High-performance pickleball paddles for 2025 are built on innovative manufacturing techniques and superior materials. In this article, we explore the challenges of producing such paddles, examine advanced production processes like hot pressing1, cold pressing2, and thermoforming3, and discuss how materials such as different types of carbon fiber4, fiberglass, and various composite cores contribute to performance and durability. Our goal is to help procurement managers and product development specialists make informed decisions by comparing these technical processes and materials.

In today's competitive sports equipment market, producing a top-tier 2025 pickleball paddle demands a careful balance between performance, durability, and cost-effectiveness. Manufacturers are increasingly focused on advanced production methods and high-quality raw materials to deliver products that meet the high expectations of modern players. With evolving trends such as quick rebound force and enhanced vibration reduction, the production process has become as critical as the selected materials.

Key challenges include:

- Maintaining structural integrity while optimizing the weight and balance of the paddle.

- Achieving exact material properties such as hardness, flexibility, and vibration absorption.

- Balancing production efficiency with the flexibility required for custom designs.

These challenges require a clear technical approach that incorporates innovations in material science and production engineering. When partnering in an OEM/ODM5 project, procurement managers look for manufacturers who not only understand these needs but can also provide consistent quality through advanced production techniques.

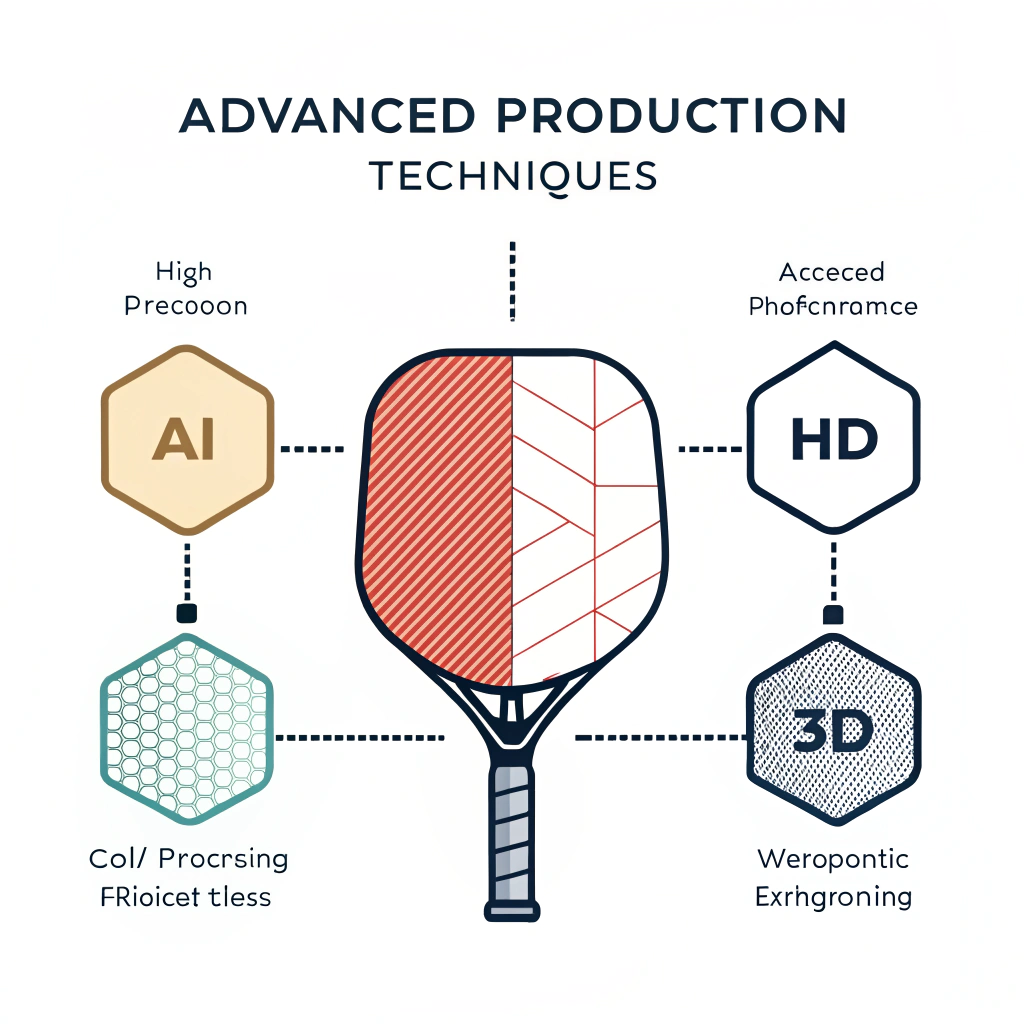

Professional sports equipment manufacturing has embraced a trio of advanced production techniques. Each method offers unique benefits and trade-offs:

Hot pressing involves the simultaneous application of heat and pressure to mold raw materials into a coherent paddle structure. This method is renowned for creating a durable, high-strength paddle.

