurally sound product for high-performance play

- Disadvantages:

- Potential alteration of some material properties

- Requires high investment in specialized equipment

Cold pressing is ideal when precision and control are critical. By shaping materials at room temperature, we preserve the inherent attributes of our raw materials:

- Advantages:

- Maintains material properties intact

- Offers precise control over thickness and structure

- Yields a superior ball feel and responsiveness

- Disadvantages:

- Longer production cycles compared to hot pressing

- Demands precise pressure control using high-quality machinery

Thermoforming involves heating the materials to a softening point and molding them into shape. This method is perfect for paddles with intricate designs and varied thickness:

- Advantages:

- Enables complex paddle designs with precise material distribution

- Enhances the overall stability and performance of the final product

- Versatile in adapting to a variety of high-performance materials

- Disadvantages:

- Higher production time and equipment costs

- Best suited for premium and custom-made paddles

The choice between these methods depends on your desired paddle characteristics, budget constraints, and the target market. The following table summarizes these production processes for a quick comparison and decision-making reference:

| Production Process | Advantages | Disadvantages | Ideal For |

|---|---|---|---|

| Hot Pressing | High efficiency, excellent impact resistance, robust structure | Altered material properties, high equipment cost | Large-scale, high-performance paddles |

| Cold Pressing | Precise control, maintains material integrity, superior responsiveness | Longer production cycle, requires high-quality machinery | Paddles prioritizing feel and precision |

| Thermoforming | Intricate design creation, stable performance, excellent material distribution | Longer lead times, higher equipment cost | Premium or custom-designed paddles |

