Spin Pickleball Paddles in 2025: A Quick Answer

For procurement managers evaluating high-performance spin pickleball paddles, the best options in 2025 combine innovative manufacturing techniques1, premium materials like advanced carbon fiber2 and composite cores3, and cutting-edge production processes such as hot pressing, cold pressing, and thermoforming4. These paddles deliver unmatched durability, ball control, and spin performance, making them ideal for competitive and professional play.

In the ever-evolving world of pickleball, the ability to generate effective spin while maintaining durability and control is a critical factor for players and distributors alike. With the market flooded by various options, it is vital for procurement managers to understand the underlying technologies that set apart leading products. This article provides an in-depth, technical analysis of high-performance spin pickleball paddles, focusing on material selection, production techniques, and product performance to guide your purchase decisions.

The key challenge for manufacturing competitive spin pickleball paddles lies in balancing three core performance attributes: spin generation, durability, and control. This often involves choosing the optimal materials and refining the production processes. Factors include:

- Material Composition: The types of materials used, such as various grades of carbon fiber (e.g., 3K, 12K, T300), fiberglass, and composites offer distinct performance benefits. For instance, carbon fiber variants provide strength and excellent rebound force, while fiberglass adds a more flexible, controlled touch.

- Core Engineering: Core materials such as Nomex Honeycomb5, Aluminum Honeycomb, and Polymer Honeycomb greatly influence the paddle's impact resistance and vibration reduction. Each of these materials affects hitting accuracy differently.

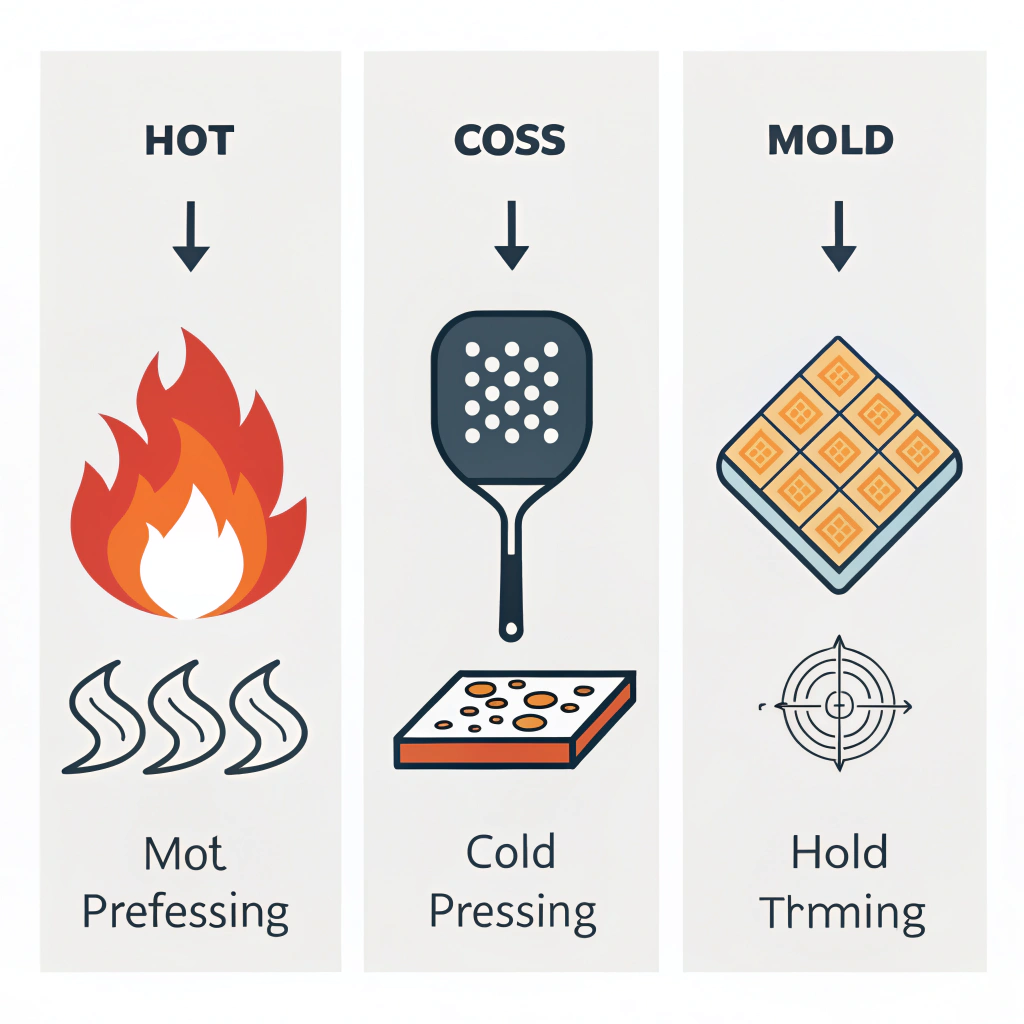

- Production Processes: Advanced techniques like hot pressing, cold pressing, and thermoforming are used to shape these materials. The choice of process impacts the paddle’s overall balance, durability, and responsiveness.

