Quick Answer: Choosing the most effective finish for high-performance pickleball paddles requires a clear comparison of techniques like hot pressing1, cold pressing2, and thermoforming3—each offering unique benefits in terms of performance enhancement, durability, and aesthetic appeal. In this article, we compare these methods, discuss material compatibility (including carbon fiber, fiberglass, and composite materials), and provide a clear table breakdown to help procurement specialists make informed decisions aligned with their brand and production requirements.

For manufacturers in the sports equipment industry, selecting the right finishing technique for pickleball paddles is a critical step in achieving a competitive edge. Premium finishes not only define the visual appeal of the product but also affect paddle performance, durability, and player comfort. Production methods such as hot pressing1, cold pressing2, and thermoforming3 each play a key role in the final product’s quality.

The finish of a paddle involves a set of precise surface treatments that enhance characteristics such as rebound force, vibration reduction, and overall structural integrity. With growing demand for top-tier equipment, it is essential to balance process efficiency, material compatibility, and performance enhancement when choosing a finishing technique.

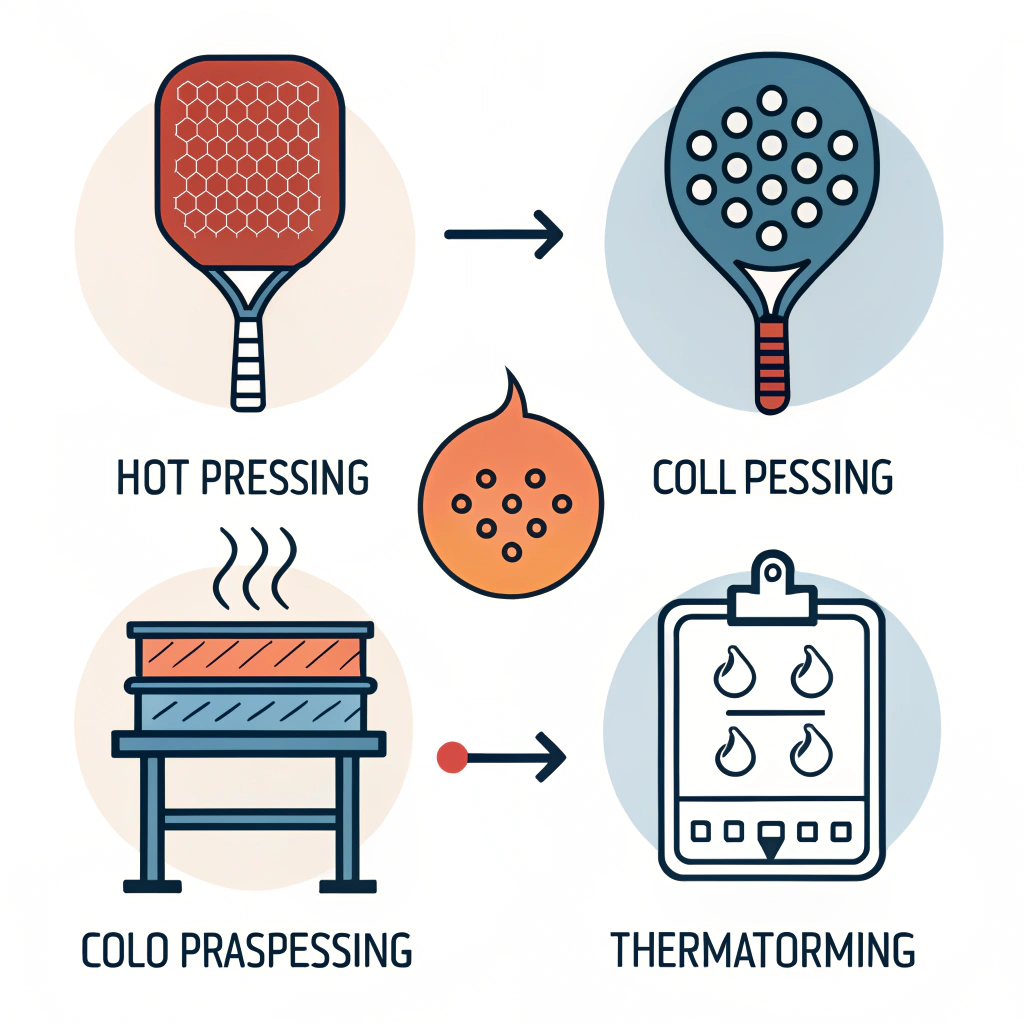

When considering finishing techniques for pickleball paddles, manufacturers typically evaluate three primary methods:

-

Hot Pressing

This technique uses heat and pressure to shape the paddle material, ensuring strong bonding among layers and achieving a robust surface finish. It delivers excellent impact resistance—ideal for paddles that encounter high-speed plays—and is highly efficient for large-scale production. However, heat exposure could potentially alter some material properties, impacting the paddle’s “feel.” -

Cold Pressing

Cold pressing involves applying mechanical pressure at or near room temperature, preserving the intrinsic properties of the base materials. This method offers exceptional control over thickness and structure, resulting in improved ball feel and responsiveness. Although cold pressing benefits precision, it generally has longer production cycles compared to hot pressing. -

Thermoforming

In the thermoforming process, materials are heated to a softening point and then molded into intricate shapes. This technique is invaluable when designing paddles with complex geometries and where precise material distribution is key. While thermoforming can produce paddles with enhanced stability and elaborate designs, it requires longer production times and higher equipment investments.

Each method has its own set of trade-offs, and the choice largely depends on production volume, cost considerations, and the desired performance outcomes.

When deciding on the optimal finish, it is important to evaluate several factors in a manufacturing context:

-

Performance Enhancement:

Techniques that result in superior impact resistance and vibration reduction are preferred for competitive play. For example, paddles finished with hot pressing tend to offer high rebound force, while cold pressing is known for preserving material flexibility. -

Durability:

Durability is crucial as paddles are subject to repeated impacts. A strong bond between surface layers is essential to ensure longevity. Hot pressing typically induces stronger bonds, but thermoforming, with its ability to create nuanced designs, can also enhance overall stability. -

Aesthetic Appeal:

The premium finish not only contributes to the paddle's functional performance but also to its market appeal. For instance, finishing techniques that allow for custom paddle designs or the integration of unique graphic patterns can help differentiate a brand in a competitive market.

Manufacturers must also consider how these finishing methods interact with various paddle core materials (such as Nomex Honeycomb4, Aluminum Honeycomb, and Polymer Honeycomb) and face materials (including different grades of carbon fiber and fiberglass). The right match can lead to superior performance characteristics—a critical factor when catering to both professional athletes and recreational players.

The table below summarizes key aspects of the three main finishing techniques:

| Technique | Advantages | Limitations | Cost-Effectiveness | Performance Characteristics |

|---|---|---|---|---|

| Hot Pressing | - High production efficiency - Superior impact resistance - Excellent structural integrity | - Potential alteration of material feel - High initial equipment investment | Ideal for large-scale runs and premium quality | Delivers robust paddles with high rebound and reduced vibration |

| Cold Pressing | - Precise control over thickness and structure - Maintains material properties - Enhanced ball feel and responsiveness | - Longer production cycles - Requires high-precision equipment | Best for products where control and finesse are prioritized | Offers a refined touch for defensive and control-oriented play |

| Thermoforming | - Capable of complex designs - Precise material distribution - High product stability | - Longer production time - Higher equipment costs | Suitable for custom or boutique product lines | Provides optimized weight distribution and aesthetic versatility |

This table serves as a quick reference guide, allowing decision-makers to assess how each process might align with their production needs and brand standards.

An effective finishing process is deeply intertwined with the choice of materials used in paddle manufacturing. Our high-performance pickleball paddles incorporate materials like 3K Carbon Fiber, 12K Carbon Fiber, and T300 Carbon Fiber5, each contributing unique advantages. For instance:

-

3K Carbon Fiber Finish:

Emphasizes flexibility and high impact resistance, making it ideal for aggressive play styles. It is frequently paired with hot pressing to ensure durability. -

12K Carbon Fiber Finish:

Offers a smoother surface with extreme strength, often integrated with thermoforming techniques to achieve a custom aesthetic alongside performance. -

Fiberglass Finish:

Provides excellent ball control and boasts a wider sweet spot. It is typically used in conjunction with cold pressing to retain material elasticity and detail precision.

The finish applied not only enhances the visual appearance but also contributes to the overall performance profile of the paddle. In our production, combining these materials with the three finishing techniques allows us to meet various market demands—whether the focus is on sleek, custom paddle designs for competitions or reliable, durable paddles for recreational play.

