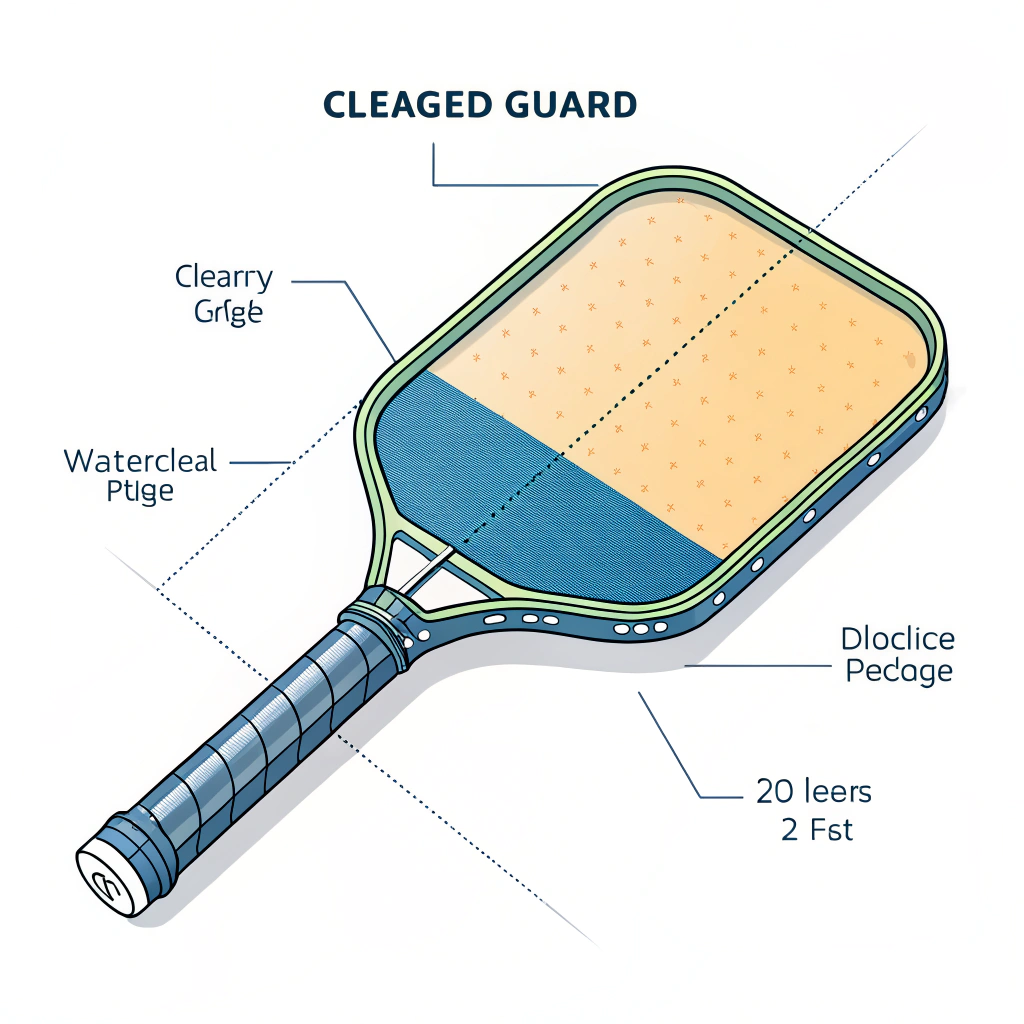

Quick Answer: A 20 mm edge guard tape is an essential component designed to provide optimal protection and durability for pickleball paddles, balancing coverage and performance. It enhances paddle longevity by protecting edges from impacts while maintaining an ideal balance between aesthetics and functionality.

In today’s competitive pickleball market, achieving a high-performance paddle means paying close attention to every detail, including the choice of edge guard tape1. For manufacturers and procurement managers, selecting the right tape is critical to ensuring product longevity and performance. In this article, we discuss the industrial application of a 20 mm edge guard tape for pickleball paddles, examine its technical benefits, compare it to other options, and offer actionable recommendations geared toward optimizing your product design and procurement strategies.