Advantages:

- High Production Efficiency: Suitable for large-scale manufacturing.

- Strong Impact Resistance: Results in a paddle with excellent durability.

- Structural Integrity: Provides robust performance for competitive play.

Disadvantages:

- Material Property Alteration: The elevated temperature can modify some desirable properties of the raw material.

- High Equipment Investment: Requires specialized machinery capable of withstanding high-pressure heat cycles.

Cold pressing uses mechanical pressure at room temperature to form the paddle, offering superior control during production.

Advantages:

- Precision Control: Maintains the original properties of the materials without additional thermal effects.

- Enhanced Ball Feel: Results in a balanced paddle with exceptional responsiveness.

- Design Flexibility: Ideal for designs requiring very specific thickness or balance.

Disadvantages:

- Longer Production Cycle: The process is slower compared to hot pressing.

- Pressure Sensitivity: Demands precise control, which may require more sophisticated equipment.

Thermoforming involves heating a material until it becomes pliable, then molding it into a specific shape using precise molds. It is particularly useful for complex designs where uniform material distribution is crucial.

Advantages:

- Complex Shape Capability: Allows for intricate design features that optimize the paddle's surface texture and weight distribution.

- Enhanced Paddle Stability: Produces paddles with consistent and balanced performance over repeated use.

- Material Versatility: Ideal for premium materials including advanced grades of carbon fiber.

Disadvantages:

- Extended Production Time: More time consuming than other techniques.

- Higher Equipment Costs: Investment in high-end molds and heating systems is required.

Below is a summary table that compares these three production methods:

| Production Process | Key Advantage | Main Disadvantage | Ideal For |

|---|---|---|---|

| Hot Pressing | High production efficiency | Alteration of material properties | Mass-production of high-strength paddles |

| Cold Pressing | Precise control over materials | Longer cycle time | Custom designs demanding precision |

| Thermoforming | Complex shape formation | Higher production costs | Premium, high-performance products |

