The optimal sweet spot on a pickleball paddle is achieved by carefully balancing materials, manufacturing processes, and design variables to enhance performance, durability, and playability. This article explains the key factors that determine the sweet spot, how different production techniques contribute to it, and offers actionable insights for R&D engineers and procurement specialists aiming to innovate and choose superior pickleball paddles.

The sweet spot is the area on a paddle that delivers maximum performance with minimal vibration or energy loss when striking the ball. It is where the impact force is distributed most effectively, resulting in enhanced control, power, and reduced shock feedback to the player's hand. For professionals in design and procurement, comprehending how different materials and production processes influence this sweet spot is essential for product optimization.

A well-designed sweet spot can dramatically improve a paddle's playability. Key benefits include:

- Enhanced Control: A larger sweet spot minimizes mis-hits and provides a more forgiving surface.

- Reduced Vibration: Efficient impact absorption lowers the strain on the player’s arm, ensuring a comfortable playing experience.

- Optimized Power and Spin: A precise sweet spot allows for improved ball response, achieving both power and finesse.

Designers work meticulously to calibrate the paddle’s balance, shape, and material composition so that when a ball strikes within this zone, the energy transfer is maximized while minimizing any adverse shock or vibration.

Several variables work together to define the sweet spot, including the following key factors:

-

Material Composition:

- Carbon Fiber:

- 3K Carbon Fiber1 is known for its blend of strength and flexibility, enhancing rebound force while reducing vibration.

- 12K Carbon Fiber provides a smoother surface due to its higher thread density, delivering greater hardness and improved durability.

- T300 Carbon Fiber balances tensile strength with lightweight performance and is particularly effective in high-performance paddles.

- Fiberglass2:

- E-Glass Fiberglass offers excellent elasticity and tensile strength, ensuring a comfortable ball feel and effective control.

- Composite Materials:

- Combining carbon fiber with fiberglass can create a composite that delivers both strength and a wider sweet spot.

- Bamboo core and honeycomb core structures absorb shocks better, enhancing paddle durability and playability.

- Carbon Fiber:

-

Core Materials:

- Nomex Honeycomb Core3: Provides high shock absorption, ensuring a durable and stable paddle feel.

- Aluminum Honeycomb Core: Balances weight distribution for power and precision.

- Polymer Honeycomb Core: Known for its elasticity and improved shock reduction, making it ideal for both competitive and recreational play.

-

Manufacturing Processes:

Production techniques such as hot pressing4, cold pressing, and thermoforming5 not only define the paddle’s structure but also play a vital role in optimizing the sweet spot. The method chosen affects material density, weight distribution, and structural integrity.

Choosing the right manufacturing process is critical for ensuring an optimal sweet spot. Here is a detailed comparison of the three main production methods:

| Process | Advantages | Disadvantages | Impact on Sweet Spot |

|---|---|---|---|

| Hot Pressing4 | • High production efficiency • Strong, durable structure • Excellent impact resistance | • Can alter some material properties • Requires high equipment investment | Provides a robust structure with a consistent impact area, though slight modifications in material properties may affect the natural feel. |

| Cold Pressing | • Precise control over thickness • Maintains material properties • Offers great ball feel | • Longer production cycles • Demands high-quality pressure control | Ensures a clear and genuine ball response with a well-defined sweet spot, particularly beneficial in customized designs. |

| Thermoforming5 | • Allows intricate design and precise material distribution • Enhances overall paddle stability | • Longer production time • Higher equipment cost | Creates complex shapes that distribute impact force evenly, potentially enlarging the effective sweet spot. |

Each of these processes has a distinct role in balancing performance attributes. Designers must evaluate the trade-offs to choose a method that aligns with targeted performance metrics.

To design a paddle with a maximized sweet spot, engineers and product managers focus on:

-

Material Selection:

The choice between various types of carbon fiber and fiberglass will affect not only the paddle's weight and durability but also how impact energy is dissipated. For instance, while 3K carbon fiber offers flexibility, 12K provides a smoother, sturdier surface for a larger sweet spot. A composite approach may involve combining the rigidity of carbon fiber with the elasticity of fiberglass, giving designers a powerful tool to engineer the ideal impact zone. -

Core Design:

The core material plays a decisive role in shock absorption:- Nomex and polymer honeycombs are known to absorb energy effectively, reducing vibrations and ensuring consistent performance.

