The best pickleball paddle in 2025 is one that expertly balances advanced materials and precise production techniques to deliver unparalleled performance and durability. For B2B decision-makers, choosing the right paddle involves a detailed comparison of material types and manufacturing processes that suit both recreational and competitive markets.

B2B buyers face a complex decision when evaluating pickleball paddles. The challenge lies in selecting a product that not only meets the rigorous performance expectations of athletes but also reinforces your market reputation as a provider of cutting-edge sports equipment. With technological advances in carbon fiber1 variants, fiberglass, and composite materials2, and with differing production processes such as hot pressing3, cold pressing4, and thermoforming5, it is imperative to compare the strengths and limitations of each option.

A critical factor in the decision-making process is the paddle's material composition. Today’s top paddles incorporate innovative materials like:

- 3K Carbon Fiber: Renowned for its excellent strength and flexibility, offering a high rebound force while reducing vibration.

- 12K Carbon Fiber: Provides a smoother surface with increased hardness and durability, making it ideal for competitive play.

- T300 Carbon Fiber: Known for its exceptional tensile strength, it offers a balanced performance of strength and lightweight design.

- Fiberglass: This material is lauded for its balance between power and control, featuring a wider sweet spot and superior elasticity.

- Composite Materials: Such as carbon fiber and fiberglass composites or bamboo core composites, which combine the benefits of multiple materials for enhanced performance.

- Core Materials: Options like Nomex honeycomb, aluminum honeycomb, and polymer cores also play a strategic role in determining the paddle's rigidness, shock absorption, and overall feel.