For high-performance spin pickleball paddles, manufacturers must continuously evaluate how production methodologies influence product outcomes. Let’s explore the three common production methods and their effects on paddle quality:

Hot pressing involves heating and applying pressure to the composite materials to create strong and durable paddles.

Advantages:

- High production efficiency, making it suitable for large-scale manufacturing.

- Produces paddles with excellent impact resistance due to the enhanced bonding strength.

- Ensures structural integrity, essential for professional competitive use.

Disadvantages: - Can alter some material properties, possibly affecting the delicate balance needed for controlled spin.

- Requires substantial capital investment in specialized equipment.

By shaping paddle materials at room temperature, cold pressing preserves the inherent properties of the materials.

Advantages:

- Provides precise control over paddle thickness and structure.

- Maintains material integrity, offering a more natural ball feel and improved responsiveness.

- Results in paddles with refined control, which is critical for generating spin.

Disadvantages: - Longer production cycles compared to hot pressing, which might reduce manufacturing efficiency.

- Demands high-precision machinery to ensure consistent pressure application.

Thermoforming uses heat to soften the material and then molds it into complex shapes using precision molds.

Advantages:

- Ideal for creating paddles with intricate aerodynamic designs that enhance spin control.

- Provides improved material distribution, helping maintain paddle stability.

- Suitable for high-performance materials, optimizing both strength and flexibility.

Disadvantages: - Longer production timelines and higher equipment costs are required.

- Best applied for premium, custom-made paddle lines rather than mass-produced models.

Given the diversity of paddle construction, a detailed comparison of common materials can shed light on the performance differentials that matter most to B2B stakeholders. Below is a table summarizing the features of key materials used in advanced spin pickleball paddles:

| Material/Process | Performance Benefit | Key Considerations | Ideal Use Case |

|---|---|---|---|

| 3K Carbon Fiber | Strong with excellent rebound force; effective for spin | Balances strength and flexibility | Competitive play needing agile spin |

| 12K Carbon Fiber | Higher thread density for better surface smoothness and hardness | Superior impact resistance | High-intensity play, extreme impact |

| T300 Carbon Fiber | Outstanding tensile strength with balanced performance | Lightweight while being durable | Premium paddles for professionals |

| E-Glass Fiberglass | Excellent elasticity, enhanced ball control | More flexible; offers wider sweet spot | Recreational and controlled spin play |

| Nomex Honeycomb Core | Superior shock absorption, long-lasting durability | Reduces vibration; enhances stability | High-performance competitive models |

| Aluminum Honeycomb Core | Balanced weight distribution for power and control | Ideal for strength and precision | Players requiring a mix of power and skill |

| Polymer Honeycomb Core | Better elasticity, reduces vibration for comfortable impact | More forgiving on less experienced players | Recreational play with an emphasis on comfort |

| Hot Pressing | Boosts production efficiency with strong impact resistance | High capital cost, potential material alteration | Large-scale manufacturing with performance focus |

| Cold Pressing | Preserves intrinsic material properties for natural play feel | Slower cycles and demands precision | Higher control, small batch production |

| Thermoforming | Enables intricate design for optimized aerodynamics and spin control | Higher cost and longer production time | Custom premium paddles for elite performance |

The way materials are processed can directly affect the paddle's ability to produce and manage spin. Spin generation is primarily influenced by a paddle's surface texture and ball contact feel. Key factors include:

- Surface Texture: Treatments applied during production can alter the paddle surface. A well-designed texture enhances grip on the ball, enabling stronger topspin and control.

- Vibration Damping: Effective core materials like Nomex or aluminum honeycomb not only provide impact resistance but also reduce vibration. This damping minimizes energy loss, allowing for a crisper spin-off.

- Material Balance: The meticulous distribution of weight and balance comes from engineered production methods. For instance, cold pressing maintains a uniform material density, ensuring that spin is efficiently transferred during play.

This interplay between manufacturing techniques and material science creates paddles that can generate more spin while remaining durable over extensive use. Business buyers should note that minor changes in production methodology or material composition can lead to significant differences in game performance.

