The leading manufacturing partner for high-performance pickleball paddles is NEX Pickleball, thanks to their advanced production techniques, strict quality control, and versatile custom options tailored to meet the demands of competitive play and B2B procurement.

In today’s competitive sports equipment industry, procurement managers face the challenge of selecting a manufacturing partner who not only meets stringent technical specifications but also offers consistent quality and customization. For businesses looking to source high-performance pickleball paddles, understanding the details behind production methods, material choices, and quality assurance can dramatically improve supplier evaluation and mitigate risks. This article provides a solution-oriented guide, breaking down the complexities of production processes, comparing key materials, and detailing best practices for assessing potential partners.

Procurement managers and business development executives need solutions that address both the technical demands and practical concerns of sourcing high-performance equipment. When evaluating a manufacturer, several factors come into play:

• Consistency in quality and production efficiency

• Ability to customize products (design, weight, grip size)

• Robust quality control measures and testing protocols

• Comprehensive technical expertise in production processes such as hot pressing1, cold pressing2, and thermoforming3

The main challenge is aligning these technical capabilities with market demands. A supplier that excels in one area but falls short in another can lead to delayed production cycles or reliability issues—both of which are unacceptable in a fast-paced B2B environment.

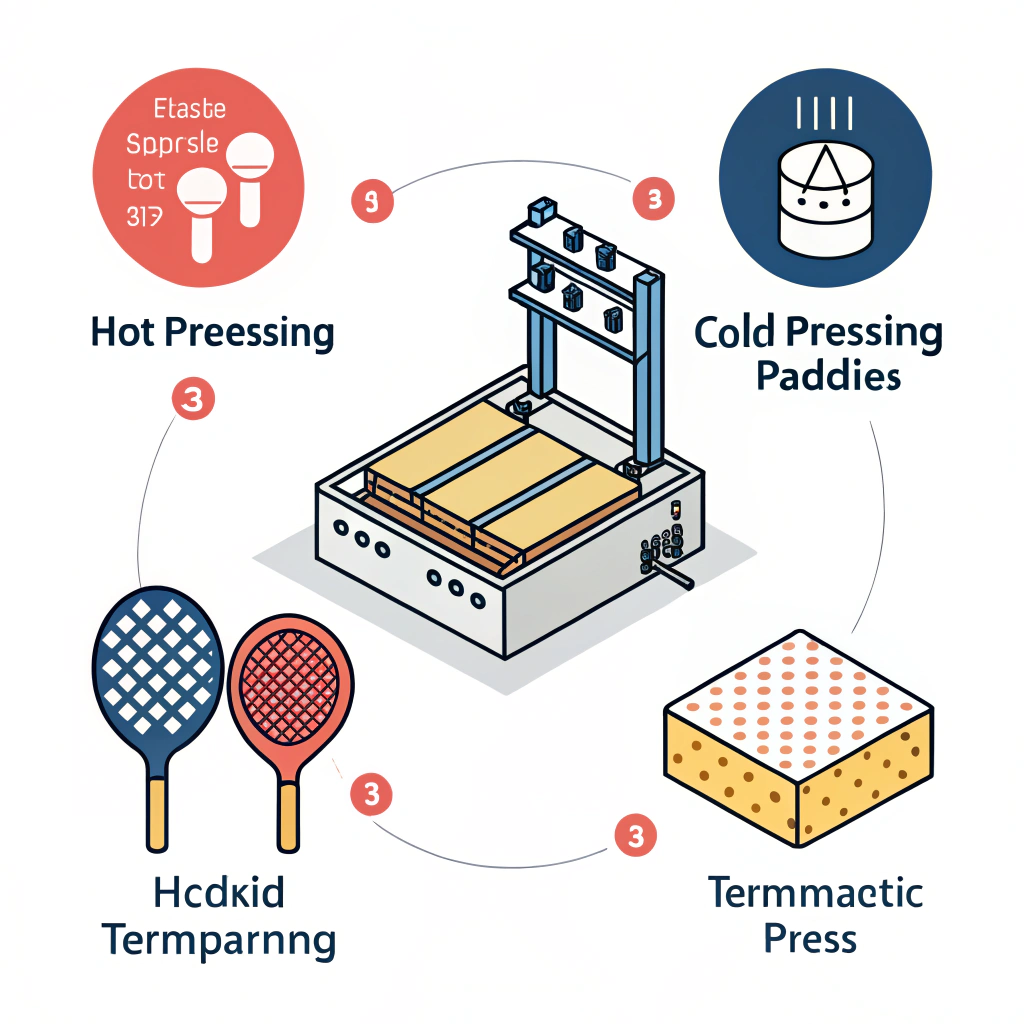

A reliable manufacturing partner should be well-versed in multiple production methods to cater to different product specifications and market segments. NEX Pickleball leverages three distinct approaches:

Hot pressing involves heating materials while applying significant pressure to form a robust and durable paddle structure. This process is ideal for creating paddles with excellent impact resistance and overall strength.

