In short: Advanced production techniques such as hot pressing1, cold pressing2, and thermoforming3 are critical to manufacturing superior pickleball paddles by ensuring optimal durability, performance, and quality control, allowing partners to make informed procurement decisions.

Pickleball paddle manufacturers face a unique challenge: balancing performance, durability, and cost-efficiency. With the rapid growth of pickleball as a competitive sport worldwide, B2B decision-makers and procurement managers must evaluate suppliers who not only rely on advanced production processes but also can maintain consistent quality. The market demands paddles that provide a high degree of control and power without compromising on structural integrity. Key issues include:

• Ensuring precise material properties while meeting high production volumes.

• Adapting manufacturing processes to incorporate premium materials like carbon fiber, fiberglass, and various composite materials4.

• Recognizing that the core structure (using materials such as Nomex, aluminum, or polymer honeycomb) plays a significant role in overall paddle performance.

These challenges, combined with ever-increasing consumer expectations, create a pressing need for manufacturers to adopt and continuously improve their production techniques.

Several factors drive the need for advanced production techniques in pickleball paddle manufacturing:

-

Material Complexity:

Paddle construction now relies on multiple high-performance materials with specific characteristics. For example, 3K carbon fiber is valued for its rebound force and vibration reduction, while 12K carbon fiber brings enhanced hardness and a smoother surface. Balancing these materials in a single product presents inherent manufacturing challenges. -

Increasing Performance Standards:

As players demand paddles that offer a balanced mix of power and control, the manufacturing process must ensure that every detail, from the surface treatment to core composition, contributes to optimal performance. This is especially critical for professional and competitive use. -

Market Competition:

Leading brands invest heavily in production technologies and quality control measures. For B2B purchasers, partnering with suppliers who adopt innovative manufacturing processes is crucial to remain competitive and provide products that meet or exceed industry benchmarks. -

Design Customization Requirements:

Today’s sports equipment buyers seek custom solutions that align with their brand vision and performance targets. Custom paddle options—such as tailored weight distribution, grip design, and balance—are increasingly important. This requires a manufacturing process that is both precise and flexible.

