Intermediate pickleball paddles combine advanced materials and production techniques to deliver the perfect balance of power, control, and durability—ideal for businesses looking to provide premium sports equipment at competitive prices.

Procurement managers and sports equipment distributors face a critical decision when selecting pickleball paddles for intermediate players. The key is to choose products that not only perform well on the court but also provide dependable production quality and cost efficiency. In today’s competitive retail environment, understanding the differences in materials and production processes is essential to making informed decisions.

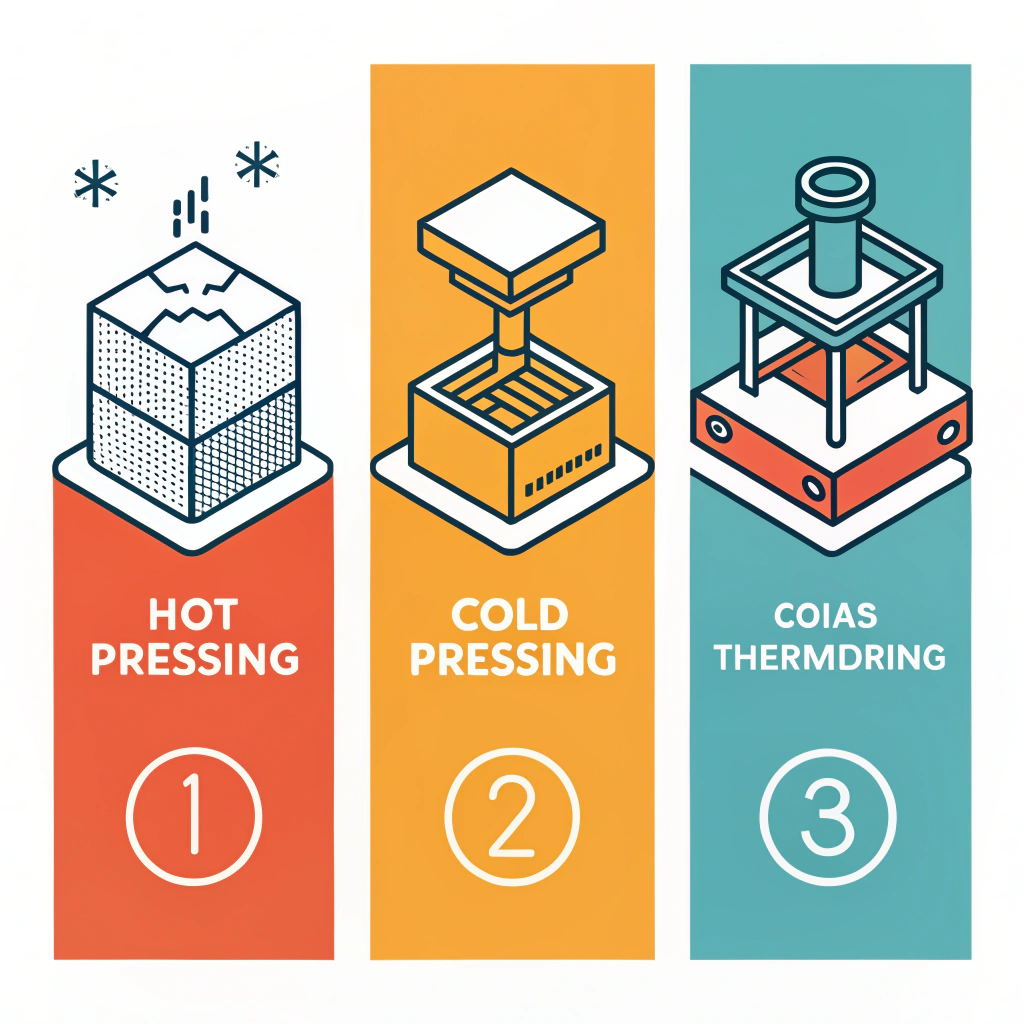

In this article, we compare various paddle options by analyzing core materials, production techniques, and performance attributes. We evaluate common production methods—hot pressing, cold pressing1 and thermoforming2—and the unique benefits of materials such as carbon fiber, fiberglass, and composite options. Our goal is to guide you, as a procurement manager, through the process of choosing paddles that will enhance your product lineup while meeting consumer expectations.

The production process influences the paddle’s performance attributes and durability. At NEX Pickleball, we employ three primary production methods that cater to diverse performance needs and cost considerations. Below is an overview of these techniques:

Hot pressing involves heating the materials and applying pressure to form the paddle.