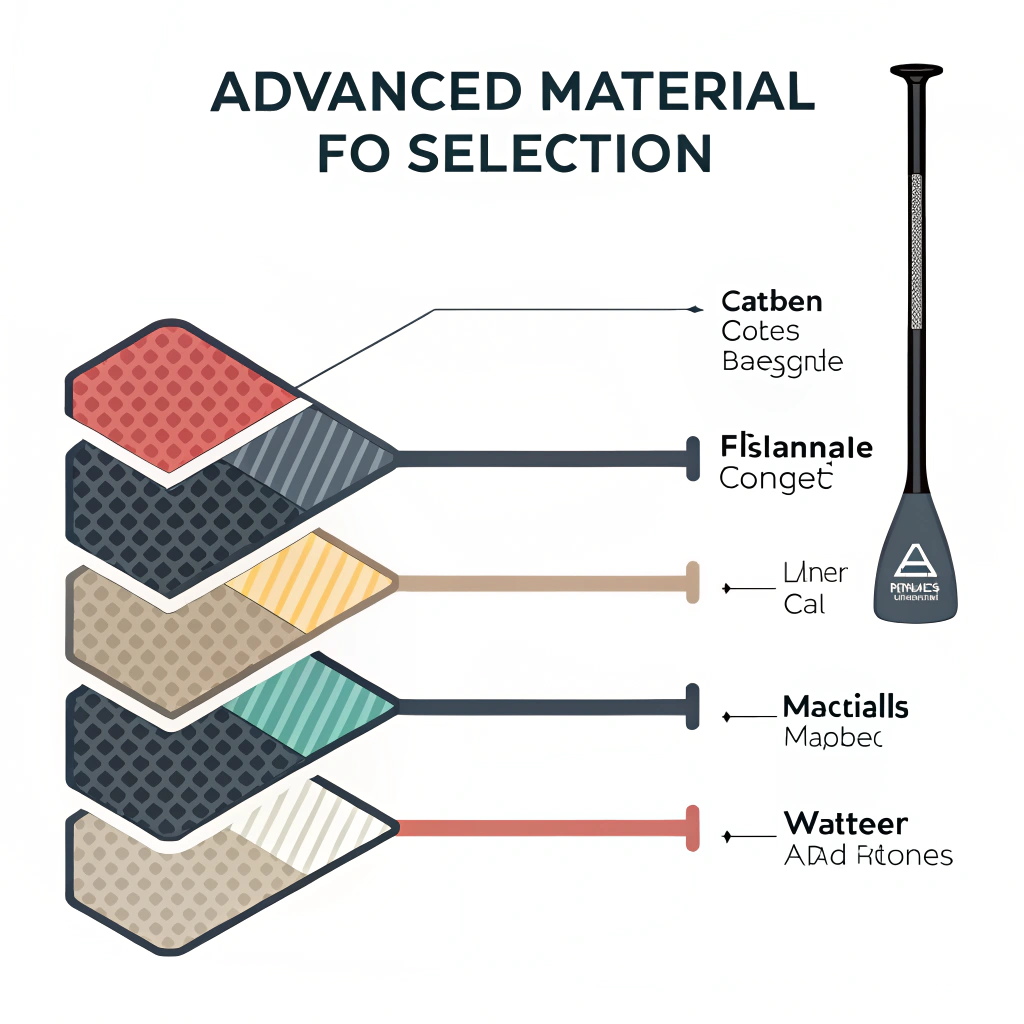

Material quality is the cornerstone of any competitive pickleball paddle. At NEX Pickleball, we use a wide variety of premium materials to strike the perfect balance between strength, durability, and performance.

We employ different types of carbon fiber, each offering distinct performance benefits:

- 3K Carbon Fiber: Provides excellent flexibility and high rebound force while reducing vibration. It is ideal for paddles needing high durability.

- 12K Carbon Fiber: With its higher thread density, it results in a smoother surface, increased hardness, and exceptional durability, all of which are perfect for competitive gameplay.

- T300 Carbon Fiber: Renowned for its tensile strength, T300 ensures a balanced mix of light weight and strength, making it a favorite among players seeking precise control.

Fiberglass paddles provide a harmonious balance between power and control. The E-Glass Fiberglass variant offers enhanced elasticity and tensile strength, ensuring a larger sweet spot and outstanding ball control.

For maximum performance, many advanced paddles integrate composite materials:

- Carbon Fiber and Fiberglass Composite: Merges the benefits of both materials to deliver a well-rounded performance.

- Bamboo Core Composite: Known for its lightweight nature and high impact resistance, it provides a distinct hitting feel and long-lasting play.

- Honeycomb Core: Often made from high-density polymer, this core offers excellent shock absorption and significantly reduces vibration.

The core material directly affects the paddle’s hitting feel, hardness, and overall performance:

- Nomex Honeycomb Core: Delivers exceptional shock absorption and long-term durability—ideal for high-frequency use.

- Aluminum Honeycomb Core: Strikes a balance between weight and power, providing precision and control.

- Polymer Honeycomb Core: Favoured for its elasticity and vibration reduction, making it comfortable for long-term play.

Through rigorous selection and innovative production, our materials not only meet but exceed the expectations of competitive players. We understand that for B2B partners, reliability and sustained quality are paramount.

Importantly, NEX Pickleball isn’t just about producing paddles; we offer fully customizable solutions:

- Custom Paddle Options: Whether for personal use, team branding, or distributor-exclusive designs, you can specify details like paddle weight, grip size, and balance. This flexibility enables you to create products that resonate with your target market.

- OEM Services: As the original equipment manufacturer for prestigious brands such as Joola and Selkirk, our expertise extends from the design phase to the final production process. This makes us an indispensable partner for achieving superior product lines.

- On-Demand Print Services: With state-of-the-art printing services available on our paddles, you can incorporate your brand message, logos, or any custom graphics that enhance your market appeal.

Our ability to tailor production meets the unique needs of each client, ensuring consistency, quick turnaround times, and uncompromising quality. With increasing demand for pickleball and customization trends, our approach not only aligns with current market trends but is also future-ready.