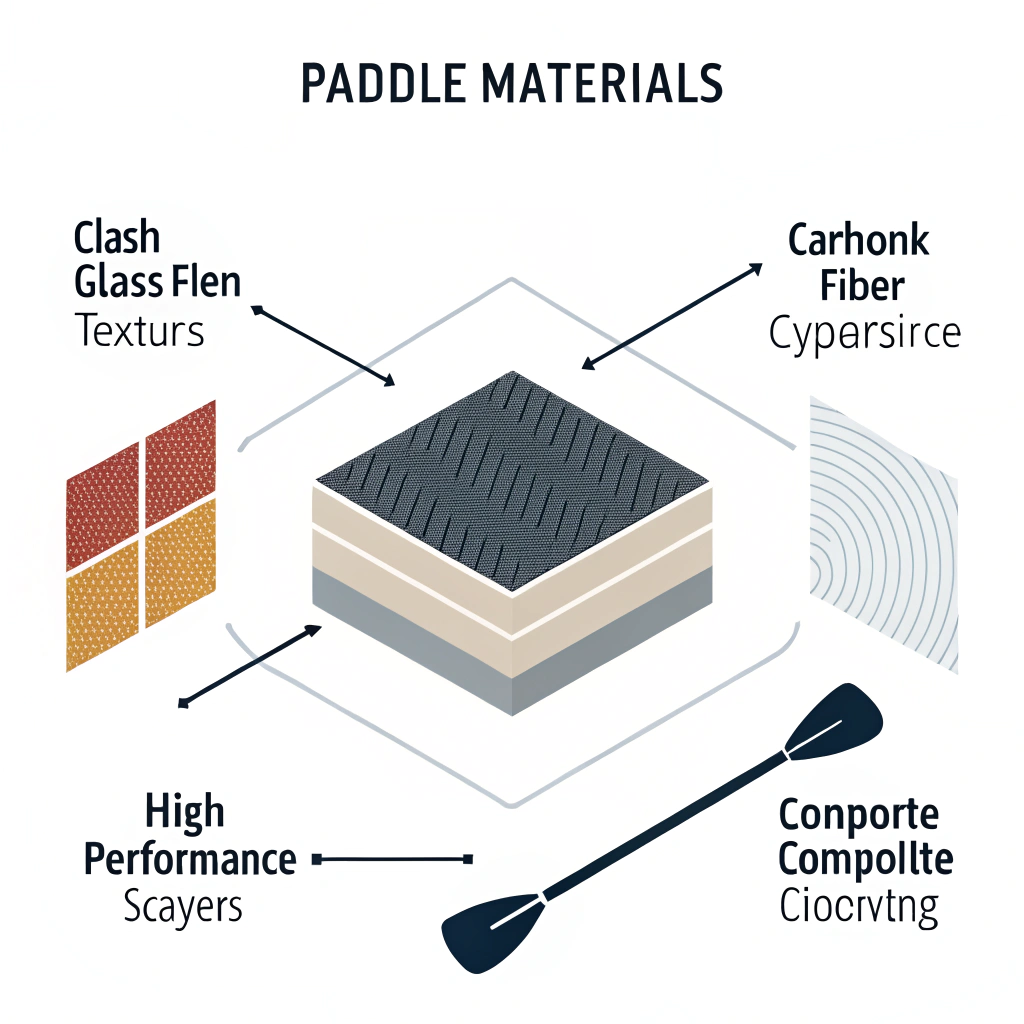

The performance of a pickleball paddle is closely linked to the materials selected during manufacturing. Here’s a closer look at the key materials and advanced composites used in today’s paddles.

Carbon fiber is a cornerstone in high-performance paddle production. The differences among 3K, 12K, and T300 carbon fiber offer varying benefits:

- 3K Carbon Fiber: Known for its exceptional flexibility and high rebound force, making it ideal for paddles that require a blend of power and durability.

- 12K Carbon Fiber: With a higher thread density, it provides a smoother surface and exceptional impact resistance, perfect for competitive scenarios.

- T300 Carbon Fiber: Balances light weight with high tensile strength, suited for paddles needing overall dynamic performance.

These materials not only improve power and control but also minimize vibration, which is a critical factor for prolonged play. The selection of the appropriate grade of carbon fiber depends on the intended paddle use and target player level.

Fiberglass, particularly E-Glass Fiberglass, offers a great balance between power and control. Its inherent flexibility enhances the ball control, making it suitable for players who prioritize feel over sheer power.

In combination with carbon fiber, manufacturers are now using composite materials to maximize performance. Some notable composite structures include:

- Carbon Fiber and Fiberglass Composite: Achieves a balanced mix of strength, lightness, and flexibility.

- Bamboo Core Composite: Offers an extremely lightweight structure with high impact resistance, providing a clear and responsive hitting sensation.

- Honeycomb Core: Typically manufactured from high-density polymer, this structure is excellent for shock absorption and reducing vibration.

The core of a paddle determines its overall feel, control, and durability. Popular core materials include:

- Nomex Honeycomb Core: Offers excellent shock absorption and long-lasting durability, well-suited for high-intensity play.

- Polymer Honeycomb Core: Known for superior elasticity and comfort, reducing vibration during hits and ideal for recreational players.

- Aluminum Honeycomb Core: Provides a balanced weight and is excellent for delivering both power and precision.

This table provides a comparative summary of these core options:

| Core Material | Key Characteristics | Best For |

|---|---|---|

| Nomex Honeycomb Core | High durability, excellent shock absorption | High-performance competitive paddles |

| Polymer Honeycomb Core | Superior elasticity, immediate feel | Recreational use and comfort |

| Aluminum Honeycomb Core | Balanced weight, strong power control | Mixed usage needing precision and power |

For B2B procurement managers, partnering with a manufacturer like NEX Pickleball—which is a leading producer and contract manufacturer for brands such as JOOLA and Selkirk—can provide significant competitive advantages. Understanding OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) roles can help in aligning production capabilities with market needs.

- Customization: Many buyers require tailored paddle designs. With custom paddle options, clients can specify design, weight, and balance to suit specific team brands or player preferences.

- Quality Assurance: Advanced production processes such as hot pressing, cold pressing, and thermoforming ensure that each paddle meets rigorous performance standards.

- Innovative Materials: Utilizing premium materials like 3K, 12K, and T300 carbon fiber as well as diverse core compositions enhances the product's performance.

- Cost Efficiency: Streamlined production processes and experienced manufacturing partners help in balancing cost (competitive pricing) and high quality, a critical factor for B2B sports equipment procurement.

Some sports equipment companies have increased their market share by switching to suppliers who offer advanced production techniques. This switch not only improved their product durability and performance but also resulted in better brand reputation and customer satisfaction.