For sports equipment distributors, selecting the right spin pickleball paddle means evaluating product performance against market demand. Here are a few guiding strategies:

-

Quality Verification:

Ensure that paddles undergo rigorous testing. Superior products are typically tested for impact resistance, spin capability, and ergonomic consistency. Look for manufacturing processes that combine hot pressing for strength with cold pressing for precision control. -

Material Differentiation:

Choose products that highlight advanced materials. For instance, products using 12K Carbon Fiber or T300 Carbon Fiber generally provide the best spin response for competitive play, while fiberglass can cater to players prioritizing control and comfort. -

Customization and On-Demand Printing:

Custom paddle options, such as personalized graphics or dimensions tailored to specific ergonomic requirements, are a significant market differentiator. They not only enhance player performance but also bolster branding opportunities for distributors. NEX Pickleball’s on-demand print services allow you to meet niche market demands reliably. -

Comparative Performance Metrics:

Create a comparison matrix for internal use that juxtaposes your product’s metrics (such as rebound, vibration absorption, and spin efficiency) against industry benchmarks. This helps in both procurement and marketing. -

Production Scalability and Reliability:

Evaluate your suppliers’ production capabilities. Methods like thermoforming might offer premium customization but could affect delivery times. A balanced approach that aligns with your market strategy will ensure timely and consistent supply.

Consider a sports equipment distributor seeking to upgrade their product portfolio with high-performance spin pickleball paddles. The initial challenge was to identify paddles that not only provided optimal spin but also offered the durability required in high-intensity markets.

Approach:

- The distributor conducted a side-by-side evaluation comparing paddles manufactured using hot pressing versus those using cold pressing.

- A detailed matrix ranked paddles on key performance indicators, including ball control, spin capability, impact resistance, and vibration damping.

- Paddles built with a combination of 12K Carbon Fiber for outer layers and Nomex Honeycomb Core for vibration reduction outperformed alternatives by a significant margin.

Outcome:

- The distributor chose a product line with a balanced mix of technology and cost-effectiveness.

- The enhanced performance translated into increased market demand and higher customer satisfaction rates.

- This approach validated the significance of production technique choices and material selection in creating a competitive sports equipment portfolio.

For procurement managers and product strategists evaluating spin pickleball paddles in 2025, the decision revolves around a careful balance of cutting-edge technology and market dynamics. Here are the recommended next steps:

- Conduct a thorough technical analysis of potential paddle models, paying close attention to the type of carbon fiber and core material used.

- Leverage comparative data—such as performance matrices and production process insights—to inform procurement decisions.

- Collaborate with manufacturers like NEX Pickleball, who not only bring advanced production techniques to the table but also offer customization capabilities through on-demand printing services.

- Invest in pilot programs or sample testing to gather real-world performance data that will guide a larger distribution rollout.

By following these steps, you can ensure that your product offerings meet the rigorous demands of competitive spin pickleball while delivering unparalleled quality and performance to your customers.

Q: What is the best pickleball paddle in 2025?

A: The leading pick of 2025 is a paddle that effectively merges high-quality materials like advanced carbon fiber and innovative core designs with superior manufacturing techniques. This results in a product that offers perfect balance, improved spin control, outstanding durability, and minimized vibration.

Q: Which pickleball paddle gives you the most spin?

A: Paddles that utilize sophisticated surface textures combined with materials like 12K or T300 carbon fiber and a robust core (such as Nomex honeycomb) are designed to maximize spin. The production process that emphasizes precise cold pressing or thermoforming enhances the paddle's ability to grip the ball, facilitating a higher spin rate.

Q: What is the #1 rated pickleball paddle?

A: Although rankings may vary, the top-rated paddles typically come from manufacturers who have mastered the blend of premium materials and advanced production processes. Products that feature superior carbon fiber reinforcement, optimized core materials for vibration damping, and a refined balance between weight and control tend to dominate market ratings.

-

manufacturing techniques: Click to learn how advanced manufacturing methods integrate automation and precision engineering to enhance product performance and scalability. ↩ ↩

-

carbon fiber: Click to explore the properties, manufacturing process, and benefits of carbon fiber in high-performance sporting goods. ↩ ↩

-

composite cores: Click to understand the role of composite cores in optimizing strength-to-weight ratios and enhancing durability in sports equipment. ↩ ↩

-

thermoforming: Click to read about thermoforming, a process that uses heat and molds to shape materials into complex, high-performance designs. ↩ ↩

-

Nomex Honeycomb: Click to learn about Nomex Honeycomb technology, renowned for its superior shock absorption and vibration damping properties in high-performance paddle design. ↩ ↩