Pickleball paddles are subject to intense mechanical stresses during play. Constant impacts, friction, and occasional mishaps demand that the paddle edges be robust and protected. Edge guard tape serves as a protective barrier, reducing wear and tear while maintaining the paddle’s sharp appearance. However, market choices vary in material quality, width, and durability, leaving B2B buyers to deliberate over which product best fits their product lineup.

Key requirements include:

- Enhanced durability: To withstand repeated contact with hard surfaces.

- Optimal width coverage: To cover the sensitive edge without impeding play.

- Compatibility with paddle dimensions: Ensuring a precise fit for varying paddle thicknesses.

- Cost-effectiveness: Balancing quality with competitive pricing.

- Compliance with quality control standards2

Before diving into technical specifications, it is essential to understand the challenges faced by manufacturers:

- Material degradation: Inferior materials may crack or peel, reducing the paddle's protective capabilities.

- Improper installation: A mismatch in tape width relative to paddle dimensions can lead to uneven coverage and premature wear.

- Limited design flexibility: Some tapes do not adapt well to the paddle’s curvature, affecting both performance and aesthetics.

- Compliance with quality control standards: Production processes like hot pressing3, cold pressing4, and thermoforming5 require materials that can maintain integrity under each method's specific conditions.

Manufacturers must choose a tape that not only prevents damage but also integrates seamlessly with the existing paddle design, thereby protecting their investment in high-performance paddles.

When opting for a 20 mm edge guard tape, several technical factors come into play. Below is a detailed comparison of specifications and attributes critical to performance.

| Feature | 20 mm Edge Guard Tape | Alternative Widths (e.g., 25mm/30mm) |

|---|---|---|

| Coverage | Mid-range coverage ideal for 14-16mm paddles | May cover more surface area but risk overhang on smaller paddles |

| Material Quality | High-grade, durable polymer composite | Varies: some lower quality may compromise durability |

| Installation Ease | Easy to cut and apply without affecting paddle weight balance | Pre-cut designs available, but may require extra adjustments |

| Impact Resistance | Excellent resistance to cracks and abrasions | Some alternatives may have lower shock absorption |

| Production Compatibility | Suitable for hot pressing, cold pressing, and thermoforming processes | Other widths may not provide the same stability across different processes |

These key specifications illustrate why a 20 mm edge guard tape often stands out: it strikes the right balance between comprehensive edge coverage and maintaining the delicate performance characteristics of high-performance pickleball paddles.

The decision to integrate a 20 mm edge guard tape involves understanding both the materials used and the manufacturing processes:

-

Material Performance

- Durability: High-quality polymers used in 20 mm tapes can absorb shocks and reduce vibration effectively. Their composition resists degradation from thermal fluctuations during processing.

- Fit and Flexibility: A 20 mm width is designed to adapt well across various paddle thicknesses, ensuring that the tape doesn’t impede the paddle’s balance or control during rapid gameplay.