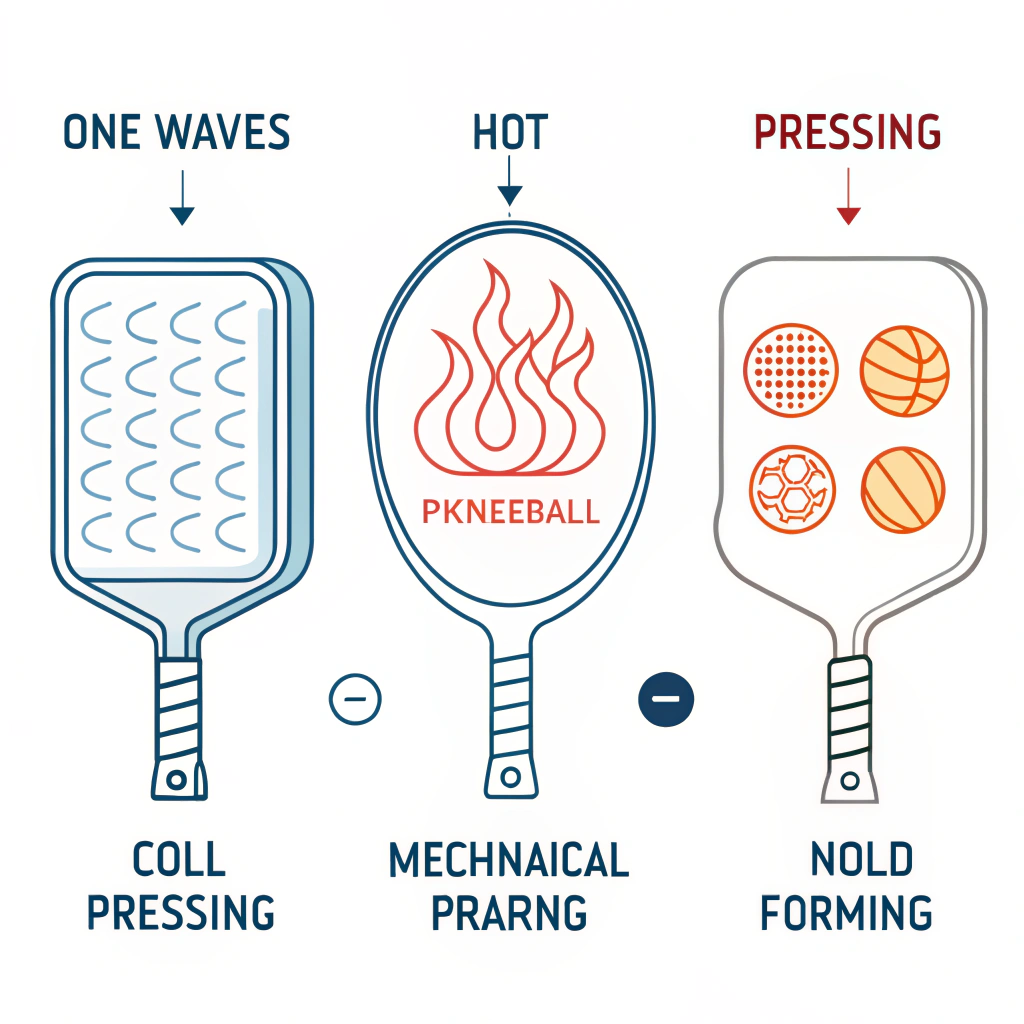

Manufacturers like NEX Pickleball have adopted advanced production techniques that minimize the inherent challenges of modern pickleball paddle production. Below is an overview of the three most critical processes:

Hot pressing involves heating materials and applying pressure to form the paddle. It is typically used to create paddles with superior impact resistance.

- Advantages:

- High production efficiency, making it ideal for large-scale manufacturing.

- Produces strong paddles with excellent impact resistance and structural integrity.

- Disadvantages:

- Potential alteration of some material properties that may affect the paddle feel.

- High initial investment in equipment.

Cold pressing shapes the paddle material at room temperature under mechanical pressure, preserving the natural properties of the material.

- Advantages:

- Provides precise control over paddle thickness and structure.

- Retains material properties to offer better ball feel and flexibility.

- Disadvantages:

- Generally slower production cycles compared to hot pressing.

- Requires high-quality pressure control equipment to ensure consistency.

Thermoforming uses heat to soften the material, which is then molded into the final shape using specific molds. This process is ideal for creating intricate designs and guaranteeing even material distribution.

- Advantages:

- Allows for complex designs and even material distribution, enhancing paddle stability.

- Ideal for high-performance products with premium features.

- Disadvantages:

- Longer production times along with higher equipment and operational costs.

Below is a comparative overview of the three techniques:

| Production Technique | Key Advantages | Main Disadvantages | Suitable For |

|---|---|---|---|

| Hot Pressing | High efficiency, strong impact resistance | May alter material feel, high equipment cost | Mass production of high-performance paddles |

| Cold Pressing | Precise control, optimal ball feel | Longer production cycle, precise control | Paddles requiring refined control and balance |

| Thermoforming | Complex designs, even material distribution | Longer process, higher production cost | Premium paddles with intricate designs |

Material innovation is as critical as production technique in producing high-performance pickleball paddles. The selection and integration of various materials can dramatically influence the final product’s characteristics. Below are some of the main materials used:

- 3K Carbon Fiber:

Renowned for its excellent strength and flexibility, it is used in paddles that require high rebound without compromising on durability. Its vibration-damping properties contribute to improved control. - 12K Carbon Fiber:

With a higher thread density, it offers a smoother playing surface and increased hardness. Perfect for competitive play, where extreme impact resistance is necessary. - T300 Carbon Fiber:

Known for its high tensile strength, T300 strikes a balance between power and weight, making it ideal for players who demand precision and swift reaction on the court.

Fiberglass materials, such as E-Glass Fiberglass, enhance paddle performance by offering a broader sweet spot and excellent elasticity. This material is chosen for its ability to provide a mix of power and control while maintaining overall durability.

Composite construction, blending both carbon fiber and fiberglass, has emerged as a superior approach. This combination leverages the best attributes of both materials and results in paddles that exhibit excellent performance characteristics—including strength, light weight, and flexibility.

The paddle’s core material is crucial to its overall performance:

- Nomex Honeycomb Core5:

Known for its superior shock absorption, this core ensures enhanced durability and stability. - Aluminum Honeycomb Core:

Offers a balanced weight distribution, which translates to a mix of power and precision control. - Polymer Honeycomb Core:

Provides increased elasticity while reducing vibration, making it a popular choice for recreational players and beginners.

Manufacturers who leverage these advanced techniques, such as NEX Pickleball, have demonstrated significant improvements in both product quality and customer satisfaction. For instance, optimizing production processes reduces the variations in paddle performance by ensuring that each paddle consistently meets strict specifications. One case study of a major pickleball brand partner showed reductions in production defects by 15% after transitioning from a traditional press method to a more refined thermoforming technique. This quality milestone not only ensured consistency but also increased end-user satisfaction.

Key performance indicators that have improved through these manufacturing practices include:

- Enhanced Vibration Reduction: Maintaining paddle feel while reducing shock.