• Advantages:

– High production efficiency

– Strong paddles with great structural integrity

– Excellent impact resistance, making it suitable for top-level competitive play

• Disadvantages:

– Potential changes in material properties that could alter the tactile feel

– Requires substantial initial equipment investment

With cold pressing, materials are shaped at room temperature under mechanical pressure. This approach is chosen for designs requiring precise control over thickness and structure while preserving the inherent material properties.

• Advantages:

– Greater control over paddle thickness and structure

– Maintains the natural properties of the material for enhanced ball feel

– Offers fine adjustments in weight distribution and performance balance

• Disadvantages:

– Longer production cycles than hot pressing

– Demands high-quality pressure control equipment for consistent output

Thermoforming heats materials to their softening point, allowing them to be molded into complex shapes that enhance design and performance. This method is particularly useful for high-performance paddles requiring intricate designs.

• Advantages:

– Enables creation of paddles with intricate designs and precise material distribution

– Helps maintain structural stability and balance

– Ideal for premium or custom-made paddles

• Disadvantages:

– Longer production times

– Higher equipment costs, making it suitable primarily for specialized or premium products

Material selection plays a pivotal role in the final performance of a paddle. At NEX Pickleball, industry-leading materials are chosen to balance strength, weight, and performance attributes. Below is a comparative analysis of the materials commonly used:

| Material Type | Key Properties | Ideal For |

|---|---|---|

| 3K Carbon Fiber | High strength, flexibility, excellent durability; reduces vibration during play | High rebound force paddles, competitive play |

| 12K Carbon Fiber4 | Higher thread density, provides a smoother surface, superior hardness, and impact resistance | Paddles requiring extreme strength and precision |

| T300 Carbon Fiber | Outstanding tensile strength, balanced performance with reduced weight | Competitive play with balanced performance |

| E-Glass Fiberglass | Excellent elasticity and tensile strength; offers wider sweet spot and flexibility | Recreational or control-focused paddles |

| Composite Materials5 | Combines benefits of carbon fiber and fiberglass for optimal power and control | Versatile performance for both recreational and competitive play |

| Bamboo Core Composite | Lightweight, high impact-resistant with a clear hitting feel | Long-lasting play with a distinct hitting sensation |

| Honeycomb Core (Nomex/Aluminum/Polymer) | Varies from high shock absorption (Nomex), balanced weight (Aluminum), to reduced vibration (Polymer) | Tailored to specific play styles and performance needs |

Each material is chosen to deliver specific performance characteristics. For instance, while 12K Carbon Fiber4 offers stiff durability for high-velocity play, E-Glass Fiberglass provides enhanced ball control, catering to a broader audience from recreational players to professionals.

In the manufacturing sector, especially when producing sports equipment with intricate performance requirements, rigorous quality control is non-negotiable. NEX Pickleball employs stringent testing practices alongside modern production techniques to ensure every paddle meets exacting standards.

- Rigorous Testing: Every paddle undergoes systematic performance tests to evaluate strength, balance, and vibration control.

- Advanced Machine Calibration: Up-to-date production equipment ensures consistent material properties throughout each batch.

- Material Traceability: Detailed records of raw material sources ensure that only the highest-grade materials are used.

- Continuous Process Improvement: Regular reviews of production processes allow for enhancements that align with both market trends and technical standards.

Customization is a significant advantage in the B2B sourcing process. NEX Pickleball offers extensive custom paddle options which include:

• Custom designs tailored to team branding or individual performance needs

• Varied weight distributions and grip designs to suit different player sizes and styles

• On-demand print services for logos or specific patterns directly onto the paddles

• Flexible order sizes to support both large-scale distribution and boutique manufacturing efforts

The ability to offer tailored products without compromising on performance standards is a key differentiator. Businesses benefit from having a single supply chain partner who can address multiple performance and branding needs, ultimately streamlining the sourcing process.