- Advantages:

• High production efficiency suitable for large-scale manufacturing.

• Produces paddles with strong impact resistance.

• Enhances structural integrity for high-performance use. - Disadvantages:

• Possibility of altering some material properties, which may affect the tactile feel of the paddle.

• Requires a significant equipment investment.

Cold pressing shapes the paddle material at room temperature using precise mechanical pressure.

- Advantages:

• Yields precise control over thickness and structural elements.

• Preserves the inherent properties of the materials, ensuring better control and flexibility.

• Delivers an excellent ball feel and responsiveness, critical for intermediate-level play. - Disadvantages:

• Slower production cycles compared to hot pressing.

• Demands high-quality equipment and stringent pressure control.

Thermoforming involves heating the material until it softens and then forming it using detailed molds.

- Advantages:

• Allows creation of paddles with intricate designs and precise material distribution.

• Improves stability and balance, enhancing overall performance.

• Ideal for premium or custom-made paddle offerings. - Disadvantages:

• Longer production times and higher installation costs.

• Best suited for niche, high-end market segments.

The following table summarizes the key differences:

| Production Process | Advantages | Disadvantages |

|---|---|---|

| Hot Pressing | High efficiency, strong impact resistance, excellent structural integrity | May alter material feel, high equipment cost |

| Cold Pressing | Precise control, maintains material properties, excellent ball feel | Longer production cycle, requires precise pressure control |

| Thermoforming | Intricate design, enhanced stability, ideal for premium products | Longer production time, high cost |

Understanding these methods allows you to compare production quality and production cost factors that directly impact the final product performance.

The choice of material in paddle manufacturing is paramount to the playing experience. At NEX Pickleball, our paddles are crafted using a range of premium materials tailored to intermediate players. Here we dive deeper into the most common options:

Carbon fiber is celebrated for its strength, lightweight design, and durability. It is available in several variants:

- 3K Carbon Fiber:

• Offers excellent durability and a high rebound force.

• Provides flexibility and reduces vibrations during gameplay. - 12K Carbon Fiber:

• Features a higher thread density for a smoother surface finish.

• Delivers enhanced hardness and superior impact resistance, making it optimal for more aggressive play. - T300 Carbon Fiber3:

• Strikes a balance by providing superior tensile strength while remaining lightweight.

• Ideal for paddles that require a mix of strength and rapid responsiveness.

Fiberglass is another excellent material known for balancing control and power:

- E-Glass Fiberglass:

• Offers remarkable elasticity and tensile strength.

• Enhances ball control while ensuring an expansive hitting surface, which is beneficial for precision hits.

Composite materials merge the advantages of different materials to create paddles that cater to diverse performance needs:

- Carbon Fiber and Fiberglass Composite:

• Combines the rigidity and strength of carbon fiber with the flexibility and control of fiberglass.

• Ideal for players seeking both power and hand-in-hand precision. - Bamboo Core Composite:

• Utilizes bamboo cores for lightweight design and high impact resistance.

• Provides a unique hitting feel and durability suitable for prolonged play. - Honeycomb Core:

• Typically constructed from high-density polymers, these cores provide superior shock absorption.

• Reduces paddle vibration, enhancing overall durability and comfort during extended play.

Each material brings its own set of characteristics that affect performance. For example, while carbon fiber paddles are often favored for their power and durability, fiberglass paddles offer more flexibility and control, which is particularly appealing to intermediate players who may prioritize precision over sheer strength.

Below is a simplified comparison of the key materials:

| Material Type | Key Benefits | Ideal For |

|---|---|---|

| 3K Carbon Fiber | High durability, flexibility | Rebounding and power-focused play |

| 12K Carbon Fiber | Smoother surface, hardness | High-impact competitive play |

| T300 Carbon Fiber | Balanced strength and weight | Intermediate to competitive play |

| E-Glass Fiberglass | Excellent elasticity and control | Players valuing precision and control |

| Carbon Fiber & Fiberglass Composite | Balanced performance across metrics | Dual demands for power & control |

| Bamboo Core Composite | Lightweight, robust | Extended play and custom designs |

| Honeycomb / Polymer Cores | High shock absorption, reduced vibration | Recreational and endurance play |

This table helps in understanding the trade-offs between materials and making an informed decision aligned with your product portfolio strategy.

For procurement managers, the decision often comes down to a strategic balance between material performance and production efficiency. Intermediate players demand paddles that offer both refined control and robust power. Therefore, aligning the production method with the chosen material is critical.