- The innovative use of composite cores can enhance the balance between power and control, crucial for achieving an optimal sweet spot.

- Adjusting the core density and layering during production processes can fine-tune the paddle’s responsiveness when the ball is hit at various angles.

-

Thickness and Weight Distribution:

The distribution of weight across the paddle is crucial. A balanced paddle with an intelligently expanded sweet spot can:- Improve performance by reducing the likelihood of off-center hits.

- Lower the energy loss and absorb shock more effectively.

Engineers often use simulation tools and iterative testing to determine the optimal thickness that allows the sweet spot to extend over a larger area without compromising the paddle’s structural integrity.

-

Ergonomics and Grip Design:

While material and structural properties are vital, the ergonomic design of the paddle, including grips and handle length, can also influence the effective sweet spot. A shorter handle might provide a larger paddle face area (as seen in some top-line models like those from Selkirk), while a handle designed for comfort and control ensures that the sweet spot’s benefits fully translate into improved play performance. -

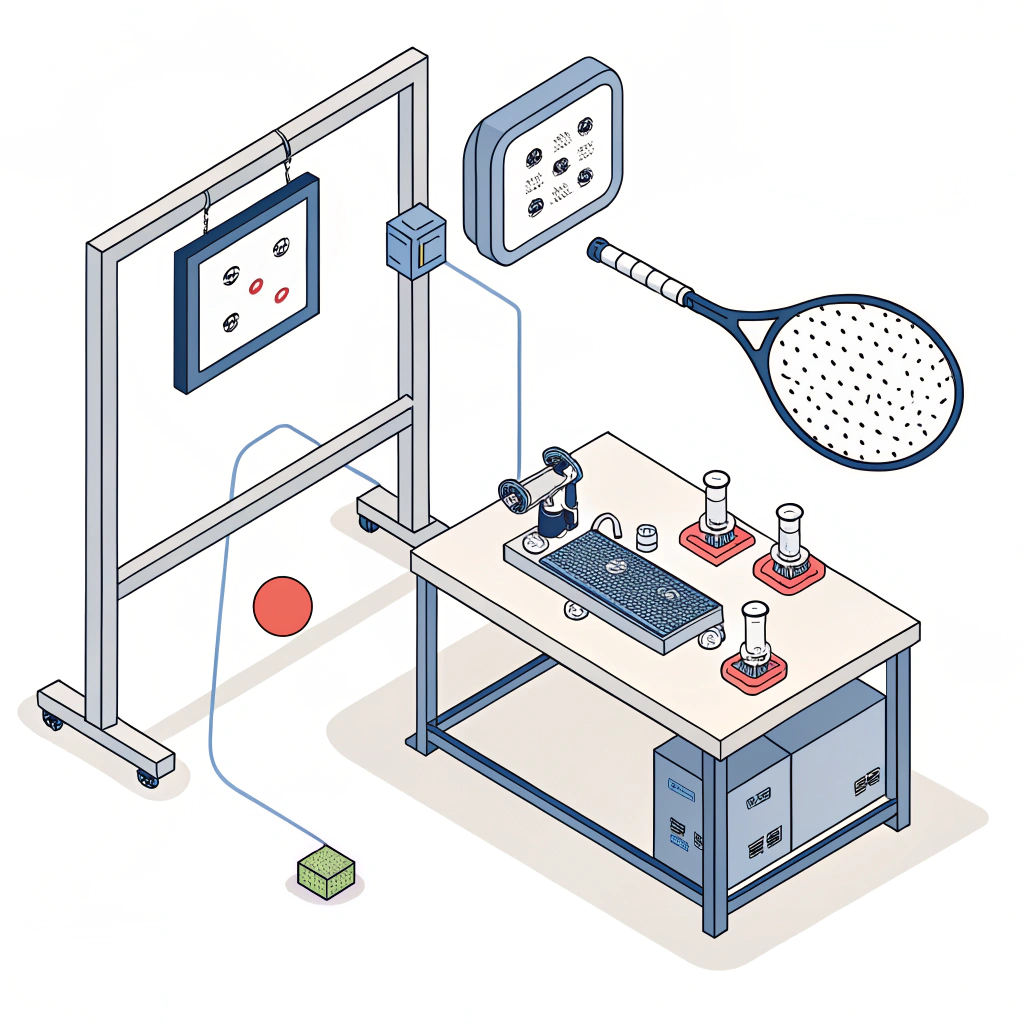

Rigorous Quality Control and Testing:

Every paddle undergoes extensive testing to ensure consistency in the size and position of the sweet spot. Quality control mechanisms involve:- Vibration analysis during impact tests.