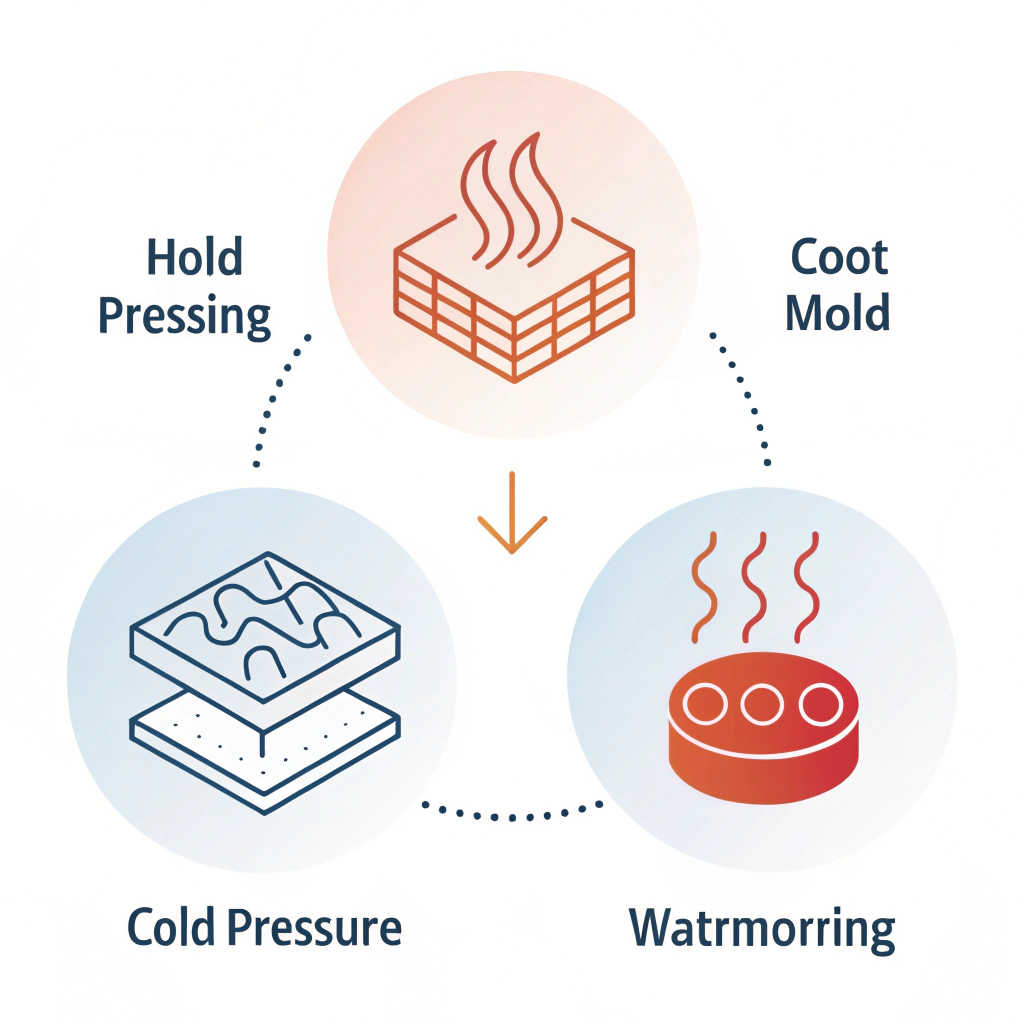

For procurement managers, understanding how these materials interact under different production techniques is crucial. Each production method—hot pressing, cold pressing, and thermoforming—can affect the paddle's quality attributes such as density, weight distribution, and durability.

The manufacturing process of a pickleball paddle significantly influences its performance and longevity. Here is a detailed look at the three primary techniques used by top manufacturers like NEX Pickleball:

| Production Method | Advantages | Disadvantages |

|---|---|---|

| Hot Pressing | • High production efficiency • Produces strong, durable paddles with excellent impact resistance • Ensures structural integrity for high performance | • May alter some material properties affecting the paddle’s feel • Requires significant investment in specialized equipment |

| Cold Pressing | • Offers precise control over thickness and structure • Maintains inherent material properties for better control and flexibility • Yields an enhanced ball feel and responsiveness | • Longer production cycles which reduce efficiency • Requires high-quality pressure control systems |

| Thermoforming | • Allows for complex, intricate designs with precise material distribution • Maintains stability of the paddle during play • Ideal for premium or custom paddle production | • Involves longer production times and higher equipment costs • Best suited for specialized products rather than mass production |

Each technique brings a unique balance of quality, cost, and performance. When evaluating which process to partner with, consider the production volume needed and the targeted market segment. A high-end sports retailer might prioritize the precision of cold pressing for an enhanced playing feel, whereas a distributor aiming for volume may value the efficiency of hot pressing without compromising durability.

Manufacturers like NEX Pickleball offer a diverse range of paddles by utilizing advanced material technology. Understanding how these different materials contribute to performance is essential:

-

3K Carbon Fiber

Early in the production process, 3K carbon fiber stands out for its great strength-to-weight ratio and flexibility. It is highly effective in paddles where high rebound force is required, making it perfect for players who demand a vibrant hit with reduced vibrations. -

12K Carbon Fiber

With a higher thread density, 12K provides a smoother surface and increased hardness. This kind of paddle is more resilient, ideal for competitive scenarios where impact resistance and durability are paramount. -

T300 Carbon Fiber

T300 delivers a balanced performance with enhanced tensile strength and lightweight properties. It fits well in paddles designed for players who need both power and speed.

Fiberglass paddles are celebrated for providing a blended experience of control and power. They typically offer:

- A wider sweet spot that naturally improves ball contact

- Enhanced elasticity ensuring a softer rebound effect

- Superior control making them suitable in scenarios that value finesse over raw power

Composite paddles that combine materials like carbon fiber and fiberglass can provide a superior blend of properties. These paddles may be engineered with:

- Bamboo Core Composite: Offering a lightweight design while ensuring excellent impact resistance.

- Honeycomb Core (Nomex, Aluminum, Polymer): Each variant provides unique benefits, such as enhanced shock absorption and optimized balance between hardness and flexibility.

Here’s a summary comparison table that highlights key material characteristics:

| Material Type | Key Benefits | Ideal For |

|---|---|---|

| 3K Carbon Fiber | Strength, flexibility, and reduced vibration | Recreational to competitive play where bounce is critical |

| 12K Carbon Fiber | Smooth surface, high durability, increased hardness | High-impact competitive environments |

| T300 Carbon Fiber | Balanced strength with lightweight design | Players needing both power and precision |

| Fiberglass | Excellent elasticity, wider sweet spot | Offering a controlled hitting experience |

| Composite (Carbon + Fiberglass) | Merges strength with flexibility | Versatile performance for varied playing styles |

| Bamboo Core Composite | Lightweight and impact resistant | Players looking for long-lasting performance |

| Honeycomb Cores (Nomex/Aluminum/Polymer) | Superior shock absorption and balance control | Targeting specific player needs based on usage |

When considering bulk purchasing or expanding your sports equipment lineup, it is essential not just to evaluate the paddle's technical specifications but also to align with current market demands and production capabilities.

-

Performance and Durability Trade-Offs

Decide whether your target market values high-performance paddles that excel in competitive play or if there is a larger demand for versatile, recreational paddles with a wider sweet spot and superior ball control.- Competitive players often prefer 12K Carbon Fiber paddles for their durability despite higher production costs.