Manufacturers who can deliver consistent quality, on-time production, and innovative design techniques are ideal partners for long-term B2B relationships. For example, companies looking into new trends for the 2025 pickleball paddle are increasingly evaluating production methods that significantly reduce vibration and increase player control. These technological advancements directly impact product performance on court, making them key factors when facing a vendor comparison.

As we move deeper into 2025, the sports equipment industry is rapidly adopting new manufacturing methods. Technology and tradition are merging to produce paddles that are not only innovative in design but also reliable under the rigors of competitive play. Let’s consider the overall landscape:

- Customer Expectations: Mobile and digital engagement has increased transparency. Buyers now expect detailed technical specifications and process descriptions that justify the performance and durability of the paddles.

- Increased Competition: With more manufacturers entering the market and focusing on similar materials, the differentiation largely falls on production precision. Innovations in thermoforming, for instance, allow for sophisticated design features that can become key selling points.

- Regulatory and Standard Considerations: Manufacturing practices must align with evolving sports equipment standards. Rigorous tests ensure that products meet or exceed these benchmarks, a crucial consideration especially when a product is destined for global markets.

Data shows that paddles engineered with a perfect blend of power, control, and durability are more likely to succeed in competitive environments. Thus, integrating advanced production processes is not merely a choice—it is an imperative for sustainable growth and competitive advantage.

Manufacturers must keep investing in state-of-the-art machinery and quality control practices to stay ahead of these trends. Such investments pay off in improved product performance and higher customer satisfaction, both of which drive recurring business and loyalty among B2B partners.

To summarize, the pursuit of a high-performance 2025 pickleball paddle is deeply rooted in understanding manufacturing challenges and leveraging advanced production technologies. Key takeaways include:

- A clear grasp of hot pressing, cold pressing, and thermoforming is fundamental to selecting the right manufacturing partner.

- Material choices, including various carbon fibers, fiberglass, and diverse core compositions like Nomex and polymer cores, critically influence the paddle’s performance.

- OEM and ODM partnerships that offer customization, comprehensive quality checks, and competitive pricing are essential for building sustainable B2B relationships.

- Staying informed about emerging trends and consumer expectations will ensure that your products continue to lead in innovation and durability.

For procurement specialists and product development teams aiming to enhance their product portfolio, selecting a partner that comprehensively understands these technologies will be key to long-term success. We recommend a proactive approach: engage in technical discussions with manufacturing partners, visit production facilities if possible, and conduct thorough performance tests to ensure the paddle meets your specific requirements.

By focusing on these core production techniques and material standards, companies can successfully navigate the competitive landscape and achieve remarkable product performance in the evolving world of pickleball.

What is the best pickleball paddle in 2025?

The best pickleball paddle in 2025 combines advanced production methods such as thermoforming with premium materials like carbon fiber (3K, 12K, T300) and specialized core composites (Nomex, polymer core). This results in a paddle that delivers excellent power, precise control, and enhanced durability, meeting the rigorous demands of competitive play.

What is the newest technology for pickleball paddles?

The newest technology involves thermoforming processes that allow for a stiffer, unibody design with improved material distribution. Innovations such as raw carbon fiber integration and foam edge walls help enhance spin, control, and overall performance, marking a significant leap in paddle technology over previous generations.

Is JOOLA Gen 3 paddles still banned?

Recent assessments confirm that JOOLA Gen 3 paddles continue to face regulatory challenges as they have not consistently met the approved equipment standards. This situation underscores the importance of rigorous quality control and adherence to evolving testing protocols in high-performance paddle manufacturing.

-

Hot Pressing: Discover how the hot pressing process uses heat and pressure concurrently to mold materials into durable, high-strength products, which is essential for large-scale, efficient manufacturing. ↩

-

Cold Pressing: Learn about cold pressing—a method that preserves the original material properties through mechanical pressure at room temperature, providing precision and enhanced tactile feedback. ↩

-

Thermoforming: Explore thermoforming, a process that involves heating materials until pliable and then molding them into complex shapes, ideal for achieving innovative designs and optimized weight distribution. ↩

-

Carbon Fiber: Read more about carbon fiber’s properties and its various grades (3K, 12K, T300), which are critical for enhancing performance, durability, and weight efficiency in high-performance sports equipment. ↩

-

OEM/ODM: Understand the roles of Original Equipment Manufacturer and Original Design Manufacturer in B2B partnerships, including how these models influence customization, production processes, and overall market competitiveness. ↩