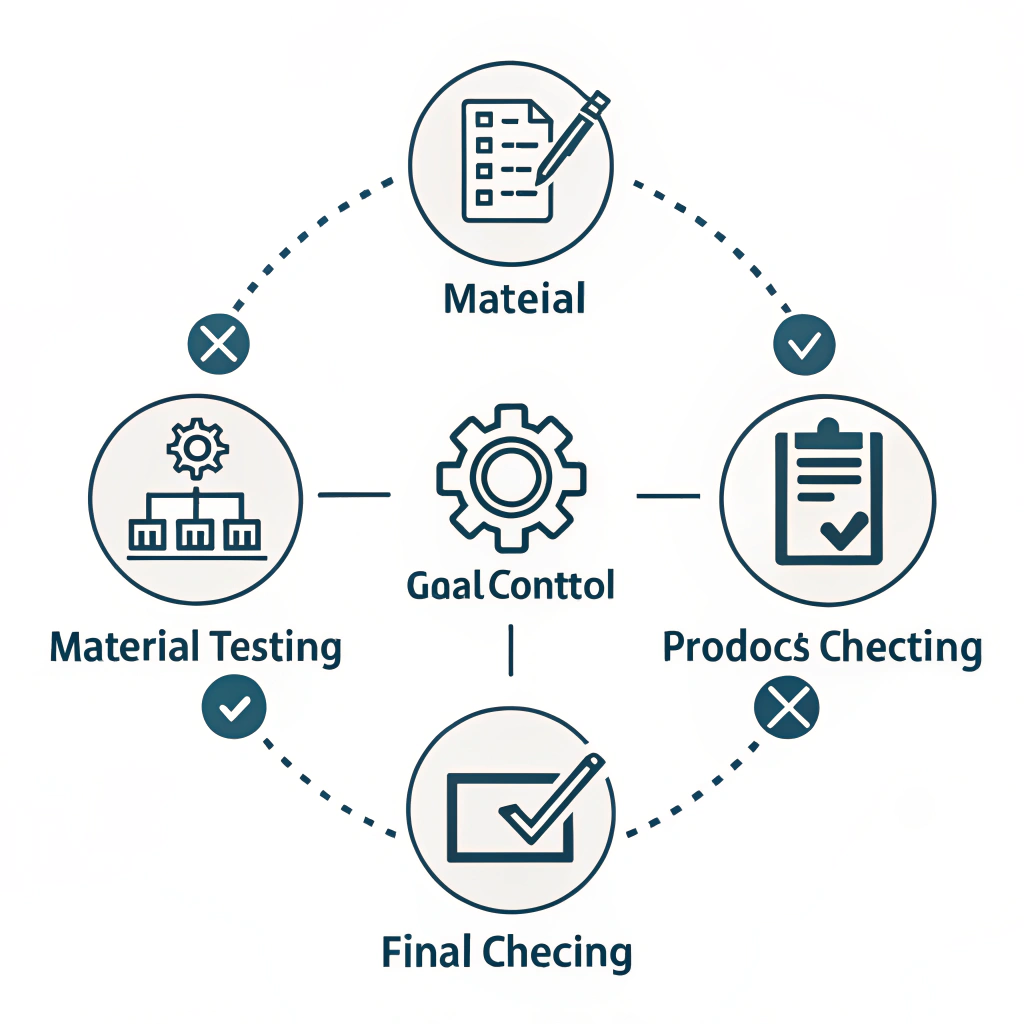

Quality Control5 and Business Reliability

A significant factor in choosing a manufacturing partner is their commitment to quality control. At NEX Pickleball, every paddle undergoes rigorous testing procedures to ensure:

- Optimal weight distribution and balance

- Ergonomic design with a focus on maximizing grip and comfort

- High impact resistance and reduced vibration

Our in-house quality assurance team plays a crucial role in ensuring that every batch meets international standards. This consistency builds your brand’s reputation and boosts consumer confidence in your products. Here’s a quick look at our quality control process:

- Material Testing – ensuring all raw materials meet strict quality benchmarks.

- In-Process Inspections – regular checks during production to catch defects early.