- Recreational customers may lean towards fiberglass or composite paddles which offer balanced playability and better cost efficiency.

-

Production Capacity and Customization Needs

The production process you select directly impacts turnaround times and the ability to customize orders. For markets requiring frequent, high-volume orders:- Hot Pressing is attractive due to its efficiency.

- For custom or limited-edition paddles where tactile feel and precise manufacturing are priorities, cold pressing or thermoforming may be preferable despite longer production cycles.

-

Cost Versus Leading-Edge Performance

While advanced materials and sophisticated production techniques can command premium pricing, understanding the price sensitivity of your clientele is crucial. Establishing a balance between cost and performance is key to long-term success in a competitive market. -

Technical Data and Benchmarking

It is advisable to request detailed technical specifications and recent performance test results from suppliers like NEX Pickleball. Data points such as impact resistance, elasticity, and weight distribution should form the basis of your comparative analysis.

-

Engage with Experts:

Consider reaching out to manufacturers with technical support teams. Such interactions allow you to ask targeted questions about material science and production techniques, ensuring that the paddle meets your customers’ exact specifications. -

Market Analysis:

Monitor trends in sports equipment demands to detect shifts towards more durable and custom-designed paddles. Align your inventory purchases with market forecasts. -

Pilot Orders:

Before committing to large-scale orders, conduct pilot purchases to assess real-world performance and customer feedback. This iterative approach minimizes risk and refines your product offerings. -

Utilize Comparative Data:

Leverage technical comparisons such as the tables provided above to facilitate discussions with your procurement team and to support informed buying decisions. -

Plan for Scalability:

Ensure that the selected production process can scale with your business growth. For instance, hot pressing offers scalability, whereas thermoforming might be best reserved for niche or high-end segments.

In conclusion, the best pickleball paddle in 2025 combines superior material technology with innovative production techniques. While 3K, 12K, and T300 carbon fibers each present distinct benefits, fiberglass and composite options provide versatile performance attributes essential for various market segments. Comparing the production methods—hot pressing, cold pressing, and thermoforming—reveals that each has its own set of trade-offs in production speed, cost, and tactile performance.

For B2B buyers in the sports equipment industry, these insights form the foundation of a sound procurement strategy aimed at balancing quality, performance, and cost. Ultimately, the best choice will depend on your target market, the specific performance attributes you prioritize, and your production and delivery requirements.

By leveraging detailed data and technical comparisons, you can confidently select a paddle that not only enhances player performance but also drives customer satisfaction and increased market share. We encourage you to collaborate with suppliers who demonstrate transparency in their production processes and offer customization options that align with your long-term business objectives.

-

What is the best pickleball paddle in 2025?

Most experts agree that the top pickleball paddles in 2025 achieve a balance between advanced material composition and precision production. Options employing 12K carbon fiber offer exceptional durability, while those using T300 carbon fiber are praised for their balanced strength and light weight. Ultimately, the best paddle will depend on whether your priority is competitive performance or versatile recreational use. -

How do production techniques affect paddle performance?

Production techniques such as hot pressing, cold pressing, and thermoforming each influence paddle performance in distinct ways. For example, hot pressing enhances structural integrity and production speed, while cold pressing provides better material control and enhanced ball feel. Thermoforming enables complex designs and precise material distribution ideal for high-end paddles. -

Why are material choices critical for pickleball paddles?

Material choices are critical because they directly impact a paddle’s durability, weight, and overall playability. Advanced materials like various types of carbon fiber and fiberglass offer unique benefits. For instance, 3K carbon fiber balances strength and flexibility, whereas composite options maximize performance by combining the best attributes of several materials.

-

carbon fiber: Read the article to understand the properties, applications, and variants of carbon fiber, and discover why it is a critical material in high-performance sports equipment. ^Return ↩

-

composite materials: Read the article to discover how composite materials combine diverse benefits from multiple constituents, resulting in enhanced performance and durability in sports equipment. ^Return ↩

-

hot pressing: Read the article to explore the hot pressing manufacturing process, its operational efficiencies, and its impact on product durability and performance. ^Return ↩

-

cold pressing: Read the article to learn about cold pressing techniques, including how they enhance material precision and contribute to a superior tactile performance. ^Return ↩

-

thermoforming: Read the article to gain insights into the thermoforming process, focusing on its advantages for achieving complex designs and precise material distribution in production. ^Return ↩