When looking to integrate a new finishing technique into production, a thorough evaluation of equipment requirements, process cycles, and quality control measures is essential. Key production considerations include:

-

Equipment Investment:

High-end production processes such as hot pressing and thermoforming demand considerable initial capital due to specialized machinery. However, these investments often result in higher quality finished products with longer lifespans. -

Cycle Time:

Efficiency is crucial in large-scale manufacturing. While hot pressing offers faster cycle times, cold pressing may extend production duration but delivers enhanced precision in material properties and design details. -

Customization Capabilities:

For brands aiming to differentiate themselves, the ability to offer custom finishes—such as specific color treatments, graphic patterns, or personalized branding—is a significant advantage. Thermoforming, for instance, can be a valuable process for creating bespoke designs that resonate with a particular target audience. -

Rigorous Quality Control:

Quality control is non-negotiable, especially when manufacturing business-critical sports equipment. Each paddle must undergo rigorous testing to ensure consistent performance, structural integrity, and longevity. From visual inspections to stress testing, maintaining stringent quality control processes helps mitigate production defects and safeguard brand reputation.

Manufacturers are encouraged to set up dedicated QA checkpoints at various stages of the production process. For example, after applying the finish through any of the three techniques, a sample batch can undergo accelerated wear testing to simulate long-term usage. This not only validates durability claims but also aids in refining process parameters for future batches.

The pickleball industry is experiencing rapid growth, boosted by the rising popularity of the sport worldwide. This expanding market also brings increased competition among brands striving to offer the best premium finishes for their equipment. Key trends shaping the industry include:

-

Enhanced Customization:

More brands are seeking advanced finishing techniques that allow for custom designs, enabling them to balance performance with aesthetic uniqueness. As competitive markets demand differentiation, manufacturers who can offer tailored solutions will have a strategic edge. -

Focus on Performance and Sustainability:

The integration of sustainable production methods with high-performance materials is becoming a priority. While high-quality finishes are essential for superior performance, there is a growing emphasis on environmentally friendly processes that also reduce waste and optimize resource use. -

Technology-Driven Innovation:

Advances in production technology—ranging from state-of-the-art thermoforming equipment to enhanced cold pressing systems—are pushing the limits of what is possible in paddle design. Manufacturers who embrace these innovations are better positioned to meet the technical demands of professional athletes and maintain a competitive edge in the market.

At NEX Pickleball, we continuously invest in research and development to refine our finishing techniques. By leveraging the latest production technologies and materials, we ensure that our paddles meet both the high standards demanded by competitive play and the evolving aesthetic preferences of modern consumers.

In summary, each finishing technique offers distinct advantages and challenges. Whether you are considering the efficiency and robustness of hot pressing, the precision and material integrity of cold pressing, or the design flexibility of thermoforming, your decision should align with your brand’s performance goals, production capacity, and target market expectations.

For procurement specialists in sports equipment manufacturing, balancing cost-effectiveness with performance enhancement is key. A detailed comparison—supported by industry data and rigorous testing—will enable you to select the finishing method that not only drives product quality but also strengthens your market position.

We recommend a pilot production run to assess how each finishing technique integrates with your current systems. Such trials will provide invaluable insights into material behavior, production efficiency, and ultimately, customer satisfaction. With the right approach, your brand can achieve a perfect harmony between innovative design and robust performance.

Q1: What finishing technique provides the best durability for pickleball paddles?

A1: Techniques like hot pressing are known for creating strong structural bonds and high impact resistance, making them ideal for durable, high-performance paddles.

Q2: Which finish method is most cost-effective for large-scale production?

A2: Hot pressing generally offers high production efficiency and cost-effectiveness for large-scale manufacturing, despite requiring a higher initial investment.

Q3: How does thermoforming compare to cold pressing in terms of performance and design flexibility?

A3: Thermoforming enables intricate designs and precise material distribution, enhancing aesthetic appeal and stability, while cold pressing preserves material integrity and offers superior tactile control.

-

Hot Pressing: Click to read an article detailing how heat and pressure are balanced in hot pressing to achieve strong bonding and rapid production cycles, crucial for high-volume manufacturing. ↩ ↩2

-

Cold Pressing: Click to discover the benefits and challenges of cold pressing, including how room-temperature processing preserves material properties and enhances precision. ↩ ↩2

-

Thermoforming: Click to explore the thermoforming process, which involves heating materials to achieve complex shapes and precise distribution, ideal for custom designs. ↩ ↩2

-

Nomex Honeycomb: Click to learn about Nomex Honeycomb and its application in reinforcing composite structures, offering exceptional strength-to-weight ratios in high-performance manufacturing. ↩

-

T300 Carbon Fiber: Click to understand the specific attributes of T300 Carbon Fiber, a high-grade material known for its superior strength and durability in advanced composite designs. ↩