- Drop tests and simulated play conditions.

- Iterative adjustments based on performance data from high-level players.

This testing regimen helps identify any anomalies in material behavior, allowing for incremental adjustments in both the production process and the final assembly of the paddle.

Consider a scenario in which two production processes are compared:

- Hot Pressed Paddle: Designed for mass production, this paddle shows excellent impact resistance but might experience subtle variations in feel due to changes in material properties.

- Cold Pressed Paddle: Although produced at a slower rate, the precision in materials retention results in a more consistent hitting experience with a clearly defined sweet spot.

Data from recent testing demonstrated that cold pressed paddles maintained a 10% superior consistency in energy absorption compared to their hot pressed counterparts. As a result, technical product managers might choose cold pressing for limited edition or performance-driven paddle models even if it demands extended production cycles.

For professionals in the sports equipment industry aiming to design, manufacture, or procure high-performance pickleball paddles, consider the following steps:

-

Evaluate Material Options:

Conduct detailed assessments of carbon fiber variants and fiberglass choices. Experiment with composite materials to achieve a balanced combination of rigidity and elasticity. -

Optimize Core Structures:

Choose core materials tailored for shock absorption and enhanced coupling with the paddle's outer layers. Experiment with different honeycomb configurations to fine-tune impact distribution. -

Select Appropriate Production Processes:

Weigh the trade-offs between hot pressing, cold pressing, and thermoforming based on your production needs. For customized, high-performance paddles, consider a hybrid approach that leverages the strength of both hot and cold pressing methods. -

Enhance Ergonomic Design:

Balance the paddle face size against handle length to maximize the sweet spot, ensuring that even players with different grip sizes benefit from improved control and reduced vibration. -

Implement Rigorous Testing Protocols:

Invest in advanced testing equipment and data analysis tools to continuously monitor the sweet spot’s performance. Use feedback from professional players and iterative testing data to refine production processes. -

Leverage Simulation Tools:

Use computer simulations to predict how different materials and design adjustments will affect sweet spot size and impact distribution, allowing for data-driven design decisions before mass production.

In conclusion, optimizing the sweet spot in pickleball paddles requires a multi-faceted approach that involves careful material selection, core design, manufacturing process choices, and ergonomic considerations. By understanding the interplay between factors such as carbon fiber variants, composite material properties, and production methods like hot pressing, cold pressing, and thermoforming, R&D engineers and technical product managers can develop paddles that deliver superior performance, durability, and comfort.

The iterative process of simulation, testing, and quality control plays a pivotal role in ensuring that the paddle optimally transfers energy upon impact. Ultimately, it is about striking the right balance between material properties and production techniques to create a paddle that not only offers an enlarged sweet spot but also caters to the varied demands of competitive play and recreational use.

For those in the B2B procurement and production industries, these insights pave the way for making informed decisions, whether you are looking into partnership opportunities or fine-tuning your own product portfolio. Embracing these technical nuances and continuously iterating on design principals will help you stay ahead in the competitive sports equipment market.

What is the largest sweet spot in Selkirk?

Selkirk’s design approach prioritizes an enlarged sweet spot typically found in their S2 mainline paddle. This design achieves a larger effective hitting area by sacrificing handle length in favor of a taller paddle face, which redistributes impact forces efficiently and enhances playability.

-

3K Carbon Fiber: Reading the article will provide insights into the properties of 3K Carbon Fiber, detailing how its blend of strength and flexibility enhances performance and minimizes vibration in high-performance sports equipment. ↩

-

Fiberglass: Reading the article will offer a comprehensive overview of Fiberglass, including its elasticity, tensile strength, and role in creating a responsive, well-balanced paddle. ↩

-

Nomex Honeycomb Core: Reading the article will explain the technical advantages of the Nomex Honeycomb Core, focusing on its excellent shock absorption and its contribution to the structural stability of advanced paddle designs. ↩

-

Hot Pressing: Reading the article will detail the Hot Pressing manufacturing process, highlighting its efficiency in producing robust structures and discussing its impact on material properties. ↩ ↩2

-

Thermoforming: Reading the article will provide an in-depth look at the Thermoforming process, emphasizing its ability to craft intricate designs and achieve precise material distribution for superior paddle performance. ↩ ↩2