-

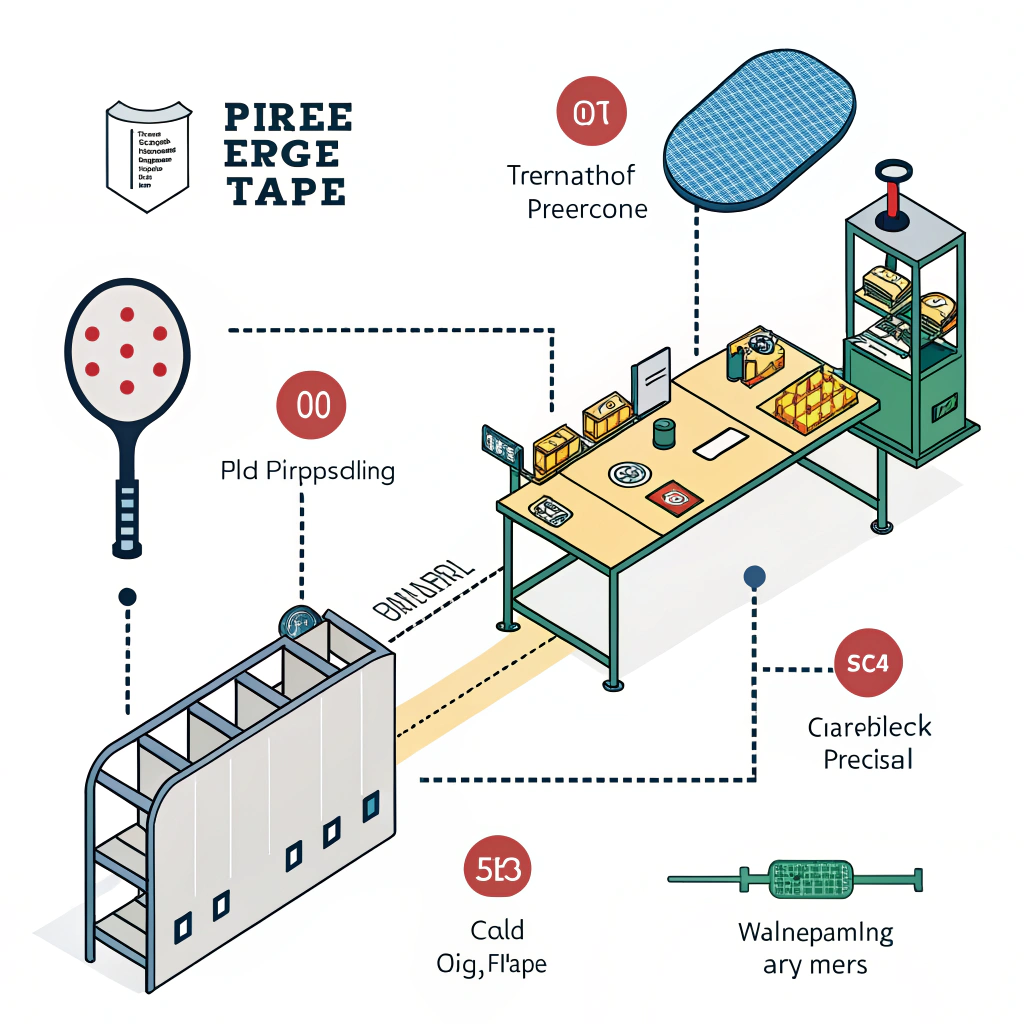

Production Process Compatibility

At NEX Pickleball, our production processes include:- Hot Pressing3: This technique yields strong, structurally reliable paddles. The 20 mm edge guard tape is compatible with this method due to its ability to withstand high temperatures and pressure without losing elasticity.

- Cold Pressing4: Precision is crucial here. Using a tape with consistent width ensures that the paddle’s precision is maintained.

- Thermoforming5: For paddles that feature intricate curves or layered composite materials, the 20 mm tape conforms well, ensuring even coverage and adhesion.

Each process has its unique demands. As such, having an edge guard tape that is versatile enough to be integrated through these varied manufacturing methods is a significant advantage. This versatility not only enhances paddle performance but also streamlines the production process, reducing waste and rework.

Implementing a 20 mm edge guard tape can revolutionize the overall durability and playability of paddles. Let’s explore several practical applications:

Scenario 1: Enhanced Durability for Competitive Play

For competitive players, every millisecond counts. The precise application of a 20 mm edge guard tape ensures minimal vibration and optimal shock absorption during high-stress plays. This leads to more consistent ball control and prolonged paddle life, especially important for professional-grade paddle designs.