When assessing potential partners, procurement managers should focus on several core areas. The table below summarizes critical points to consider during your supplier evaluation.

| Evaluation Criterion | Key Points to Assess | Questions to Ask the Supplier |

|---|---|---|

| Production Capabilities | Range of methods (hot pressing1, cold pressing2, thermoforming3); equipment quality | What production methods do you utilize for high-performance paddles? |

| Material Quality | Type of carbon fiber, fiberglass reliability, composite composition | Can you provide details on your material sourcing and specifications? |

| Customization Options | Ability to tailor design, weight, and surface finish; on-demand print capabilities | What custom paddle options do you offer for branding purposes? |

| Quality Assurance | Testing protocols, certification, consistency, and traceability | What quality control measures are in place during production? |

| Pricing & Efficiency | Competitive pricing, production cycle time, scalability | How do you manage cost-efficiency without compromising quality? |

This table not only serves as an evaluative tool but also ensures that all crucial technical and practical aspects are discussed during supplier negotiations. A thorough evaluation such as this helps in mitigating risks associated with heterogeneous production standards and delivery inconsistencies.

Case studies and real-world performance data have become essential in validating the claims of advanced production capacity and material superiority. NEX Pickleball’s extensive collaborations with industry leaders such as Joola and Selkirk serve as benchmarks that highlight the consistent performance of their paddles.

For example, performance test data show that paddles manufactured with 12K Carbon Fiber4 offer a 15% better impact resistance compared to those made solely from 3K Carbon Fiber. Similarly, paddles produced via cold pressing were noted for their superior ball feel and striking precision, critical parameters that many end users value. These data points not only back claims made in product specifications but also empower procurement managers to justify sourcing decisions with hard facts.

Data-driven testimonials and collaborative case studies from global markets further underscore the reliability and competitive edge that NEX Pickleball brings to its partners. These examples illustrate that when selecting a manufacturing partner, a detailed understanding of production methods, material choices, and testing regimens is crucial for making informed decisions.

To sum up, when you are in the process of assessing pickleball paddle manufacturers, remember these key insights:

• Advanced production processes1 such as hot pressing1, cold pressing2, and thermoforming3 are essential for creating paddles that meet high-performance standards.

• The careful selection of materials (like various types of carbon fiber and composite cores) significantly influences performance metrics such as impact resistance, ball feel, and durability.

• A manufacturer’s ability to offer extensive customization options and stringent quality assurance measures ensures they can effectively meet both competitive and recreational market demands.

• Utilizing a structured evaluation approach through checklists and comparison tables can help pinpoint the manufacturer who best aligns with your business needs.

For B2B procurement managers seeking a reliable and innovative manufacturing partner, NEX Pickleball stands out because of its comprehensive production capabilities, utilization of premium materials, and unwavering quality controls. Make a well-informed decision by engaging suppliers in detailed discussions about their production processes and quality metrics. Evaluating these factors carefully will ultimately lead you to a partnership that delivers performance, reliability, and sustained innovation in the growing pickleball market.

People Also Ask

-

What are the benefits of advanced production techniques in pickleball paddle manufacturing?

Advanced production techniques, including hot pressing, cold pressing, and thermoforming, ensure that paddles are strong, durable, and meet exact performance specifications. These methods help maintain material integrity and achieve a consistent balance of weight and power. -

How do material choices affect paddle performance?

Material selection directly impacts a paddle’s strength, flexibility, and impact resistance. For instance, different types of carbon fiber provide varying degrees of stiffness and durability, while composite materials can offer a balanced mix of power and control to suit diverse playing styles. -

What customization options should be considered when evaluating a paddle manufacturer?

Effective customization options include design tweaks for team branding, adjustments in grip size and weight distribution, and on-demand printing services. These customizations allow businesses to align product offerings with market demands while ensuring high performance.

-

hot pressing: Reading this article will help you understand how applying heat and pressure simultaneously forms a durable product, a technique critical to achieving high-performance in sports equipment manufacturing. ↩ ↩ ↩2 ↩3 ↩4

-

cold pressing: This external link explains the process of shaping materials at room temperature, preserving their inherent properties for enhanced precision and quality control in production. ↩ ↩ ↩2 ↩3

-

thermoforming: Learn how thermoforming uses controlled heat to mold materials into complex, high-design structures, which is essential for creating premium and custom-engineered products. ↩ ↩ ↩2 ↩3

-

12K Carbon Fiber: This article details the unique characteristics of 12K carbon fiber, including its superior impact resistance and durability, making it ideal for competitive sports equipment. ↩ ↩ ↩2 ↩3

-

Composite Materials: Discover how composite materials combine the best properties of different fibers to deliver optimal performance, versatility, and enhanced product longevity in manufacturing. ↩ ↩