-

Performance Consistency:

Paddles produced via processes like cold pressing maintain the original material properties, which is crucial when using premium carbon fiber or fiberglass to ensure maximum performance consistency on the court. -

Cost Efficiency vs. Quality:

While hot pressing methods allow for high production efficiency and lower unit costs, a slight trade-off in the material's tactile feel may occur. Evaluating whether this alteration affects the overall player experience is vital for your customer base. -

Customization Possibilities:

Thermoforming, despite its higher cost, provides opportunities for custom designs. Custom paddle options can offer unique grip sizes, balance tuning, and branding opportunities, which can differentiate your product range in a competitive market.

The detailed interplay between production methods and material selection gives your business a strong competitive edge by ensuring the paddles meet the nuanced demands of intermediate players.

To streamline your decision process, consider the following factors:

Intermediate players often seek a blend of power, control, and durability in their paddles. Products manufactured using high-performance materials like T300 Carbon Fiber or E-Glass Fiberglass paired with precise techniques (cold pressing) strike the right balance.

While high-end production methods such as thermoforming can drive up costs, they guarantee intricate designs and stable paddle performance. If your market segment values premium design and long-term durability, this could justify a higher price point.

Large-scale distribution channels require consistent supply and quality. Hot pressing offers faster production cycles and robust paddle results, making it an attractive option for businesses that need to scale quickly without sacrificing quality.

Monitoring industry trends is key. With the rapid evolution of composite materials and core technologies like the Nomex Honeycomb Core5 or Aluminum Honeycomb Core, staying up-to-date with the latest offerings can open new avenues for product differentiation.

Offering custom paddle options is a significant selling point. Customization not only aligns with personal player preferences but also supports team branding and exclusive retail offerings, providing an edge in competitive markets.

The following checklist can help streamline your evaluation process:

- Assess the trade-offs between production speed and material integrity.

- Align production methods with material properties for optimum player performance.

- Evaluate cost implications and return on investment for each process.

- Consider the merchandising opportunities provided by custom paddle options.

- Ensure scalable quality control measures are in place to maintain consistent product standards.

These decision-making considerations provide a robust framework for selecting the right intermediate pickleball paddle options that meet the evolving demands of your market segment.

In summary, intermediate pickleball paddles require a careful balance between high-performance materials, advanced production techniques, and cost-effective manufacturing processes. As a procurement manager or distributor, selecting the right combination of production method and material does not just ensure top quality but also enhances your brand’s reputation for reliability and innovation.

We recommend:

• Reviewing your consumer base to understand whether performance or customization is prioritized.

• Consulting with production partners to identify a process that aligns with your quality and scalability needs.

• Piloting product tests with a range of paddle options (comparing parameters like weight distribution, grip design, and ball feel) before a full rollout.

• Investing in continuous research on material innovations such as advanced carbon fiber technologies and composite cores—these investments pay off in market differentiation and consumer satisfaction.

Making an informed decision based on the detailed performance characteristics and production capabilities outlined above will help you achieve a competitive edge in the dynamic sports equipment market.

• What is the best pickleball paddle for seniors?

For seniors, pickleball paddles made of fiberglass or lighter carbon fiber are excellent choices. Their lightweight structure and enhanced control are beneficial for precision play without requiring excessive power.

• Which pickleball paddle hits the hardest?

Paddle hardness depends on the material composition and design. High-end models that incorporate advanced carbon fiber and high-density cores can deliver additional power. However, the optimal choice varies with player needs and game style.

• Do more expensive pickleball paddles make a difference?

Higher-end paddles often incorporate advanced materials like raw carbon, enhanced composites, and precise production techniques that improve control, power, and spin. While costlier, they provide performance benefits that can be significant for competitive play, even though excellent results can also be achieved with moderately priced options.

-

Cold Pressing: Click to learn about the detailed benefits and limitations of using room-temperature mechanical pressure to shape materials for enhanced control and preservation of inherent material properties. ↩

-

Thermoforming: Click to explore how the thermoforming process allows manufacturers to create intricate designs with precise material distribution, resulting in improved stability and balance. ↩

-

T300 Carbon Fiber: Click to review the properties of T300 Carbon Fiber, a balanced material choice known for its tensile strength and lightweight characteristics, ideal for achieving both power and responsiveness. ↩

-

Composite Materials: Click to understand how combining different materials can lead to optimized performance in sports equipment, merging the strengths of each component for superior overall results. ↩

-

Nomex Honeycomb Core: Click to gain insights into Nomex Honeycomb Core technology, its shock absorption capabilities, and its role in reducing vibrations while enhancing durability in high-performance equipment. ↩