Scenario 2: Custom Paddle Production

In custom orders, where players or teams seek unique branding and performance characteristics, the 20 mm tape's customizability allows for a perfect fit. With the option to adjust grip size and balance, paddles customized with this tape can achieve a bespoke feel, bolstering both performance and brand differentiation in the marketplace.

Scenario 3: Cost-Effective Industrial Integration

For large-scale manufacturing intended for retail distribution, reducing the need for frequent replacements and warranty claims is critical. The 20 mm tape’s resilience against wear and tear makes it a cost-effective component, reducing long-term maintenance and replacement expenses.

Manufacturers often incorporate extensive testing, such as drop tests and abrasion resistance assessments, to validate the performance of the edge guard tape. Data from these tests frequently demonstrate that the 20 mm option provides an optimal balance between protection and paddle sensitivity.

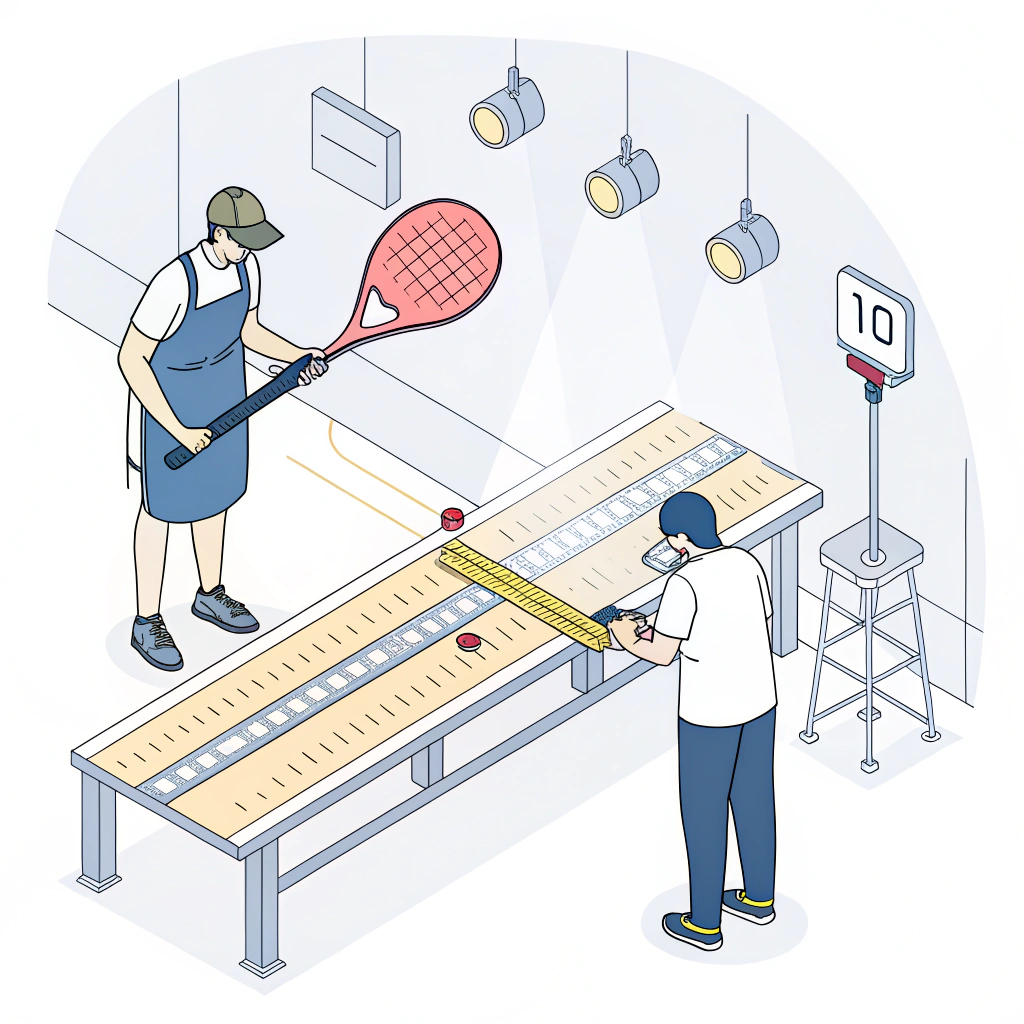

To maximize the benefits of a 20 mm edge guard tape, manufacturers should consider the following application best practices:

- Accurate Cutting: Consistency in tape length and width is essential. Automated cutting tools can ensure high precision, reducing human error and guaranteeing a uniform finish.