- Increased Durability: Prolonging the lifespan of the paddle even under intense play.

- Optimized Weight Distribution: Providing better balance, which is critical for high-level competitive performance.

These improvements are supported by rigorous quality control measures that evaluate every aspect of paddle performance from material selection to final assembly. With the application of statistical process controls and continuous performance testing, manufacturers are able to track product deviations early, ensuring high standards are met throughout the production run.

For procurement managers and B2B decision-makers, understanding the nuances of these production techniques and material innovations is essential. When evaluating potential suppliers, consider the following strategic points:

-

Production Expertise:

A supplier’s expertise in advanced production processes such as hot pressing, cold pressing, and thermoforming is a critical quality indicator. It demonstrates the supplier’s capability to meet large-scale demands while ensuring the product’s structural integrity. -

Material Innovation:

The use of multiple material types, notably premium carbon fibers, fiberglass, and high-performance composites, is a testament to a manufacturer’s commitment to innovation. This diversification can be a competitive advantage in meeting various market segments from recreational to competitive play. -

Quality Assurance Practices:

Rigorous quality control systems are essential. When a supplier implements data-driven quality checkpoints throughout the manufacturing process, the risk of product inconsistencies is minimized. This reliably translates to fewer returns and increased customer satisfaction. -

Customization Capability:

The ability to offer custom paddle options, including specified design, weight distribution, and ergonomic adjustments, enhances the value proposition for many brands. Collaborative projects and on-demand manufacturing are becoming the norm in competitive sports equipment markets.

Below is a summary table reflecting how these strategic factors map to advanced production processes:

| Strategic Factor | Production Technique Impact | Procurement Considerations |

|---|---|---|

| Production Expertise | Hot pressing for high efficiency, thermoforming for complex designs | Ability to meet large scale orders with consistent quality |

| Material Innovation | Use of 3K, 12K, T300 carbon fiber, and composites | Ensures high-performance outcomes tailored for market segments |

| Quality Assurance | Integrated quality testing and controlled processes | Reduces risk of defects and enhances consumer satisfaction |

| Customization Capability | Adaptable processes such as cold pressing for design precision | Increases product differentiation and potential for brand collaborations |

For B2B decision-makers evaluating manufacturers for high-performance pickleball paddles, consider these actionable steps:

-

Assess the supplier’s production methodology and ask detailed questions about how each technique affects the final product’s performance. Inquire specifically about control methods and quality testing protocols.

-

Request case studies and performance data from current partner brands to gauge the improvements achieved through the implementation of advanced production processes.

-

Evaluate the supplier’s ability for customization. Understand how material selection and manufacturing flexibility can be tailored to meet your target market’s needs.

-

Consider a pilot program with a supplier who employs these advanced techniques. This pilot can serve as a proof point for the expected improvements in quality and performance, reducing long-term supply chain risks.

-

Look for partners who demonstrate continuous improvement initiatives. Suppliers who invest in equipment upgrades and process optimizations are likely to stay ahead in meeting evolving market demands.

Modern pickleball paddle production is not merely a matter of assembly but a sophisticated process that hinges on advanced manufacturing techniques and meticulous material selection. By leveraging hot pressing1, cold pressing2, and thermoforming3, manufacturers like NEX Pickleball deliver products that meet the stringent demands of today’s competitive sports environment.

For procurement managers, understanding these processes is critical. The ongoing emphasis on quality control, customization, and material innovation provides a strong foundation for establishing enduring supplier partnerships. The lessons drawn from advanced production techniques highlight how strategic investments in manufacturing can drive superior product performance, leading to higher customer satisfaction and competitive advantage.

By evaluating suppliers on these criteria, B2B decision-makers can ensure their procurement strategies align with the highest industry standards and technological advancements, ultimately securing products that enhance performance on the court and profitability for their business.

-

hot pressing: Click to read an in-depth exploration of the hot pressing process, including its benefits in increasing manufacturing efficiency and enhancing product durability. ↩ ↩ ↩2

-

cold pressing: Click to understand how cold pressing preserves material integrity and offers precise control in shaping products, ensuring optimal performance. ↩ ↩ ↩2

-

thermoforming: Click to learn about thermoforming techniques, detailing how heat and molds are used to achieve complex designs and uniform material distribution. ↩ ↩ ↩2

-

composite materials: Click to explore composite materials, focusing on their role in blending different fibers for superior strength, lightweight design, and enhanced product performance. ↩ ↩

-

Nomex Honeycomb Core: Click to read about the Nomex Honeycomb Core, its shock absorption properties, and its contribution to overall product stability and durability in high-performance applications. ↩ ↩