- Final Product Testing – each paddle is tested for durability, flexibility, and performance.

- Client Feedback Integration – continuous improvement based on B2B partner feedback.

The multistage quality assurance process underpins our commitment to delivering the best products consistently. It also highlights our readiness to become your trusted production partner in the competitive sports equipment market.

When you compare us with other suppliers, several distinctive advantages emerge:

- Technical Innovation: Our mastery of advanced production techniques (hot pressing, cold pressing, and thermoforming) ensures paddles that meet specific performance requirements.

- Materials Expertise: Our extensive range of premium materials such as various carbon fibers, fiberglass, and composite options are tailored for different levels of play—from recreational to competitive.

- Customization: We offer unparalleled flexibility, allowing you to fine-tune every aspect of the paddle’s design. This includes core material selection and even on-demand printing services, enabling you to quickly adapt to market trends.

- Proven Track Record: As the manufacturing backbone for reputed brands like Joola and Selkirk, our reputation in the industry is validated by years of successful production and satisfied partners.

In a market where product performance translates directly to competitiveness, choosing a partner with an established record of technical excellence and innovative manufacturing is key. Our commitment to cutting-edge production ensures that your paddles will always perform at their peak, no matter the level of play.

If you are a procurement manager or a decision-maker evaluating suppliers, consider the following steps to ensure a sound decision:

- Assess Material and Production Technology: Review suppliers’ production processes and material options to find the best fit for your market.

- Demand Consistent Quality: Prioritize manufacturers with a robust quality control process and proven quality benchmarks.

- Evaluate Customization Capabilities: Consider how well the manufacturer can adapt to your brand’s specific needs, whether it is design specifications or OEM services.

- Review After-Sales and Support Services: A reliable production partner offers not only advanced manufacturing but also comprehensive post-production support.

By carefully analyzing these factors, you can confidently select NEX Pickleball as your manufacturing partner, ensuring high-performing, durable products that meet your market demands.

For B2B partners looking for a pickleball paddle manufacturer in China, NEX Pickleball stands out with its advanced production systems, meticulous quality control, and extensive customization options. Our capabilities—ranging from various carbon fiber options to innovative production processes such as hot pressing, cold pressing, and thermoforming—equip us to meet both the performance and business requirements of today’s competitive sports equipment market. With a proven track record as the OEM partner for leading brands and a relentless focus on quality, choosing NEX Pickleball means securing a reliable, high-performance manufacturing solution.

Embrace the opportunity to deliver superior products to your customers. Contact us for more details and let us guide your brand towards greater market success with paddles built on precision and innovation.

People Also Ask

Q: What is the best pickleball paddle manufacturer?

A: The best pickleball paddle manufacturers are those that combine technical innovation, high-quality materials, and advanced production processes. Companies like Joola, Selkirk, and quality OEM partners like NEX Pickleball have distinguished themselves by offering premium paddles with enhanced performance, durability, and customization options.

Q: Are Paddletek paddles made in China?

A: Not all pickleball paddles are made in China. For example, Paddletek and Engage manufacture their paddles in the USA. In contrast, many Chinese manufacturers, including NEX Pickleball, offer competitive, high-performance paddles and serve as OEM partners for leading brands, ensuring quality and scalability for global markets.

-

OEM: Click to learn how Original Equipment Manufacturer partnerships streamline production processes and enhance product integration from design to market launch. Back to OEM ↩

-

Thermoforming: Click to discover the thermoforming process, its benefits in producing complex designs, and why it's ideal for custom-made, premium paddle production. Back to Thermoforming ↩

-

Carbon Fiber: Click to explore the properties of carbon fiber, its various types, and how it contributes to lightweight yet durable sports equipment. Back to Carbon Fiber ↩

-

Composite Materials: Click to understand how composite materials combine different material properties to enhance paddle performance and durability. Back to Composite Materials ↩

-

Quality Control: Click to read about rigorous quality control processes that ensure every product meets international standards for performance and reliability. Back to Quality Control ↩