- Surface Preparation: Thorough cleaning and priming of the paddle edge ensure strong adhesion. Any residual dust or oil can compromise the tape’s bonding, leading to premature peeling.

- Quality Control Checks: Implement rigorous quality control protocols at each stage of production. Regular stress tests and durability assessments should be part of the finishing process.

- Employee Training: Ensure that technicians are familiar with the nuances of applying the tape in different manufacturing environments, whether using hot pressing, cold pressing, or thermoforming.

Below is an example checklist for quality assurance during tape application:

| Step | Description | Outcome Expected |

|---|---|---|

| Surface Cleaning | Removing all debris and contaminants | High adhesion and bond strength |

| Precise Cutting | Cutting the tape to exact lengths and widths | Uniform application |

| Strategic Application | Applying with even pressure using calibrated tools | Smooth, bubble-free finish |

| Final Inspection | Verifying overall coverage and adherence over edges | Consistent appearance and durability |

Adhering to these best practices not only optimizes the performance of the edge guard tape but also reinforces the overall quality agreement between suppliers and B2B partners.

Integrating a 20 mm edge guard tape into pickleball paddle production presents a robust solution for enhancing product durability and maintaining competitive performance. Its excellent compatibility with diverse manufacturing processes, superior material performance, and cost-effectiveness make it a preferred choice for manufacturers aimed at reducing maintenance costs and enhancing product lifespan.

Key action recommendations include:

- Review the specific needs of your paddle production process, including thickness and material composition.

- Test the tape under varied conditions, such as impact tests and long-term durability assessments.

- Include detailed quality control protocols during the application process to ensure optimal bonding and performance.

- Consider partnering with suppliers experienced in high-performance edge guard tape to address any integration challenges.

By focusing on these factors, you can confidently enhance your paddle products, meet the high standards expected by competitive players, and achieve a sustainable cost structure in production.

Q: What size edge tape for pickleball paddle?

A: The size of the edge guard tape is critical in achieving full coverage without interfering with paddle performance. While wider options like 30mm may be used for thicker paddles, a 20mm tape strikes an excellent balance for 14-16mm paddles, providing durable protection without excess overhang.

Q: What is the best pickleball edge guard tape?

A: The best pickleball edge guard tape is one that extends paddle longevity and maintains optimal performance. After thorough testing, premium versions, especially those designed to perfectly fit the paddle’s dimensions without affecting its balance, are highly recommended for high-end competitive play.

Q: Can you replace the edge guard on a pickleball paddle?

A: Yes, edge guards on pickleball paddles can be replaced. Some manufacturers even offer warranty services for loose or damaged edge guards. Alternatively, careful super glue application by experienced technicians can restore the edge guard without voiding the warranty.

-

edge guard tape: Click to read an article that explains the technology behind edge guard tapes, detailing their composition and how they protect sports equipment from wear and tear. ↩

-

quality control standards: Click to read about quality control standards in manufacturing, offering insights into testing protocols and methods to ensure consistent production quality. ↩

-

hot pressing: Click to learn about the hot pressing process, including how high temperatures and pressure are used to bond components in manufacturing. ↩ ↩2

-

cold pressing: Click to explore the cold pressing technique, discussing its role in precise manufacturing and its advantages for maintaining material integrity. ↩ ↩2

-

thermoforming: Click to understand thermoforming, a production process that involves heating a plastic sheet to form complex shapes with consistent quality. ↩ ↩2